The standard screw slide table is an integrated transmission mechanism, and its core working principle is mainly based on the principle of screw propulsion. The following is a detailed analysis of the standard screw slide table:

1、 Structural composition

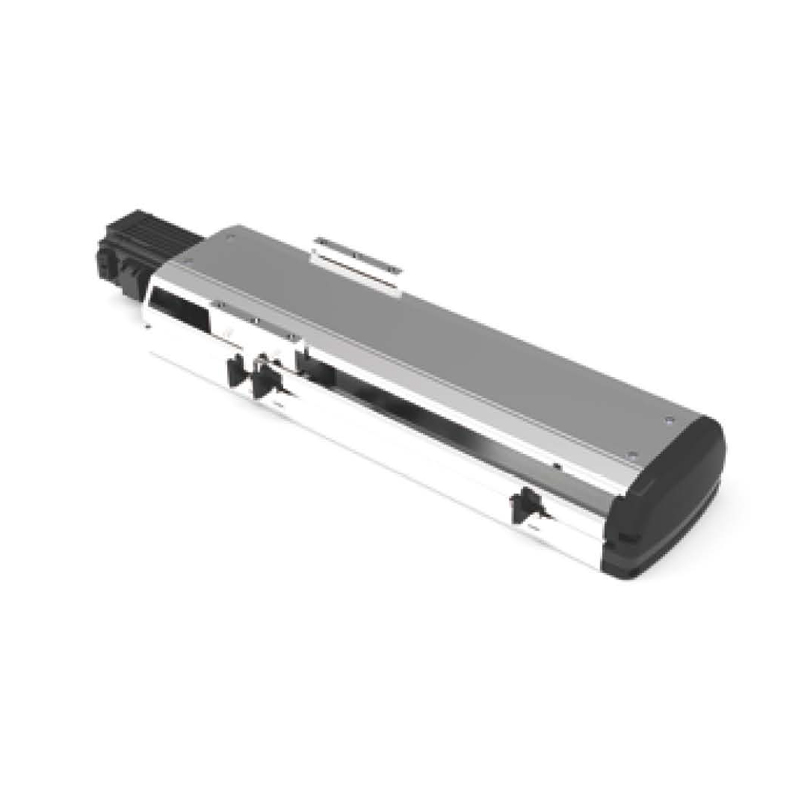

The standard screw slide table is mainly composed of components such as screws, sliders, and guide rails that are tightly combined to form a highly modular structure. A screw is a rod-shaped component with a threaded thread, a slider is a device that can move up and down or forward and backward along the screw, and a guide rail is used to fix the screw and slider.

2、 Working principle

The working principle of a standard screw slide table can be divided into the following three main parts:

Transmission principle: When the nut rotates along the screw, it drives the slider to achieve precise linear movement. During this process, a certain friction force will be formed between the nut and the screw, ensuring the stable and high-precision movement of the slider. This design enables the screw slide table to achieve efficient and reliable energy conversion, converting rotational motion into linear motion.

Control principle: In motor control mode, the motor drives the screw to rotate through the reducer, which in turn drives the nut and slider to achieve linear movement. In the handle control mode, the operator drives the nut and slider to move in a straight line by rotating the handle. This diversified control method enables the screw slide table to adapt to different application scenarios and operational requirements.

Application principle: Screw slide tables are widely used in fields such as mechanical processing and automated production lines. In mechanical processing, it can achieve precise linear motion of the workpiece and meet the requirements of precision machining. In automated production lines, it can ensure accurate transportation and positioning of materials, improving production efficiency.

3、 Characteristics and advantages

High precision: In the design and production process of the standard screw slide table, the machining and assembly accuracy of each component are strictly controlled, making its overall accuracy very high, reaching micrometer level, meeting the requirements of high-precision applications.

Strong load capacity: The screw slide table adopts high-strength materials and optimized structural design, which can withstand large loads and adapt to the needs of various application scenarios.

Energy saving and environmental protection: The screw slide table adopts advanced processing equipment and manufacturing technology, which can achieve the production goals of low energy consumption and zero pollution, meeting the requirements of green manufacturing.

Easy maintenance: The screw slide table adopts a modular design, with simple and reliable connections between various components. Disassembly and maintenance are convenient and fast, reducing maintenance costs and time.

4、 Application Fields

The standard screw slide table, as a common linear motion system, is widely used in various mechanical equipment. For example, they are widely used in industrial production equipment such as CNC machine tools, semiconductor equipment, optical equipment, and printing machines. In automated production lines, screw platform slides also have important application value, such as automatic assembly in semiconductor chip manufacturing, automatic positioning and assembly of optical instruments, and automated packaging robots. In addition, screw platform slides also play an important role in scientific research, such as precise positioning, synchronous movement, and exchange of substances in physics, fast moving test tubes and dispensing reagents in chemical experiments, as well as cell pharmacology research, gene sequencing, tissue engineering, and drug screening in biology.

5、 Safe operation and maintenance

When using a standard screw slide table, the following points should be noted to ensure safe operation and equipment maintenance:

Personal safety: Before operation, check if you are wearing protective equipment such as helmets, safety shoes, protective gloves, goggles, etc. When operating indirect contact with the electric screw slide table, ensure that the body is completely removed and the electric screw slide table is in a safe state without any interference.

Equipment safety: Regularly inspect the maintenance and upkeep of the equipment, fill out maintenance and inspection records, and perform necessary maintenance and upkeep on the equipment. During the operation of the equipment, it is not allowed to add oil or lubricate components without authorization. Before stopping the operation of the equipment, the power should be turned off according to the normal shutdown process.

Lubrication and cleaning: Clean the machine casing, inspect the surface and contact surfaces of the slider for oil stains and debris, and promptly remove them. Check the lubricating oil condition of the equipment, add lubricating oil in a timely manner, and ensure the lubrication of the equipment.

Tightening inspection: Check the tightening status and support holes of the equipment's safety bolts, make timely adjustments to the assembly structure, and ensure the reliability of the equipment.

In summary, standard screw slide tables play an important role in various fields due to their high precision, strong load capacity, energy conservation, environmental protection, and easy maintenance. During use, it is necessary to pay attention to safe operation and regular maintenance to ensure the normal operation of the equipment and extend its service life.

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

Introduction Specification Table

Specification Table Download

Download