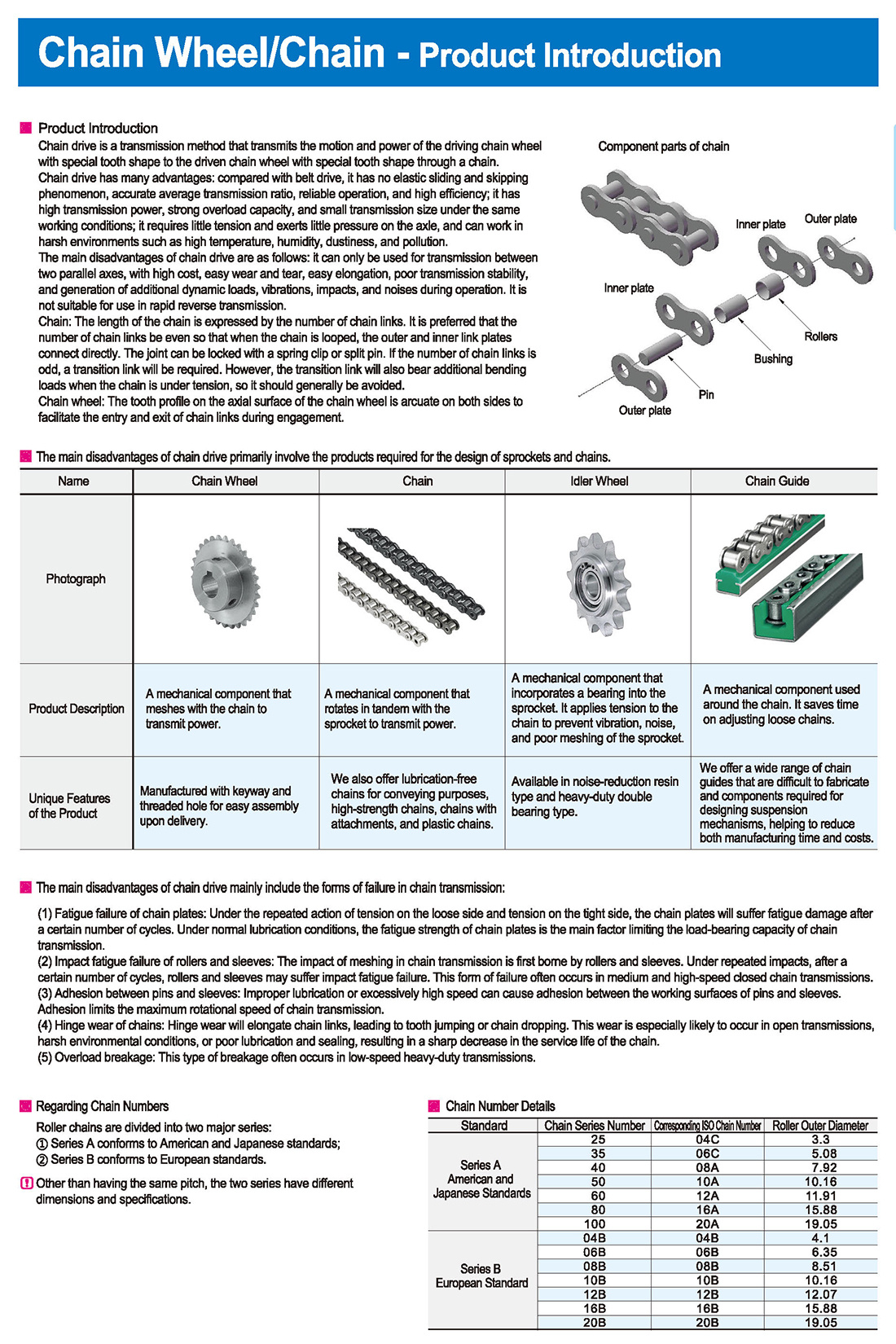

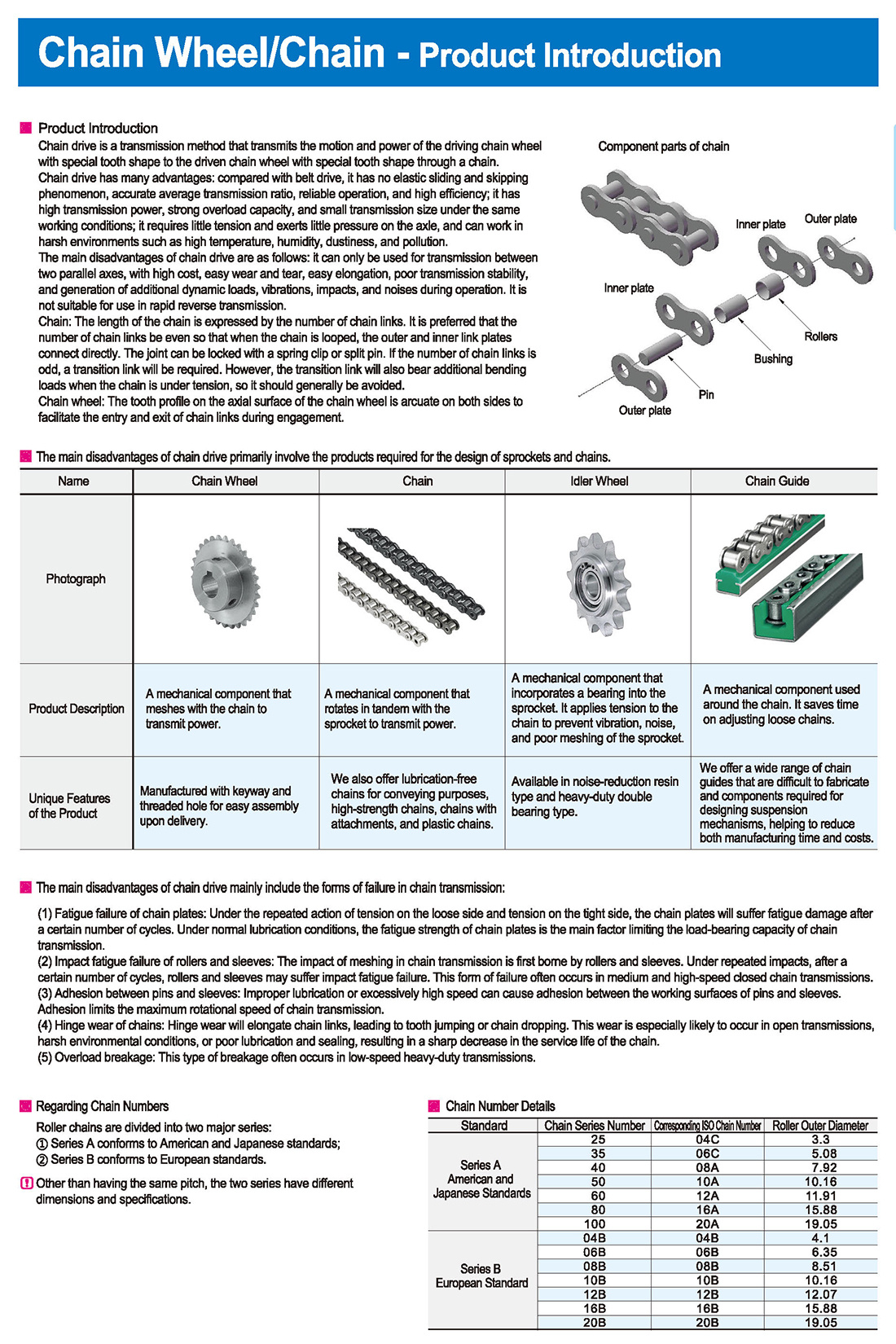

Chain drive is a transmission mode that transmits the motion and movement of the driving sprocket with special tooth shape to the driven sprocket with special tooth shape through the chain.

Chain drive has many advantages: compared with belt drive, no elastic sliding and flapping phenomenon, the average transmission ratio is accurate, reliable work, high efficiency; The transmission power is large, the overload capacity is strong, and the transmission size under the same working condition is small: the required tension is small, the pressure on the shaft is small, and it can work in the harsh environment such as high temperature, humidity, dust and pollution.

The main disadvantages of chain drive are: it can only be used for the transmission between two parallel axes, high cost, easy wear, easy elongation, poor transmission smoothness, additional dynamic load, vibration, impact and noise will be generated during operation, and should not be used in the transmission of rapid reverse.

Chain: The length of the chain is expressed by the number of chain links. The number of chain links is best to take an even number, so that when the chain is connected into a ring, the outer chain plate is connected to the inner chain plate, and the spring clamp or cotter pin can be locked at the joint. If the number of links is odd, a transition link is required. When the chain is strained, the transition link also bears an additional bending load and should usually be avoided.

Sprocket: both sides of the sprocket shaft tooth shape are circular, in order to facilitate the entry and exit of the chain.

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

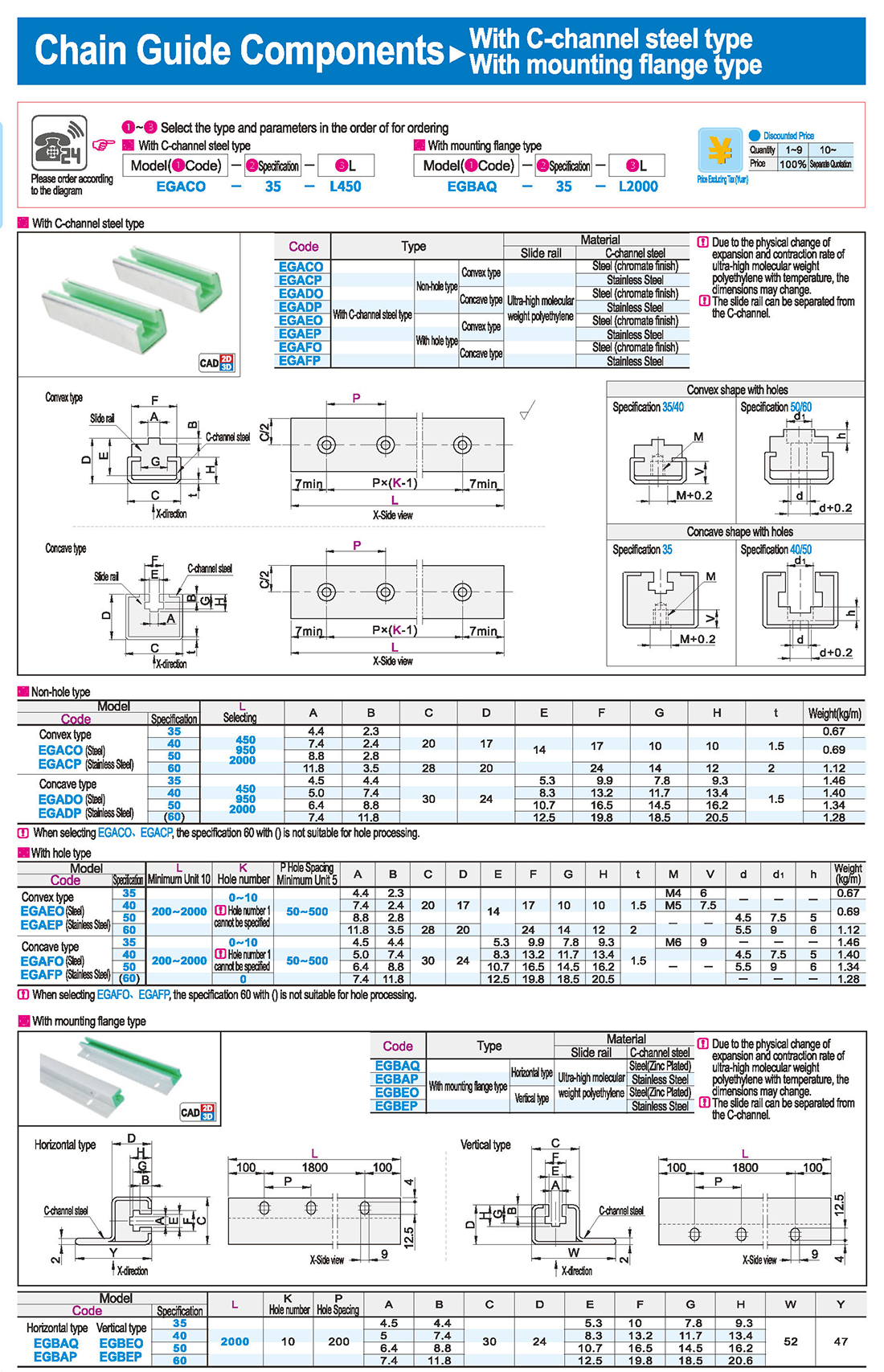

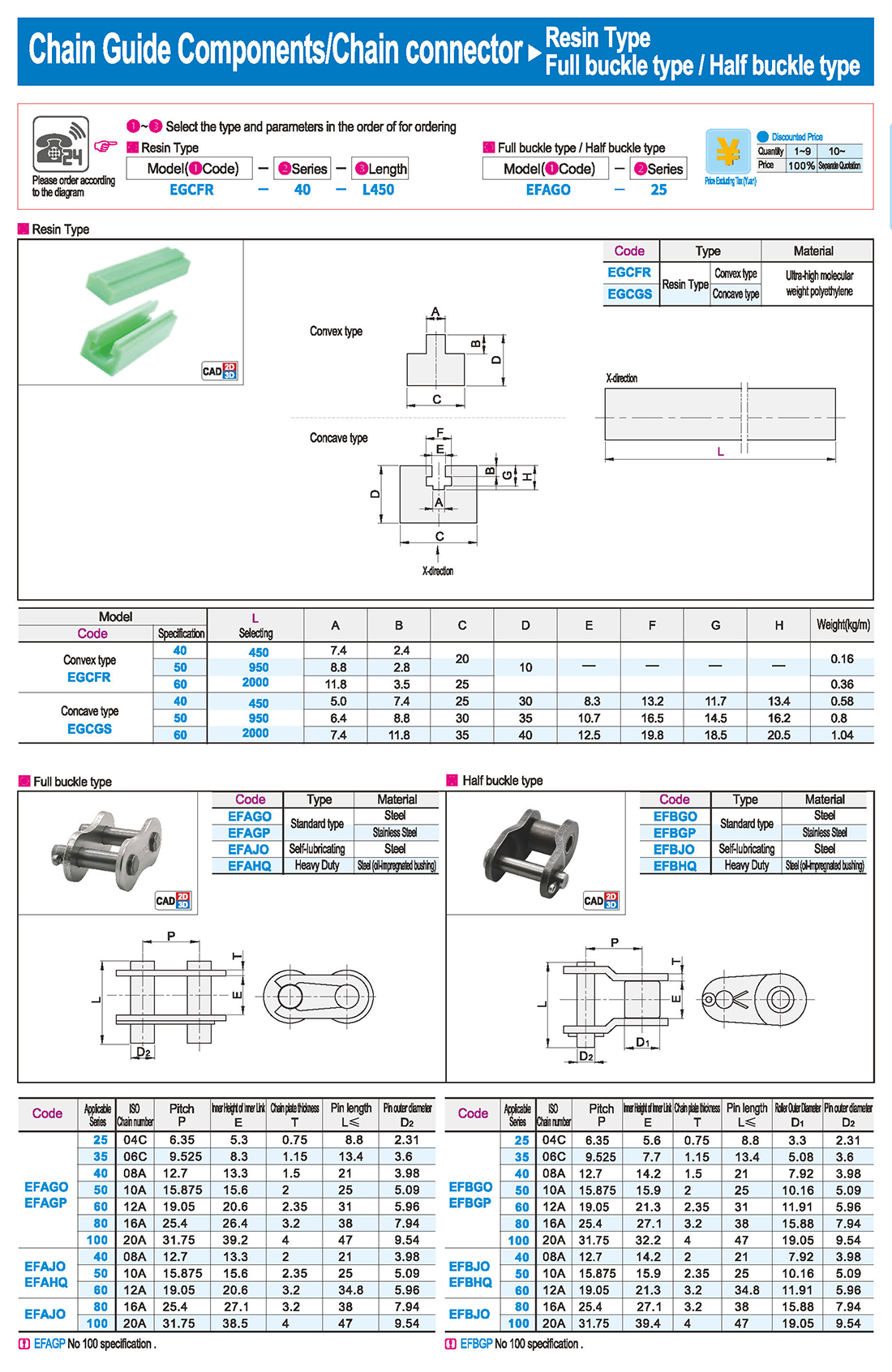

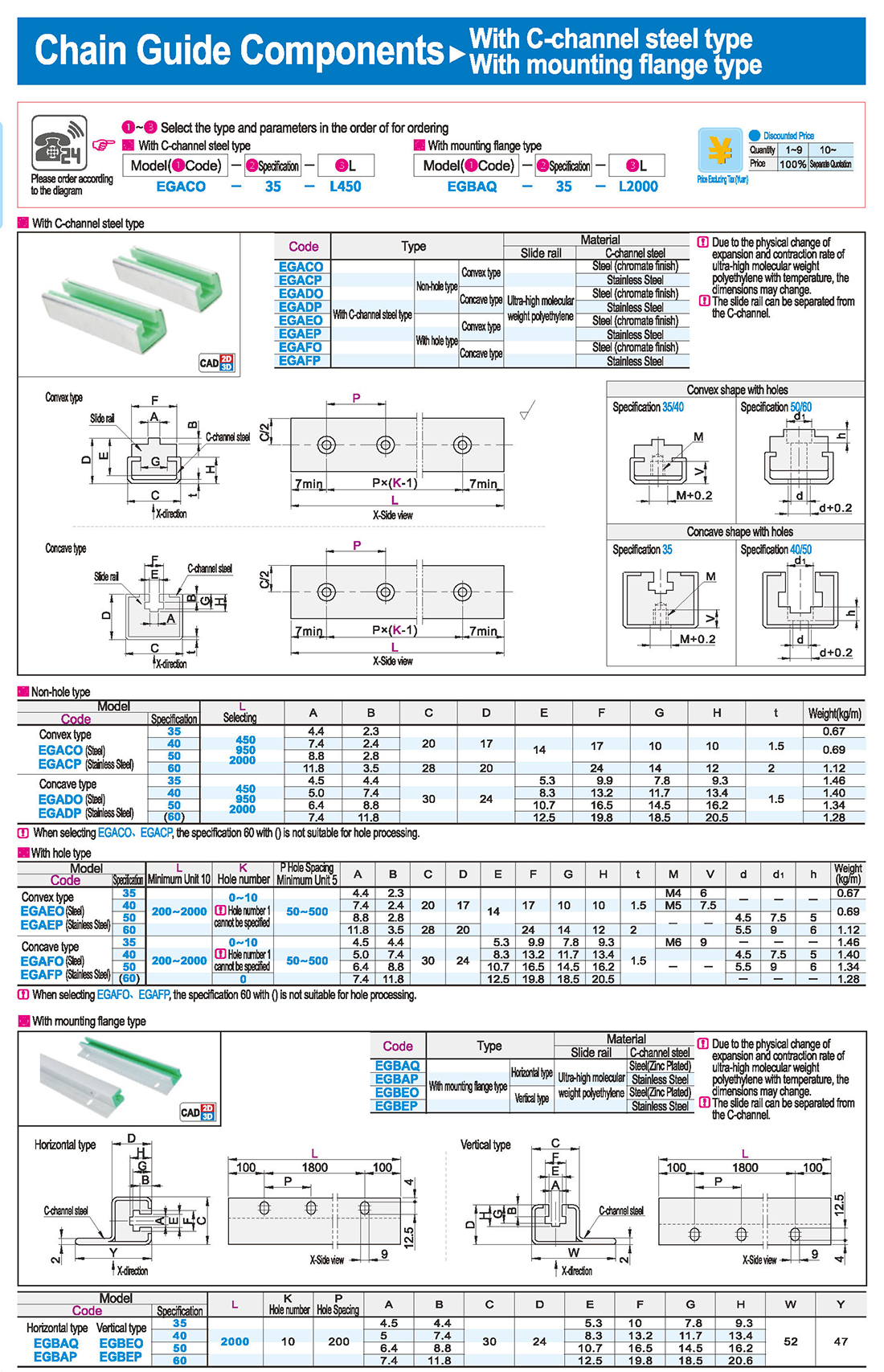

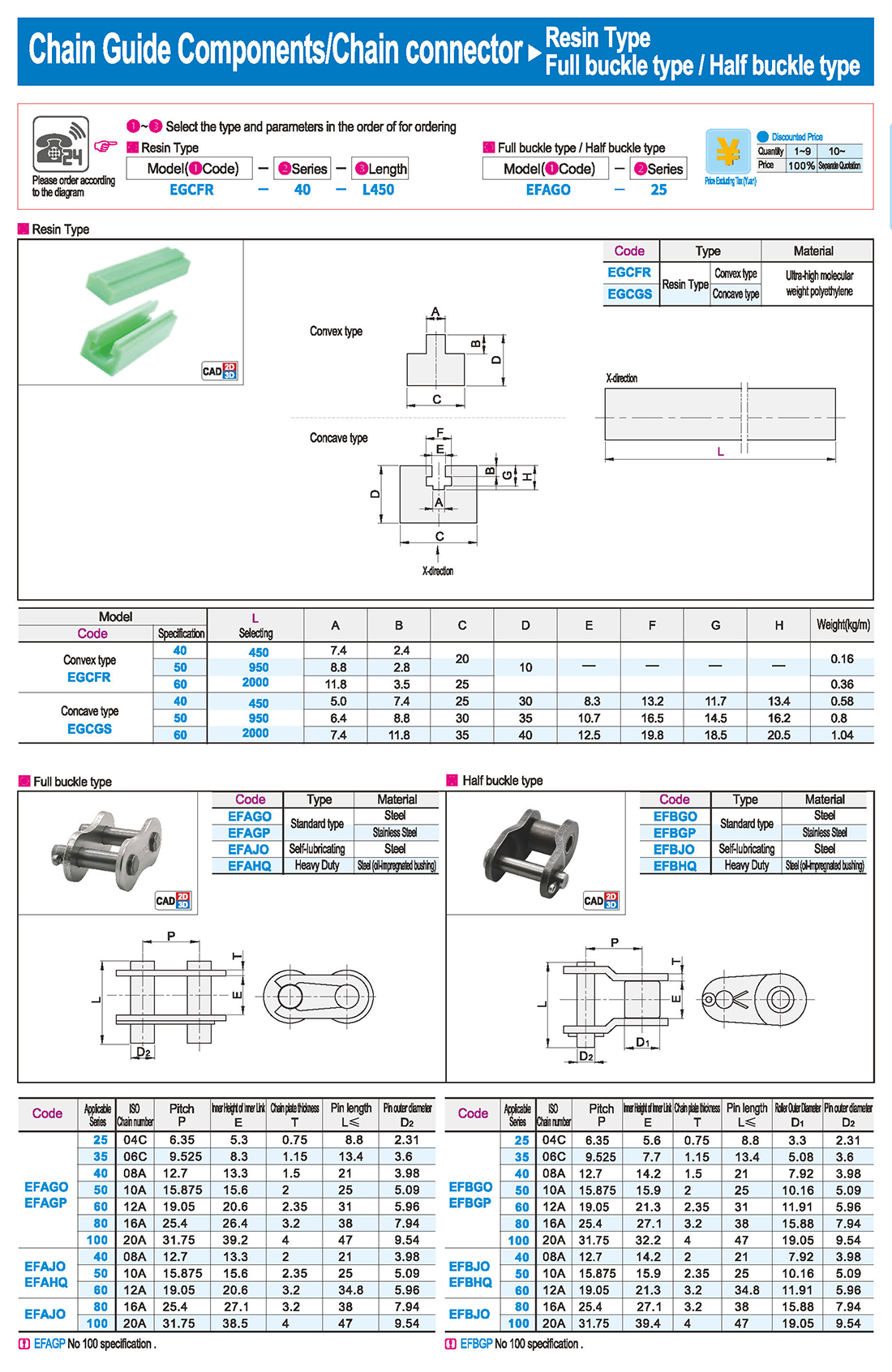

Introduction Specification Table

Specification Table Download

Download