1, the structure is stable and firm

Fixed handles usually have a stable structure and a strong connection, which allows them to maintain high strength and rigidity during use. This structural stability helps to ensure that the handle is not easy to loosen or deform when subjected to external forces or torque, thereby improving the overall stability and safety of the mechanical equipment.2, easy to operate and comfortable

Easy to hold: Fixed handles are often designed with ergonomics in mind, allowing the operator to easily hold and apply force. This design helps to reduce fatigue during operation and improve work efficiency.

Flexible operation: Although the position of fixed handles is relatively fixed, they can usually be combined with other mechanical components to achieve a variety of operating functions, such as rotation, pushing and pulling. This flexibility allows the fixed handle to be adapted to different operating requirements.

3, durable and reliable

Strong wear resistance: The fixed handle is usually made of wear-resistant materials, such as phenolic plastic (bakelite). These materials have good wear and corrosion resistance and can maintain a long service life during use.

Simple maintenance: Due to the relatively simple structure of fixed handles, their maintenance costs are also relatively low. In the event of wear or damage, the handle can be easily replaced or repaired, thus ensuring the continuous and stable operation of the mechanical equipment.

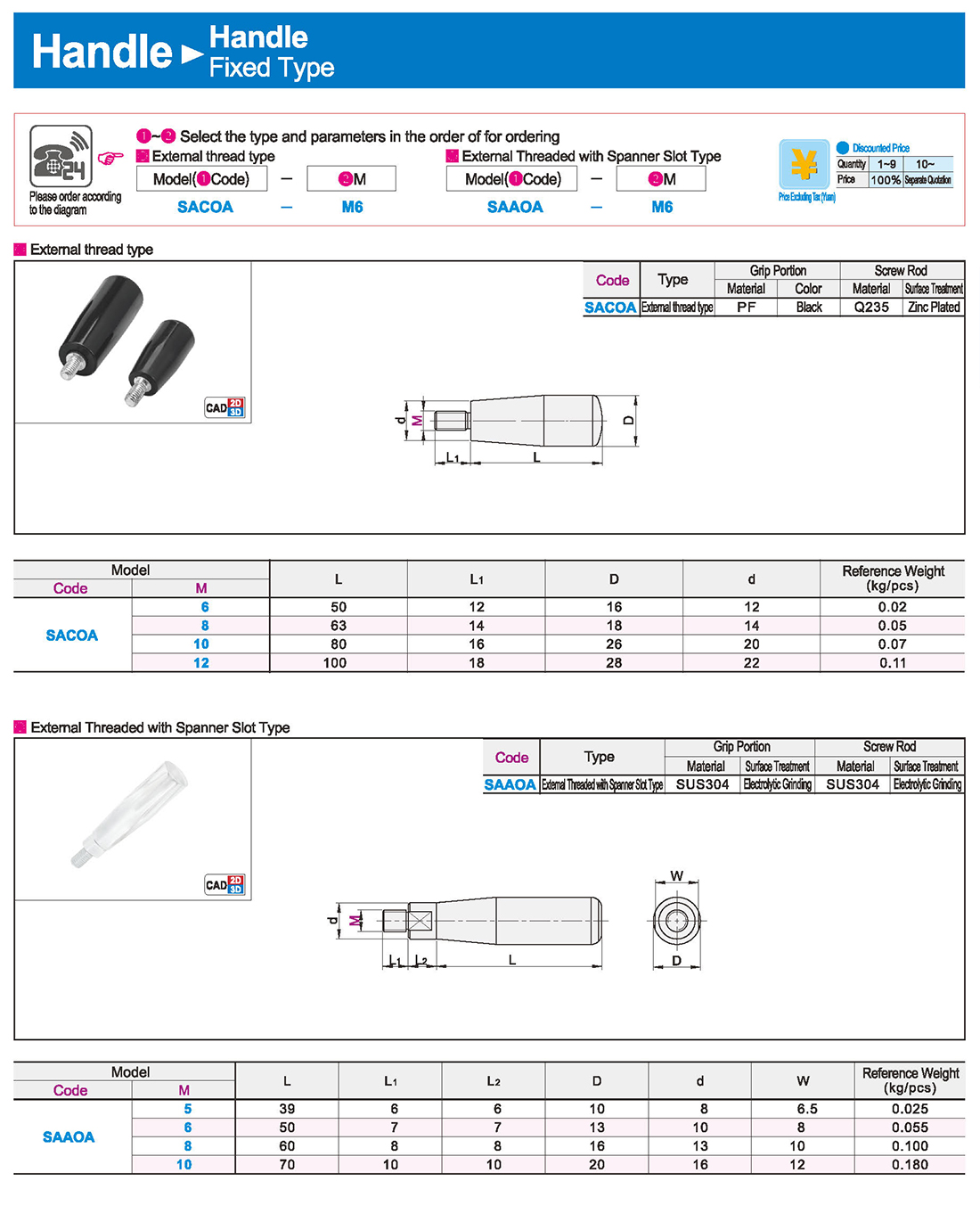

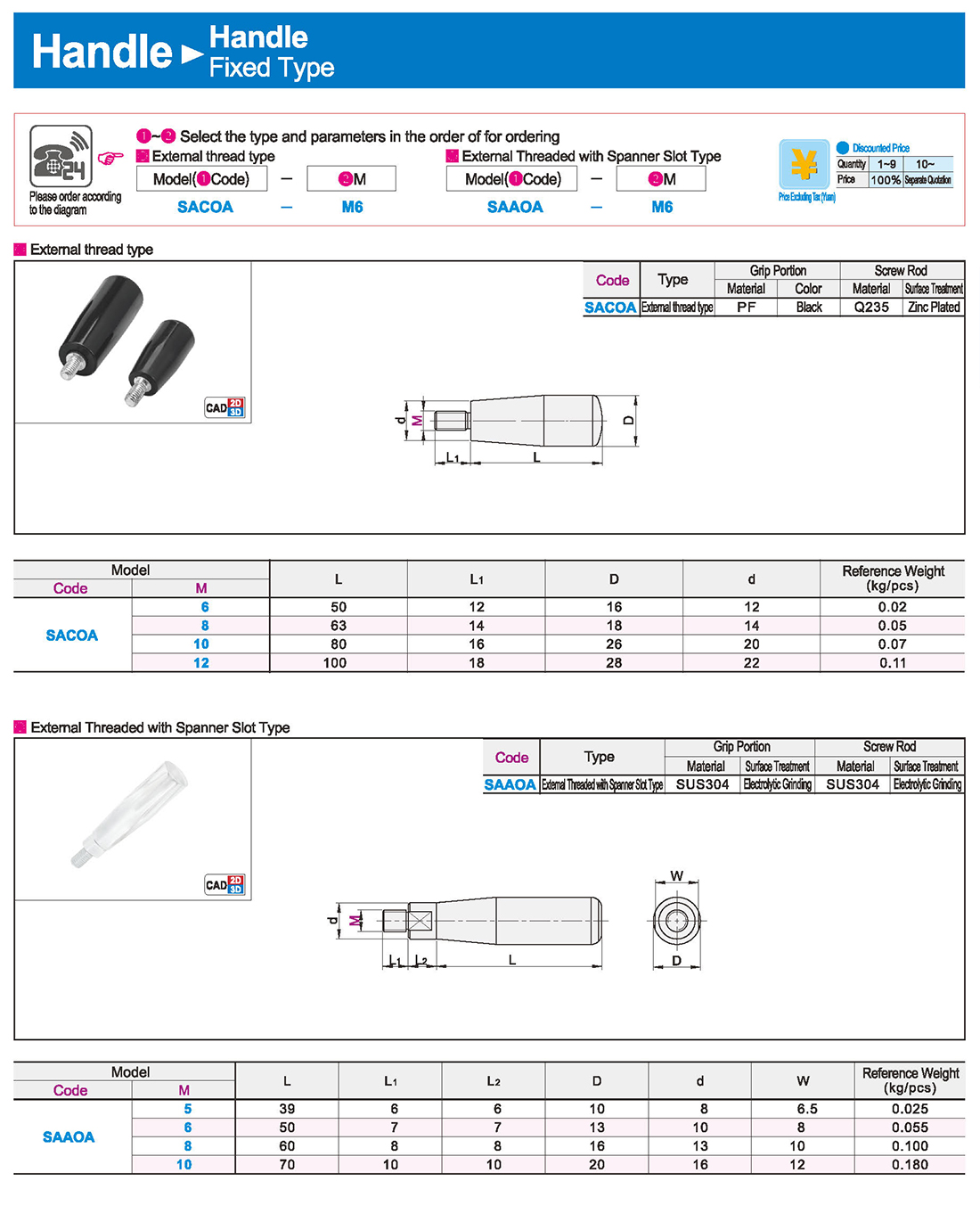

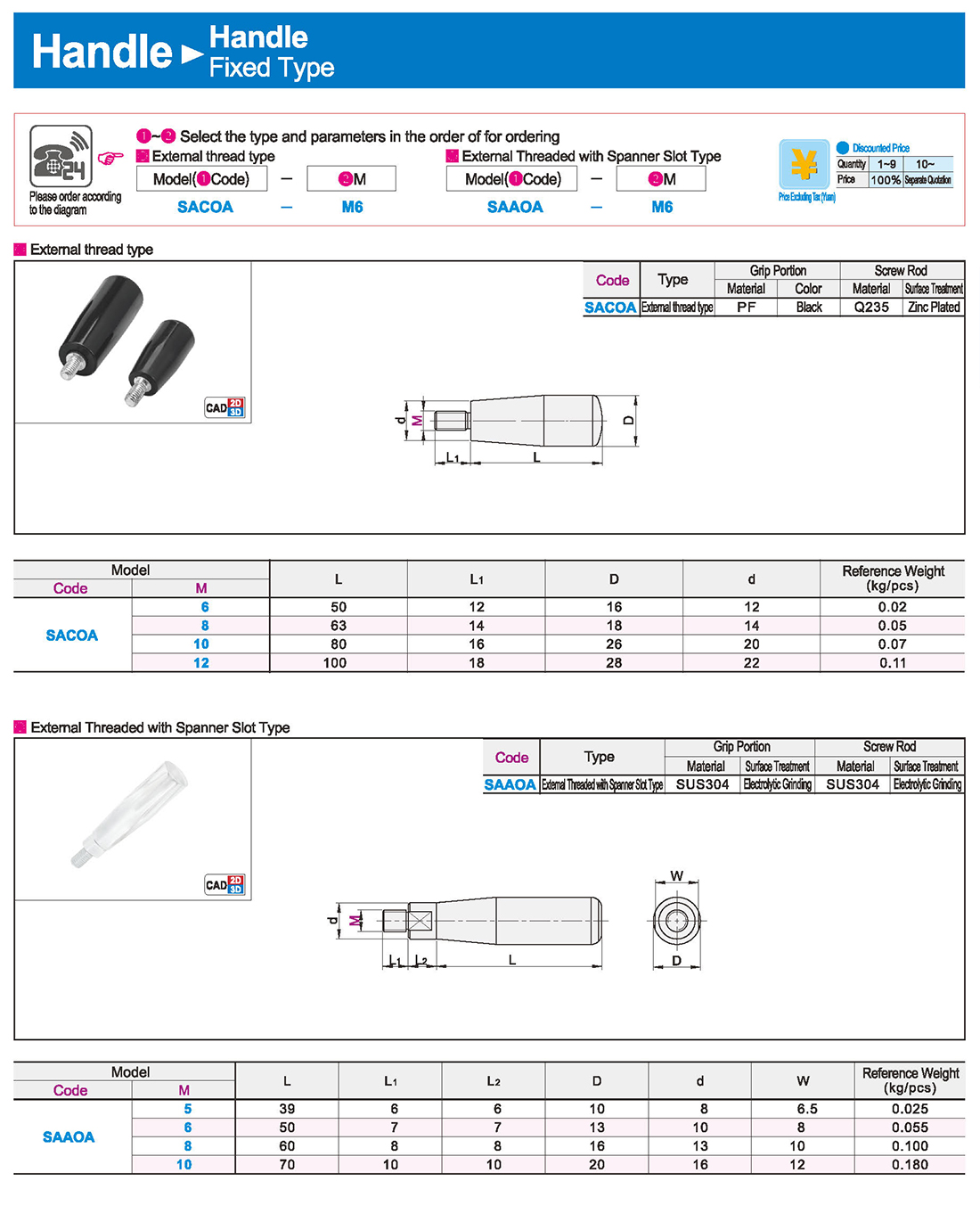

Handle - Fixed Type - External Threaded with Spanner Slot Type - Grip Portion - Electrolytic Grinding - Screw Rod

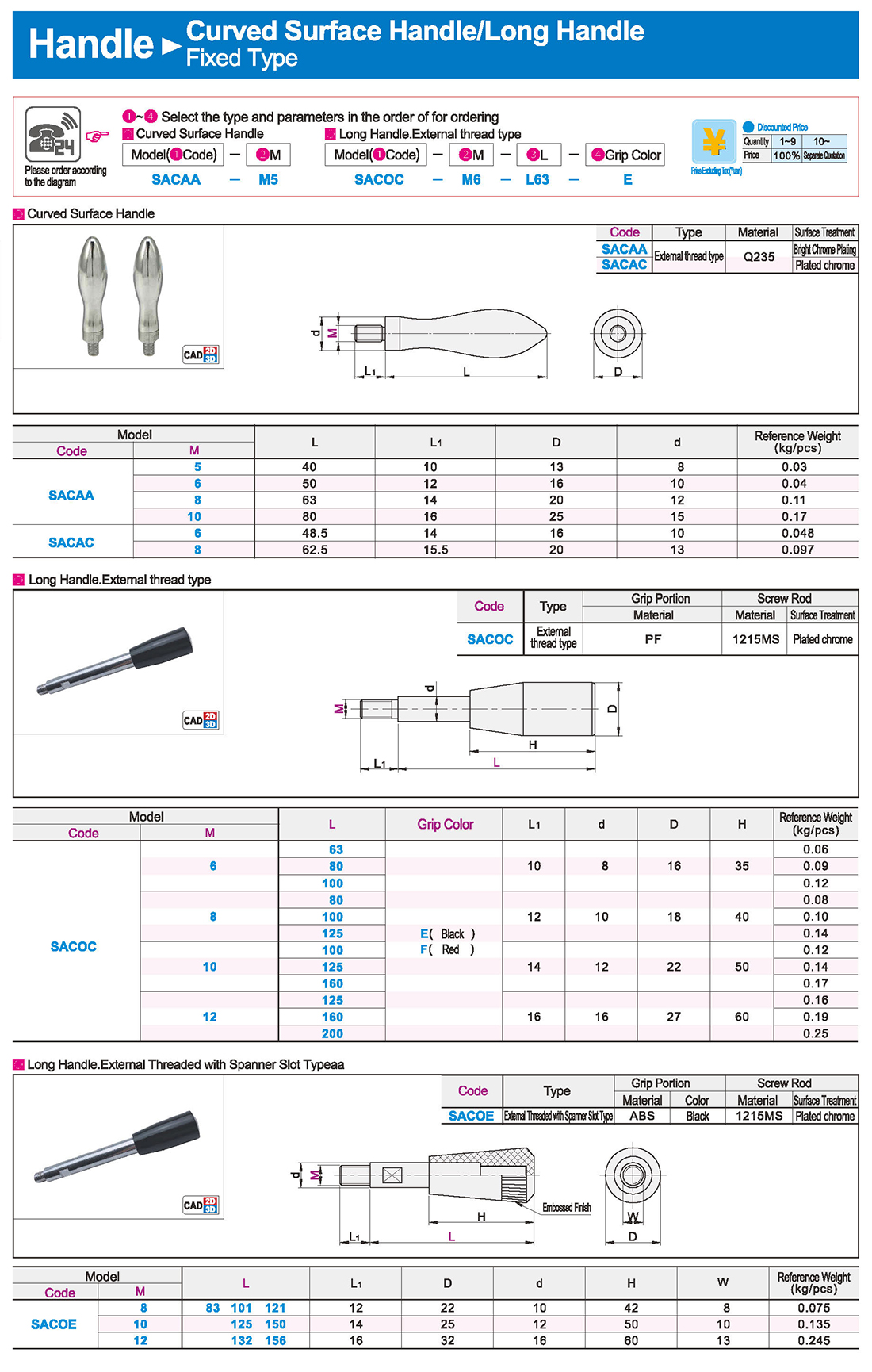

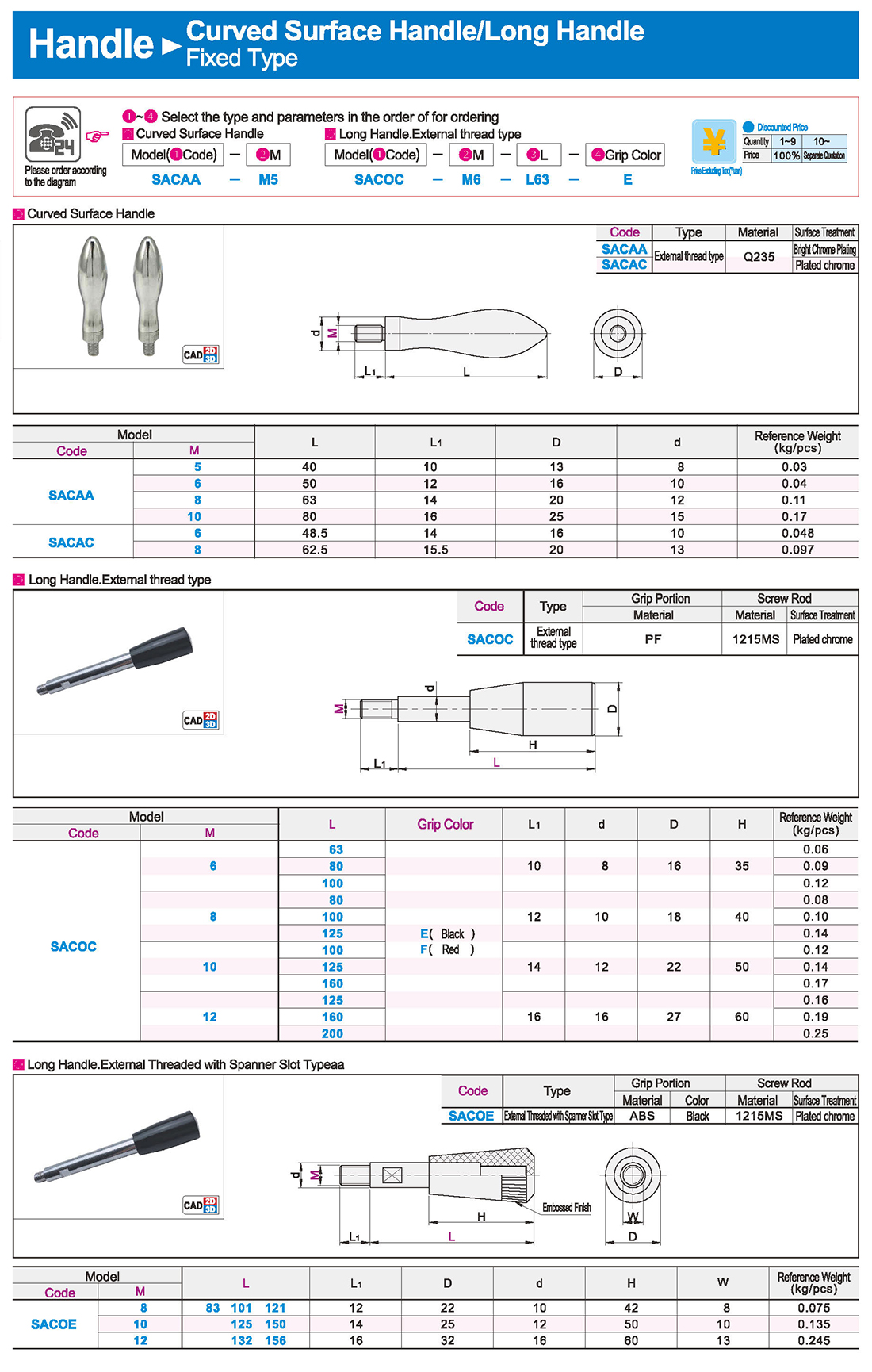

Curved Surface Handle - Long Handle - Bright Chrome Plating - External Threaded with Spanner Slot Type - Embossed Finish - Grip Color - Red

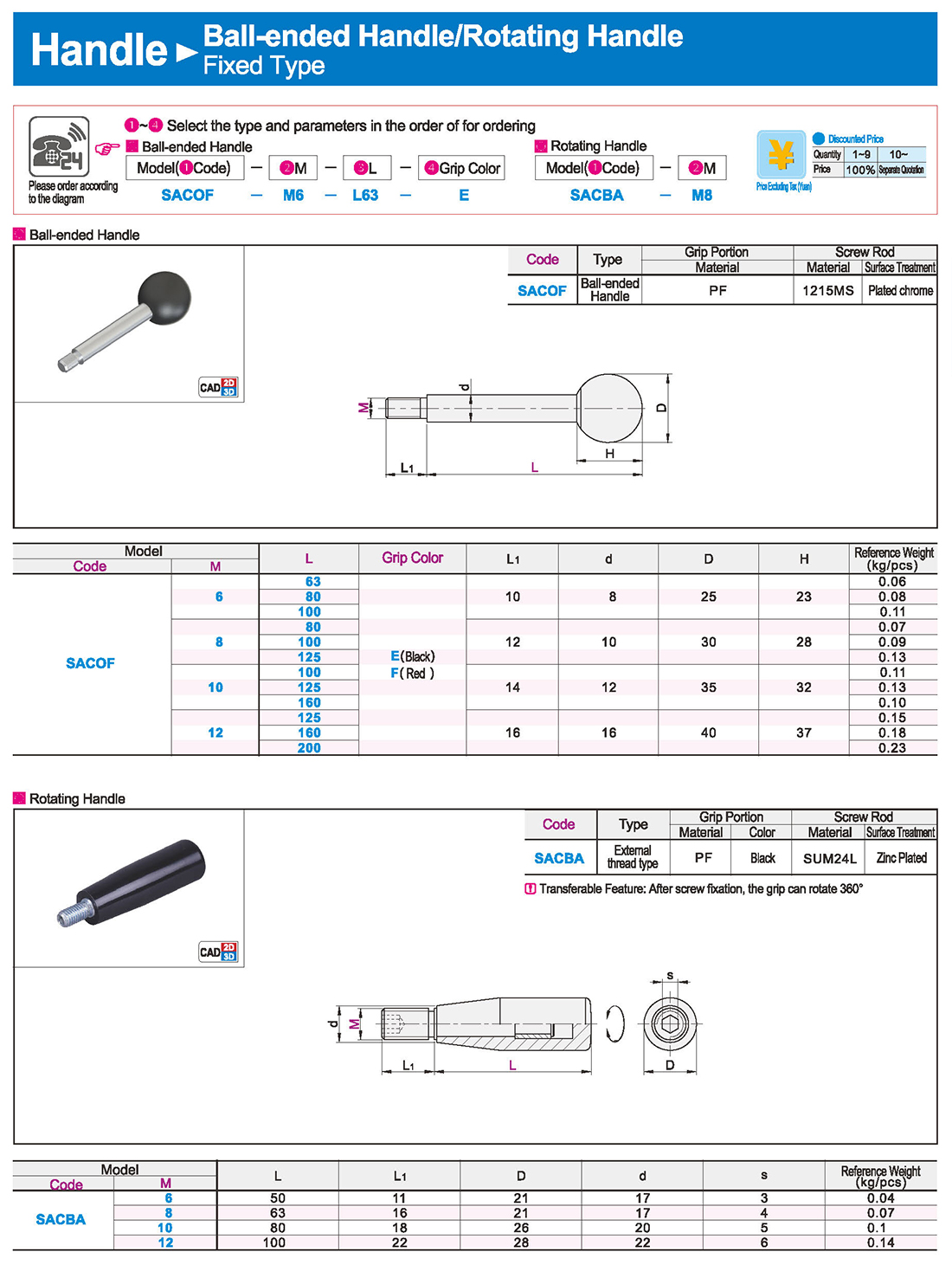

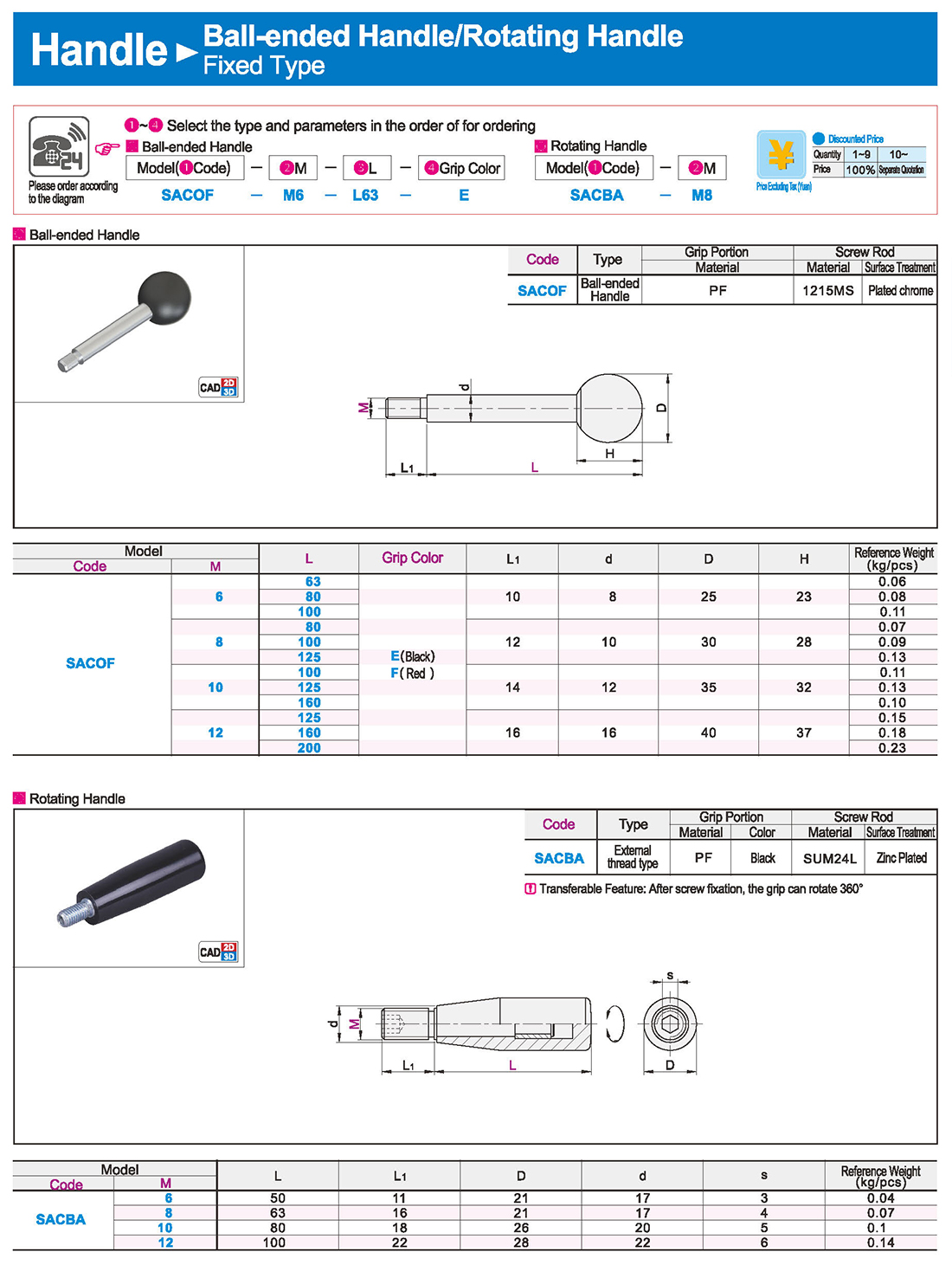

Ball-ended Handle - Rotating Handle - Transferable Feature: After screw fixation, the grip can rotate 360°

Long rotating handle, small straight rod type, rotating type, adjustable locking and pressing type, orange, silver gray

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

Introduction Specification Table

Specification Table Download

Download