High voltage DC brushless drives, as an advanced electric drive device, play an important role in multiple fields. The following is a detailed introduction to high-voltage DC brushless drives:

1、 Definition and Working Principle

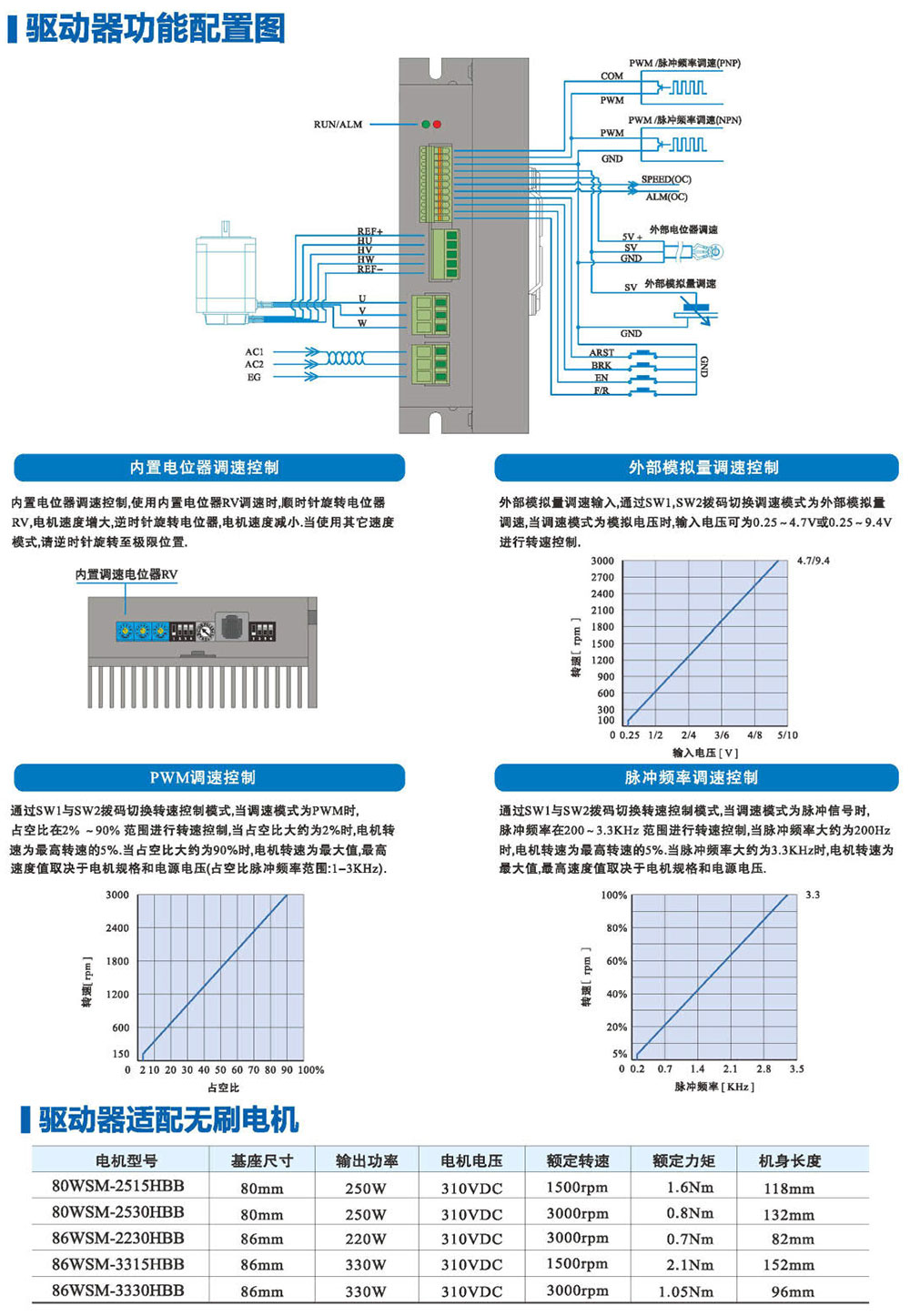

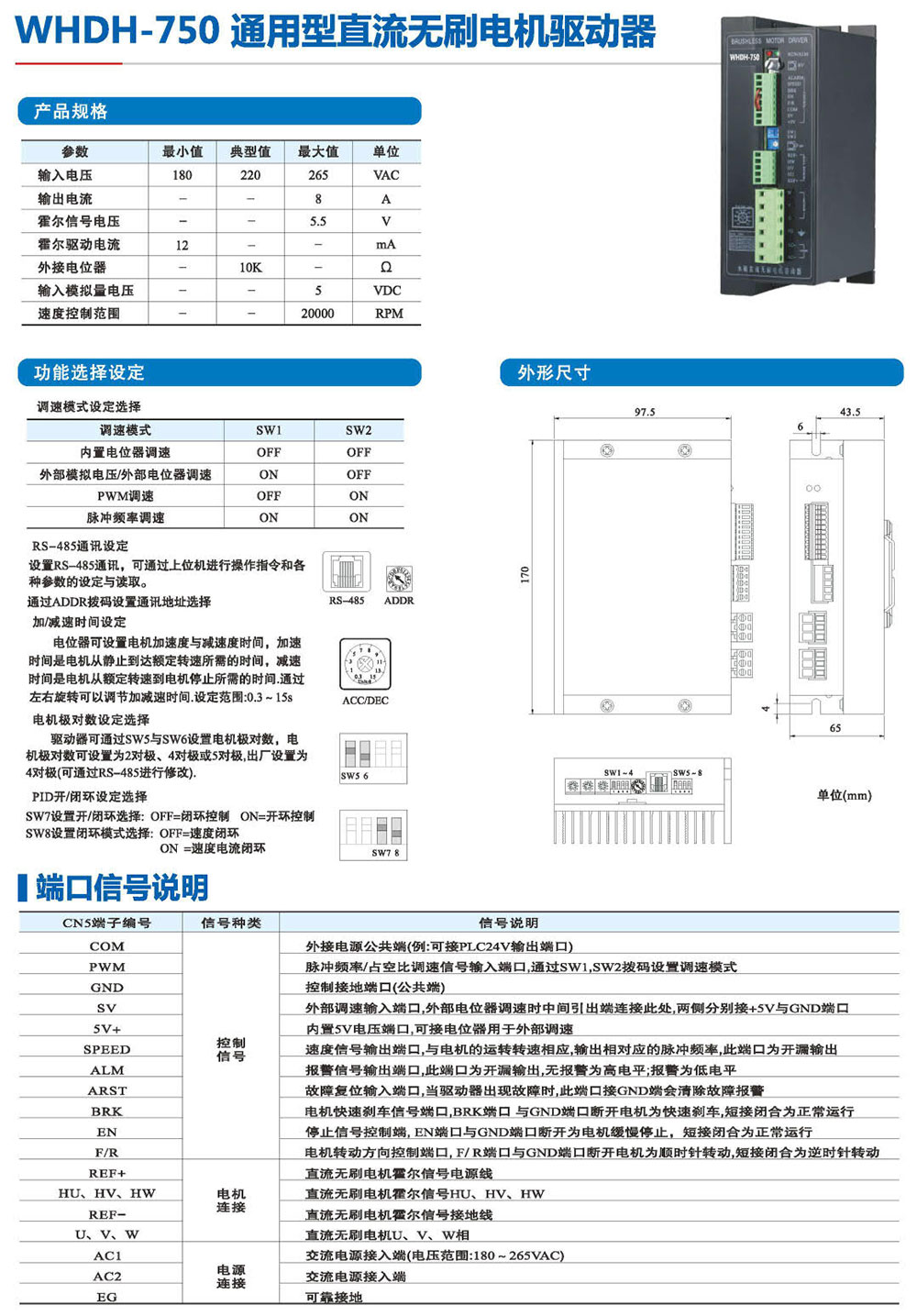

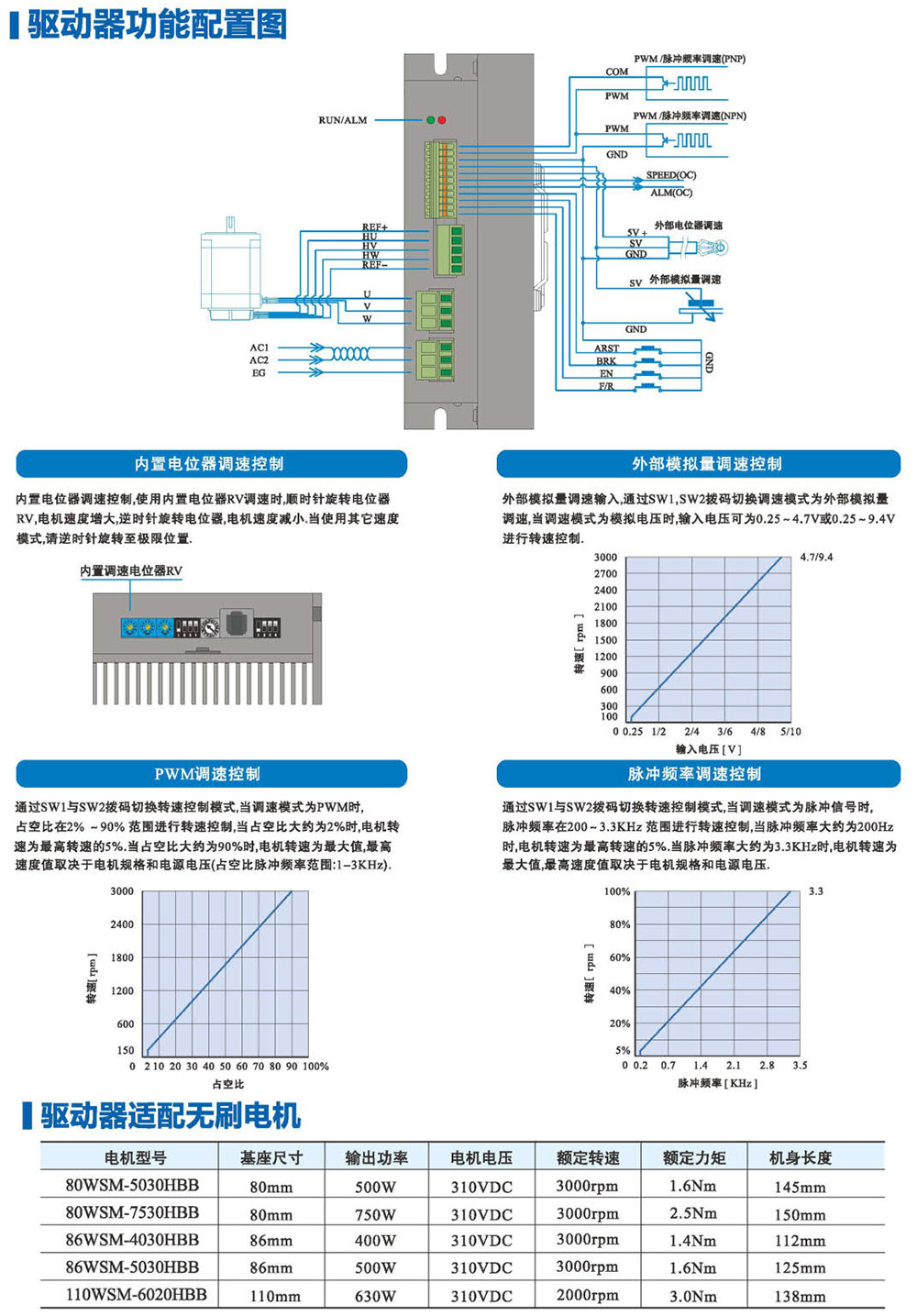

High voltage DC brushless driver refers to a device that is connected to a high power supply voltage (such as common 220V) and outputs a DC voltage (such as 310V) to drive a brushless motor. Its working principle mainly controls the speed and direction of the motor through electronic components, including power supply, motor drive circuit, and controller. The power supply provides sufficient voltage and current to the motor driver, and the motor drive circuit transmits power signals to the motor. The controller is responsible for controlling the working mode of the motor drive circuit, achieving precise speed and direction control of the motor.

2、 Characteristics and advantages

High efficiency: Due to the use of electronic commutators, the efficiency of high-voltage DC brushless drives is relatively high, reaching over 90%, which helps to reduce energy consumption and improve energy utilization efficiency.

Low noise: There is no mechanical friction between brushes and commutators, resulting in low noise during operation, which is beneficial for improving the working environment.

High reliability: reduces mechanical wear and improves equipment reliability and service life.

Good control performance: Accurate speed and position control is achieved through electronic controllers to meet the needs of various application scenarios.

Low maintenance cost: Due to the reduction of mechanical wear and tear, maintenance costs are relatively low.

Compact structure: easy to integrate into various devices, beneficial for reducing device size and improving device performance.

3、 Application scenarios

High voltage DC brushless drives are widely used in various fields due to their high efficiency, reliability, and precise control characteristics:

Industrial automation: used to drive automated equipment, robots, etc. on production lines to achieve efficient and precise production processes.

Robot technology: As the core driving component of robot actuators, it provides stable and reliable power support.

Numerical Control Machine Tool: Used for driving the spindle and feed axis, ensuring the high-precision machining capability of the machine tool.

Provide quiet and efficient motor drive solutions for high-end household appliances such as air conditioners, refrigerators, washing machines, etc.

Medical equipment: Ensure the precise operation of equipment and patient safety in medical devices such as ventilators, infusion pumps, surgical robots, etc.

Automotive industry: used for driving systems in electric and hybrid vehicles, as well as various auxiliary systems in automobiles, to enhance vehicle performance and energy efficiency.

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

Introduction Specification Table

Specification Table Download

Download