Working principle

The working principle of explosion-proof AC servo motor is similar to that of ordinary AC servo motor, mainly composed of stator and rotor. The stator core is usually made of stacked silicon steel sheets, with two phases of windings (excitation winding and control winding) embedded in the surface groove, and the two phases of windings have a 90 ° electrical angle difference in spatial position. During operation, the excitation winding is connected to the AC excitation power supply, and a control signal voltage is applied to the control winding. When the control winding current and the excitation winding current are in different phases, a rotating magnetic field is generated in the air gap and electromagnetic torque is generated, causing the rotor to rotate in the direction of the rotating magnetic field.

Application Fields

Explosion proof AC servo motors are widely used in various fields such as petroleum, chemical, coal mining, pharmaceuticals, automobile manufacturing, food and beverage processing, warehousing and logistics, military and defense. In these industries, there are a large amount of flammable and explosive gases or dust, and ordinary motors may cause explosion accidents, so explosion-proof AC servo motors have become the preferred choice. They are used to drive various devices such as pumps, mixers, compressors, mixers, dryers, conveying equipment, mining machines, lifting equipment, etc., ensuring the safety and efficiency of the production process.

Accurate, compact, safe, and energy-saving

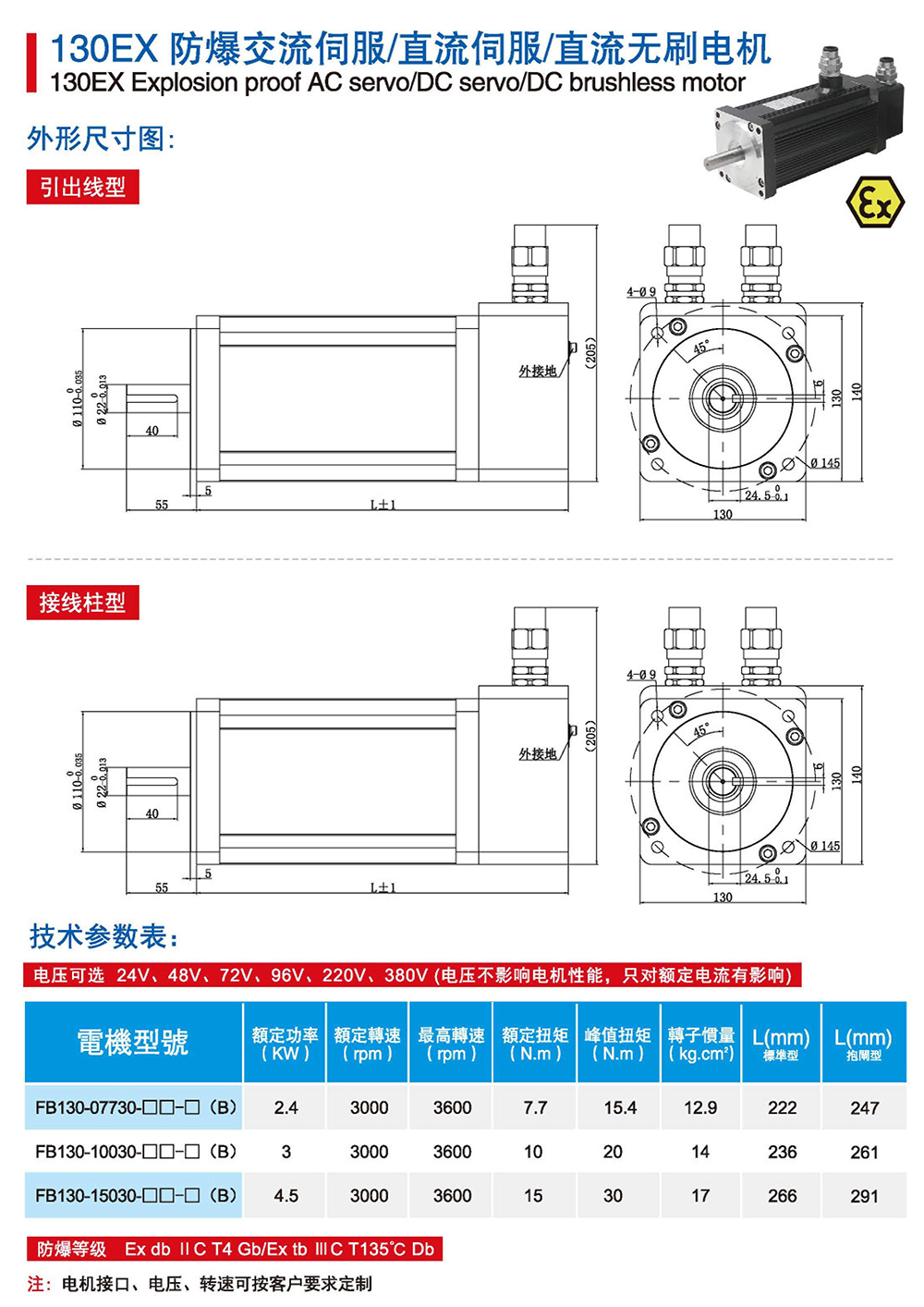

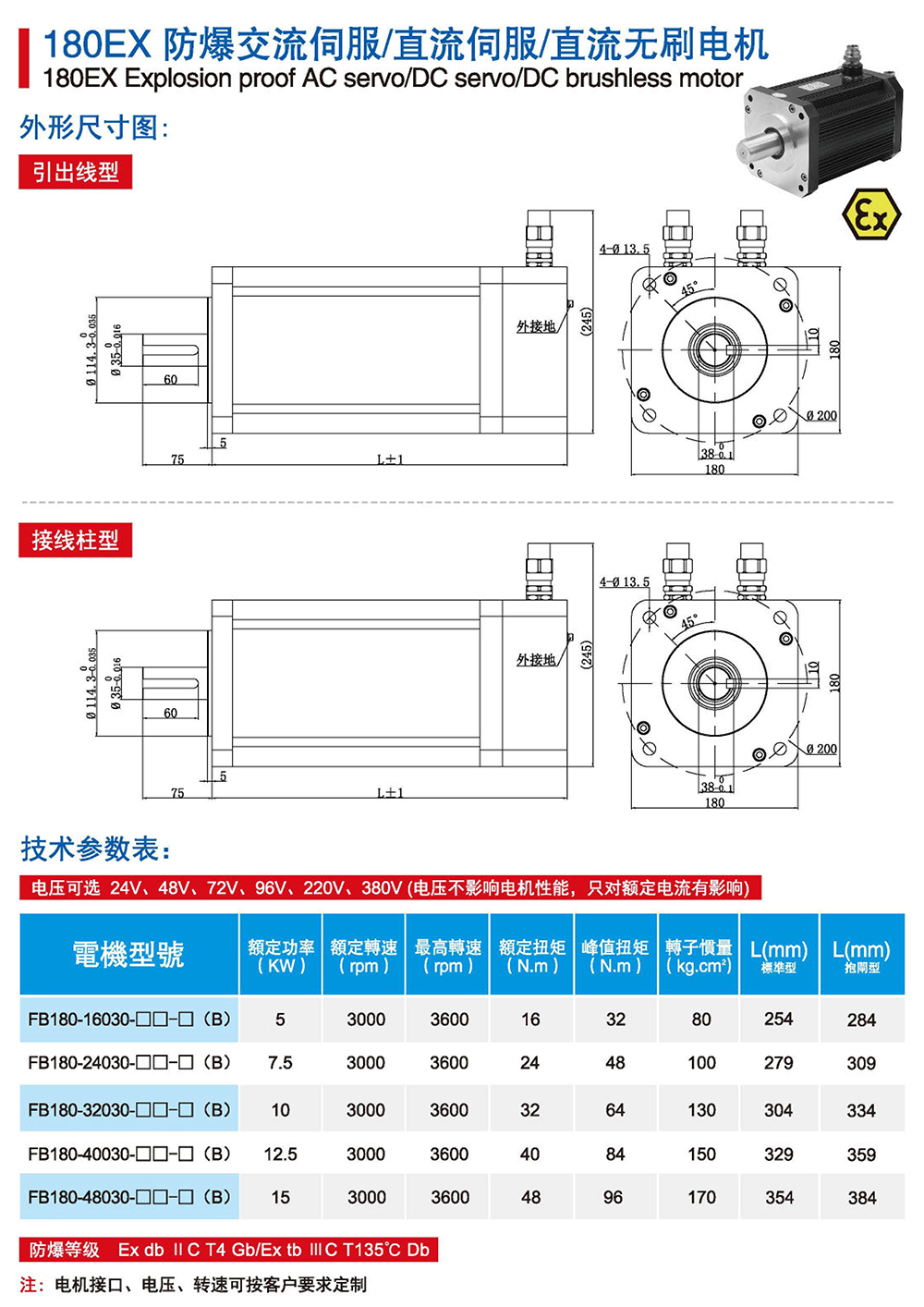

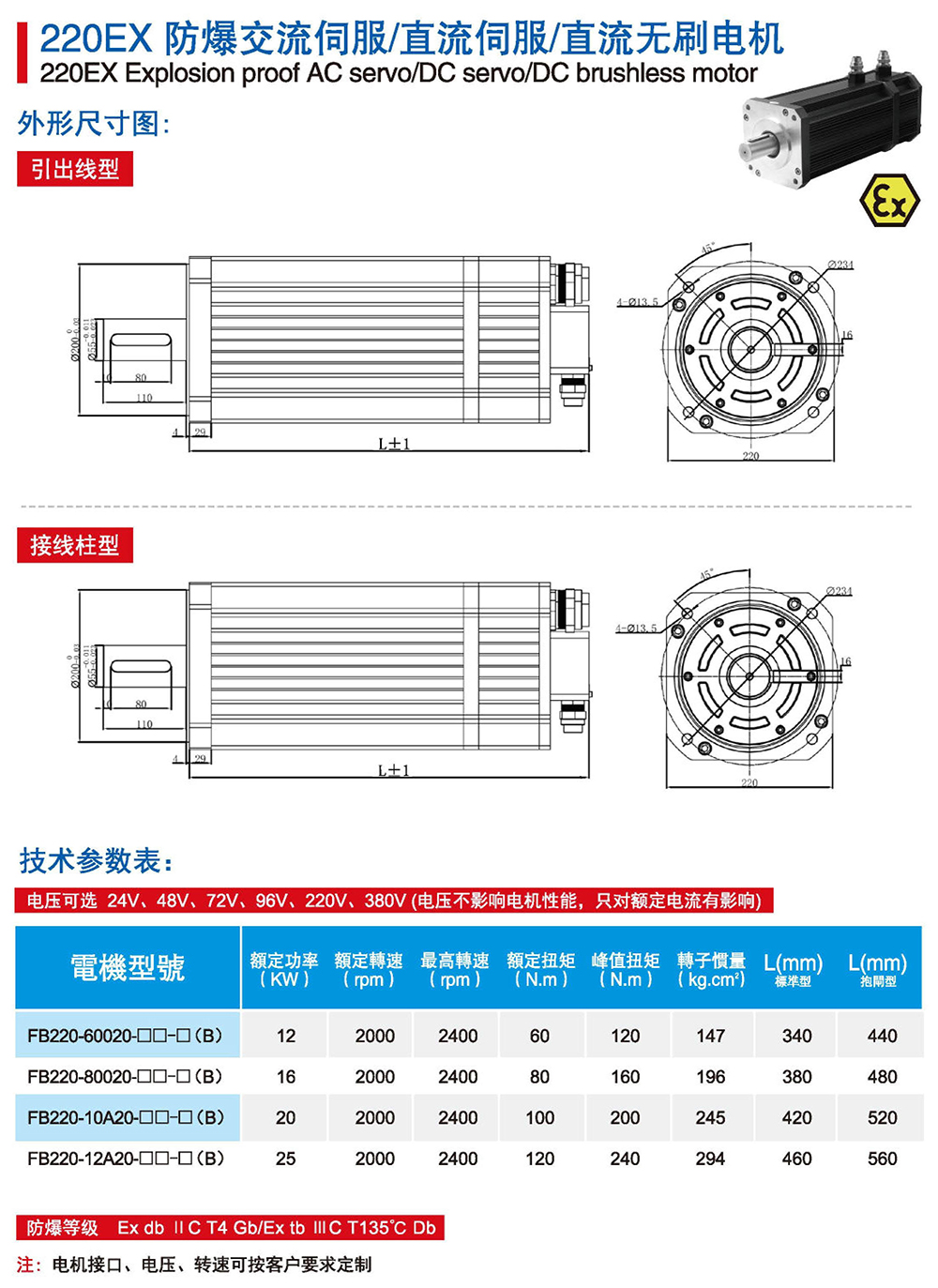

The FB series explosion-proof servo motors are suitable for gas zone 1 and dust zone 21 explosion-proof scenarios, and are widely used in industries such as oil and gas, pharmaceuticals, spraying, printing, etc. Strictly follow the explosion-proof standards for all research and development, design, and manufacturing, to ensure the application of system integrators and equipment manufacturers in explosion-proof environments.

The FB series not only has explosion-proof certification, but also has a compact exterior size and high power density. Rich speed and torque options, low current design control system cost, help create safe, reliable, efficient and energy-saving excellent equipment.

Technical highlights

FB series explosion-proof servo motor, with a brand new explosion-proof design, multiple winding types and feedback options. One zone explosion-proof design is adopted for applications that require higher explosion-proof certification, ensuring that in gas and dust explosion-proof scenarios, the motor casing can withstand internal explosions without damage, ensuring equipment safety.

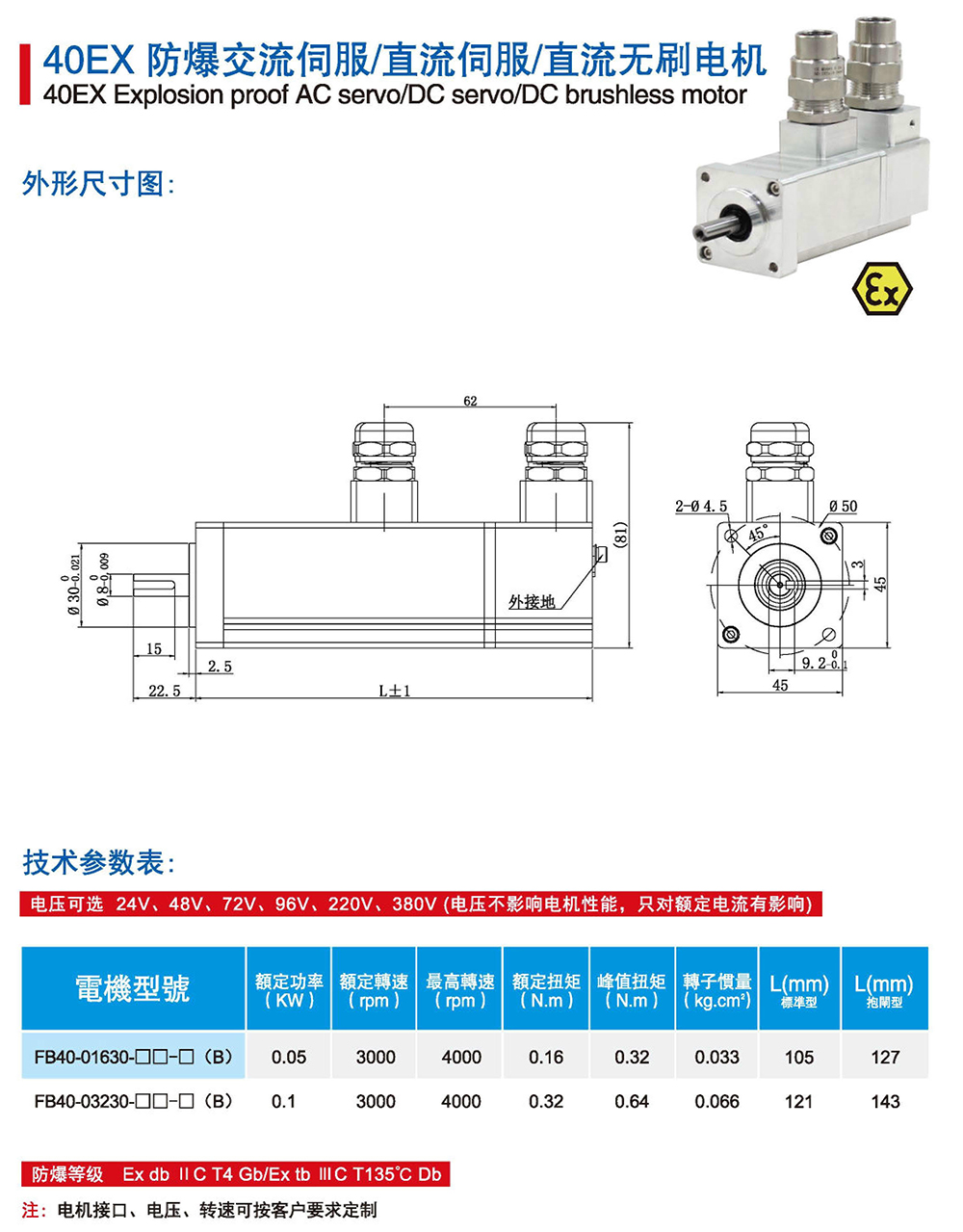

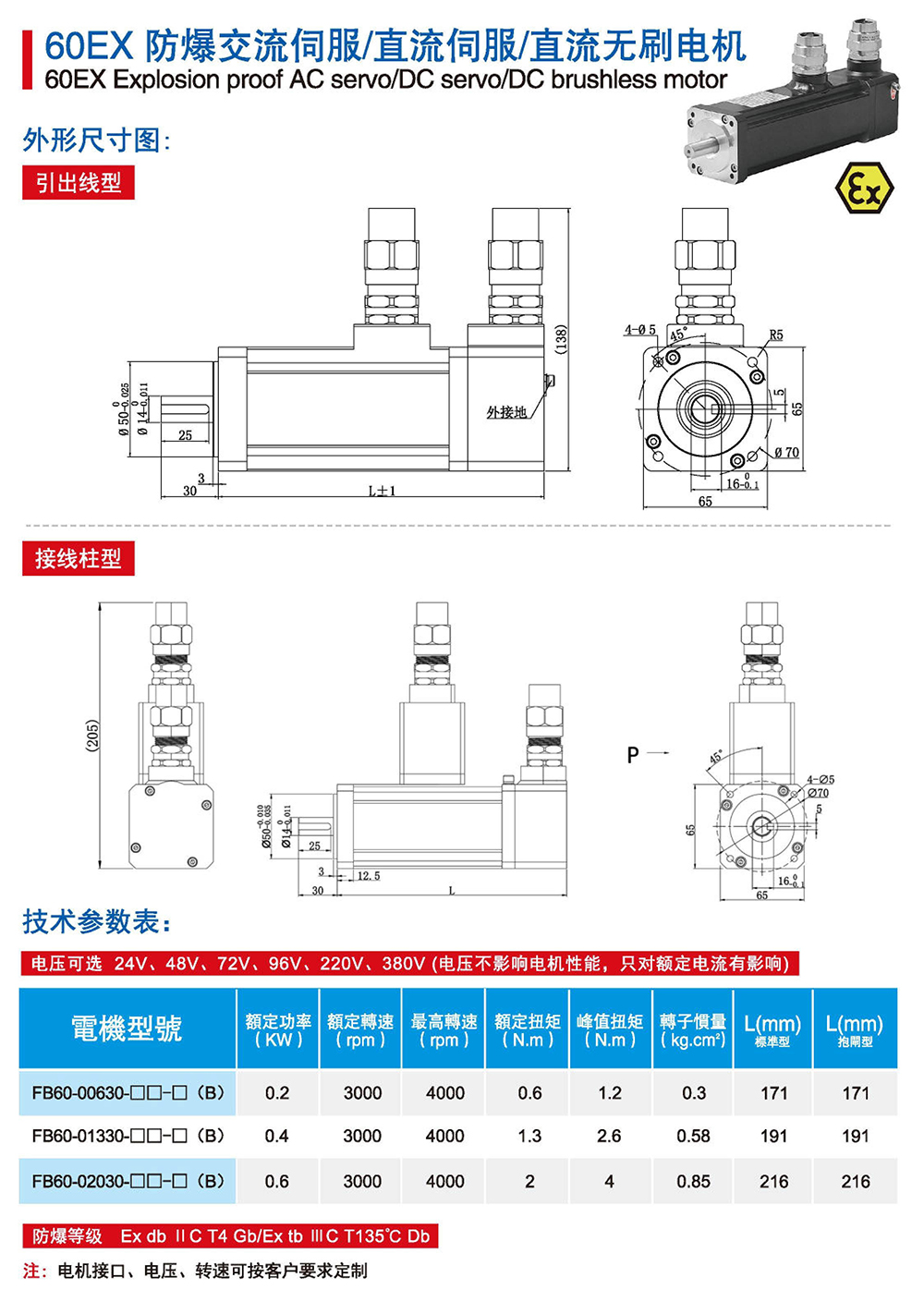

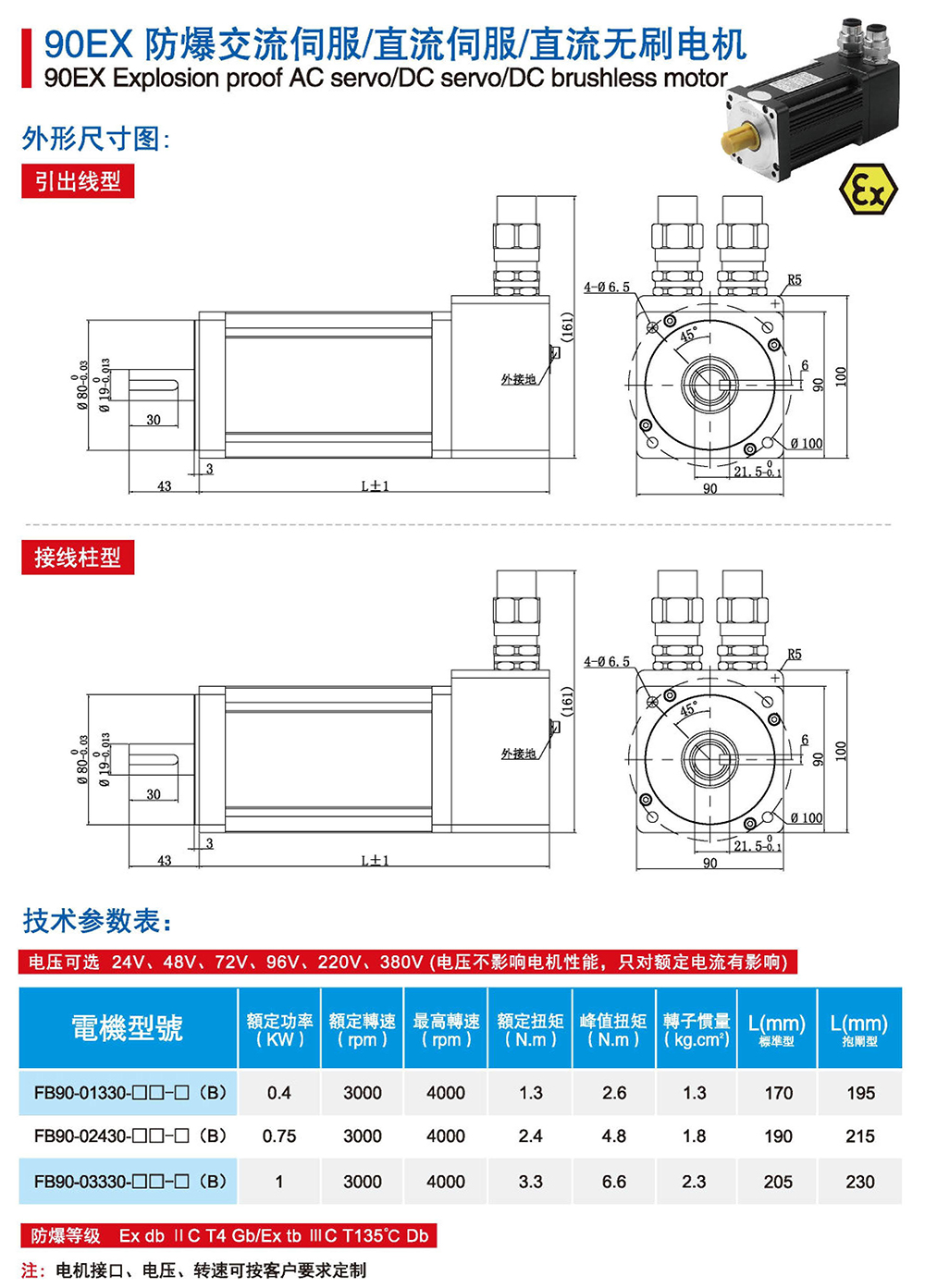

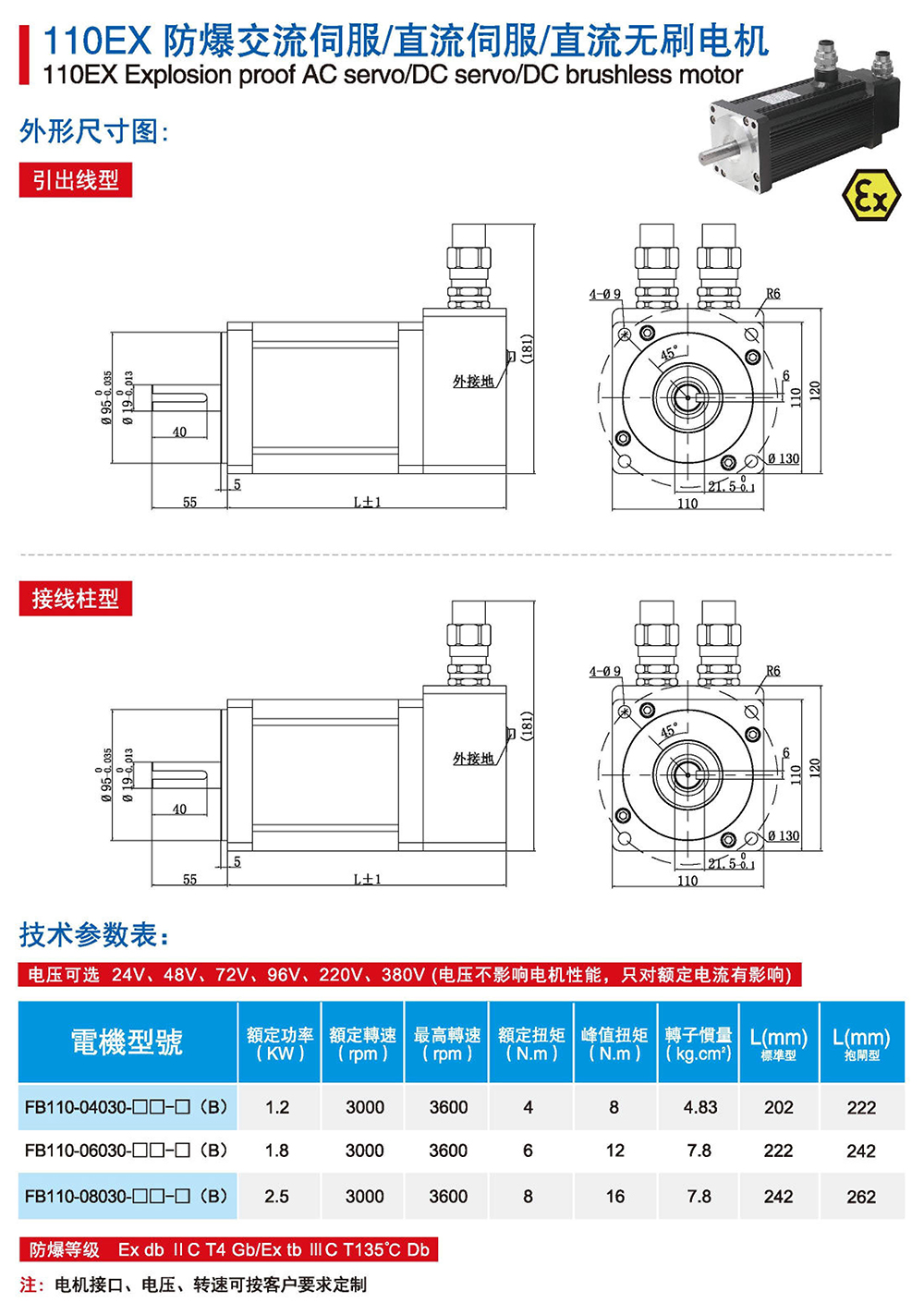

The explosion-proof performance meets the standard, and the CCC explosion-proof symbol is Ex db Ⅱ C T4 Gb/Ex tb Ⅲ C T135 ° C Db.

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

Introduction Specification Table

Specification Table Download

Download