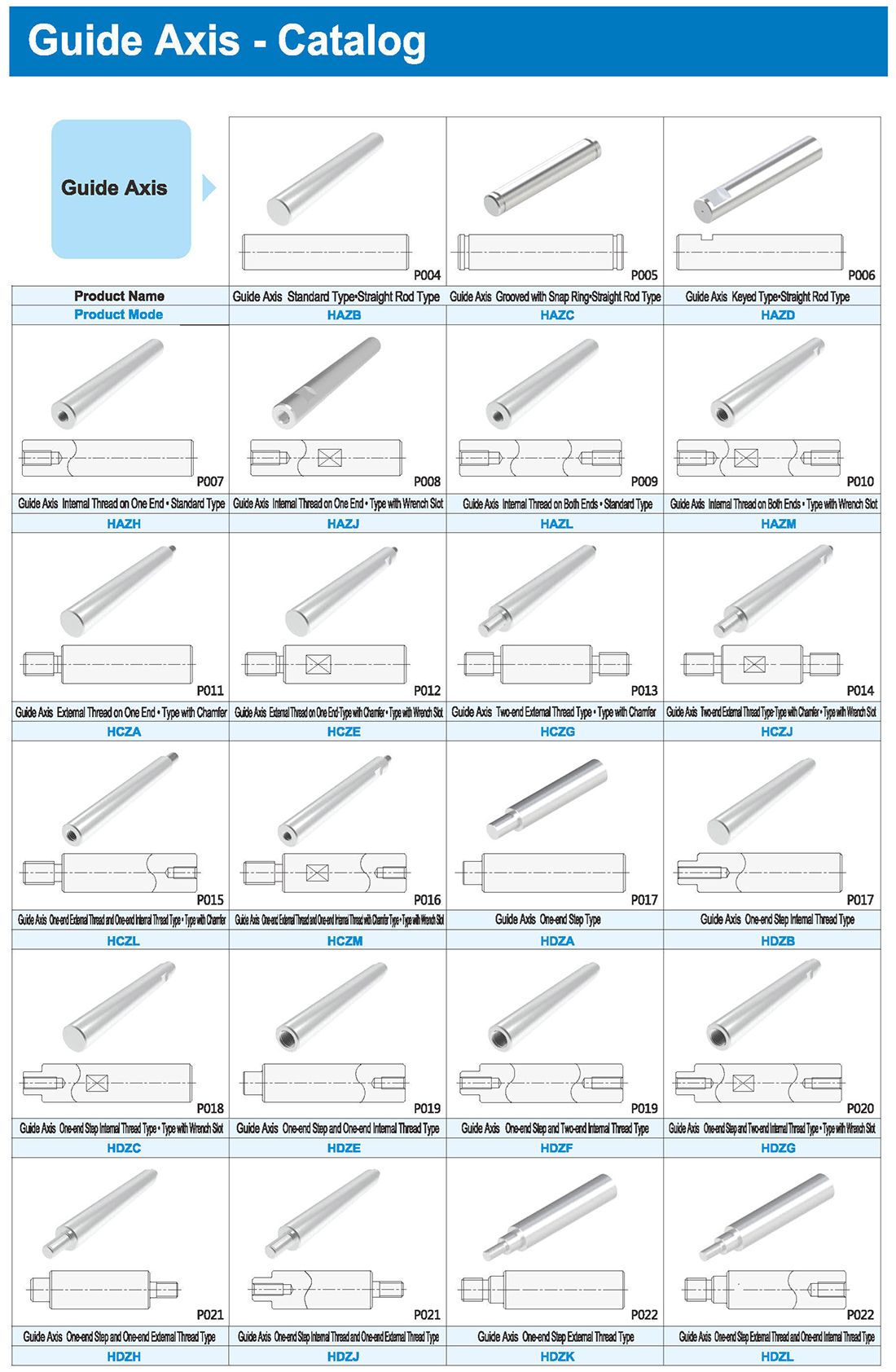

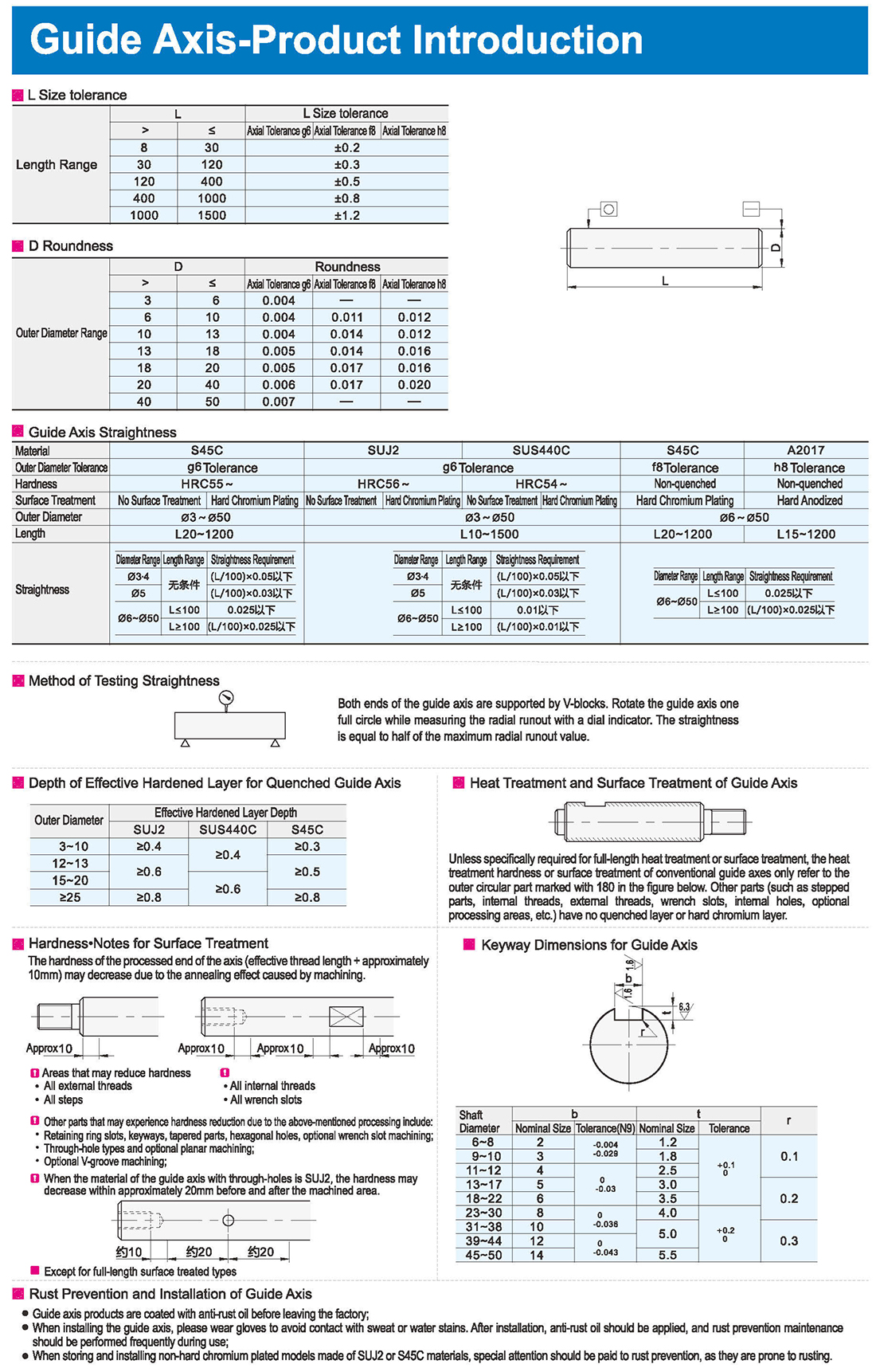

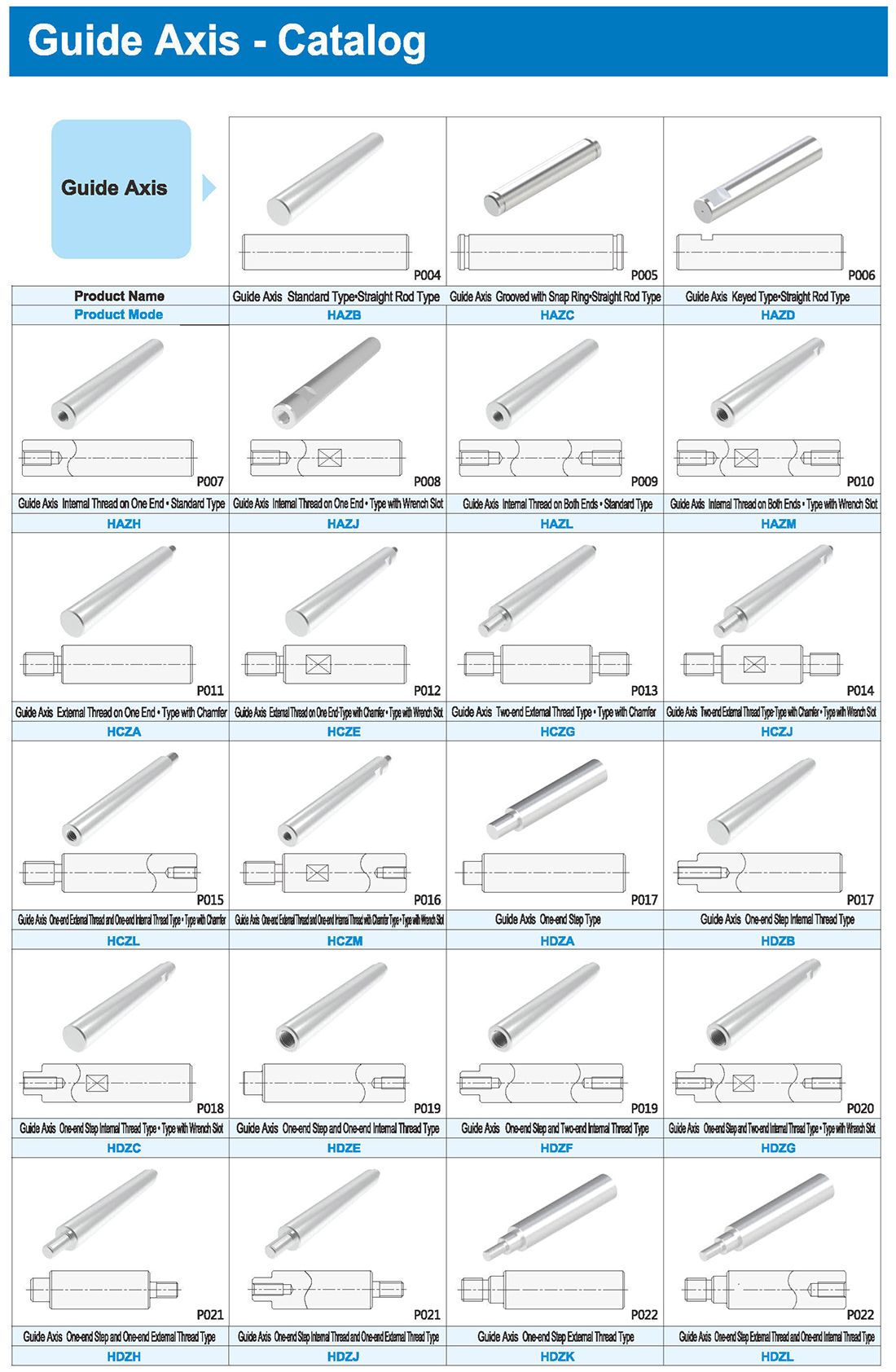

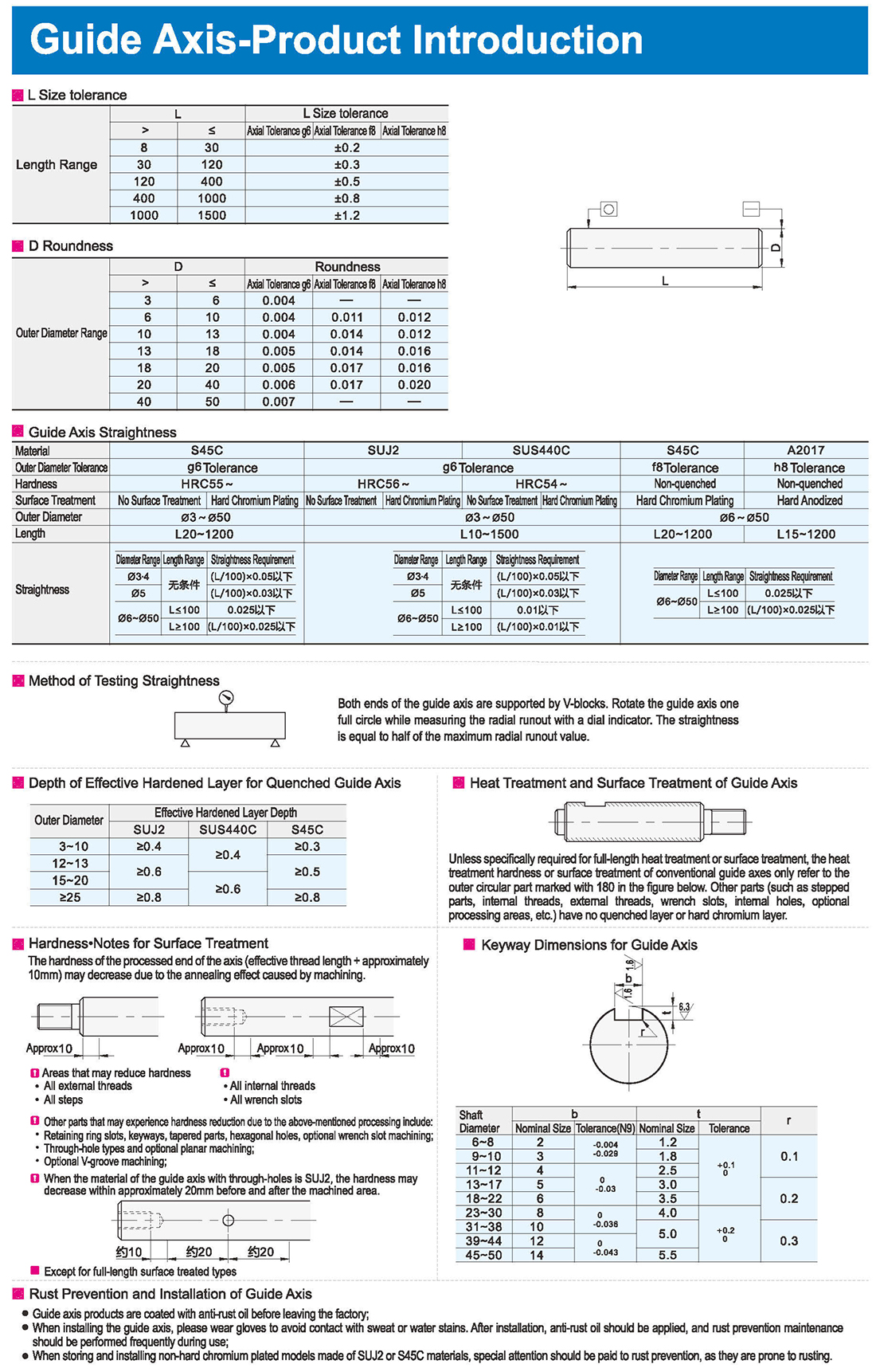

1.Depth of Effective Hardened Layer for Quenched Guide Axis

2.Heat Treatment and Surface Treatment of Guide Axis。

Unless specifically required for full-length heat treatment or surface treatment, the heat treatment hardness or surface treatment of conventional guide axes only refer to the outer circular part marked with 180 in the figure below. Other parts (such as stepped parts, internal threads, external threads, wrench slots, internal holes, optional processing areas, etc.) have no quenched layer or hard chromium layer.

3.Rust Prevention and Installation of Guide Axis

Guide axis products are coated with anti-rust oil before leaving the factory;

When installing the guide axis, please wear gloves to avoid contact with sweat or water stains. After installation, anti-rust oil should be applied, and rust prevention maintenance should be performed frequently during use;

When storing and installing non-hard chromium plated models made of SUJ2 or S45C materials, special attention should be paid to rust prevention, as they are prone to rusting.

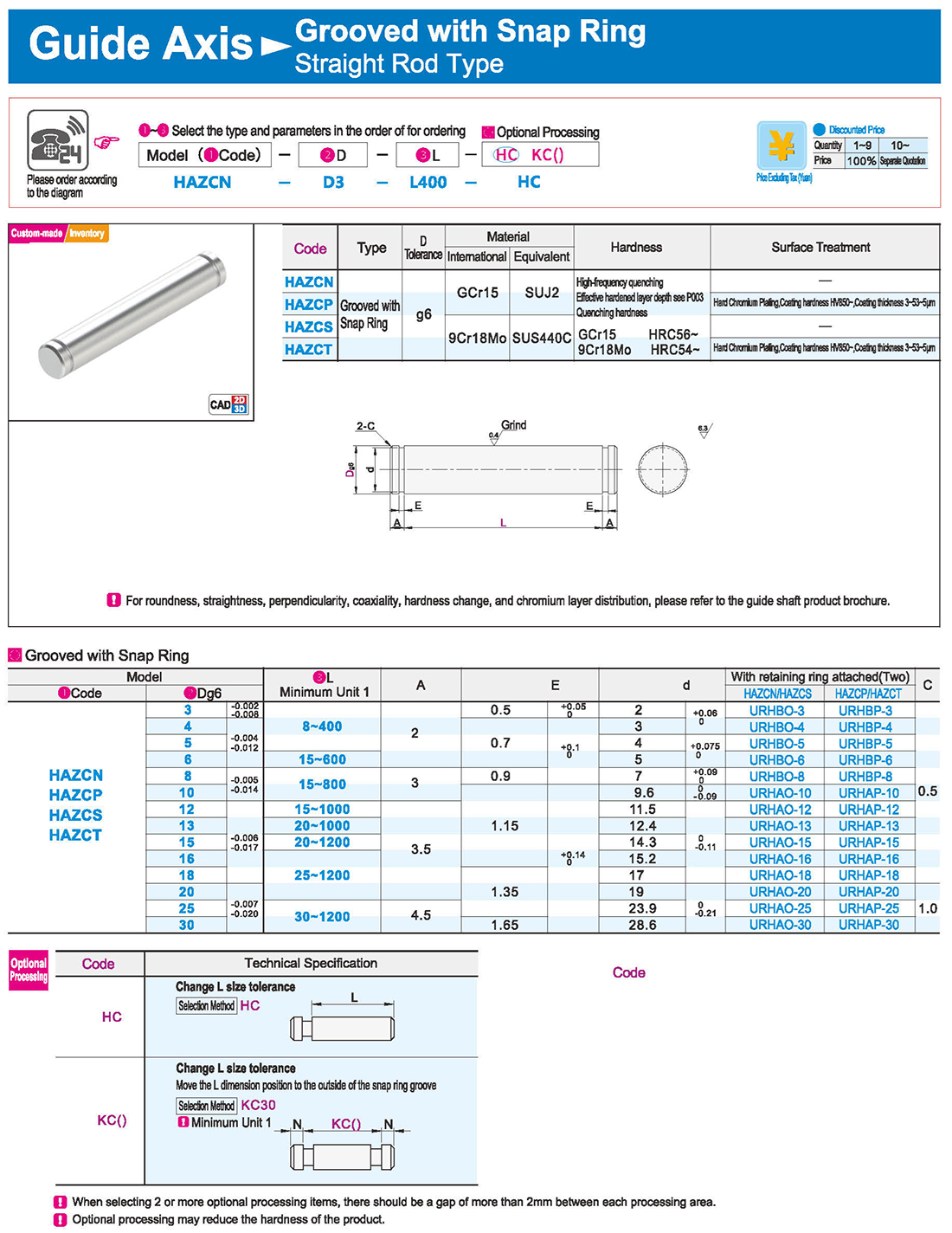

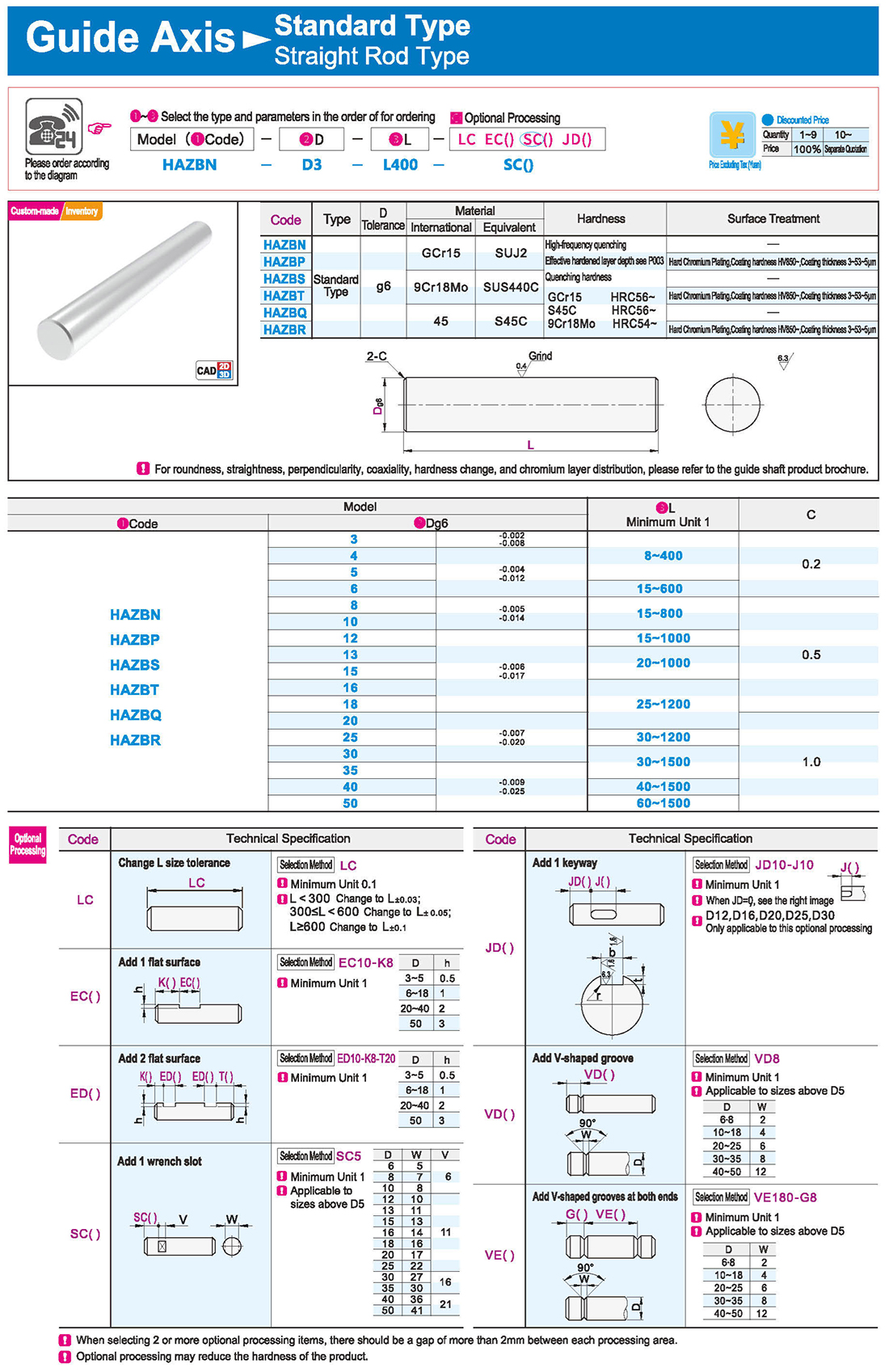

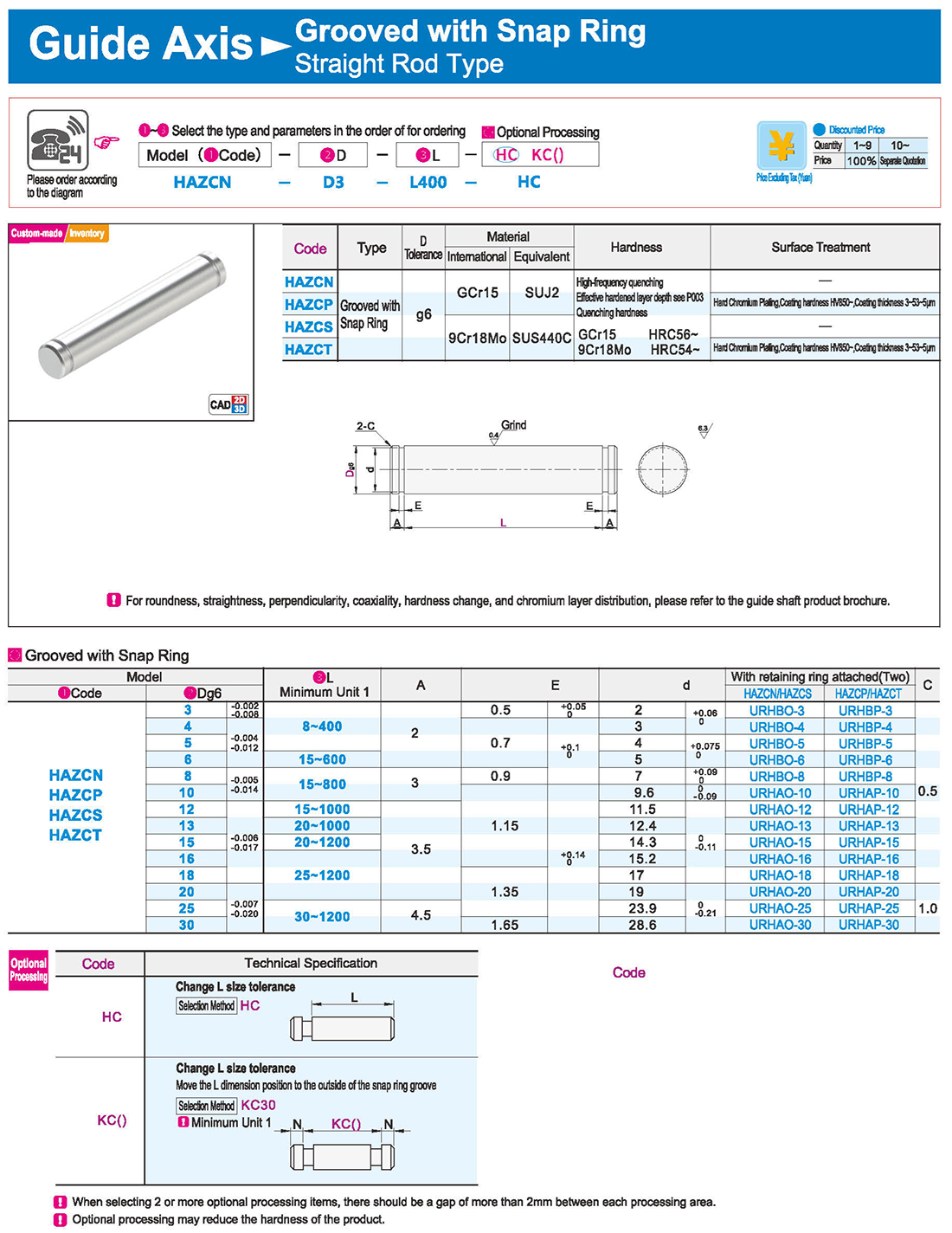

1.Grooved with Snap Ring

Cancel snap ring groove on one end Move the L dimension position to the outside of the snap ring groove

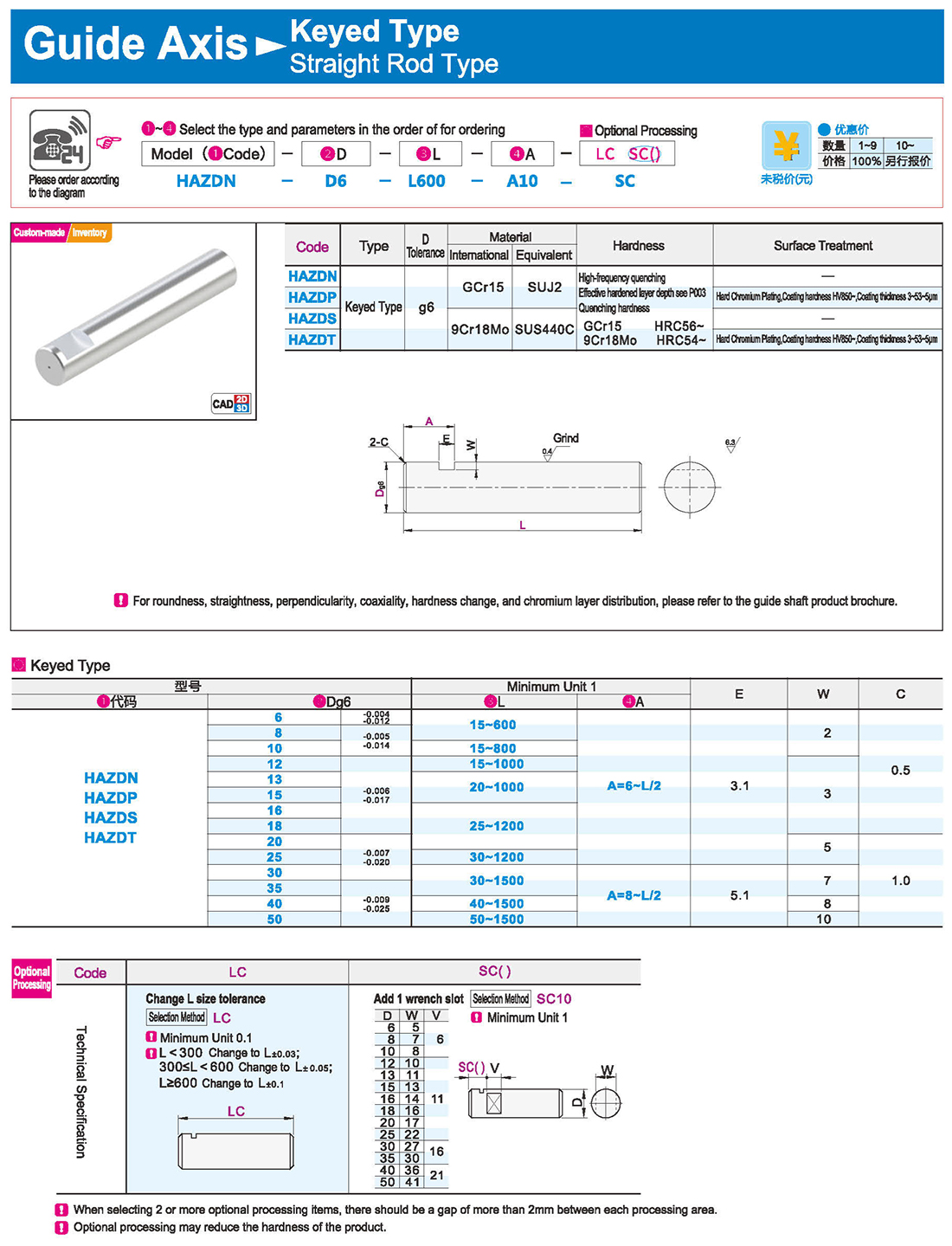

2.Keyed Type Internal Thread on One End

Precision Grade Ordinary Grade Precision Grade

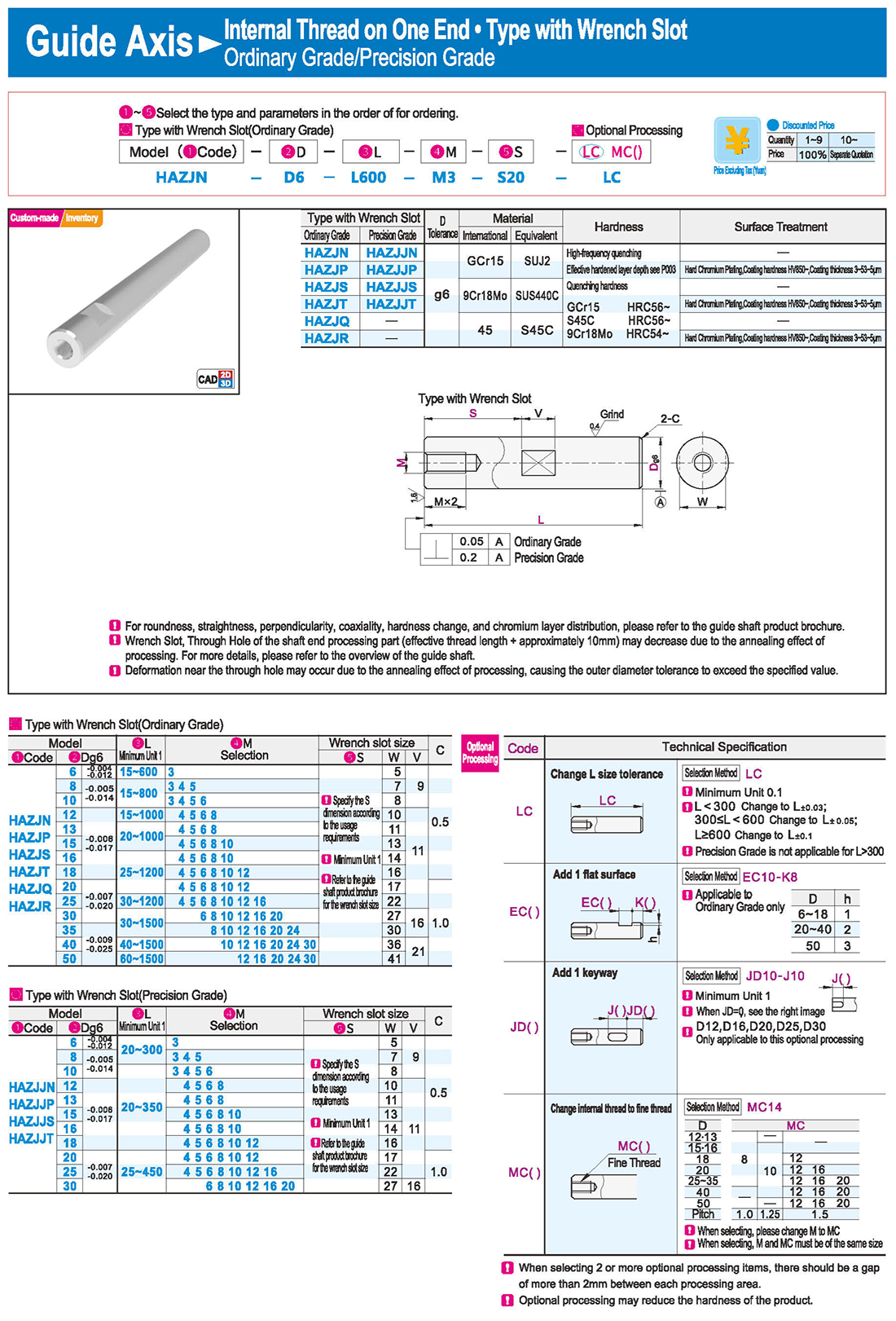

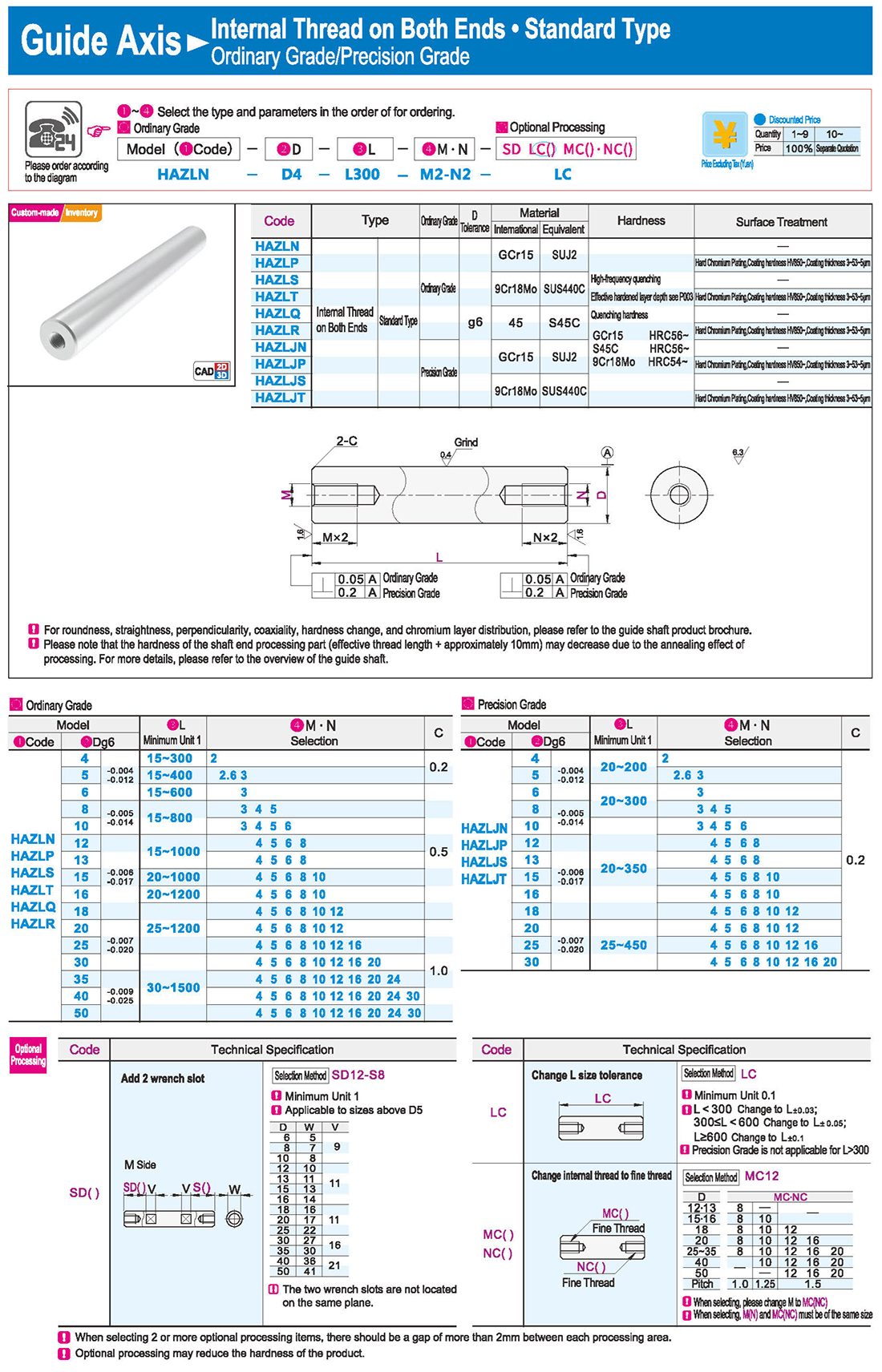

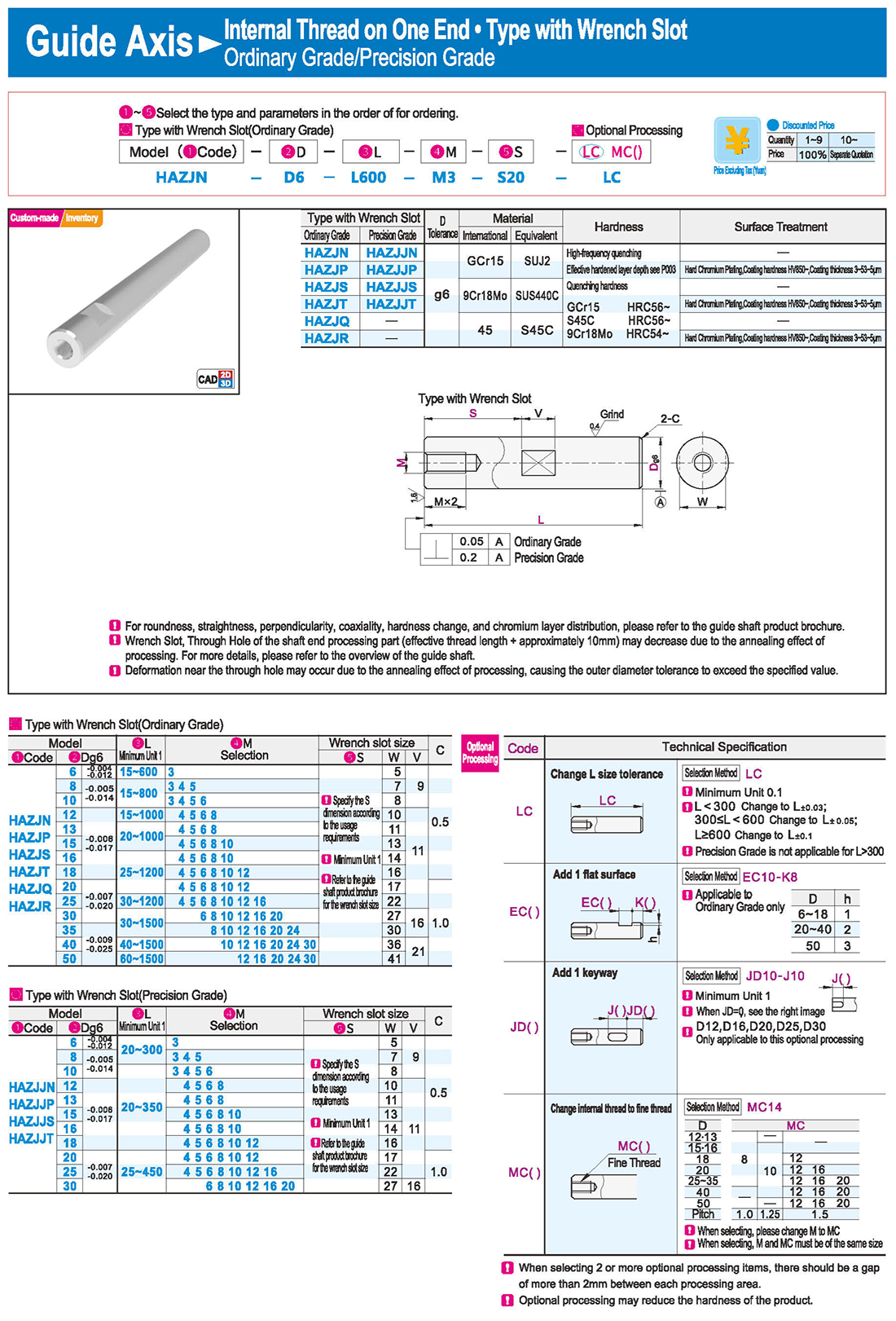

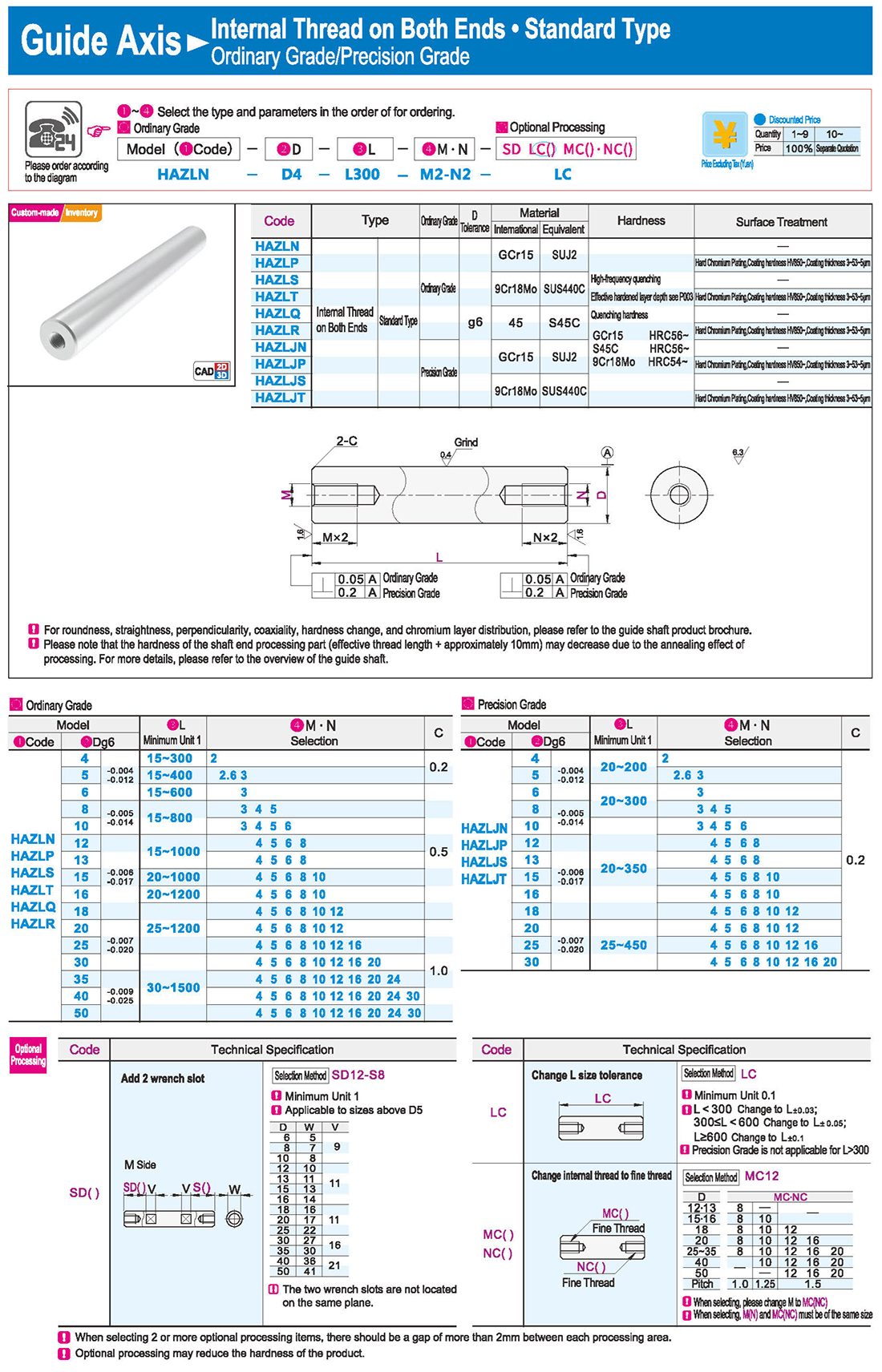

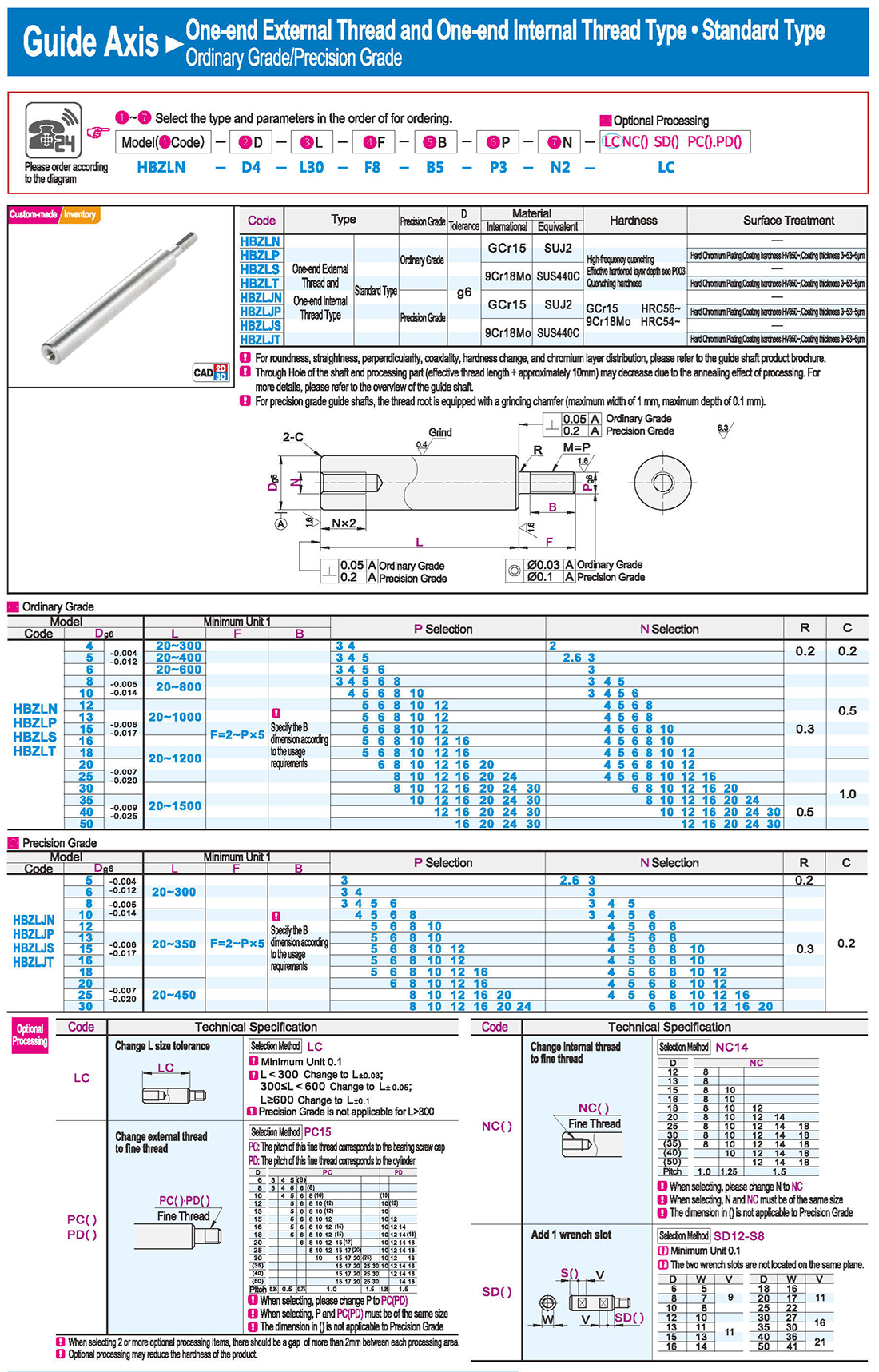

Please note that the hardness of the shaft end processing part (effective thread length + approximately 10mm) may decrease due to the annealing effect of processing. For more details, please refer to the overview of the guide shaft.

Selection: Precision Grade is not applicable for L>300

Change internal thread to fine thread Pitch Fine Thread

When selecting, please change M to MC

M and MC must be of the same size

Applicable to Ordinary Grade only

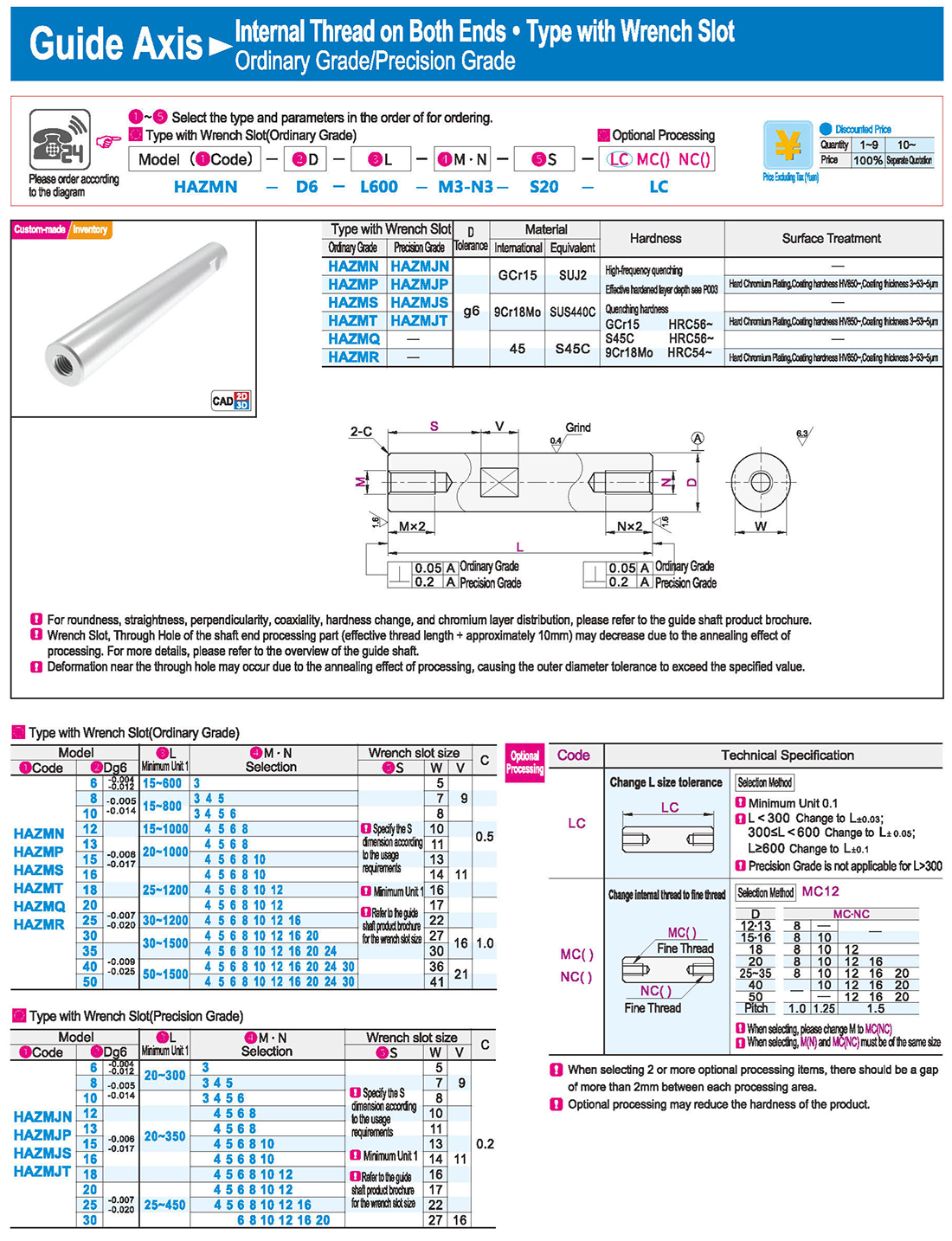

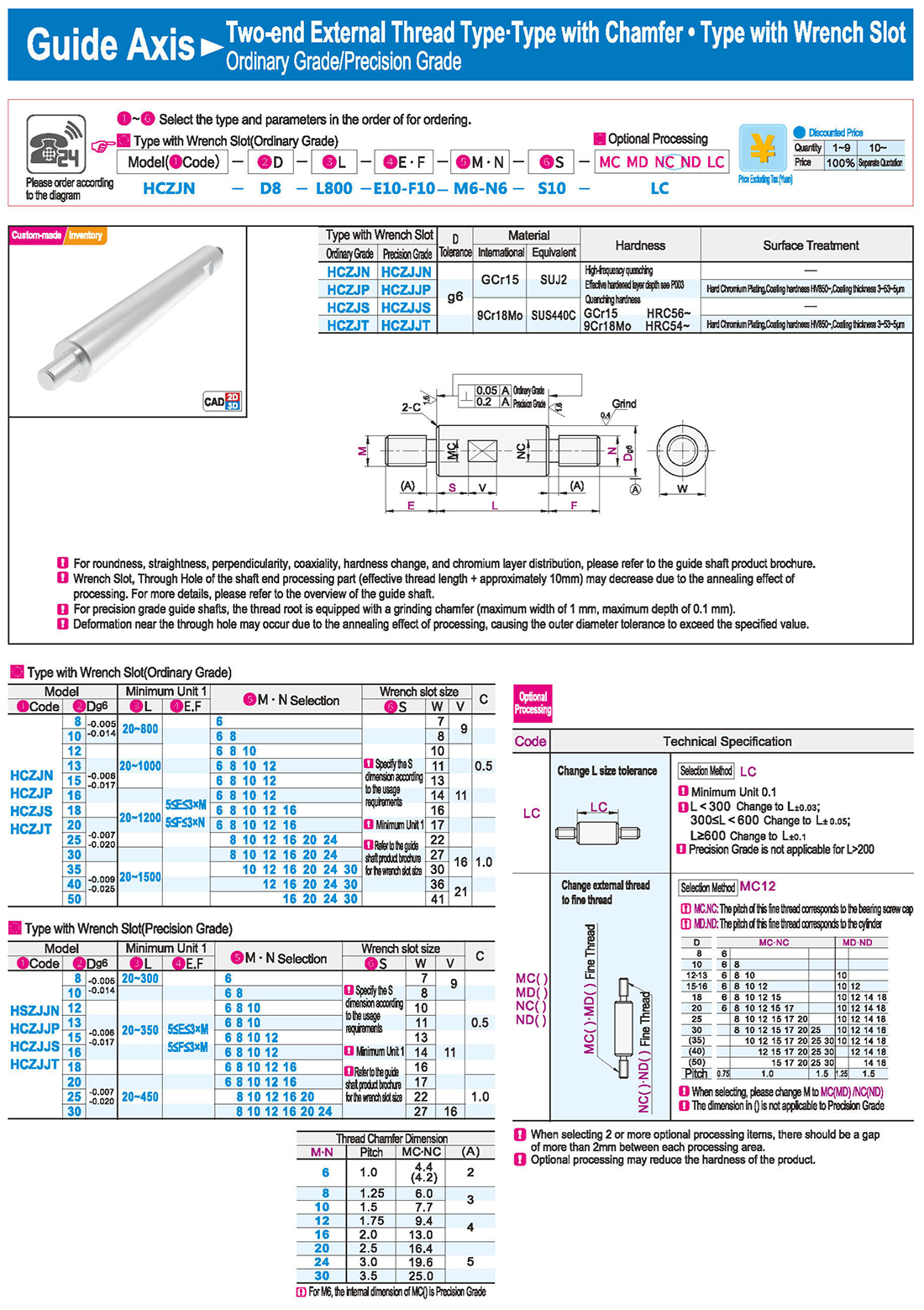

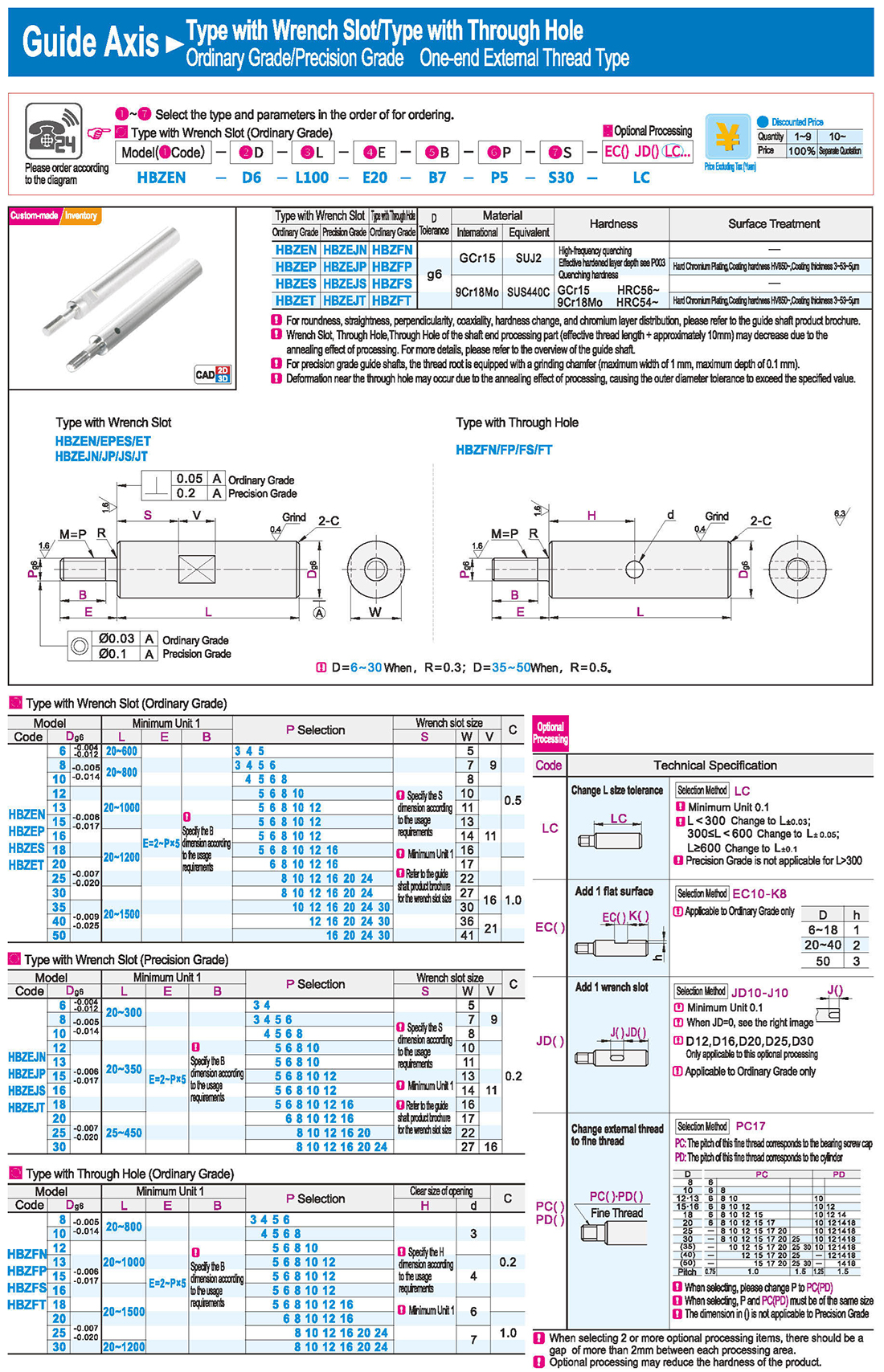

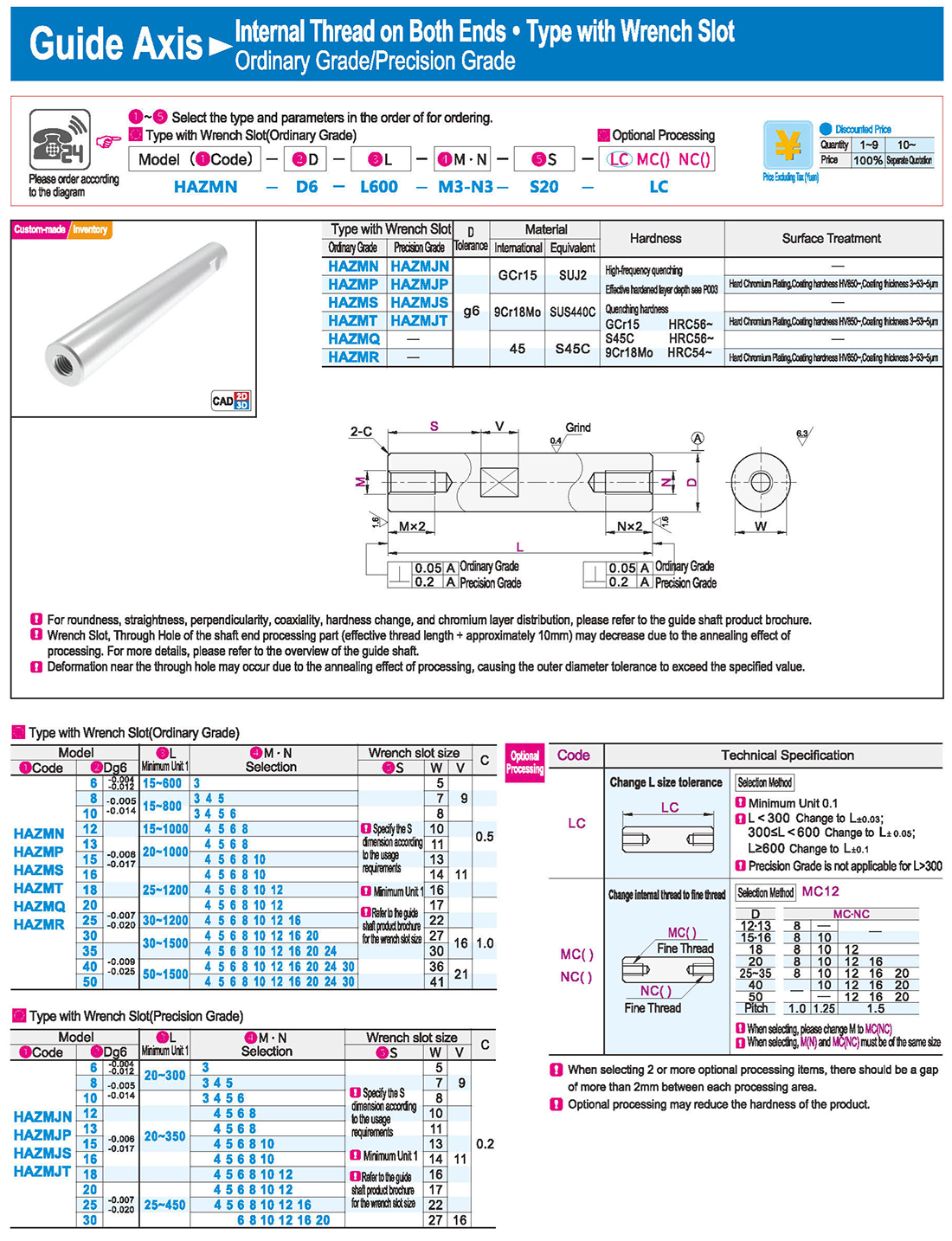

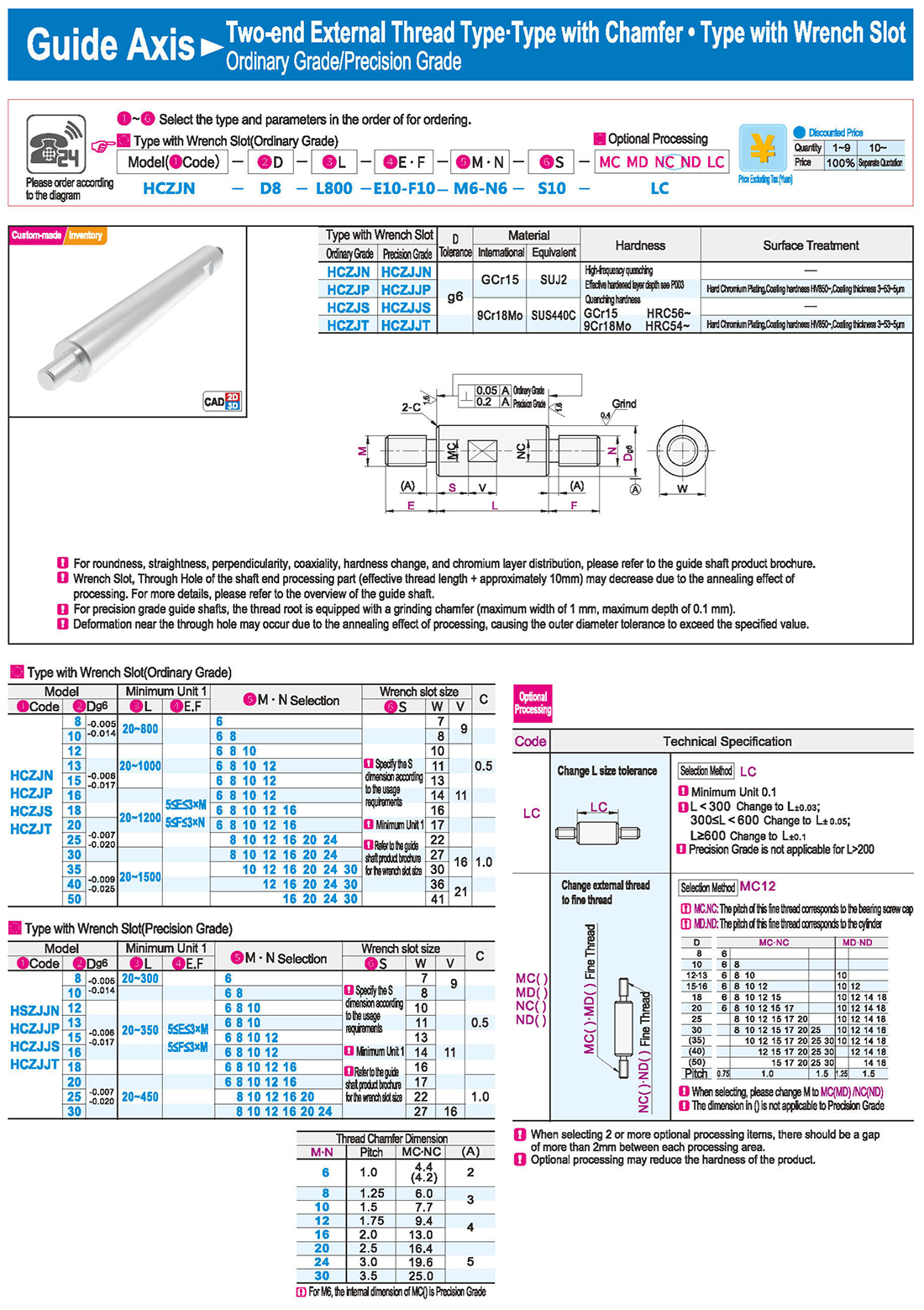

3.Type with Wrench Slot

Deformation near the through hole may occur due to the annealing effect of processing, causing the outer diameter tolerance to exceed the specified value.

Specify the S dimension according to the usage requirements

Refer to the guide shaft product brochure for the wrench slot size

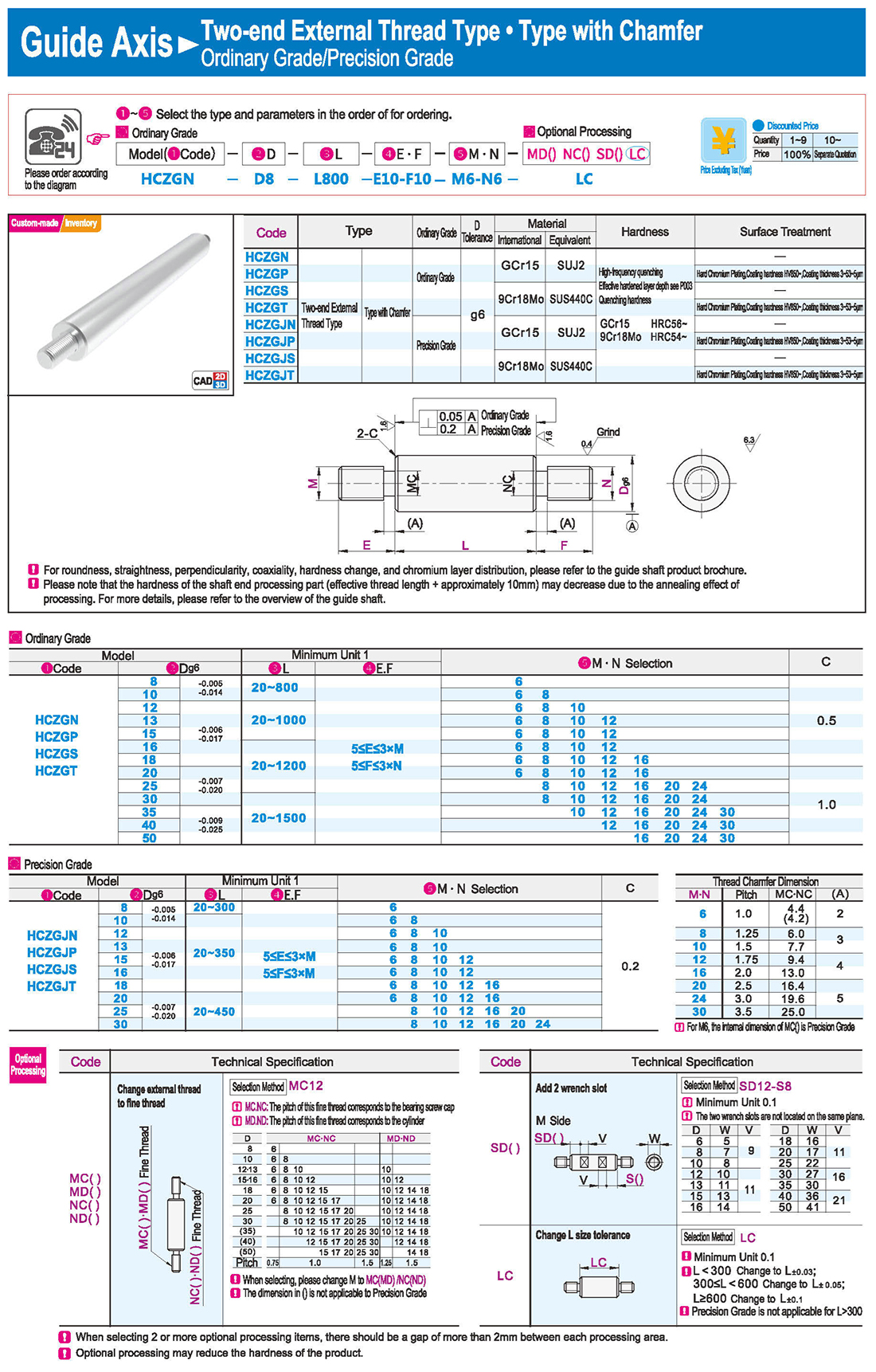

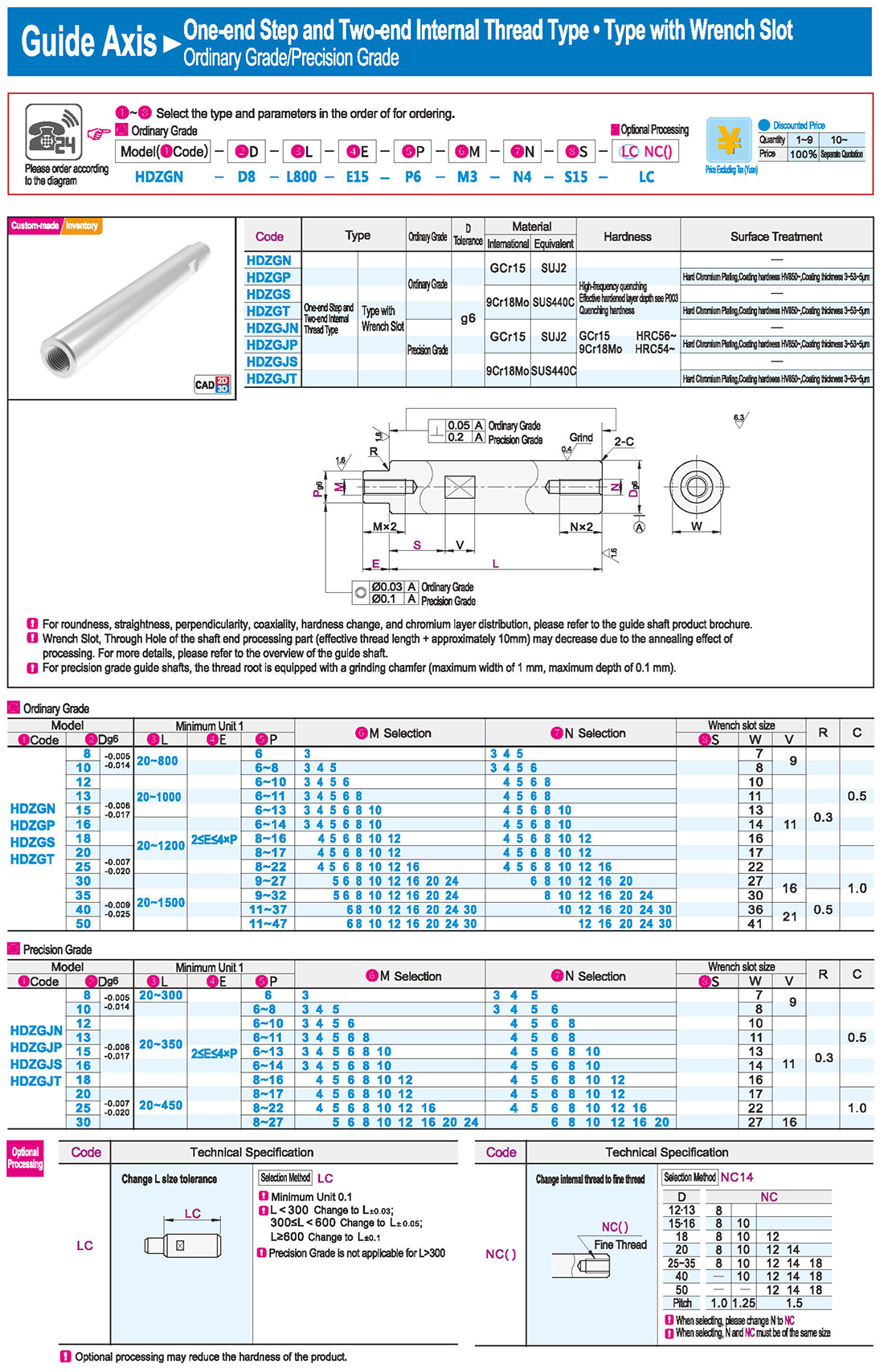

4.Internal Thread on Both Ends

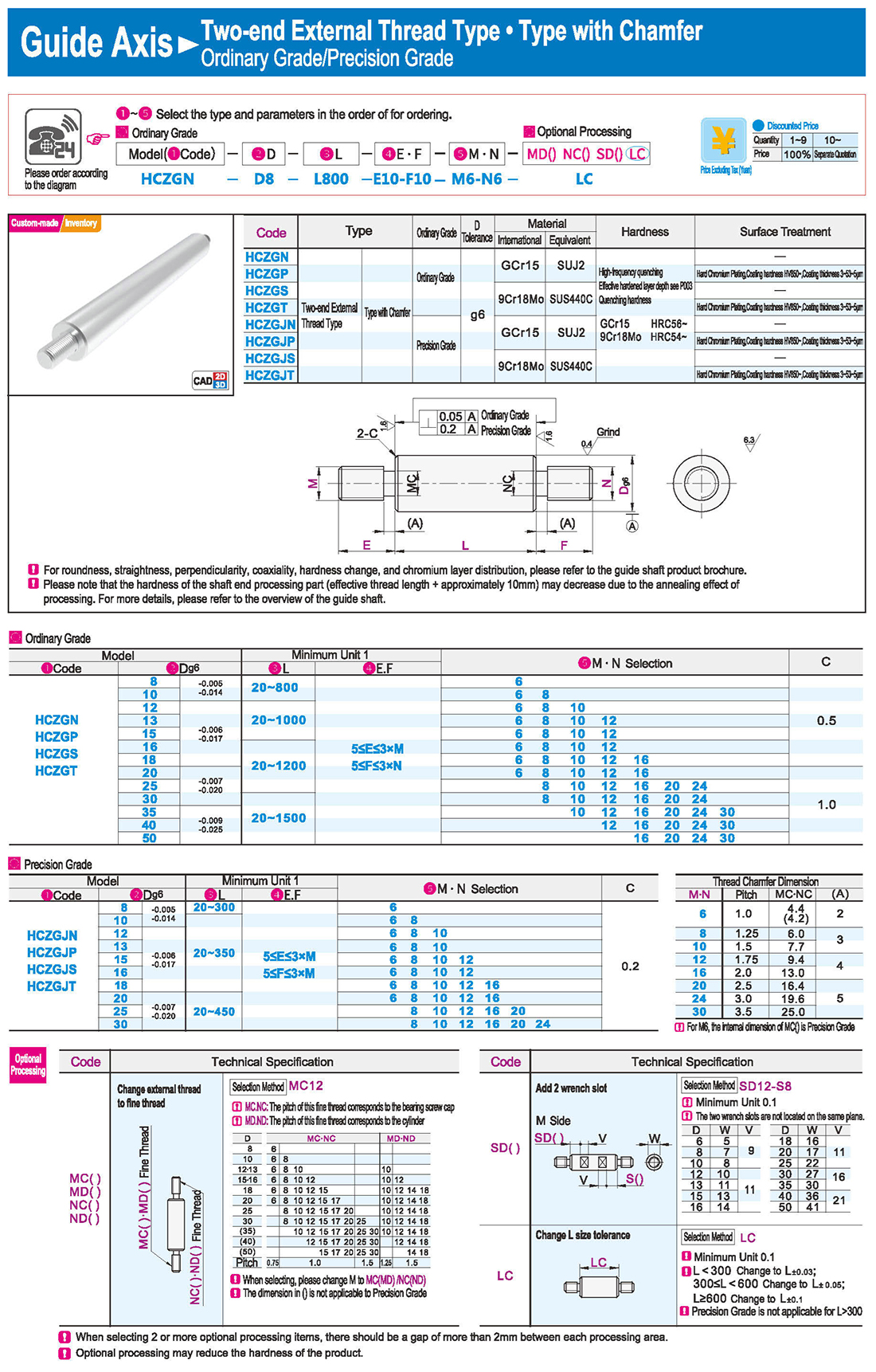

The two wrench slots are not located on the same plane.

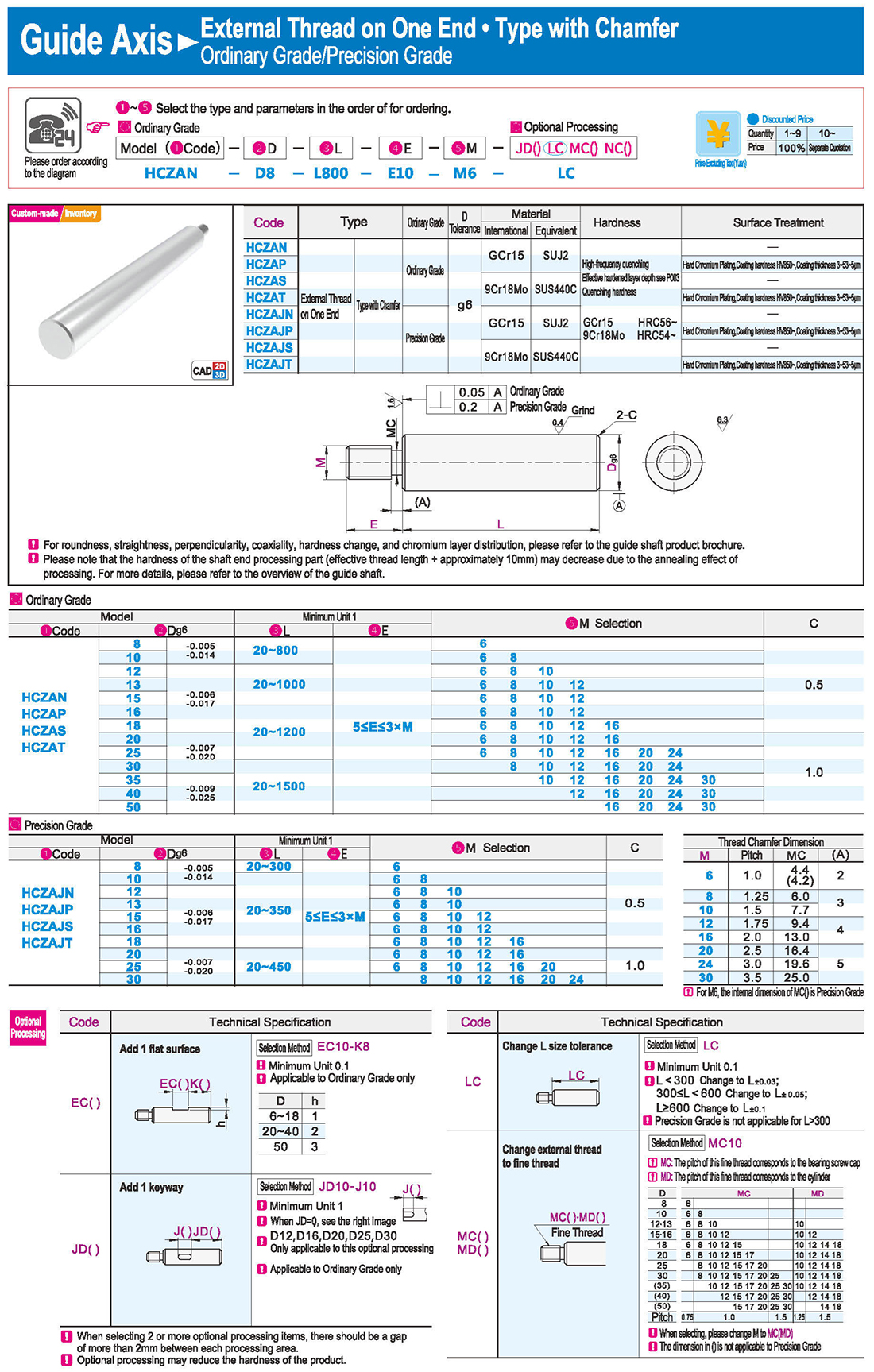

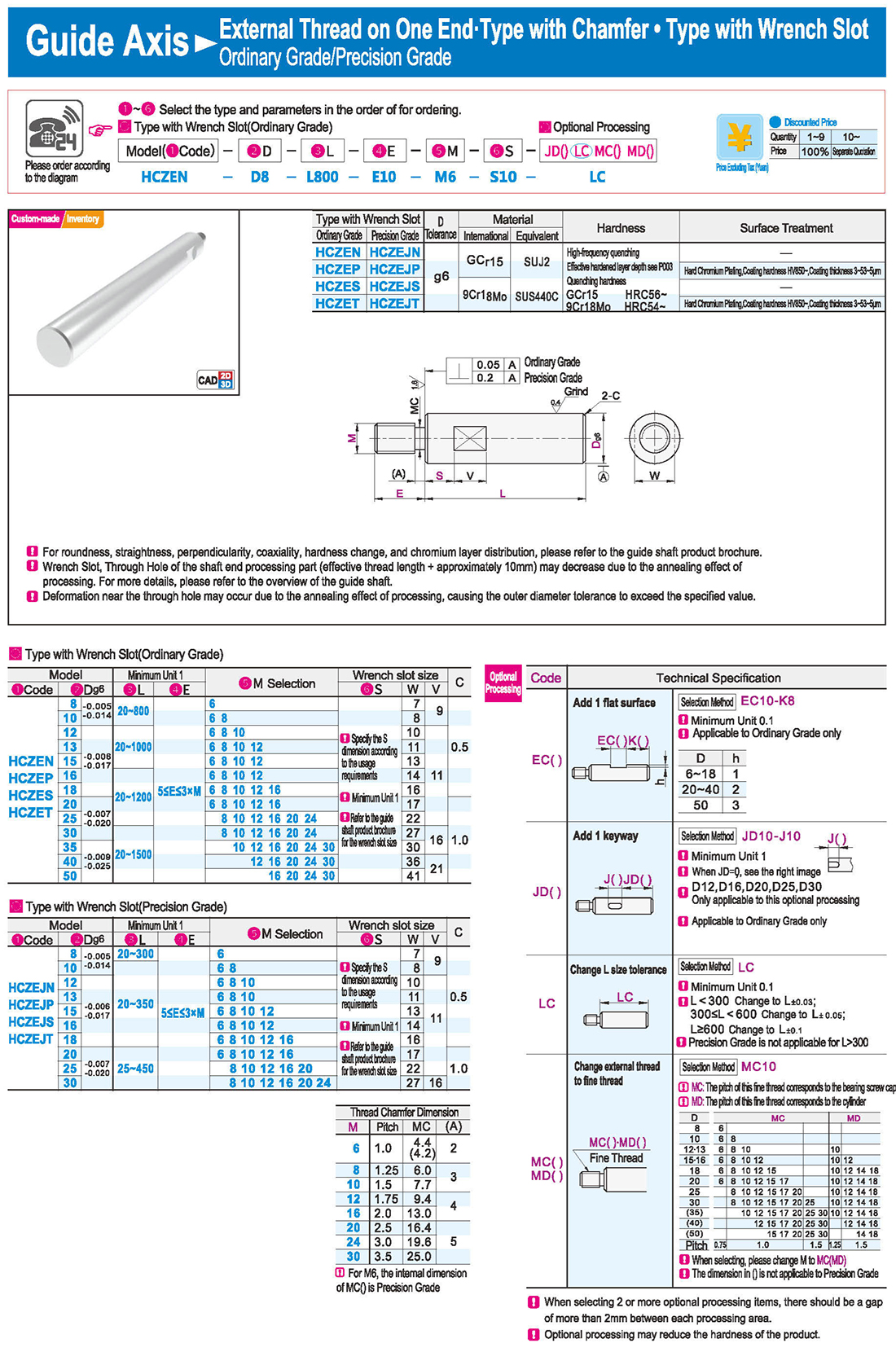

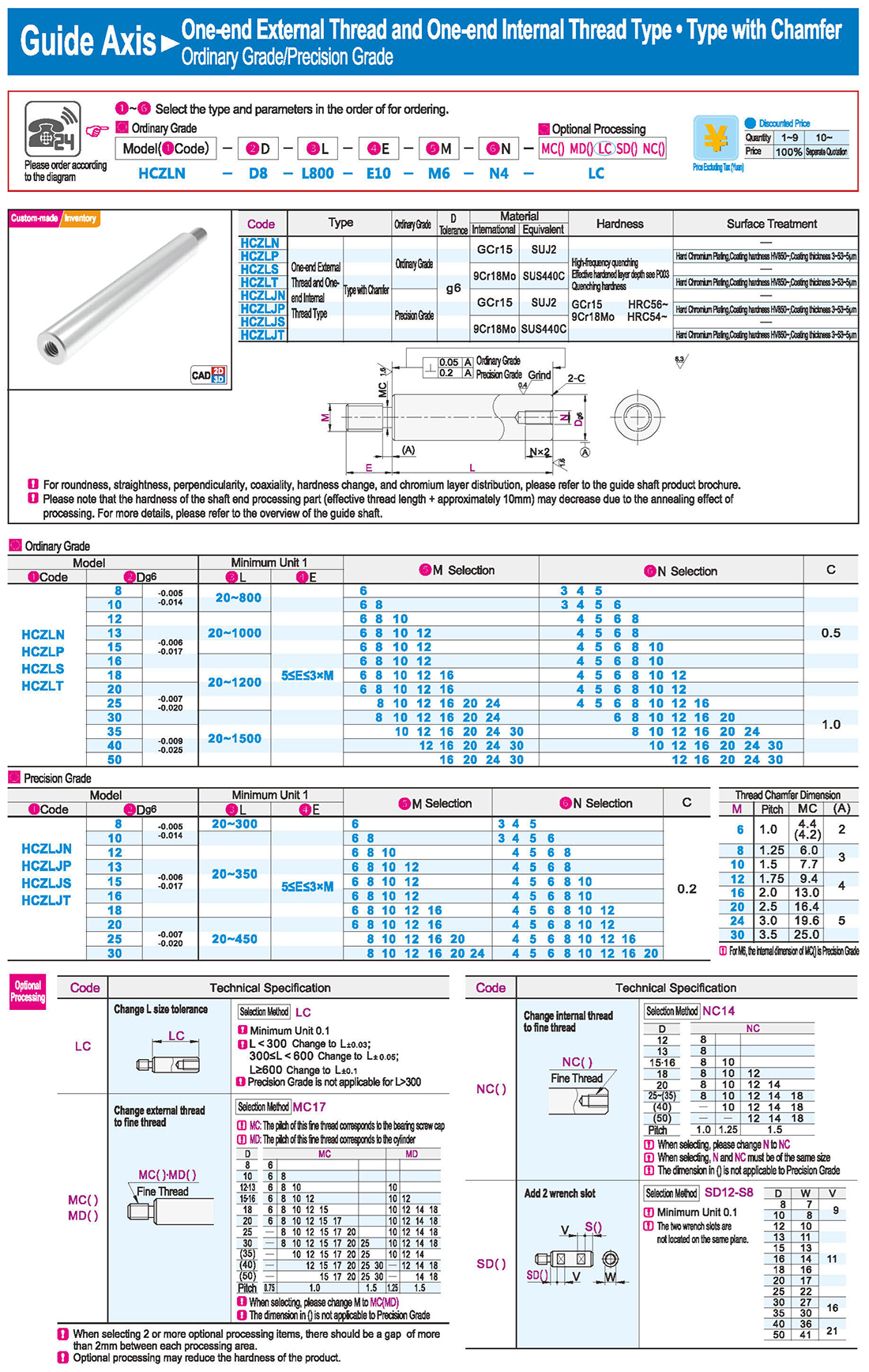

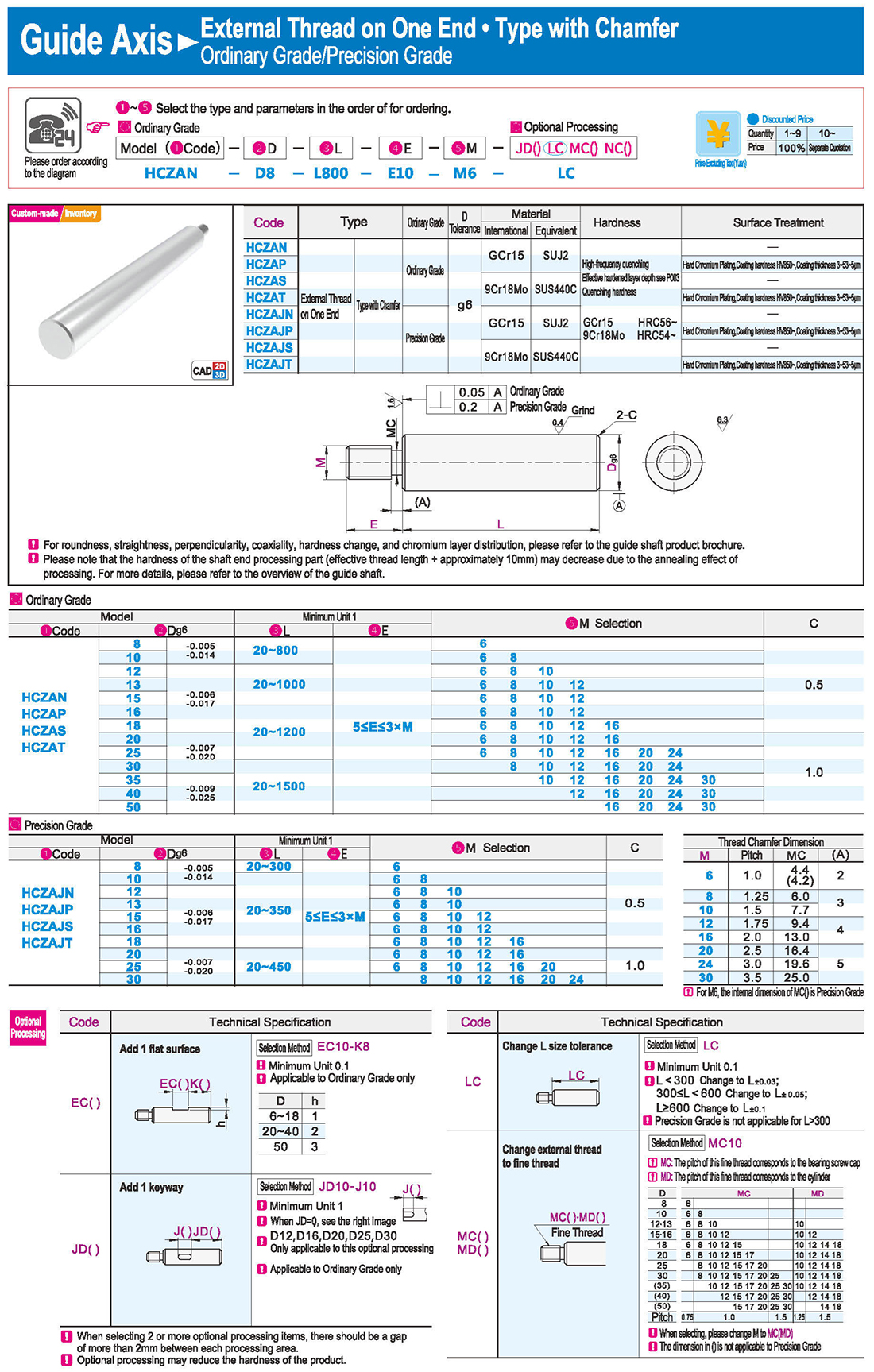

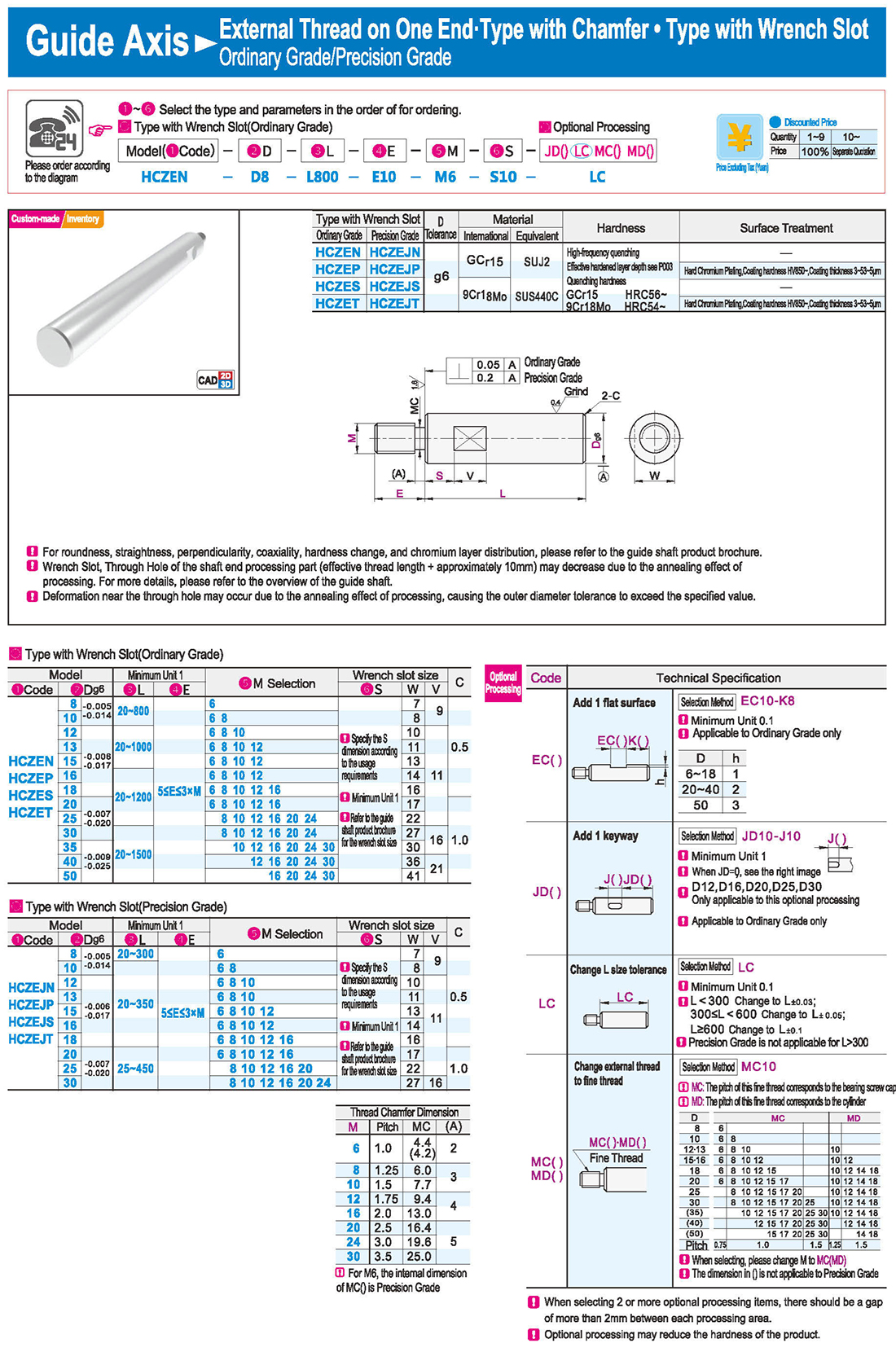

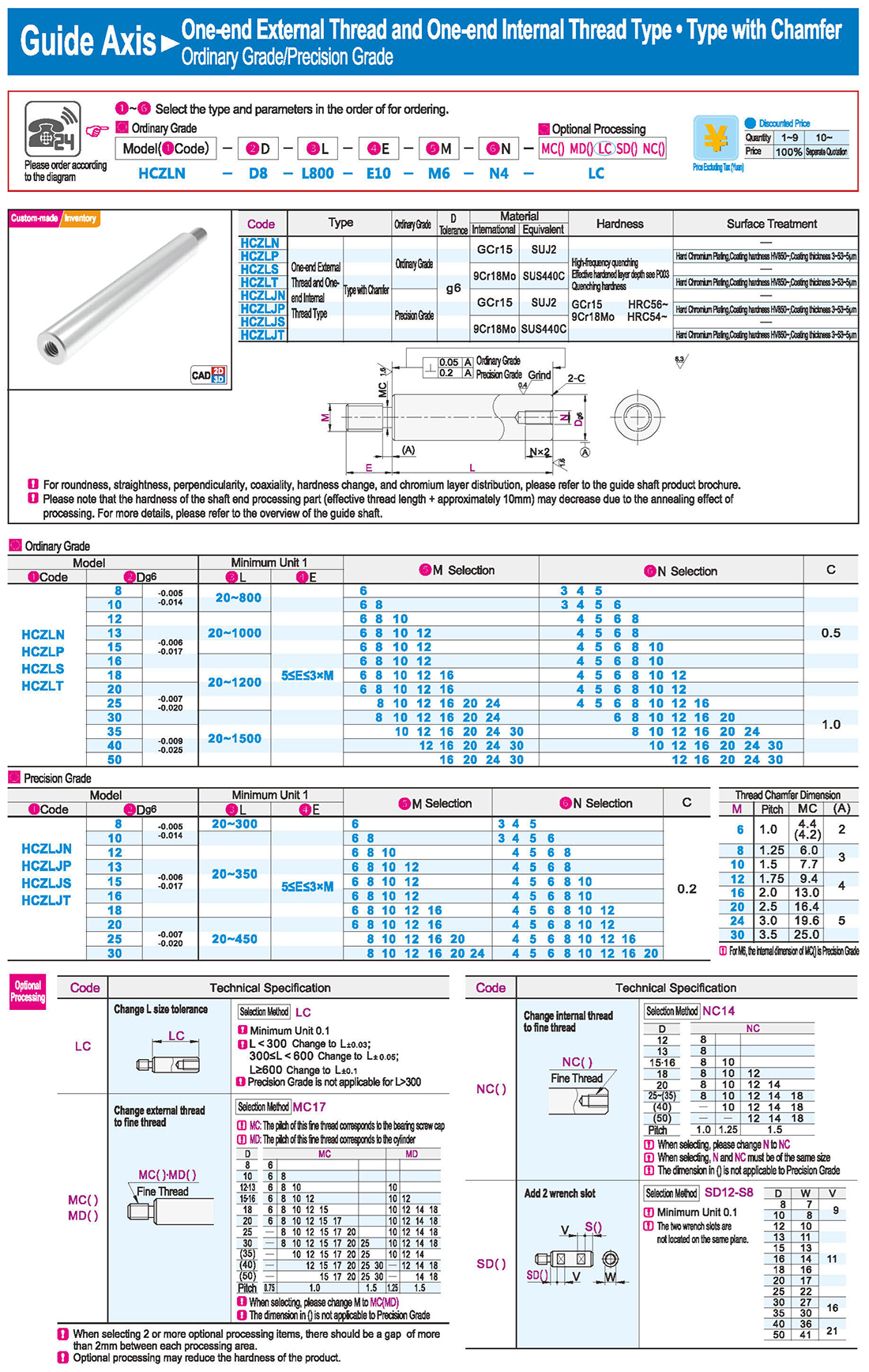

5.External Thread on One End · Type with Chamfer

Thread Chamfer Dimension

For M6, the internal dimension of MC() is Precision Grade

MC: The pitch of this fine thread corresponds to the bearing screw cap

MD: The pitch of this fine thread corresponds to the cylinder

The dimension in () is not applicable to Precision Grade

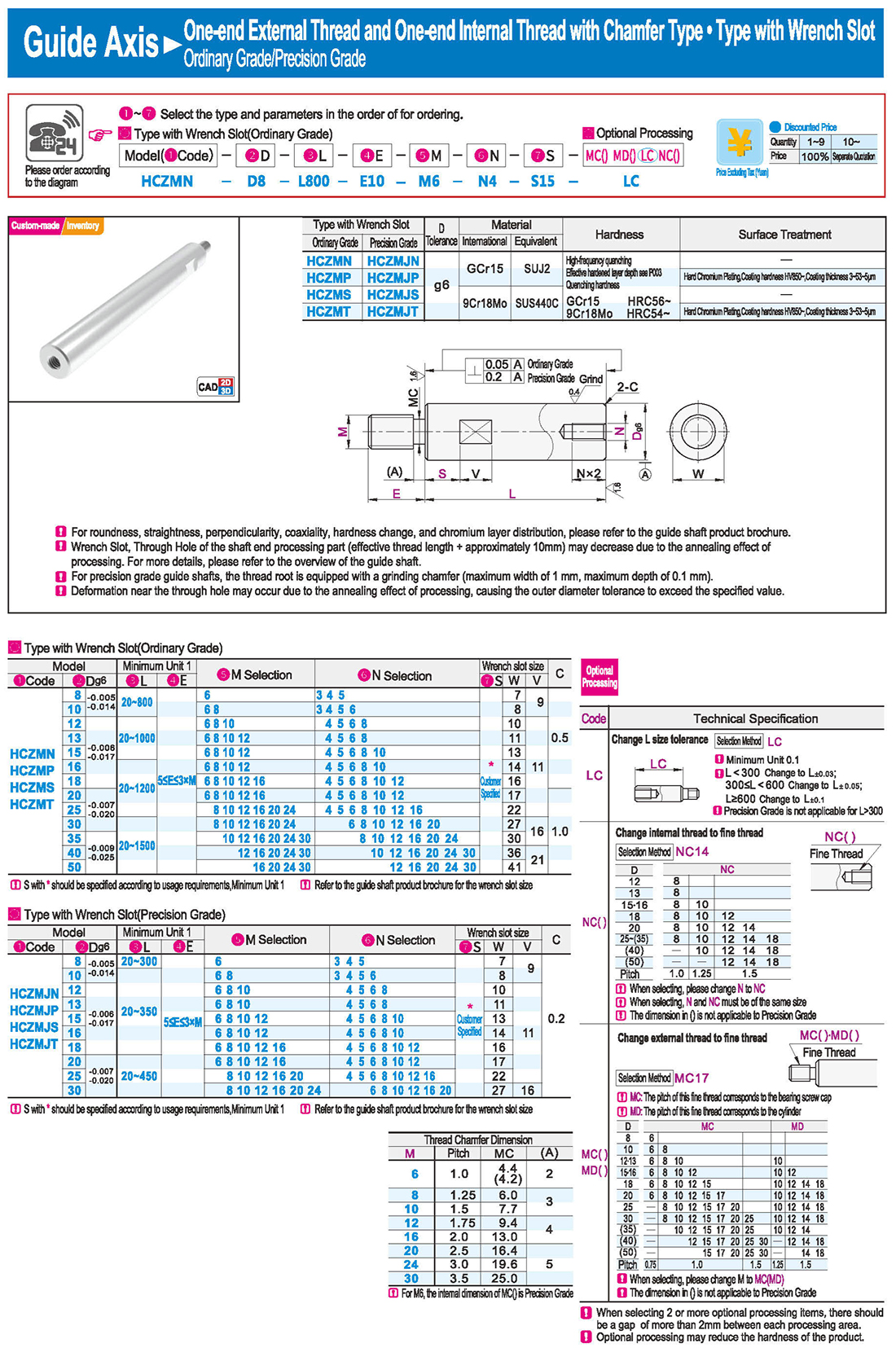

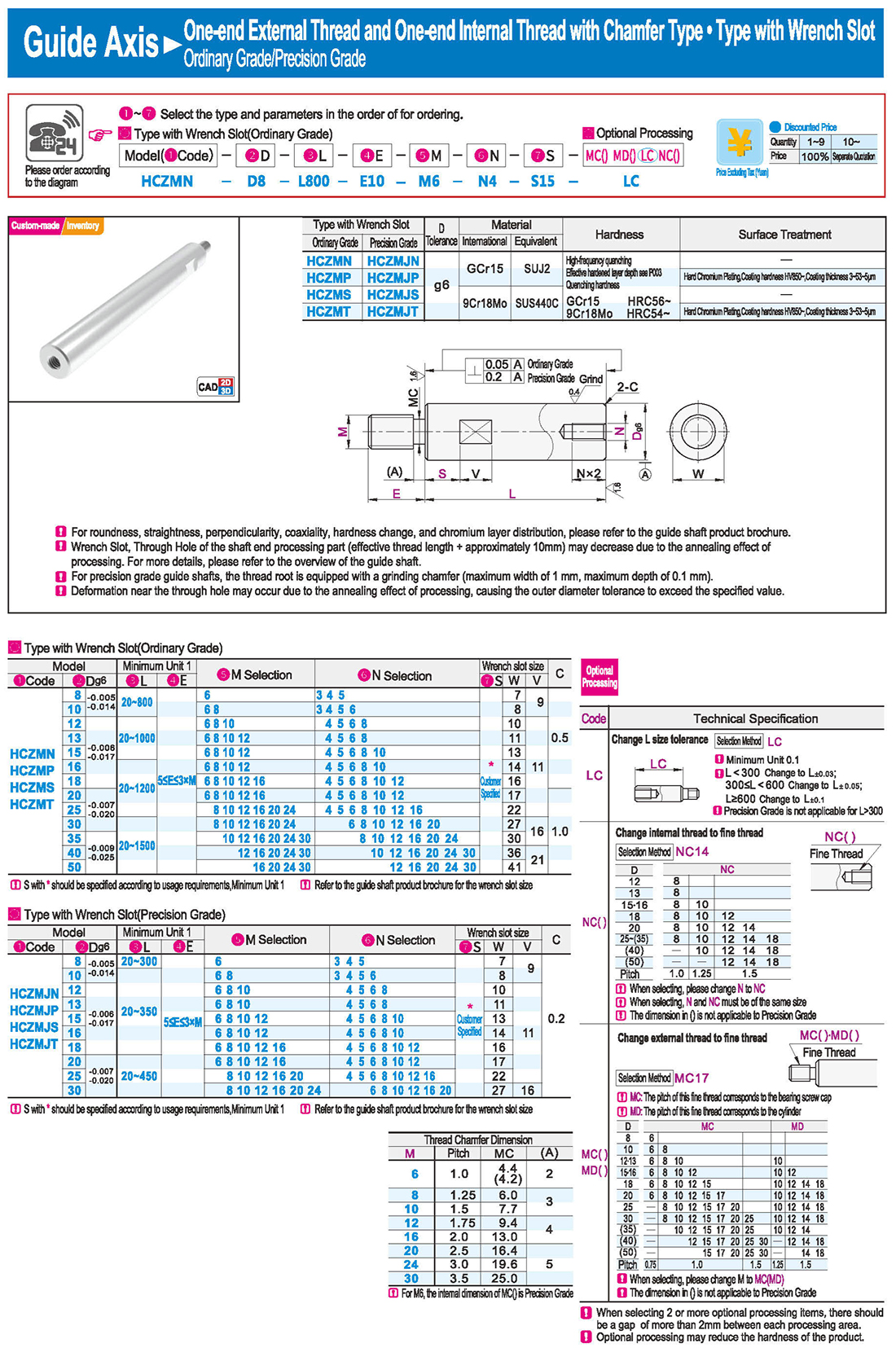

6.One-end External Thread and One-end Internal Thread with Chamfer Type

Customer Specified

S with * should be specified according to usage requirements

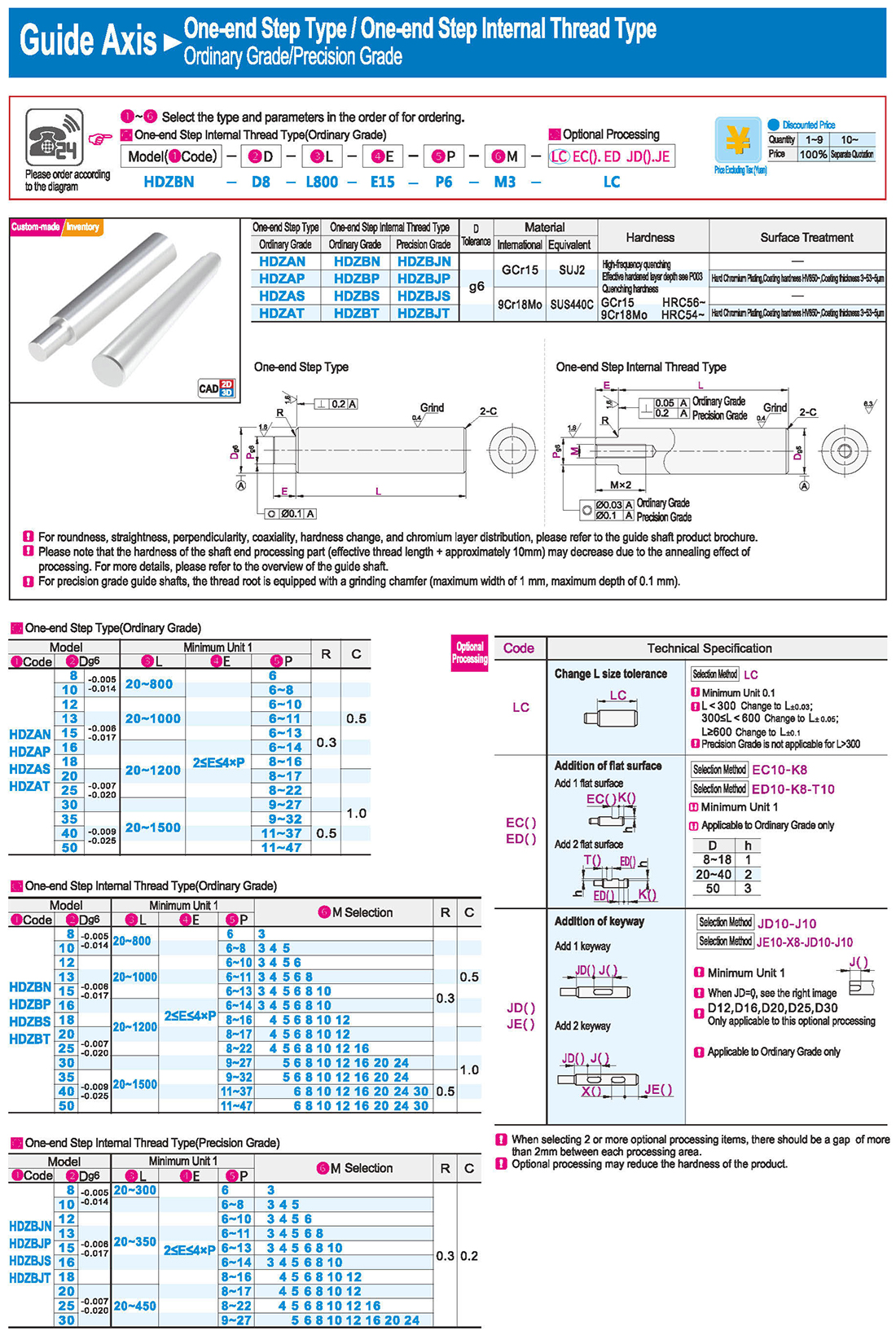

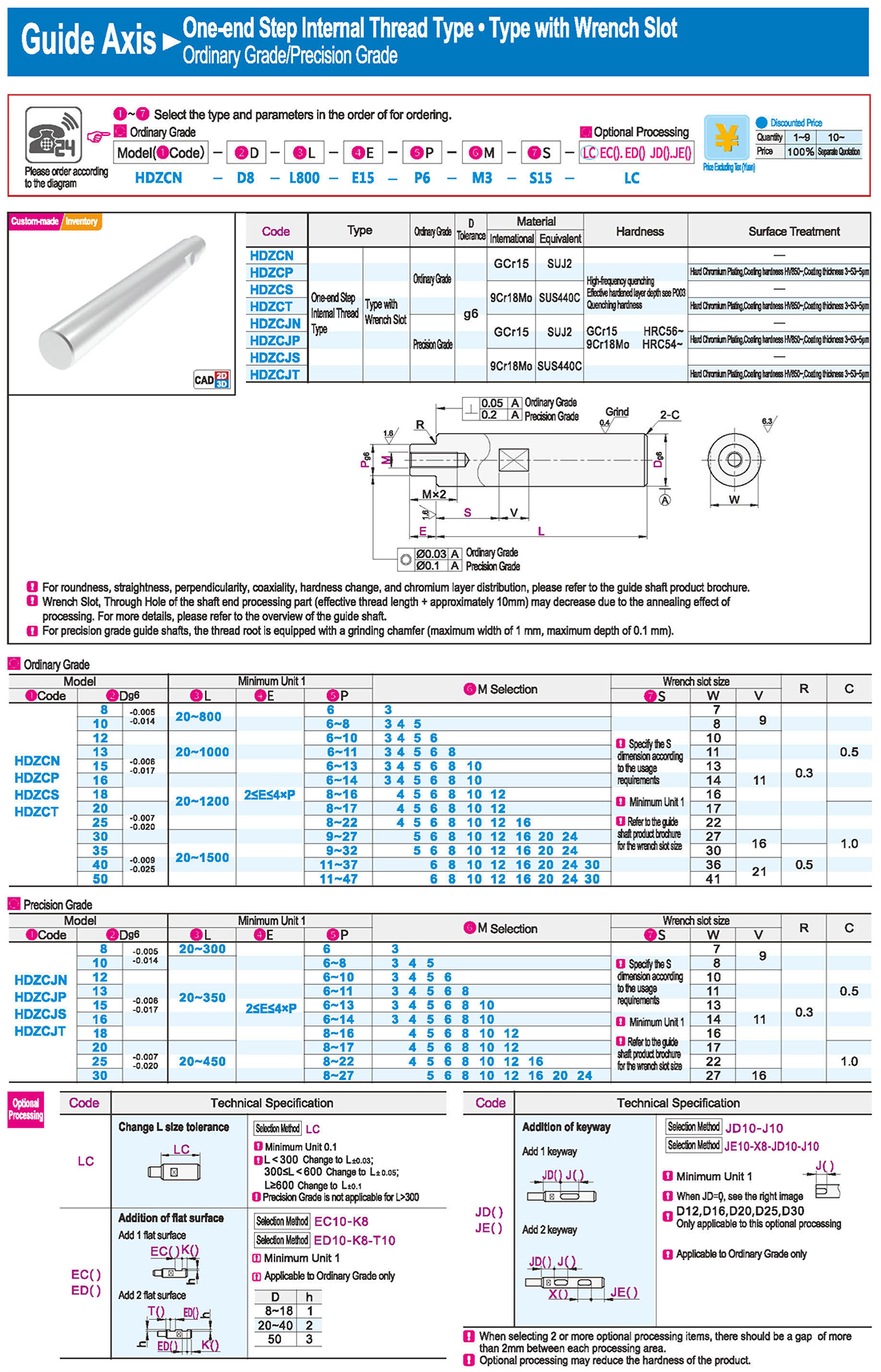

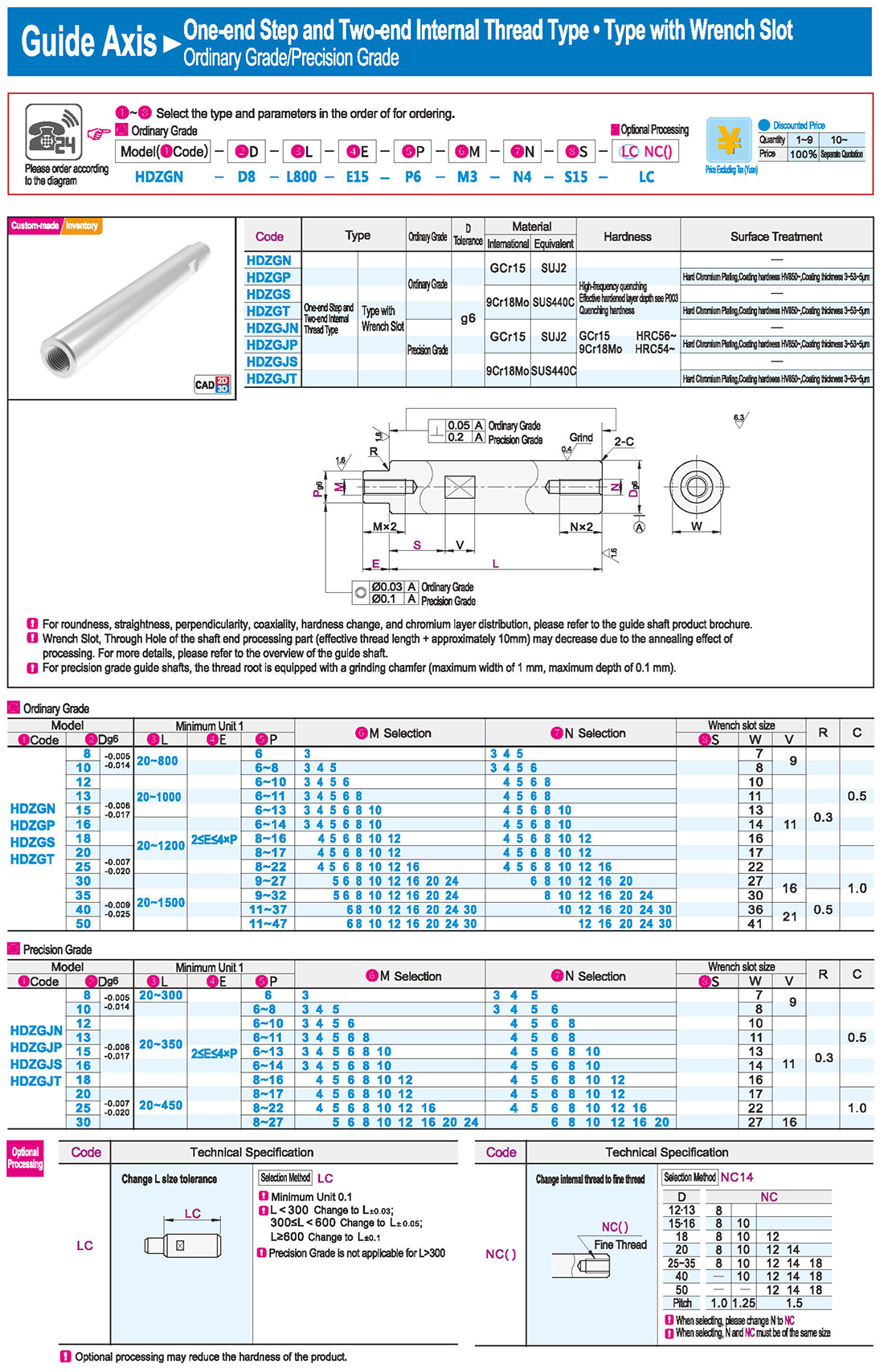

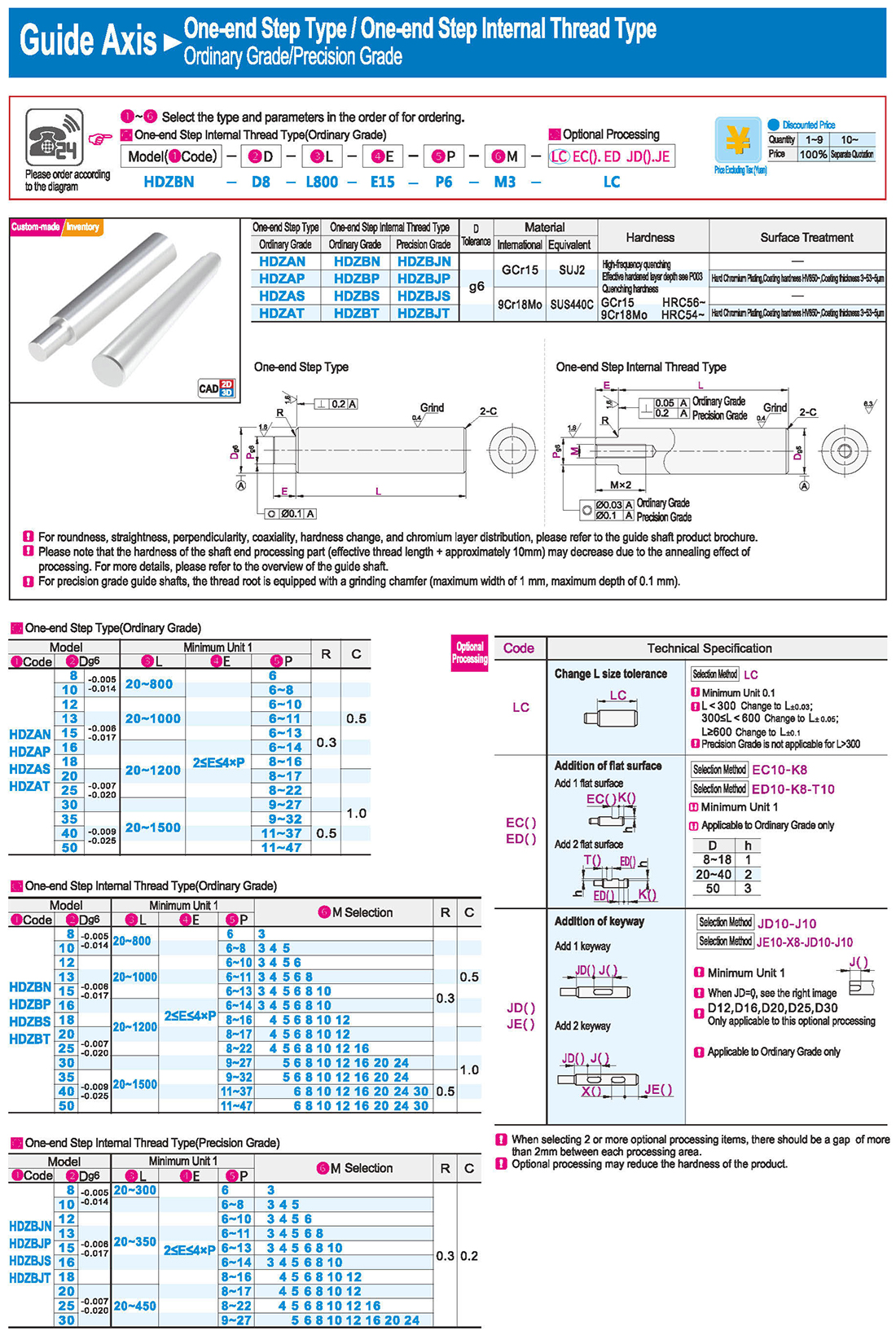

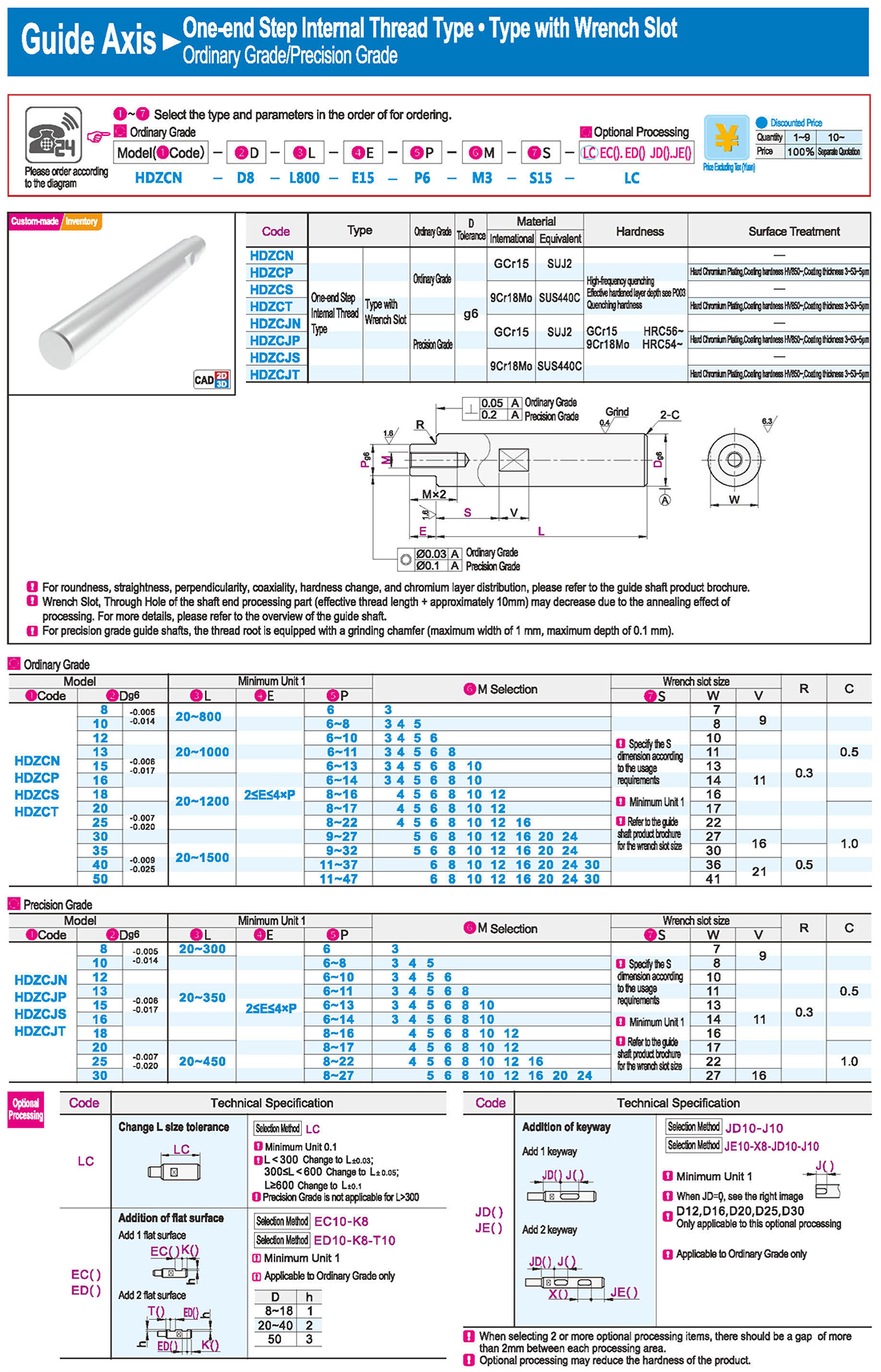

7.One-end Step Type / One-end Step Internal Thread Type

One-end Step Type / One-end Step Internal Thread Type

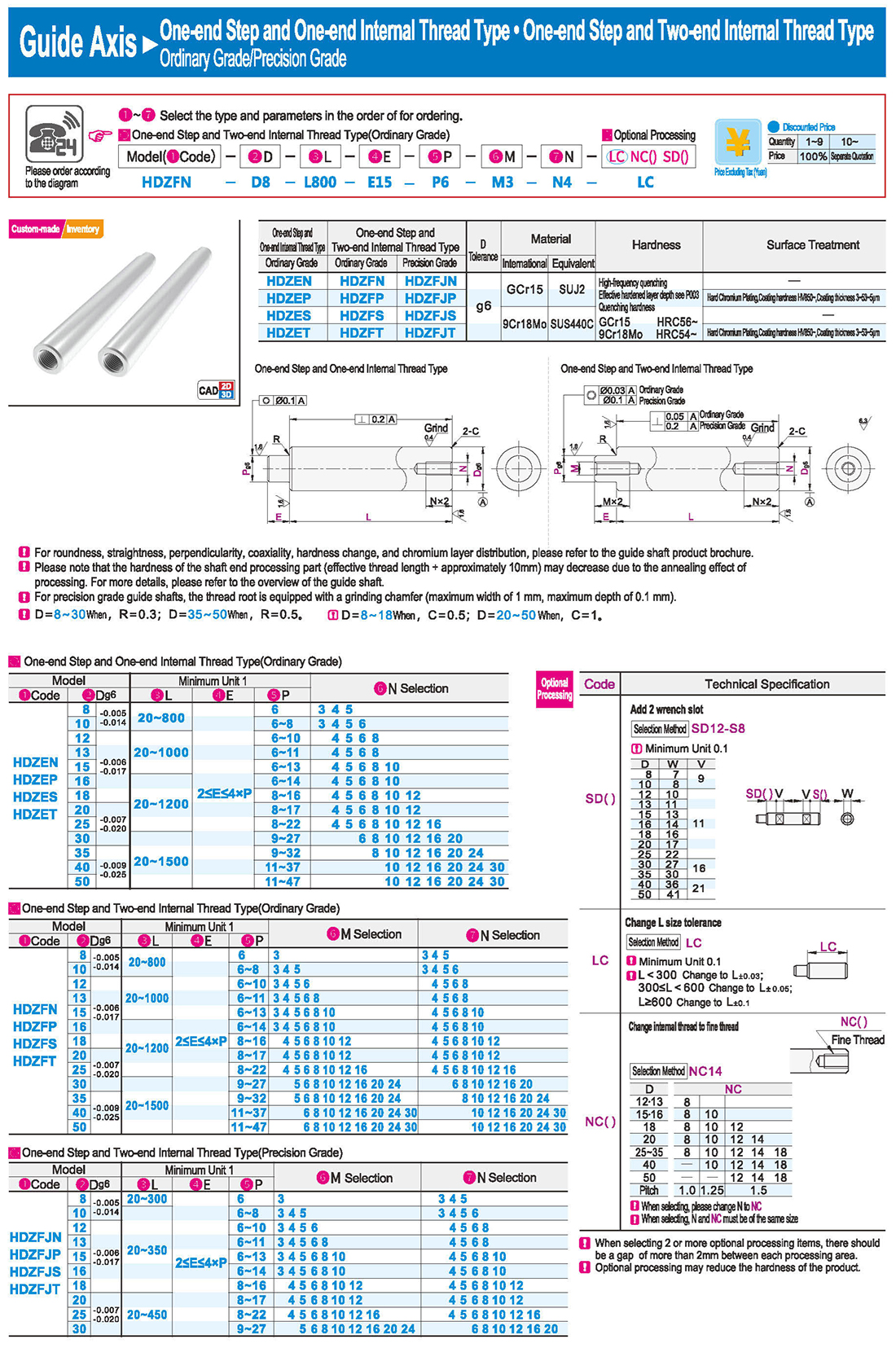

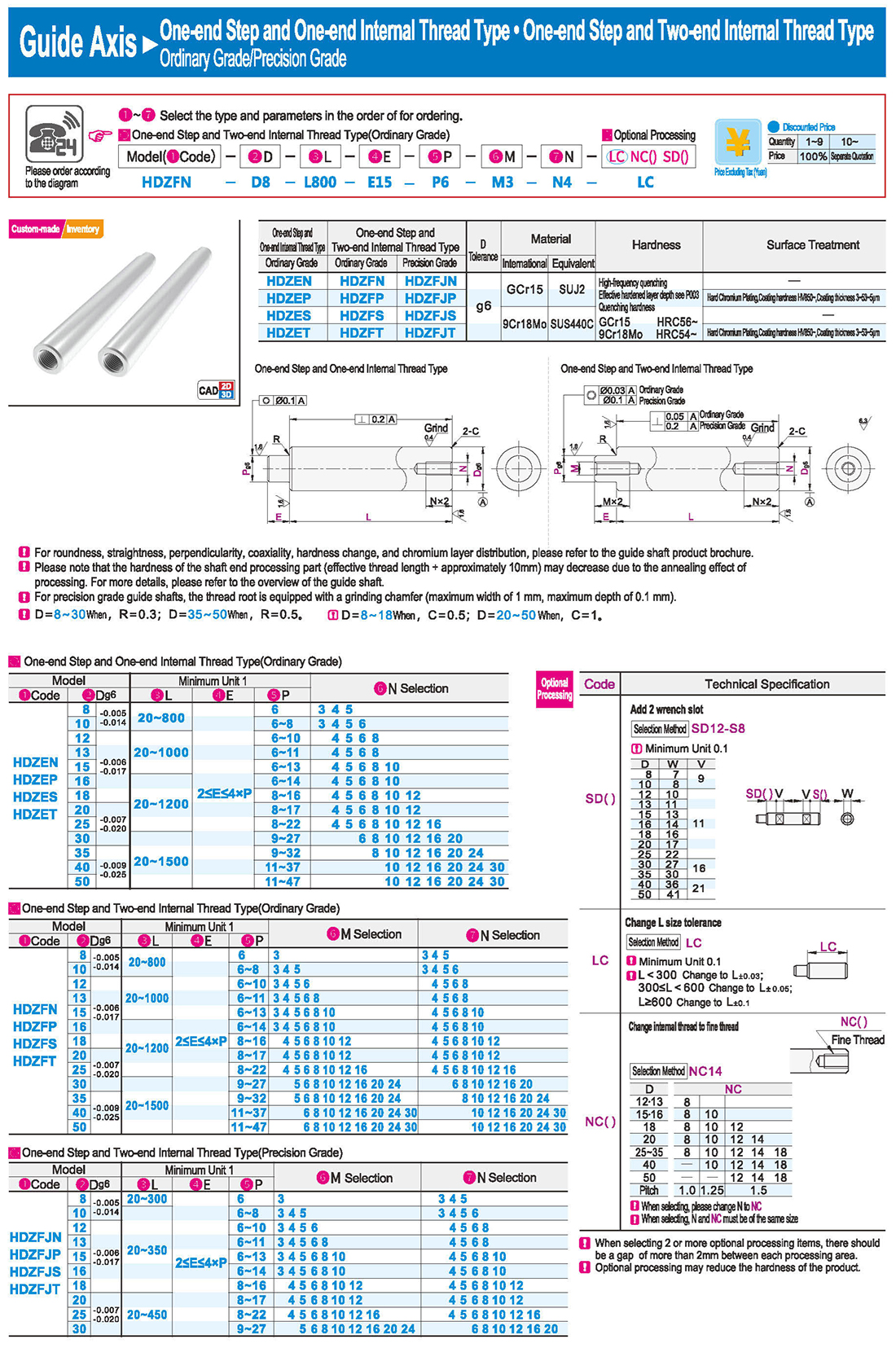

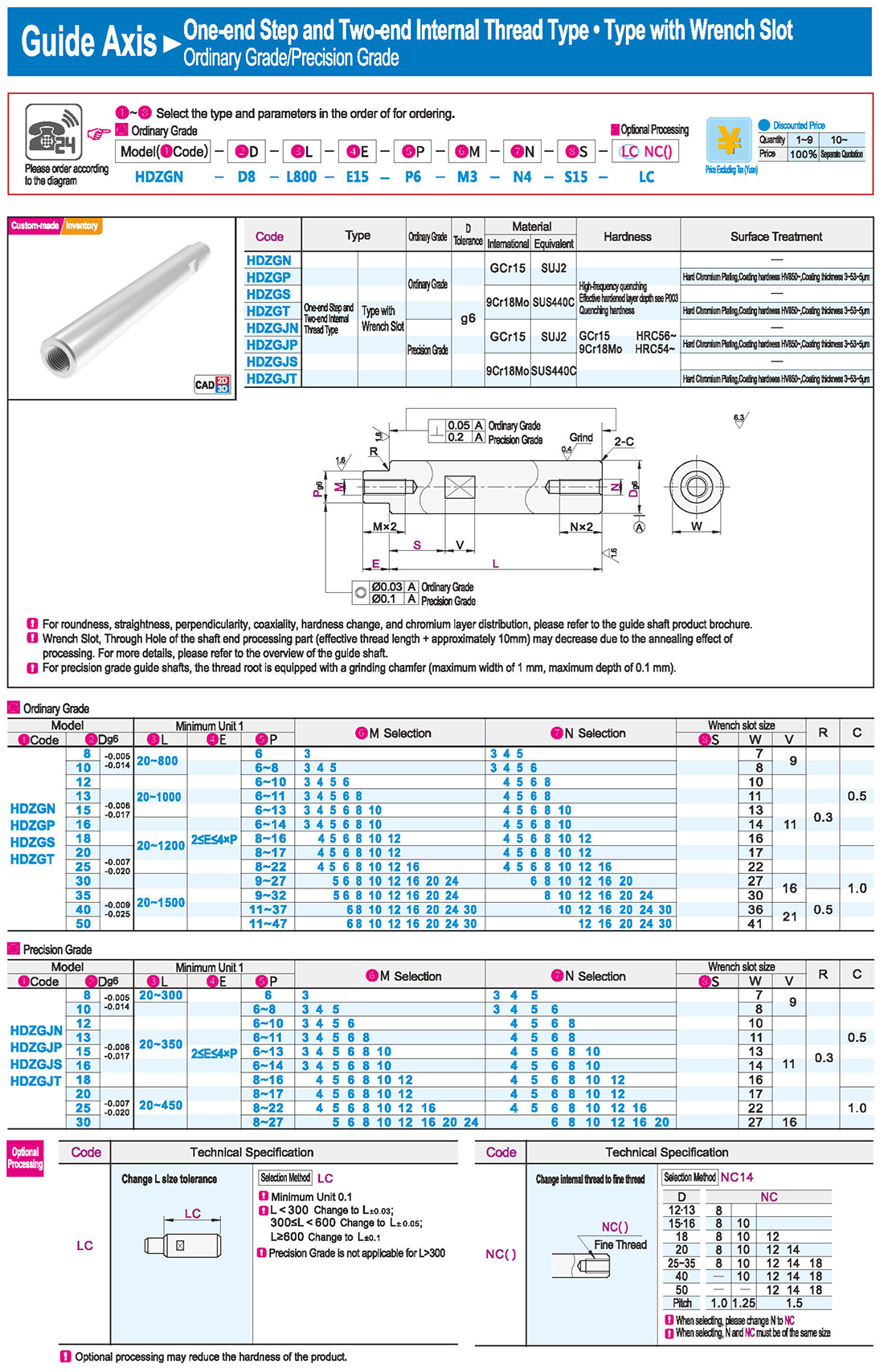

One-end Step and One-end Internal Thread Type · One-end Step and Two-end Internal Thread Type

Optional processing may reduce the hardness of the product

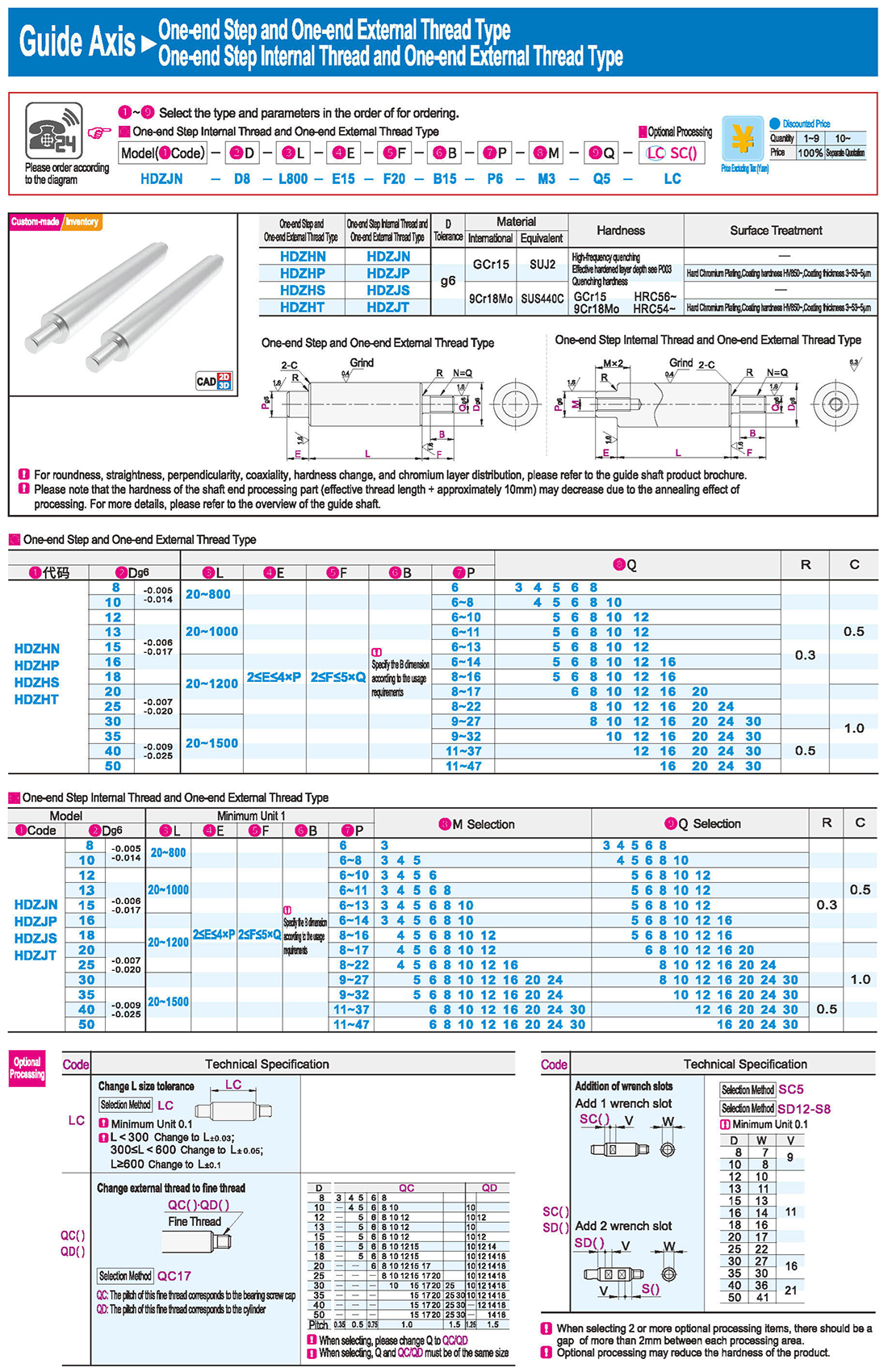

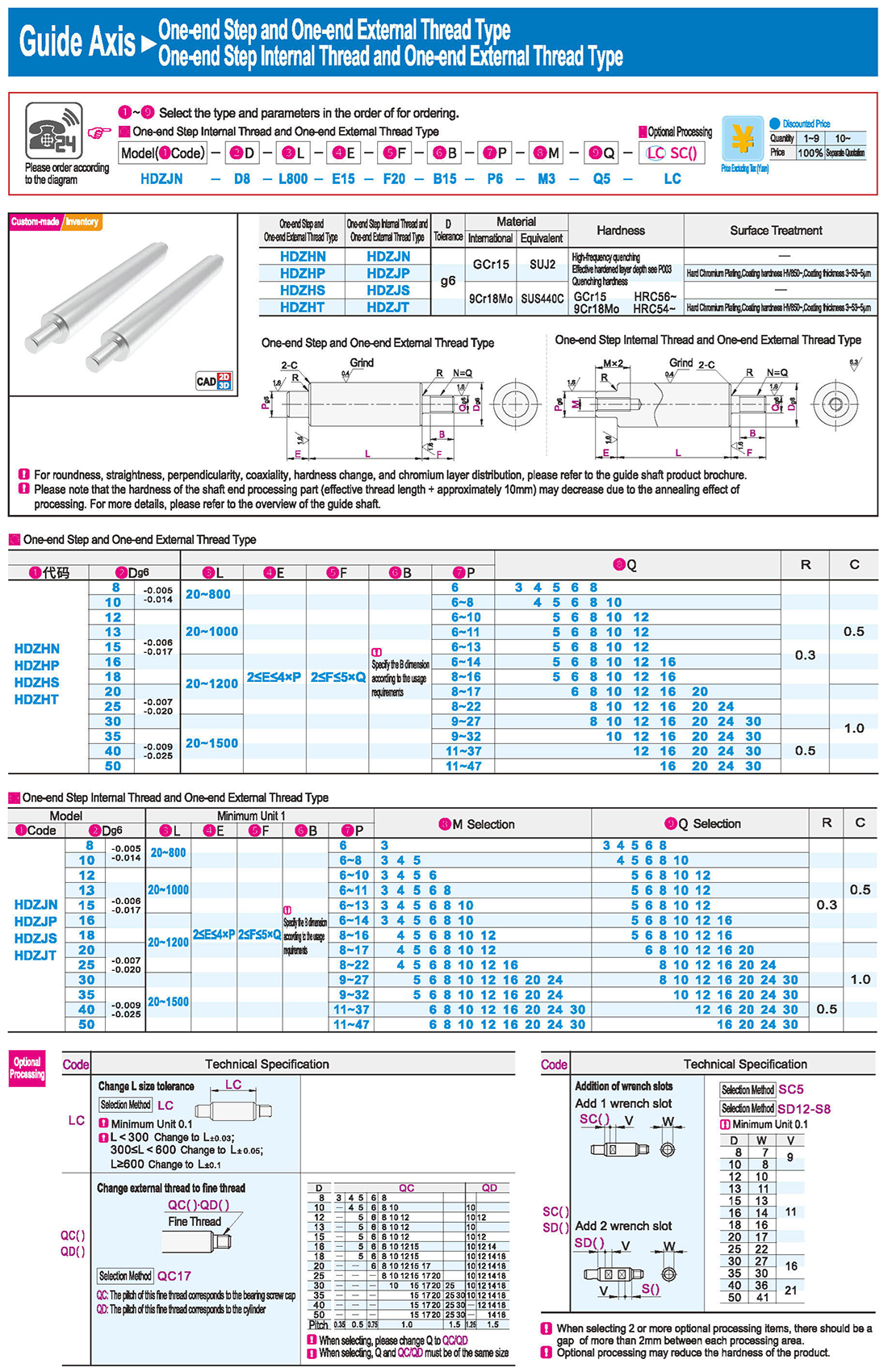

One-end Step and One-end External Thread Type

One-end Step Internal Thread and One-end External Thread Type

Change external thread to fine thread

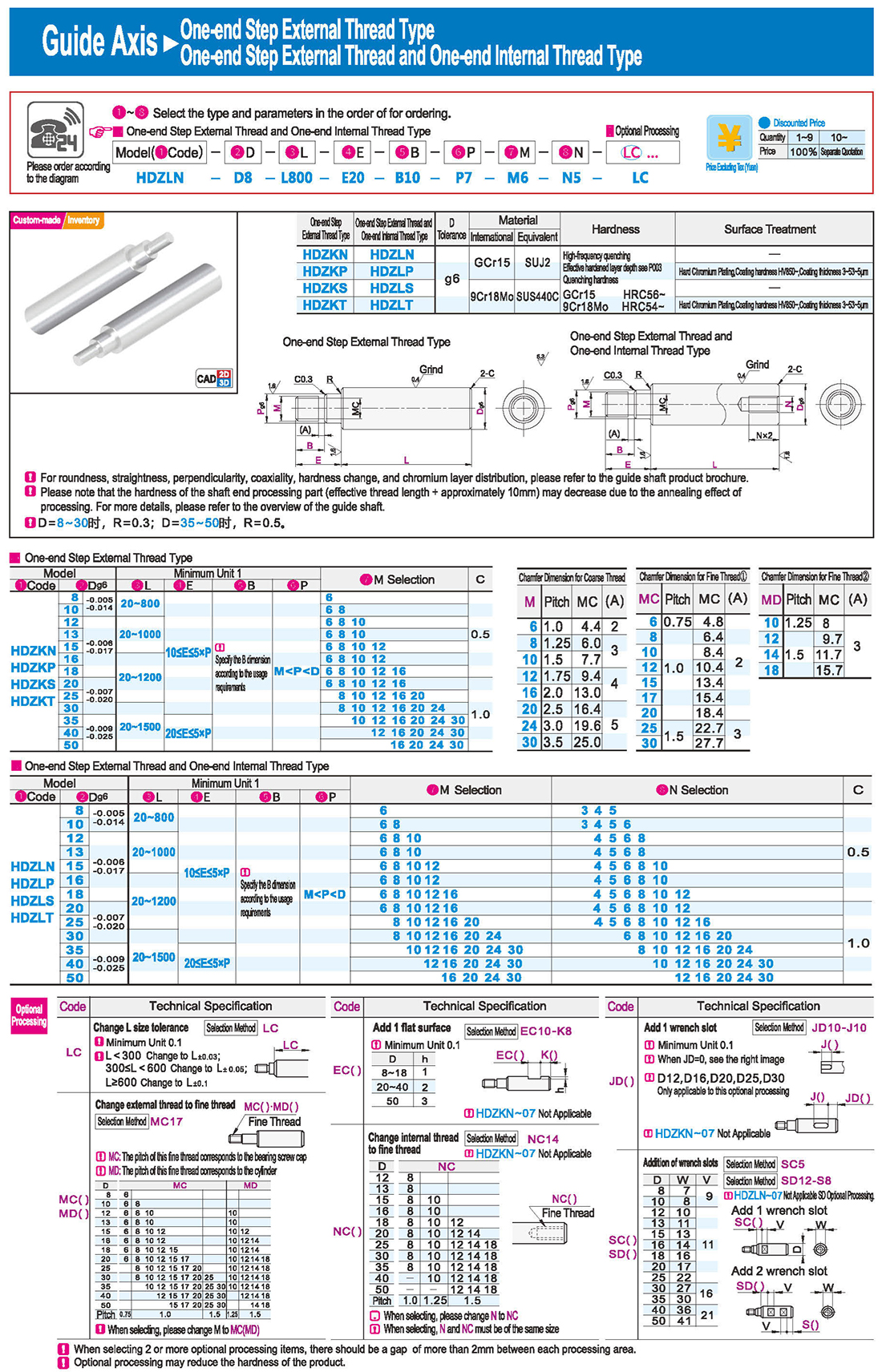

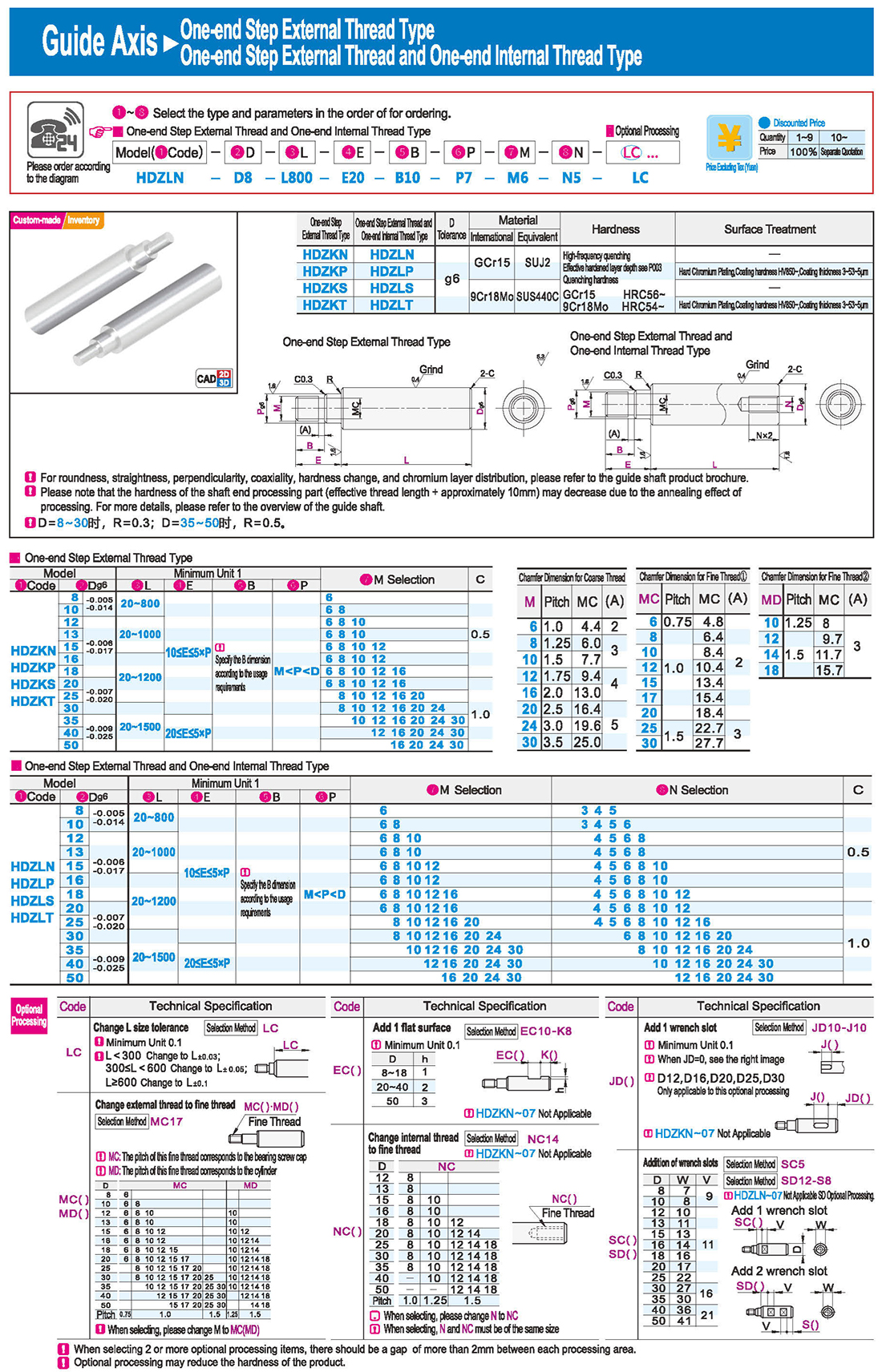

One-end Step External Thread Type

One-end Step External Thread and One-end Internal Thread Type

Chamfer Dimension for Coarse Thread

Chamfer Dimension for Fine Thread

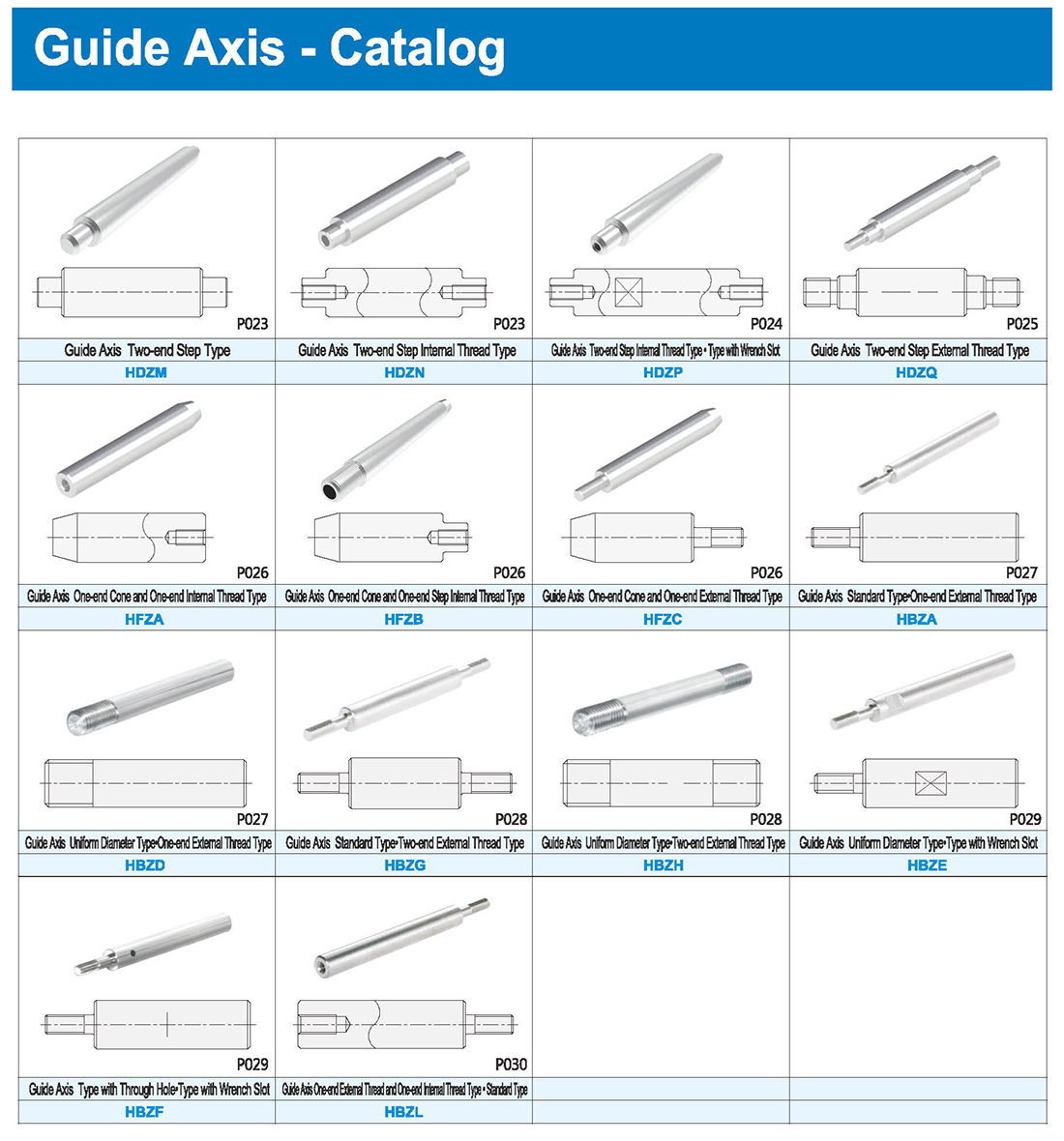

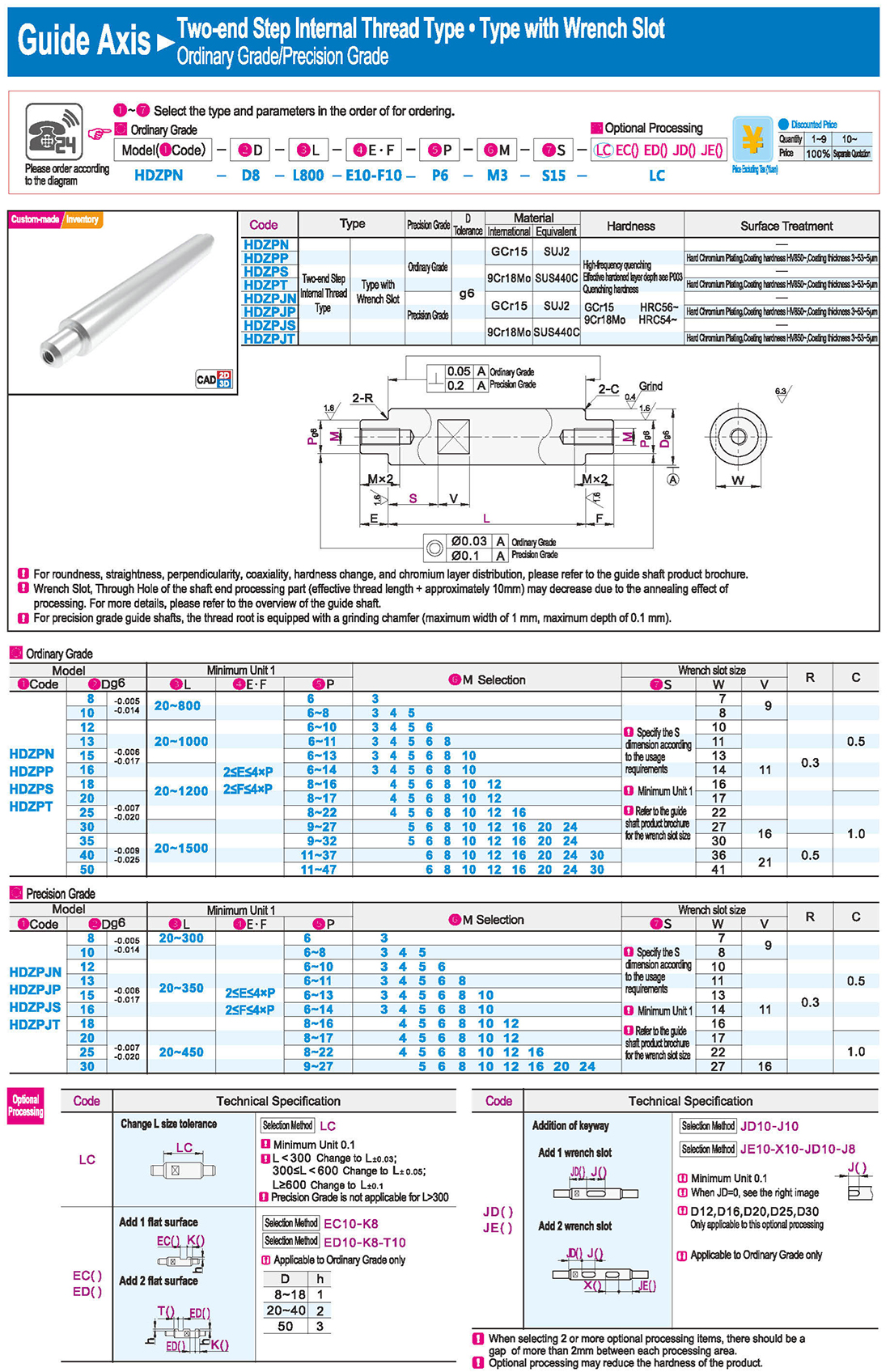

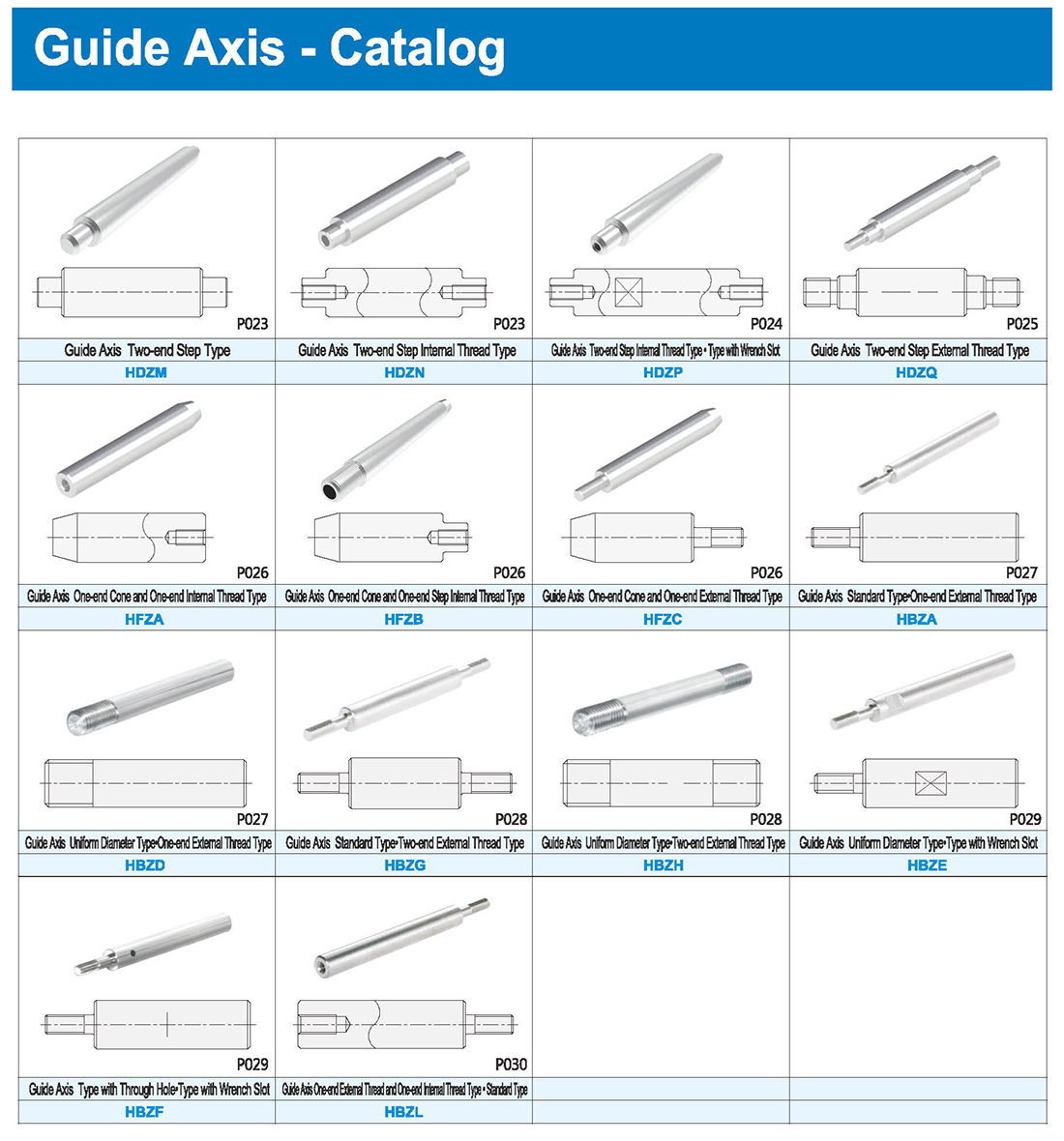

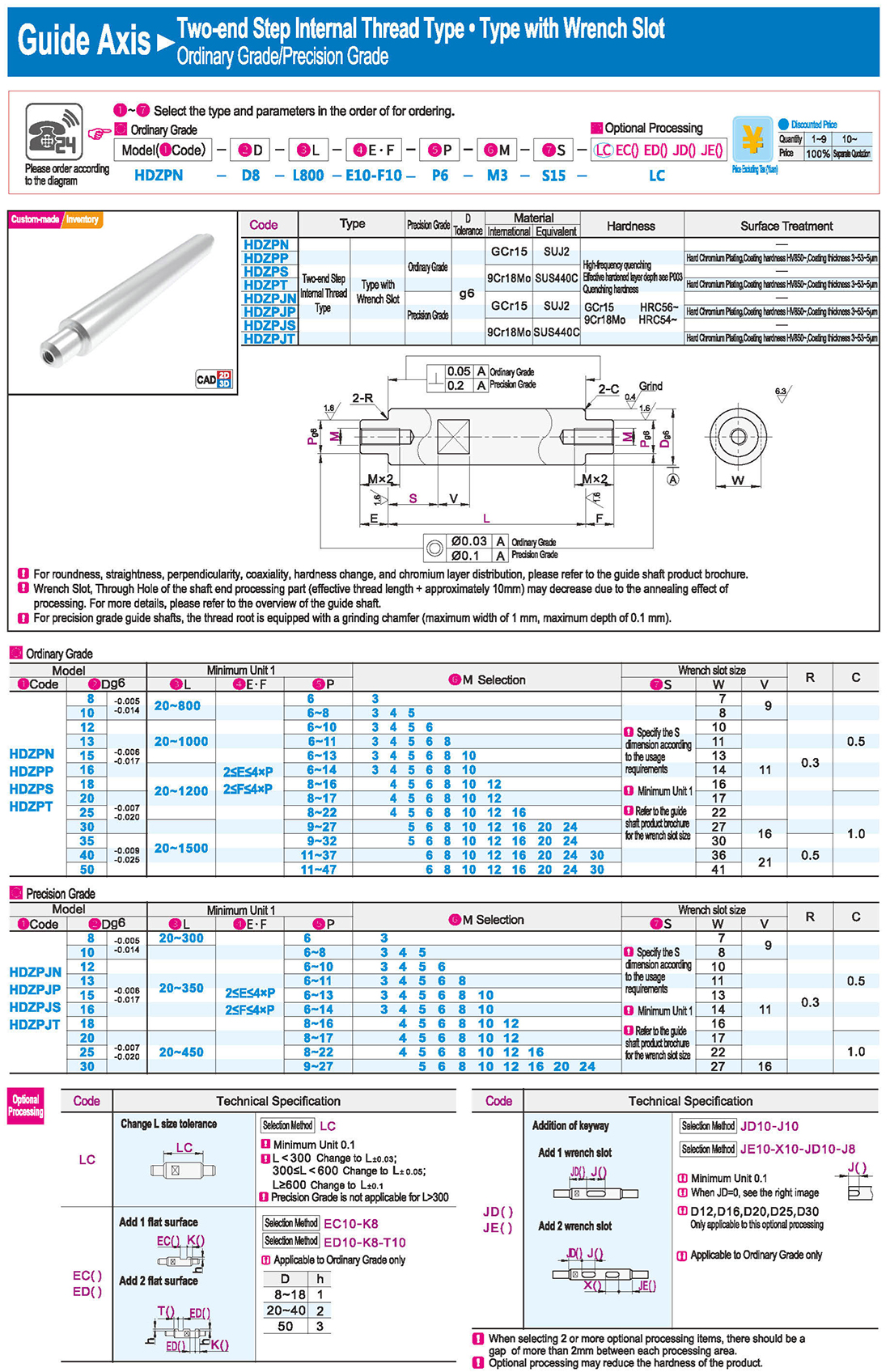

Two-end Step Type · Two-end Step Internal Thread Type

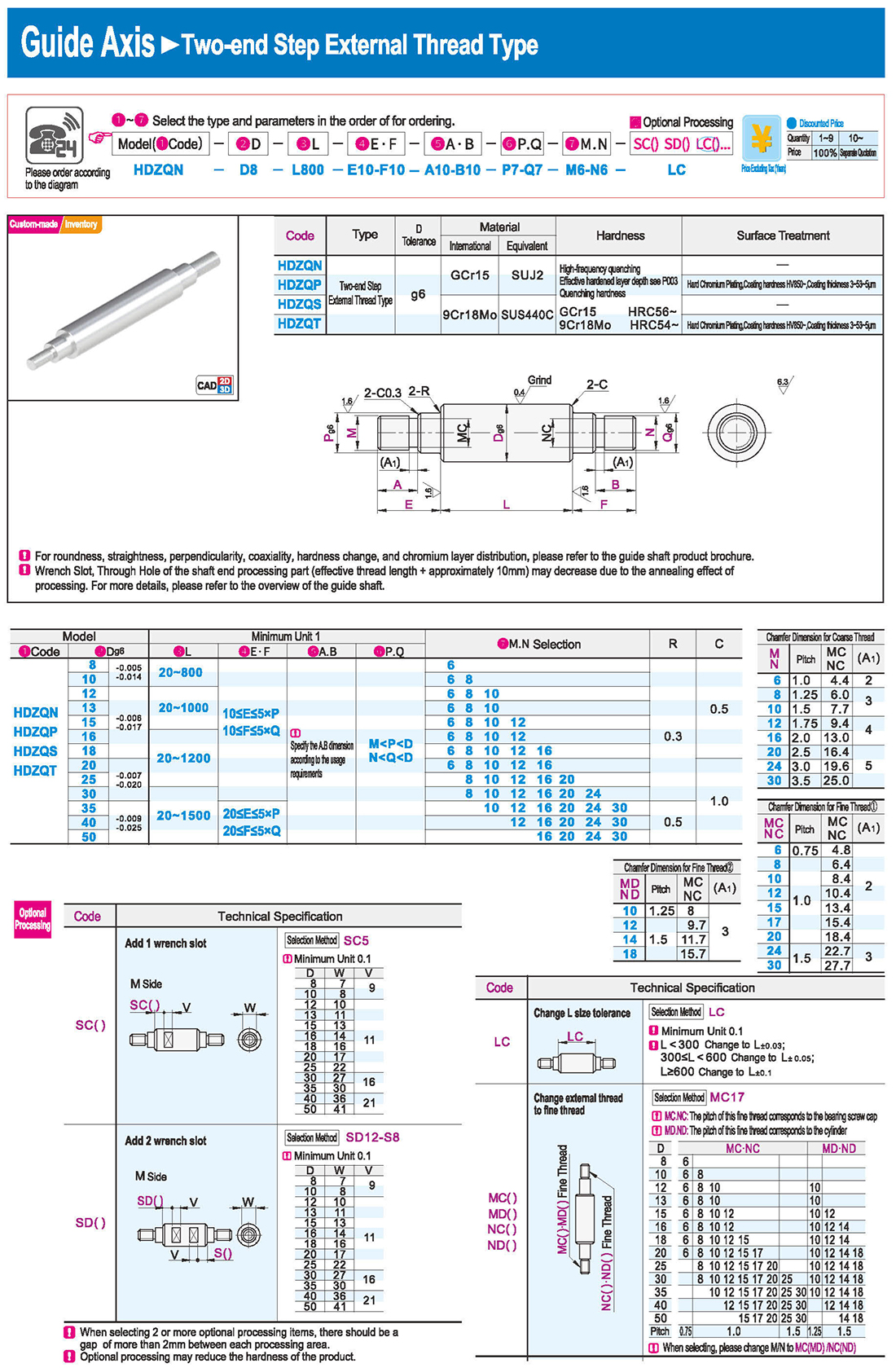

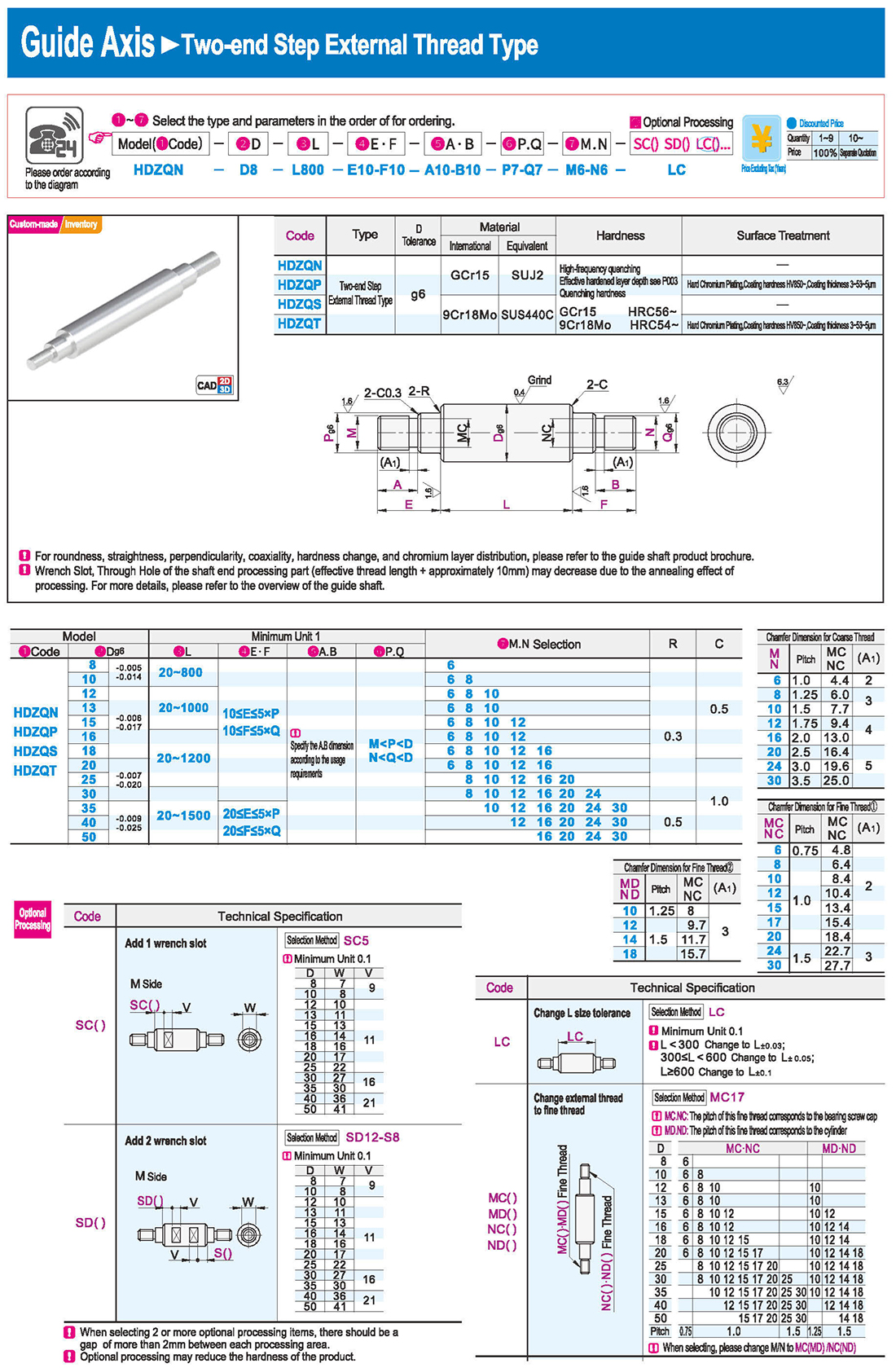

Two-end Step External Thread Type

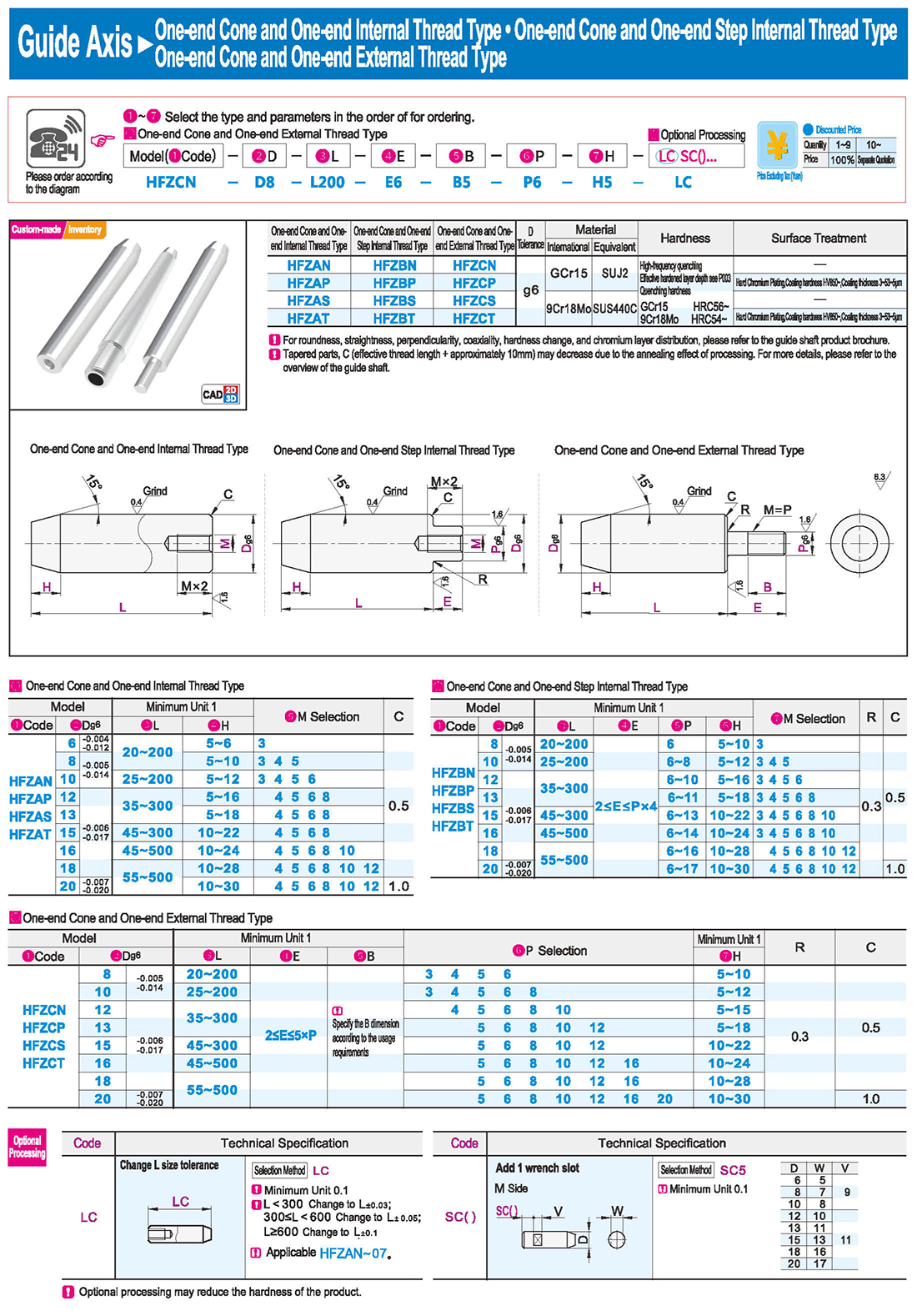

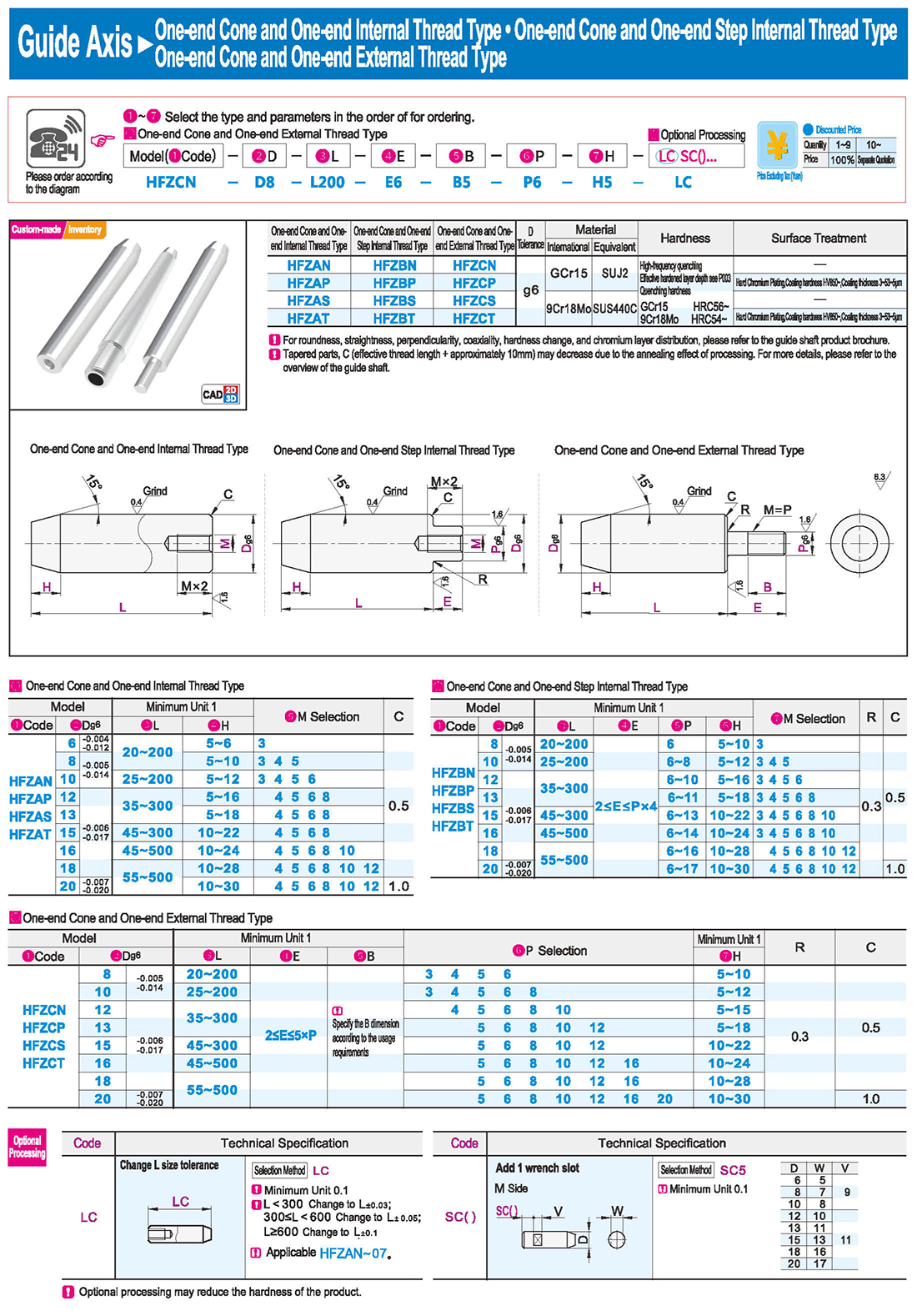

One-end Cone and One-end Internal Thread Type · One-end Cone and One-end Step Internal Thread Type

One-end Cone and One-end External Thread Type

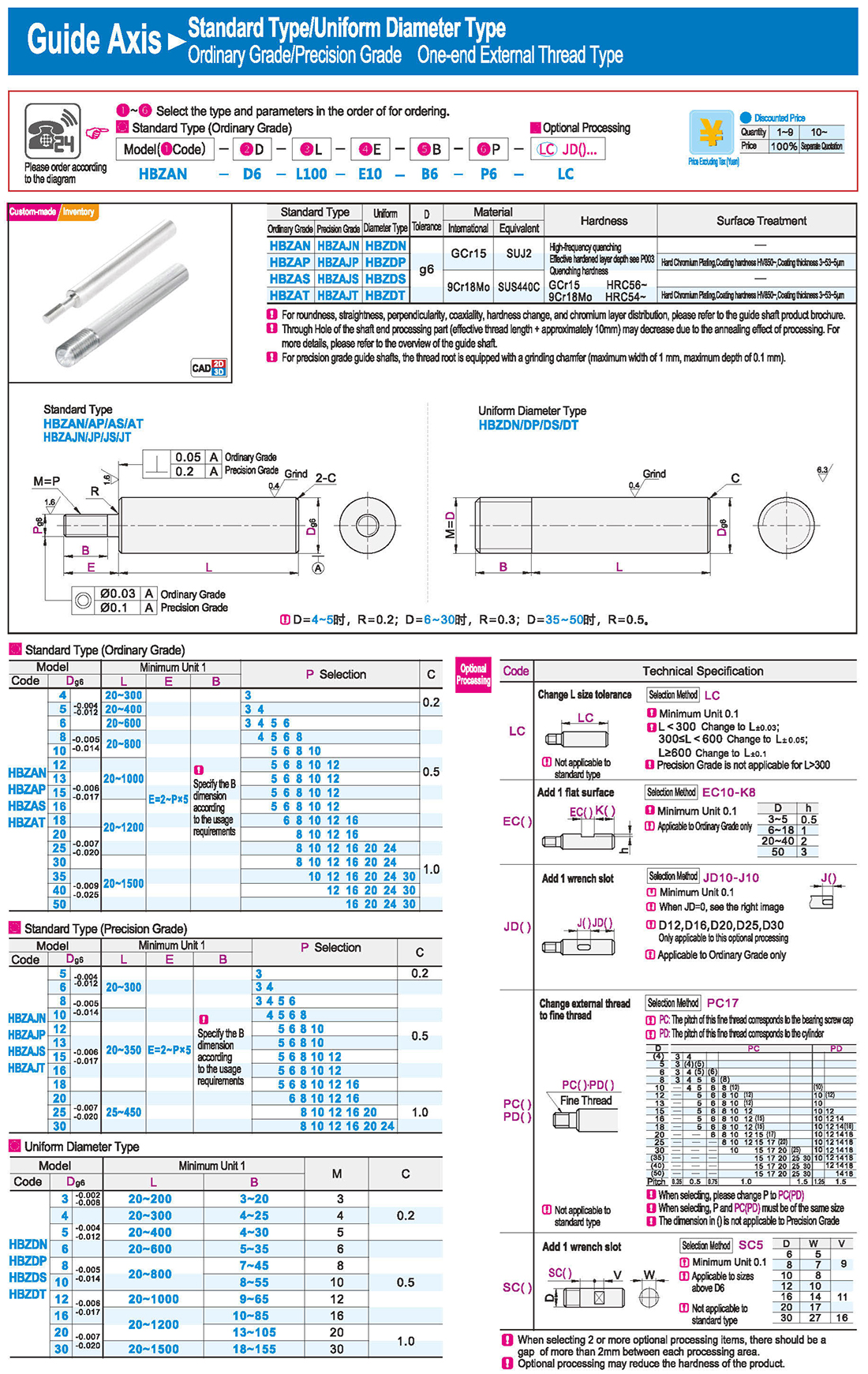

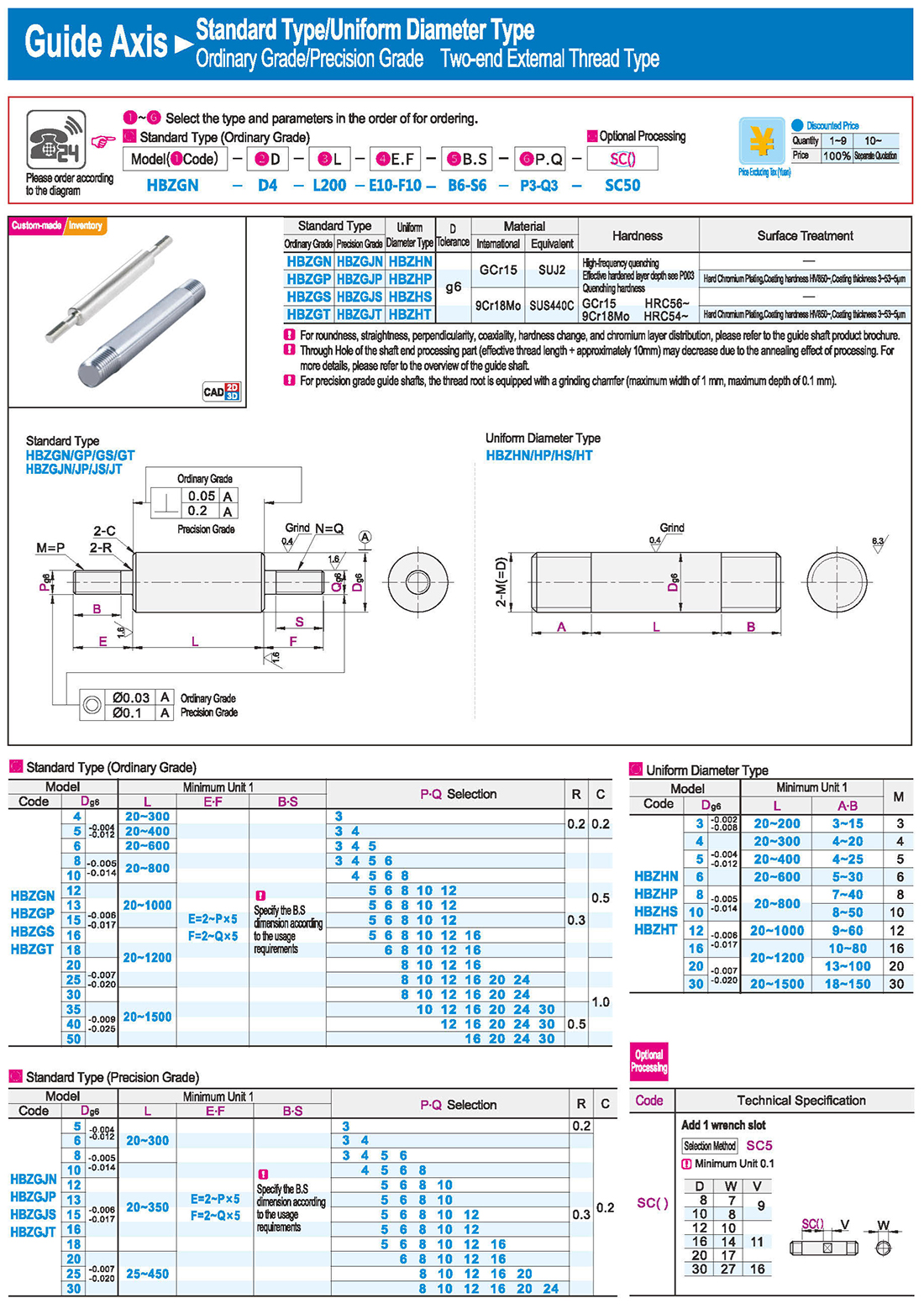

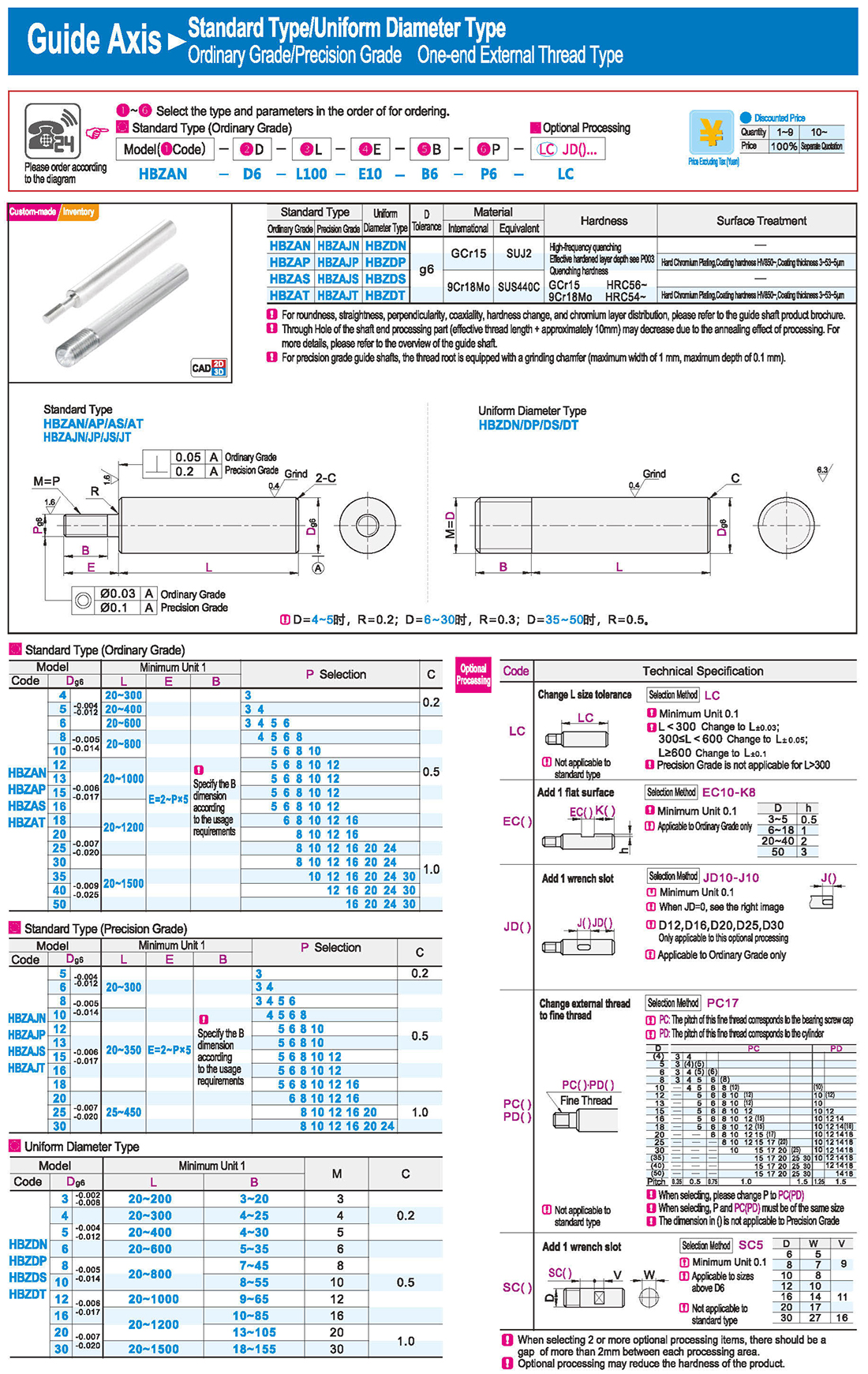

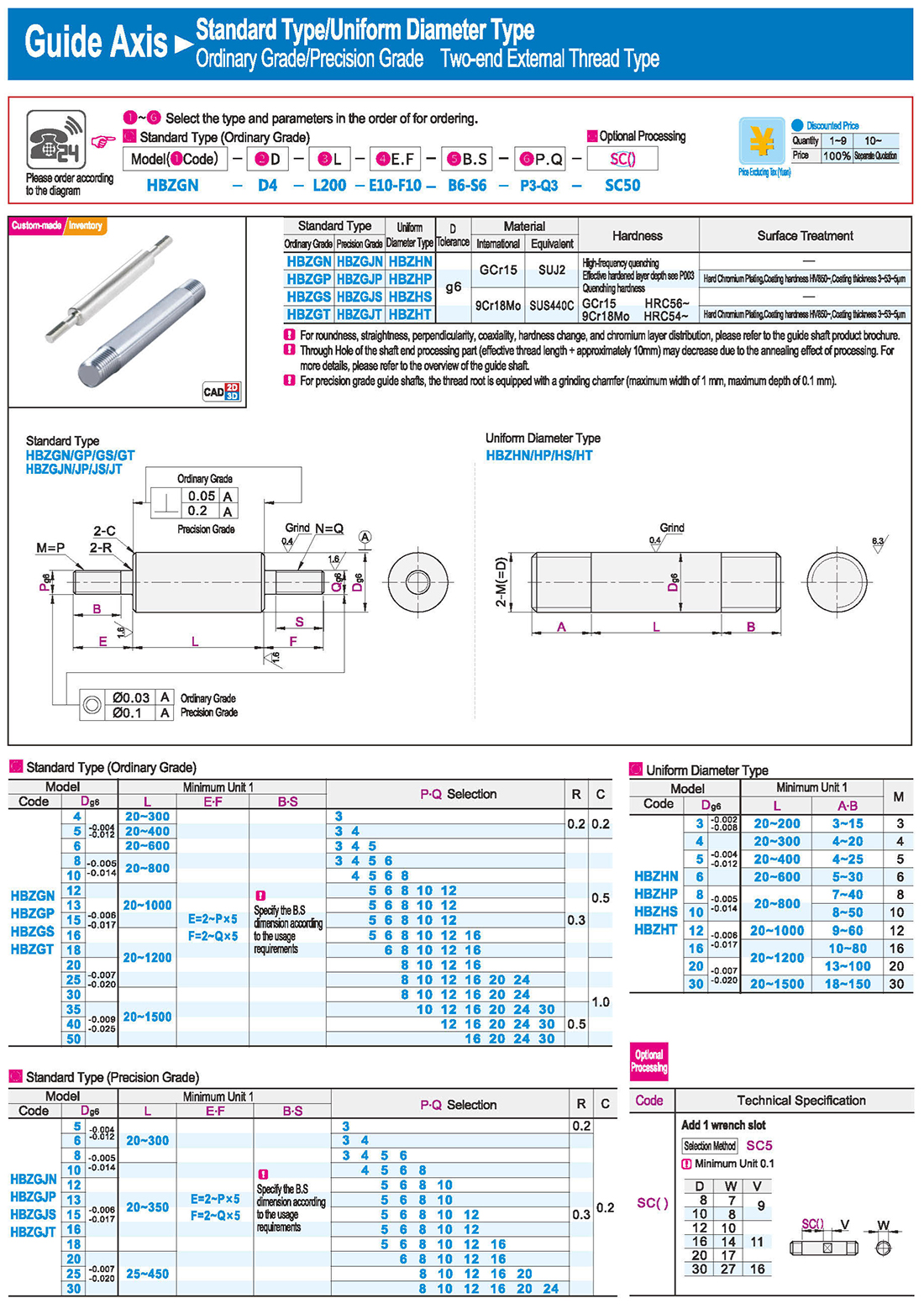

Uniform Diameter Type

Ordinary Grade/Precision Grade One-end External Thread Type

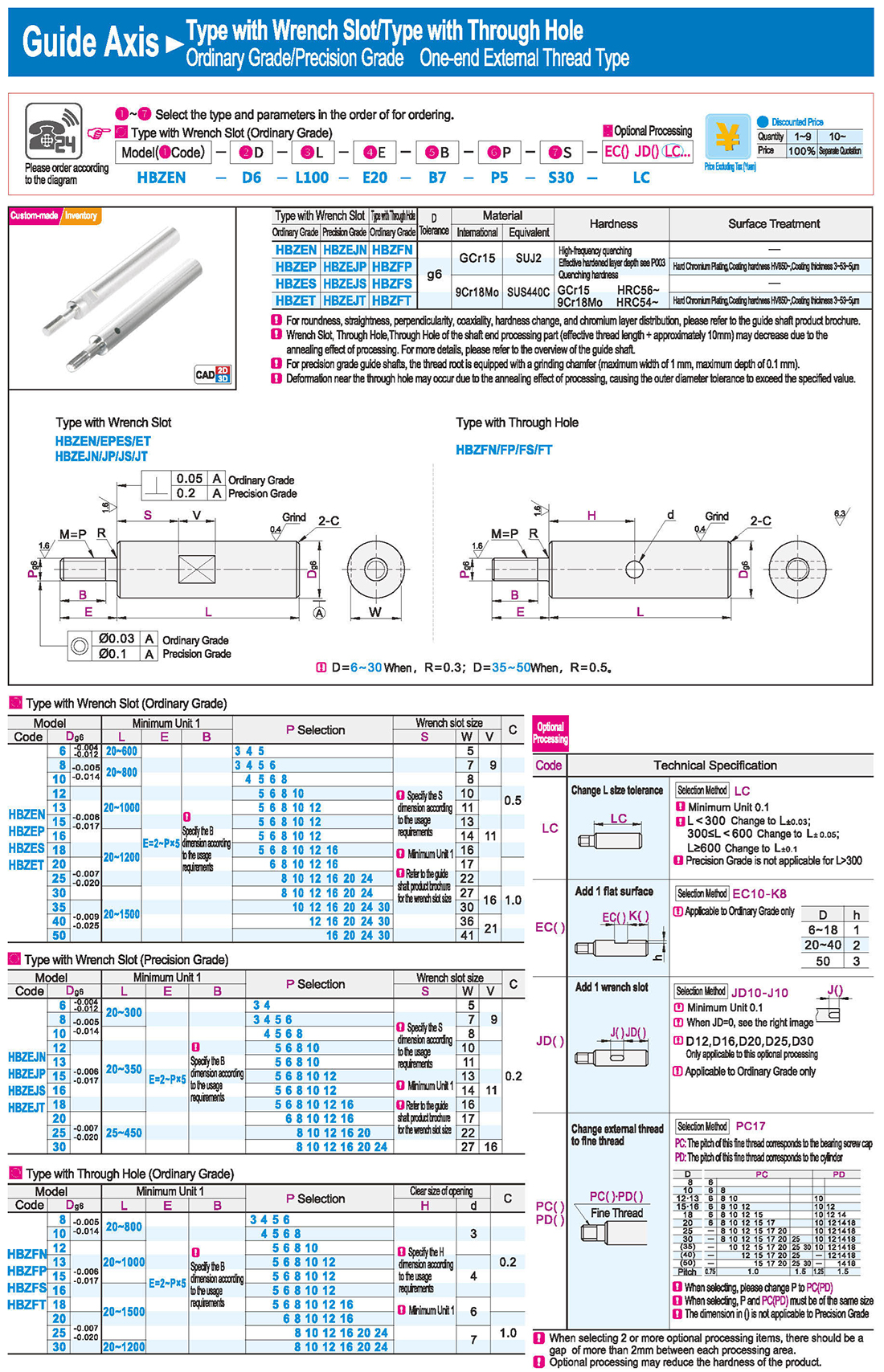

Type with Through Hole

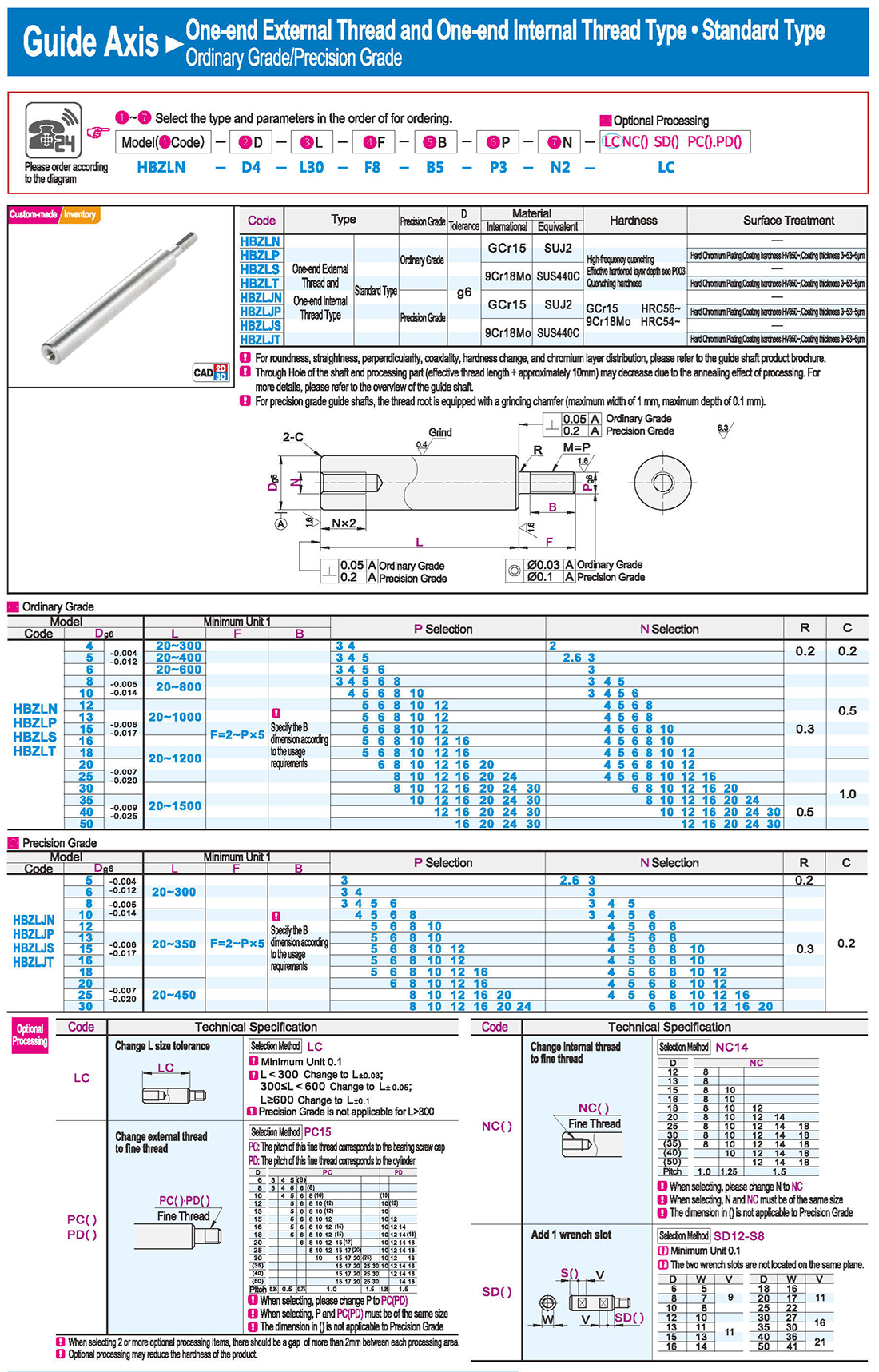

One-end External Thread and One-end Internal Thread Type

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

Introduction Specification Table

Specification Table Download

Download