1. High precision and stability

The electric displacement table adopts advanced drive system and precision mechanical structure, which can realize high-precision displacement control. Through the closed-loop control system, the position of the workbench can be monitored and adjusted in real time, so that it is constantly approaching the target position, so as to achieve high-precision positioning. Its positioning accuracy can usually reach the sub-micron or even nanometer level, meeting the needs of various high-precision experiments and manufacturing. At the same time, the electric displacement table has good stability and can maintain stable performance during long-term operation.

2. Quick response and high efficiency

The electric displacement table is directly driven by the motor, which eliminates the influence of factors such as clearance, elastic deformation and friction in the traditional transmission mechanism, so as to achieve higher response speed and high output force. This allows the electric displacement table to quickly respond to adjustment instructions and achieve high speed and high acceleration movement. In applications that require fast positioning and frequent start-stop, electric displacement stations have obvious advantages.

3. Easy integration and control

Electric displacement stations are usually equipped with standard interfaces and communication protocols for easy integration with other equipment and systems. Through computer, controller and other equipment, the remote control and programming control of the electric displacement table can be realized. This improves the degree of automation and efficiency of the experiment, making the electric displacement table widely used in automated production lines and complex systems.

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

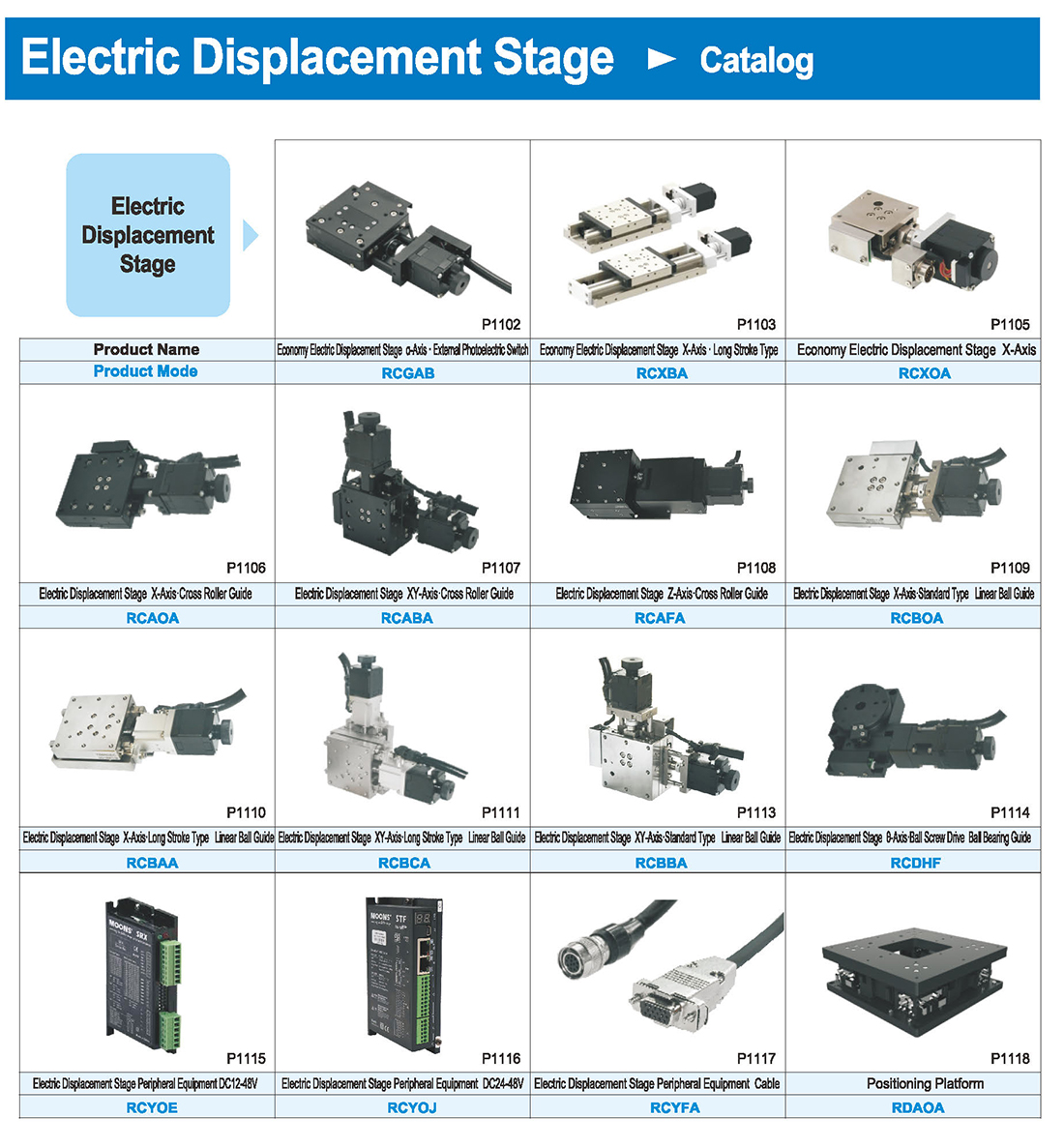

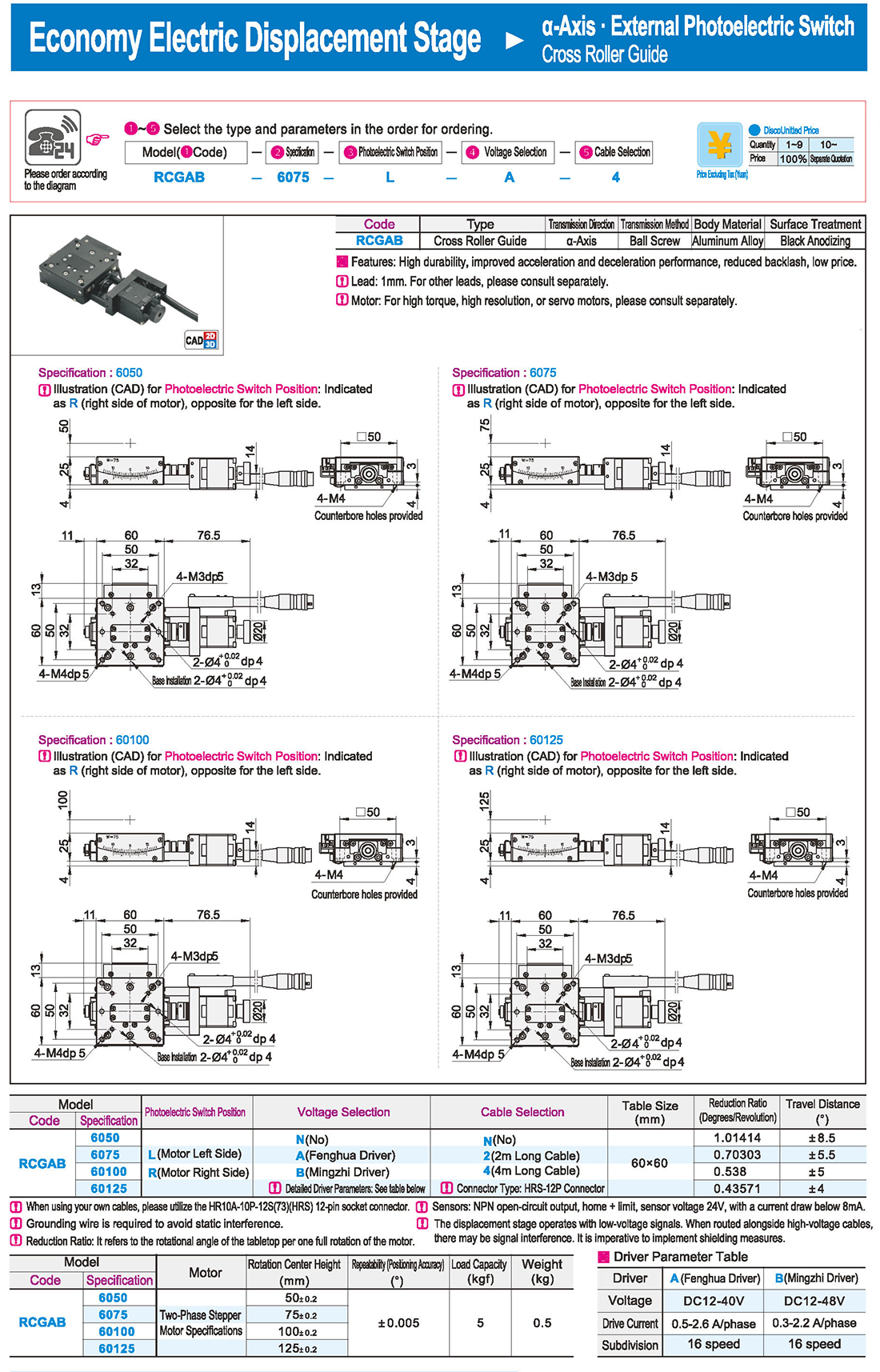

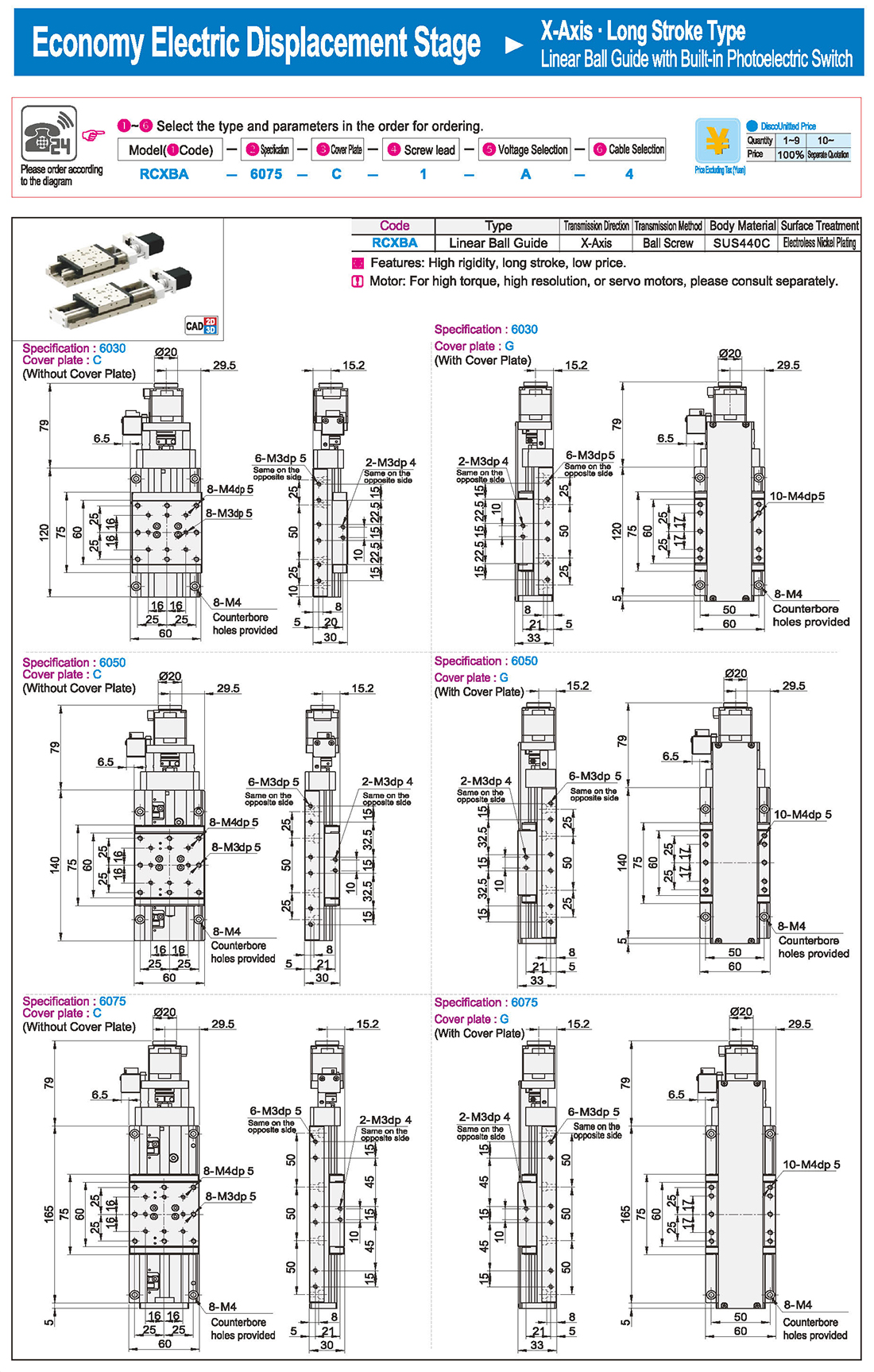

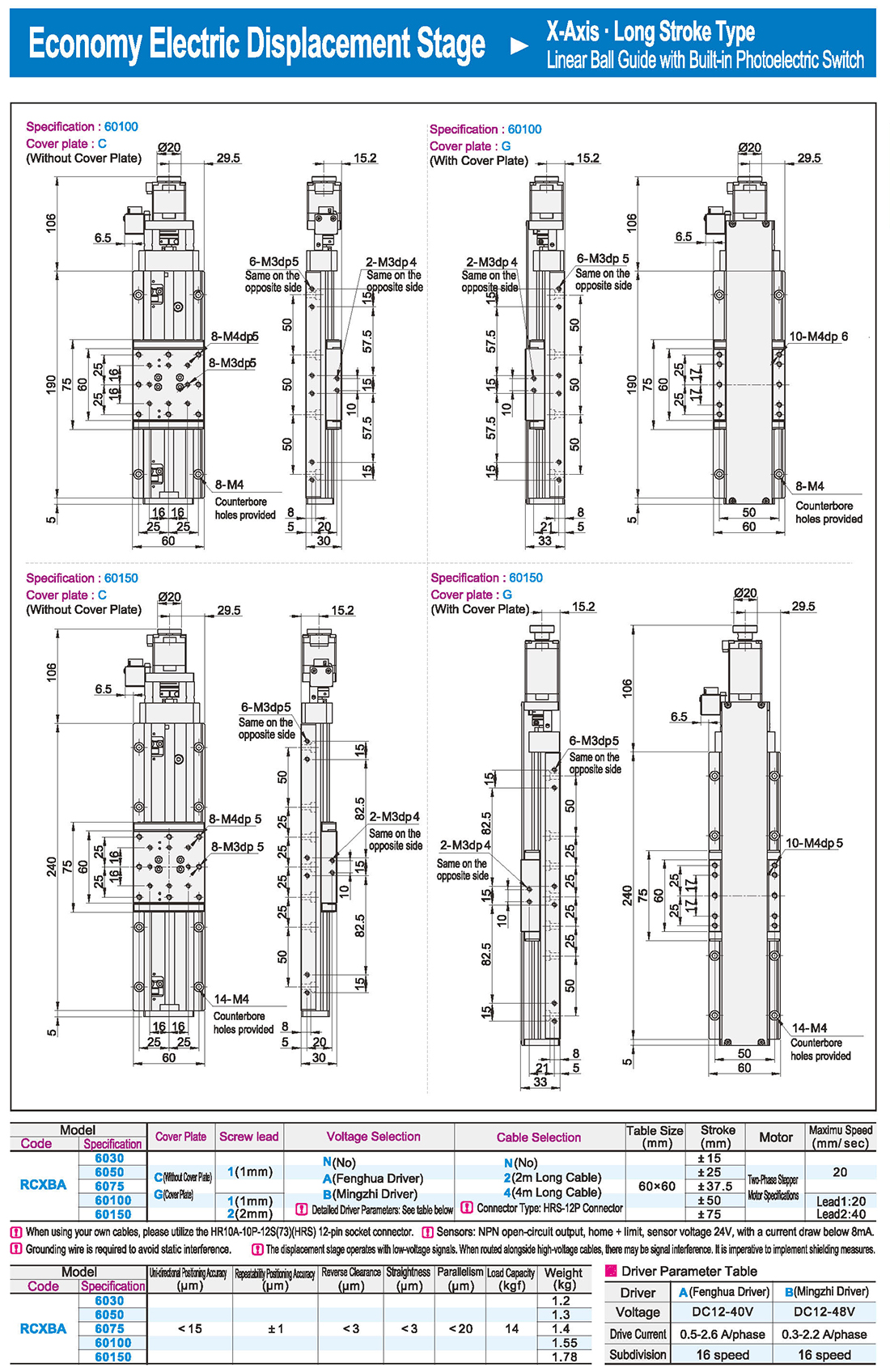

Introduction Specification Table

Specification Table Download

Download