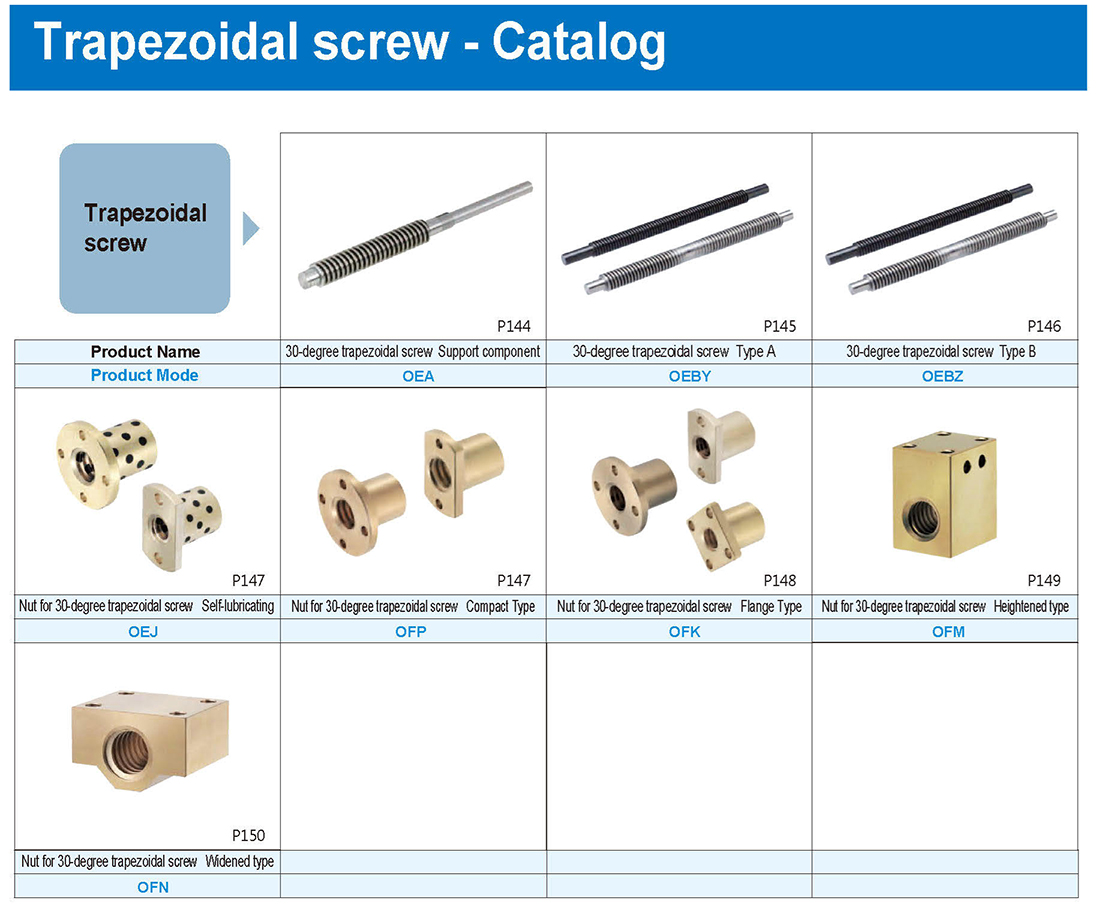

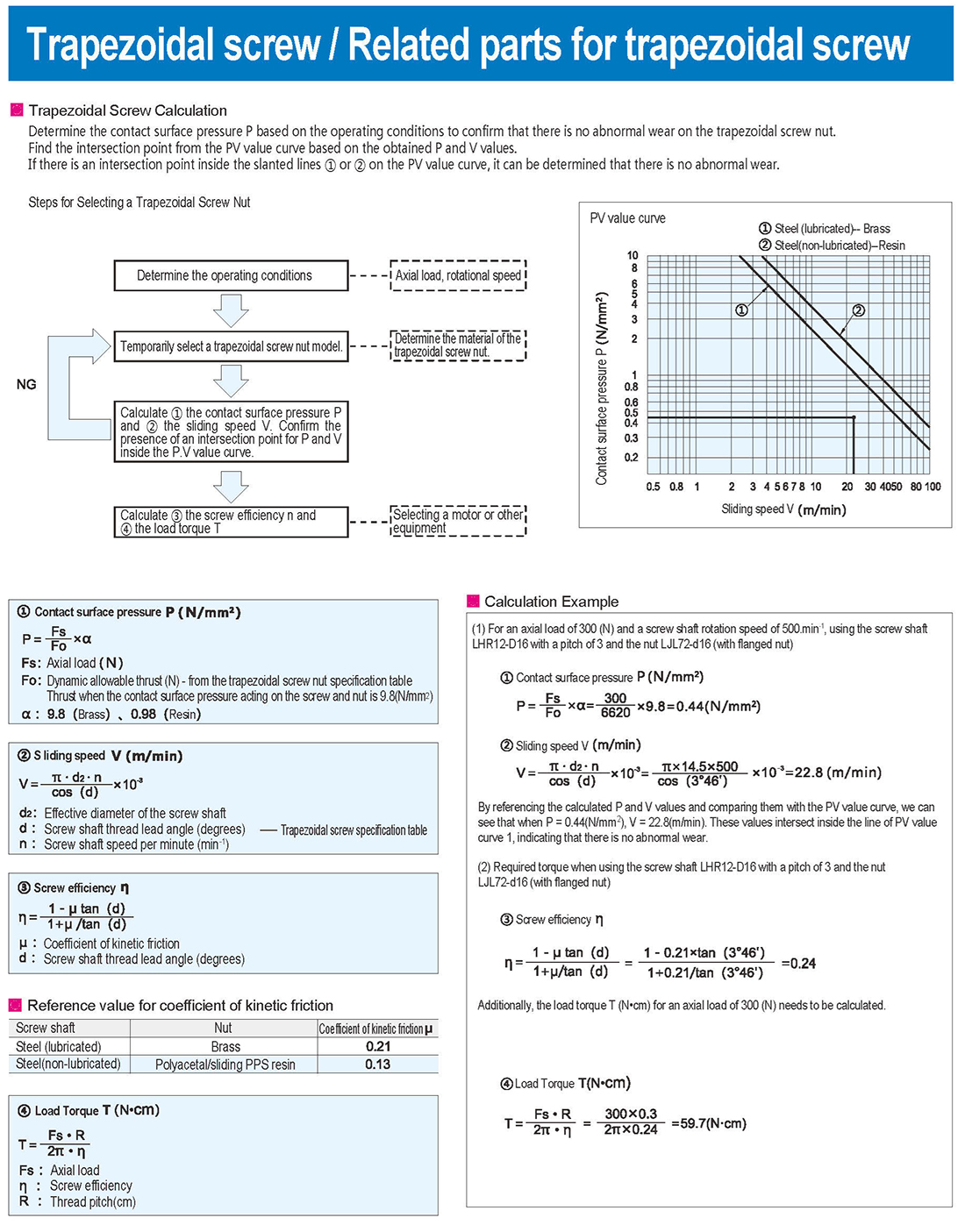

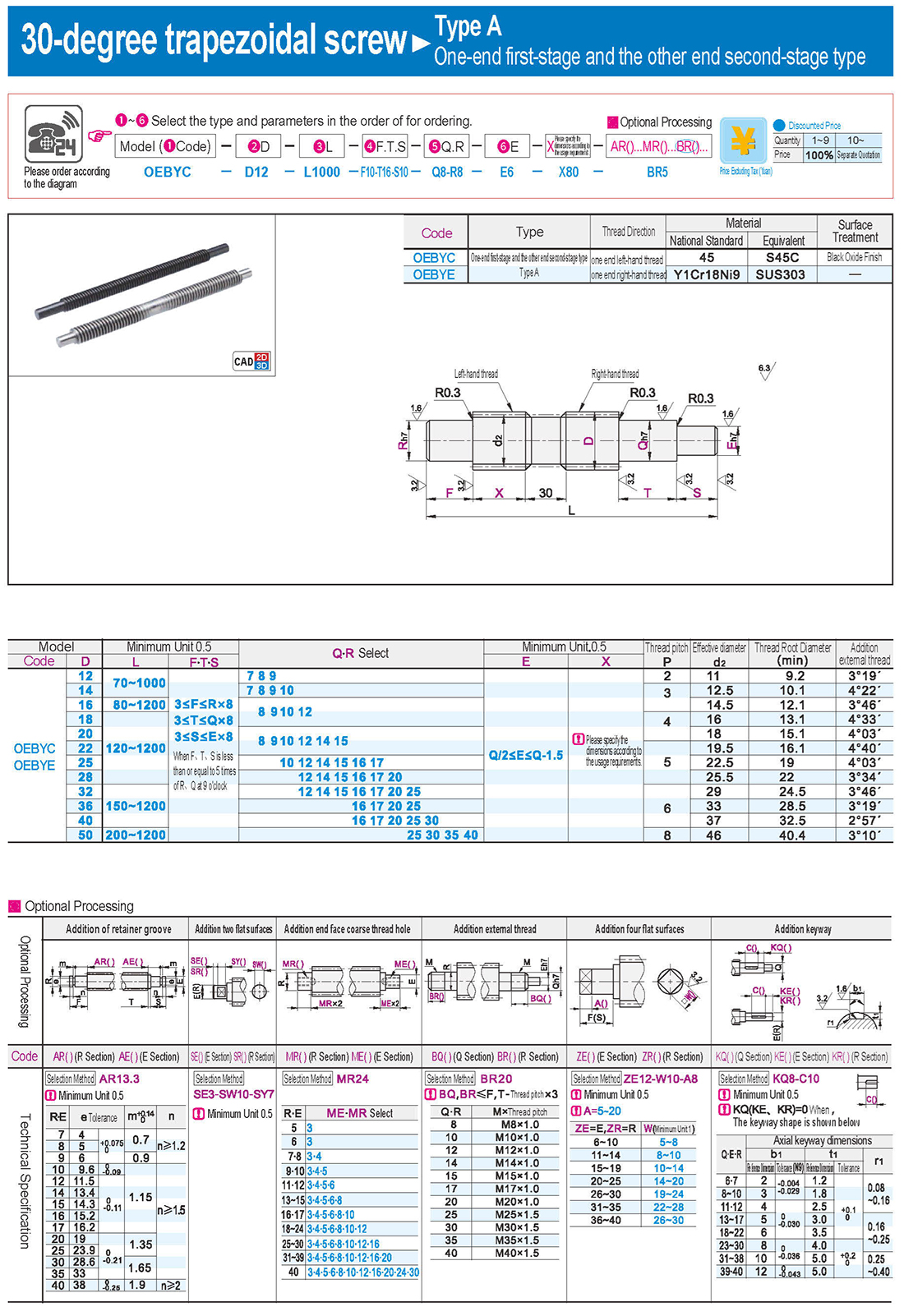

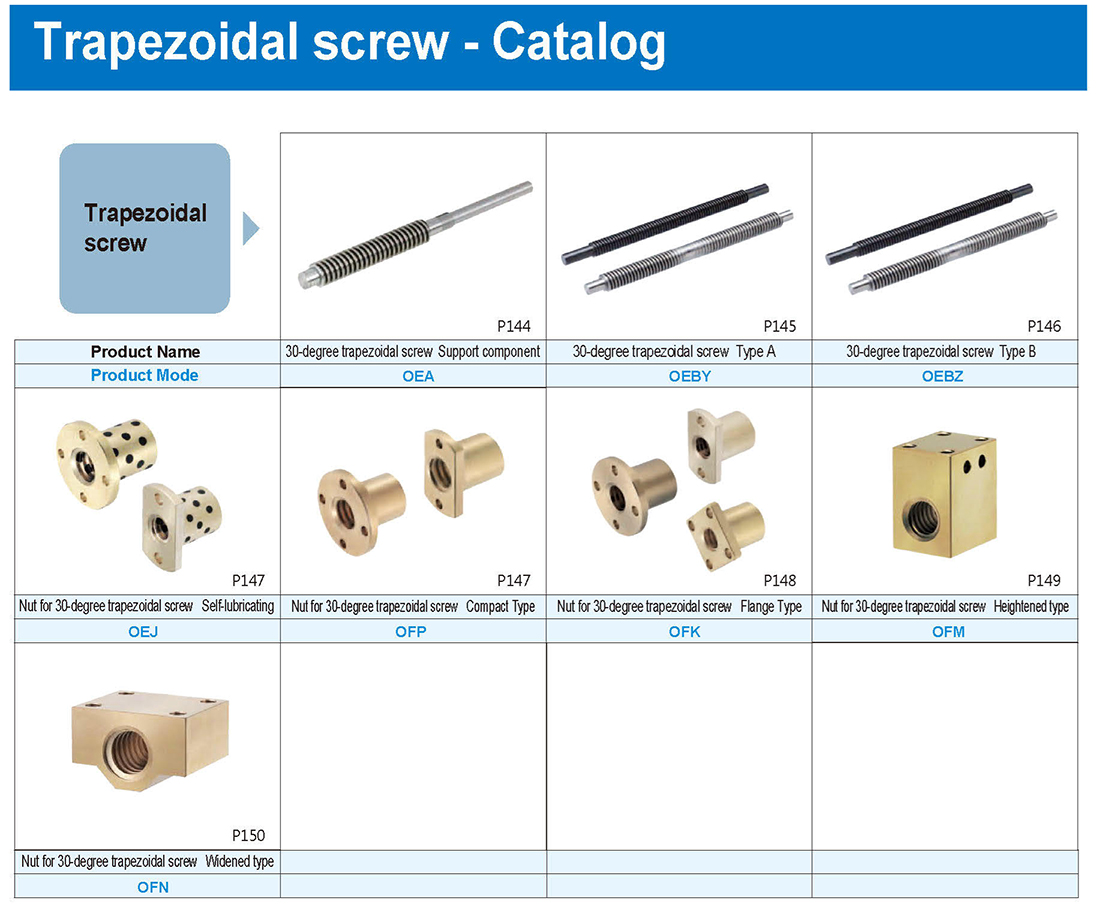

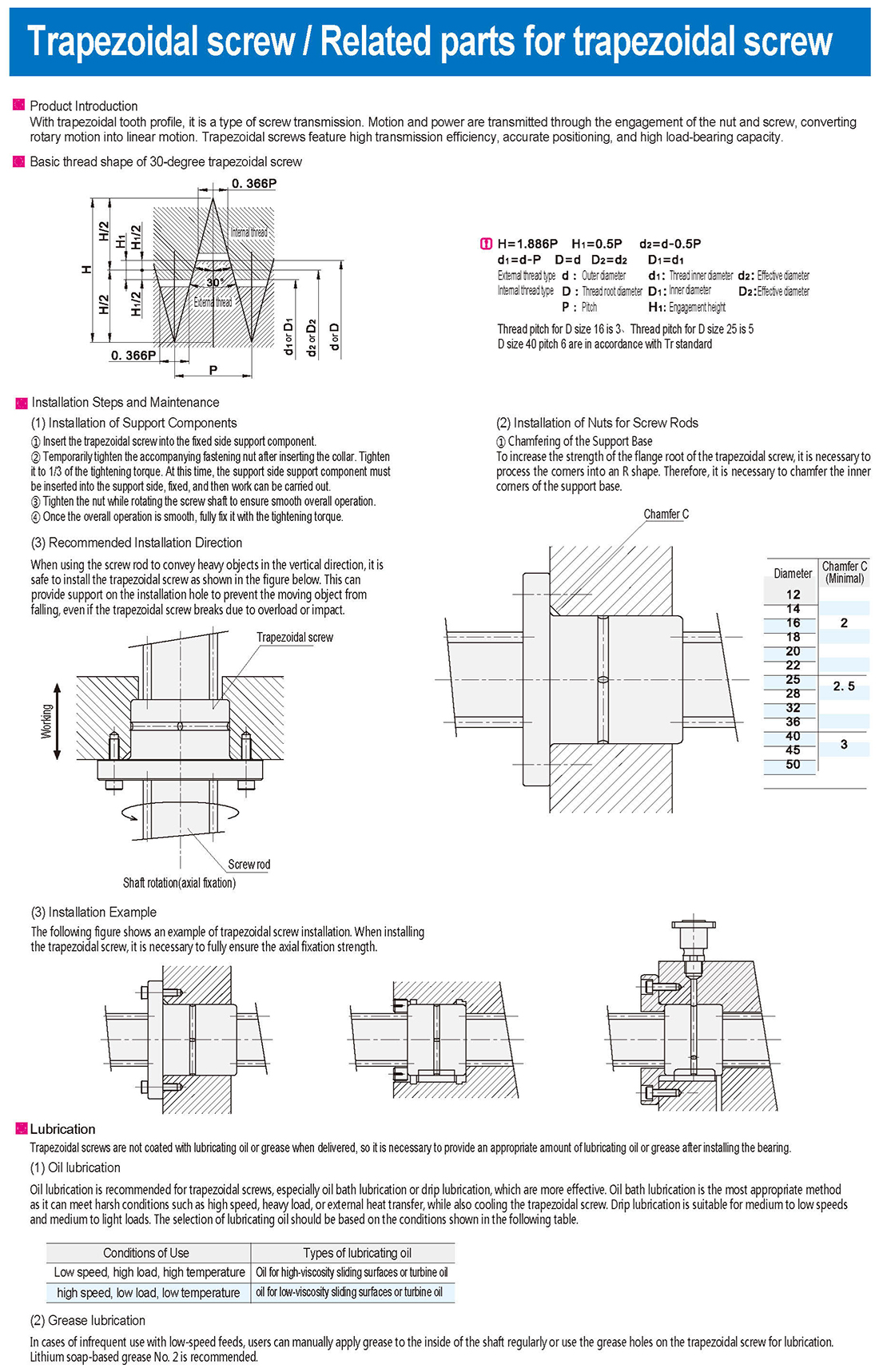

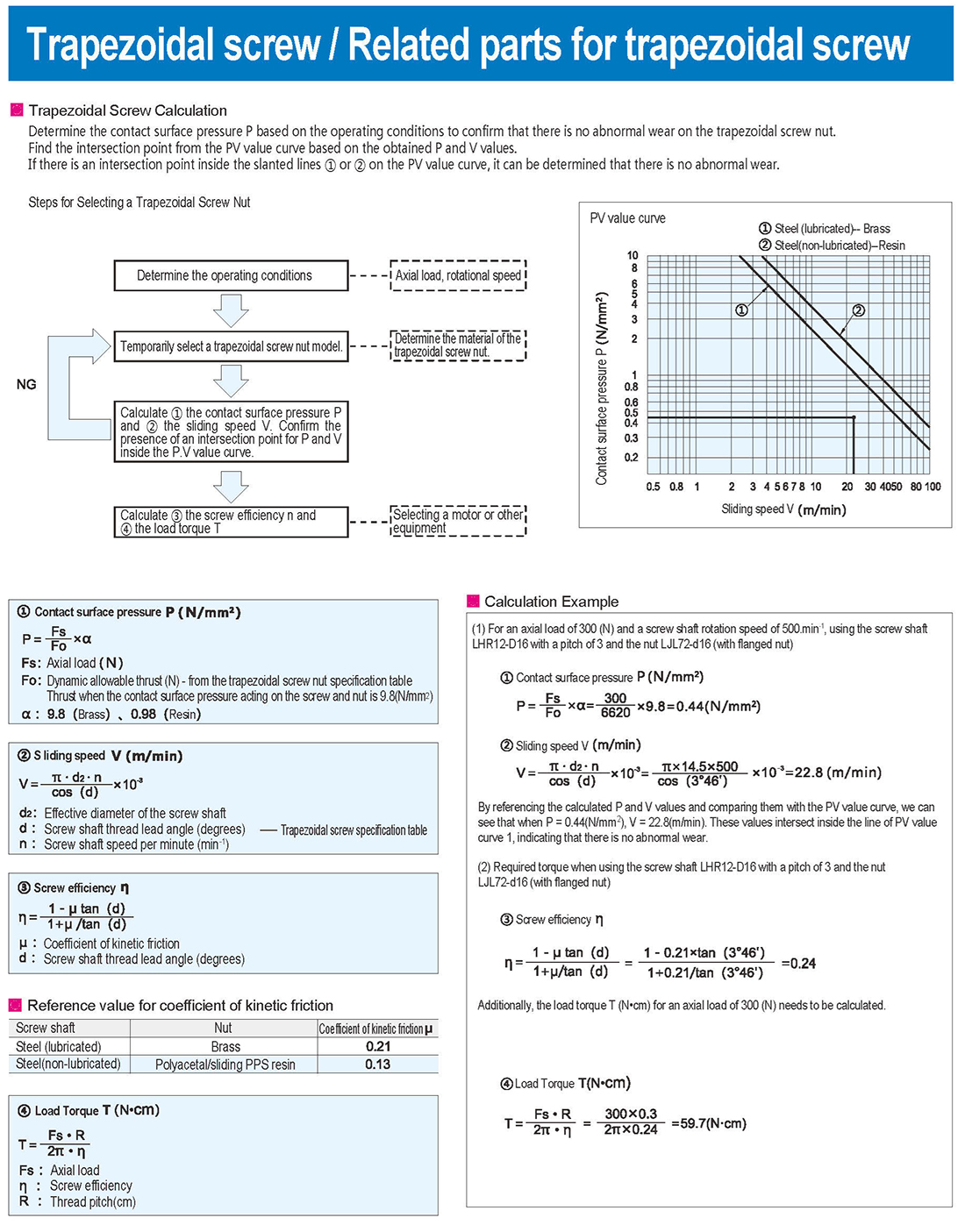

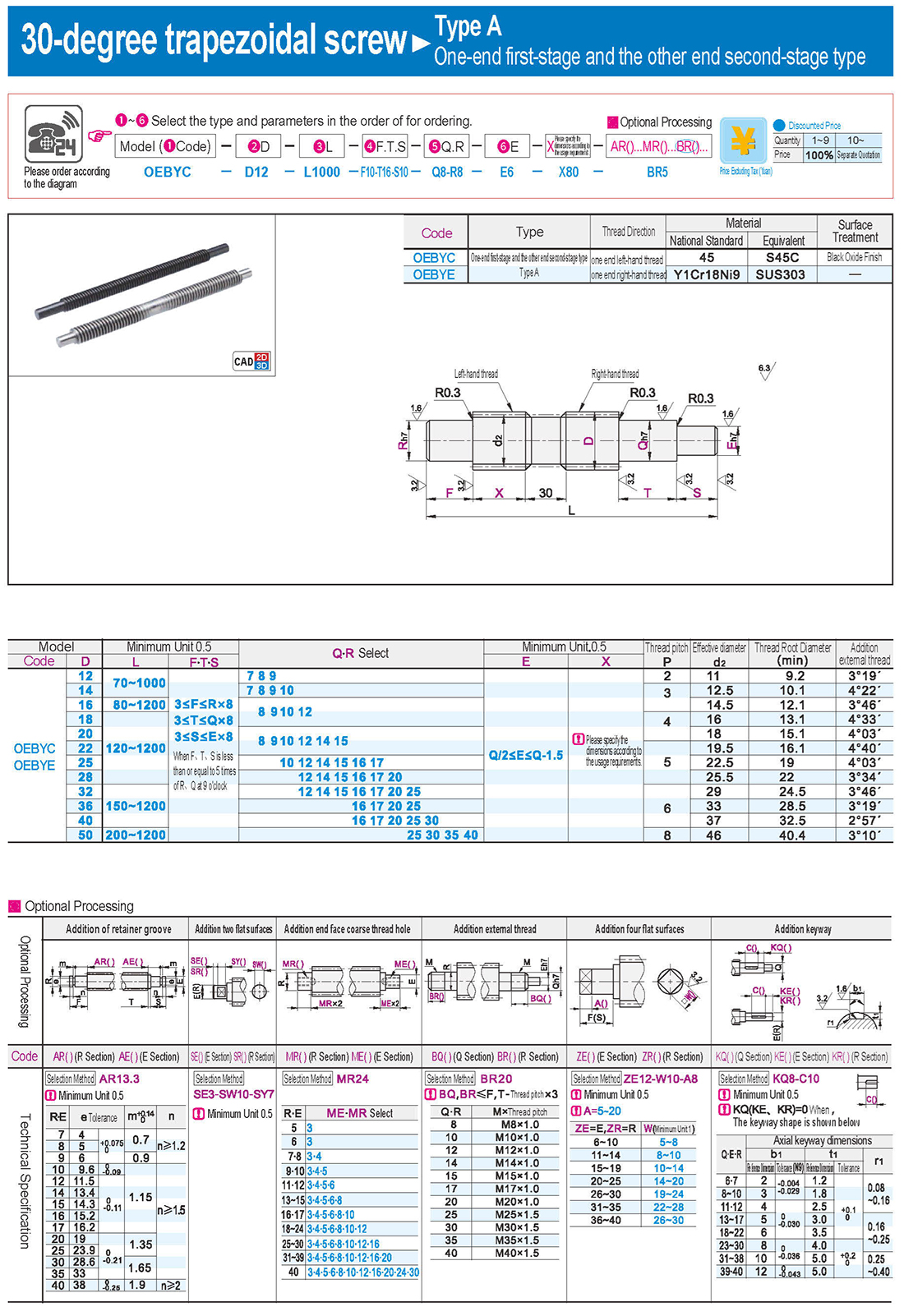

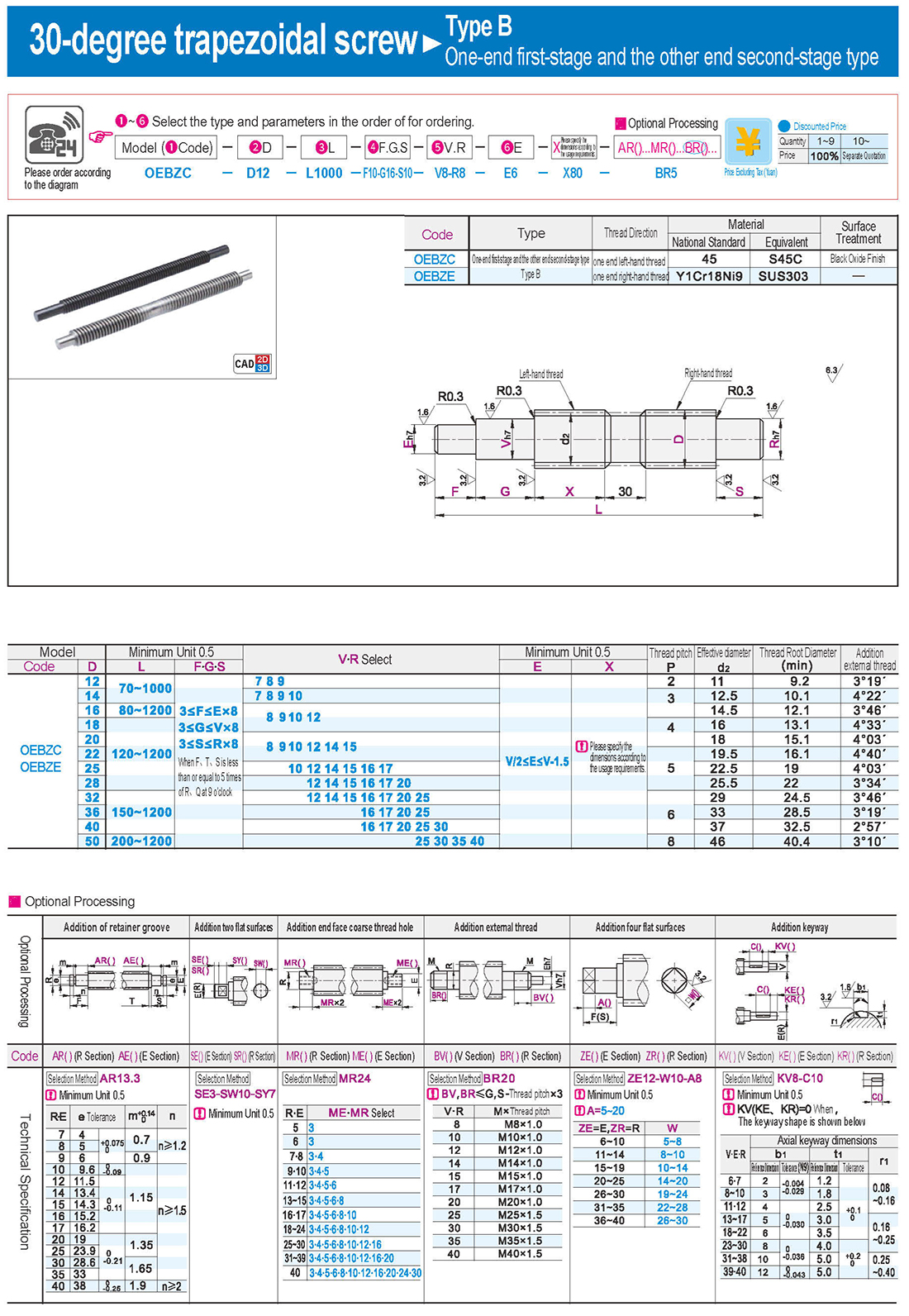

Trapezoidal screw / Related parts for trapezoidal screw

With trapezoidal tooth profile, it is a type of screw transmission. Motion and power are transmitted through the engagement of the nut and screw, converting rotary motion into linear motion. Trapezoidal screws feature high transmission efficiency, accurate positioning, and high load-bearing capacity.

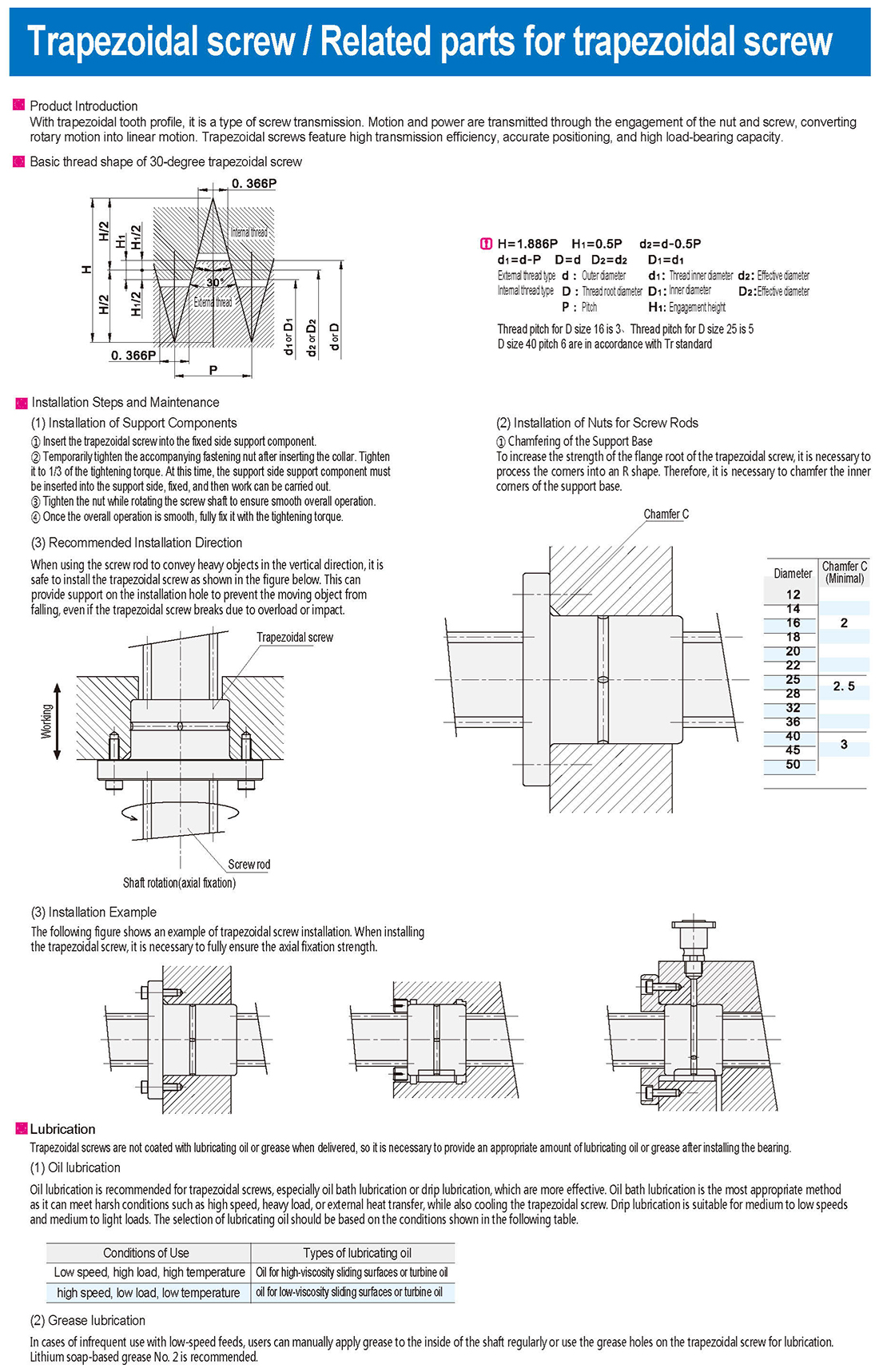

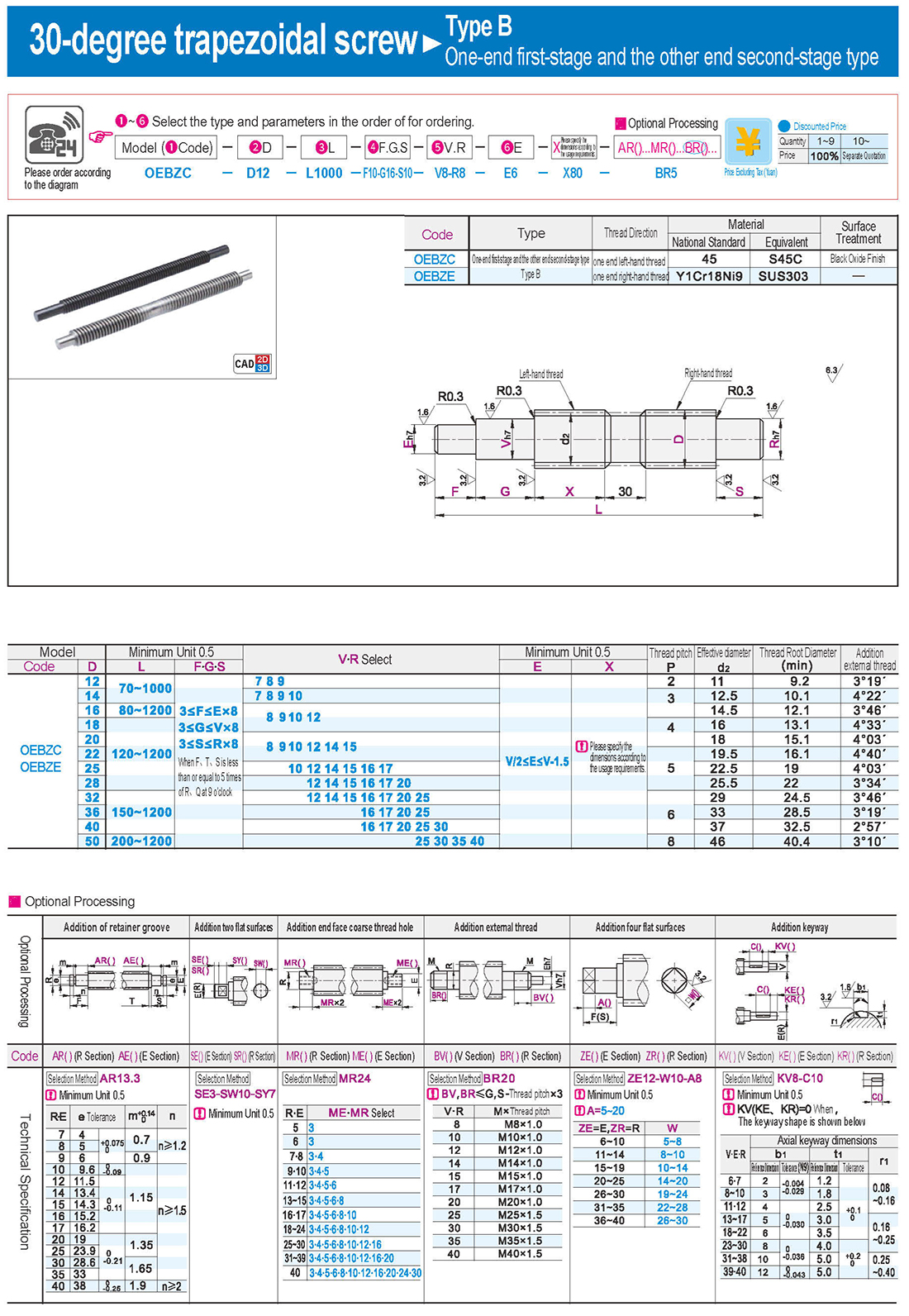

Installation Steps and Maintenance

(1) Installation of Support Components

① Insert the trapezoidal screw into the fixed side support component.

② Temporarily tighten the accompanying fastening nut after inserting the collar. Tighten it to 1/3 of the tightening torque. At this time, the support side support component must be inserted into the support side, fixed, and then work can be carried out.

③ Tighten the nut while rotating the screw shaft to ensure smooth overall operation.

④ Once the overall operation is smooth, fully fix it with the tightening torque.

(2) Installation of Nuts for Screw Rods

① Chamfering of the Support Base

To increase the strength of the flange root of the trapezoidal screw, it is necessary to process the corners into an R shape. Therefore, it is necessary to chamfer the inner corners of the support base.

(3) Recommended Installation Direction

When using the screw rod to convey heavy objects in the vertical direction, it is safe to install the trapezoidal screw as shown in the figure below. This can provide support on the installation hole to prevent the moving object from falling, even if the trapezoidal screw breaks due to overload or impact.

Screw rod Shaft rotation (axial fixation) Chamfer Diameter

(1) Installation Example

The following figure shows an example of trapezoidal screw installation. When installing the trapezoidal screw, it is necessary to fully ensure the axial fixation strength.

Lubrication

Trapezoidal screws are not coated with lubricating oil or grease when delivered, so it is necessary to provide an appropriate amount of lubricating oil or grease after installing the bearing.

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

Introduction Specification Table

Specification Table Download

Download