Oil-free Bushing -- Product Introduction

Also known as self-lubricating bearings, the oil-free bushing is a novel lubricating bearing that combines the characteristics of metal bearings and oil-free lubricating bearings. It is composed of a metal substrate that bears the load, and solid lubricating materials with a special formulation that function as lubrication. This bushing boasts high load-bearing capacity, impact resistance, high-temperature resistance, and strong self-lubrication ability. It is particularly suitable for heavy loads, low speeds, reciprocating or swinging motions, and other difficult-to-lubricate and oil-film-forming applications. It is also resistant to water flushing and the erosion and scouring of other acidic liquids. Currently, these products have been widely used in metallurgical continuous casting machines, steel rolling equipment, mining machinery, molds, lifting machinery, textile machinery, wind power generation, ships, steam turbines, water turbines, injection molding machines, and production lines.

Installation Considerations

①Before assembly, ensure that the surface of the bushing and the seat hole are free of foreign objects. The surface of the seat hole should be as smooth as possible to prevent scratching during assembly.

② During assembly, lubricant can be applied to the outer surface of the bushing to assist in its easier installation, but not too much to prevent the bushing from dislodging during heavy loads or reciprocating motion.

③ Use a mandrel to slowly press the bushing into place during assembly (hydraulic press recommended). Direct hammering of the bushing is prohibited to prevent deformation.

④ If the seat hole design involves the use of easily deformable materials such as aluminum alloy or if the wall thickness of the seat hole is relatively thin, please provide clarification to prevent deformation during press-fitting.

⑤ To simplify assembly and avoid damaging the wear-resistant layer, the end face of the shaft must have a chamfered and smoothly transitioned edge. It is recommended that the shaft material be bearing steel with a quenched surface treatment of HRC45, a surface roughness of Rz2-3, and the surface can also be hard chromium plated.

Selection Steps for Oil-free Bushings

Determine Operating Conditions → Preliminarily Select Specification → Verify Basic Safety → Complete Selection

Determine the operating environment, general usage, heat resistance, chemical resistance, load capacity, frequency of use, and the need for lubrication.

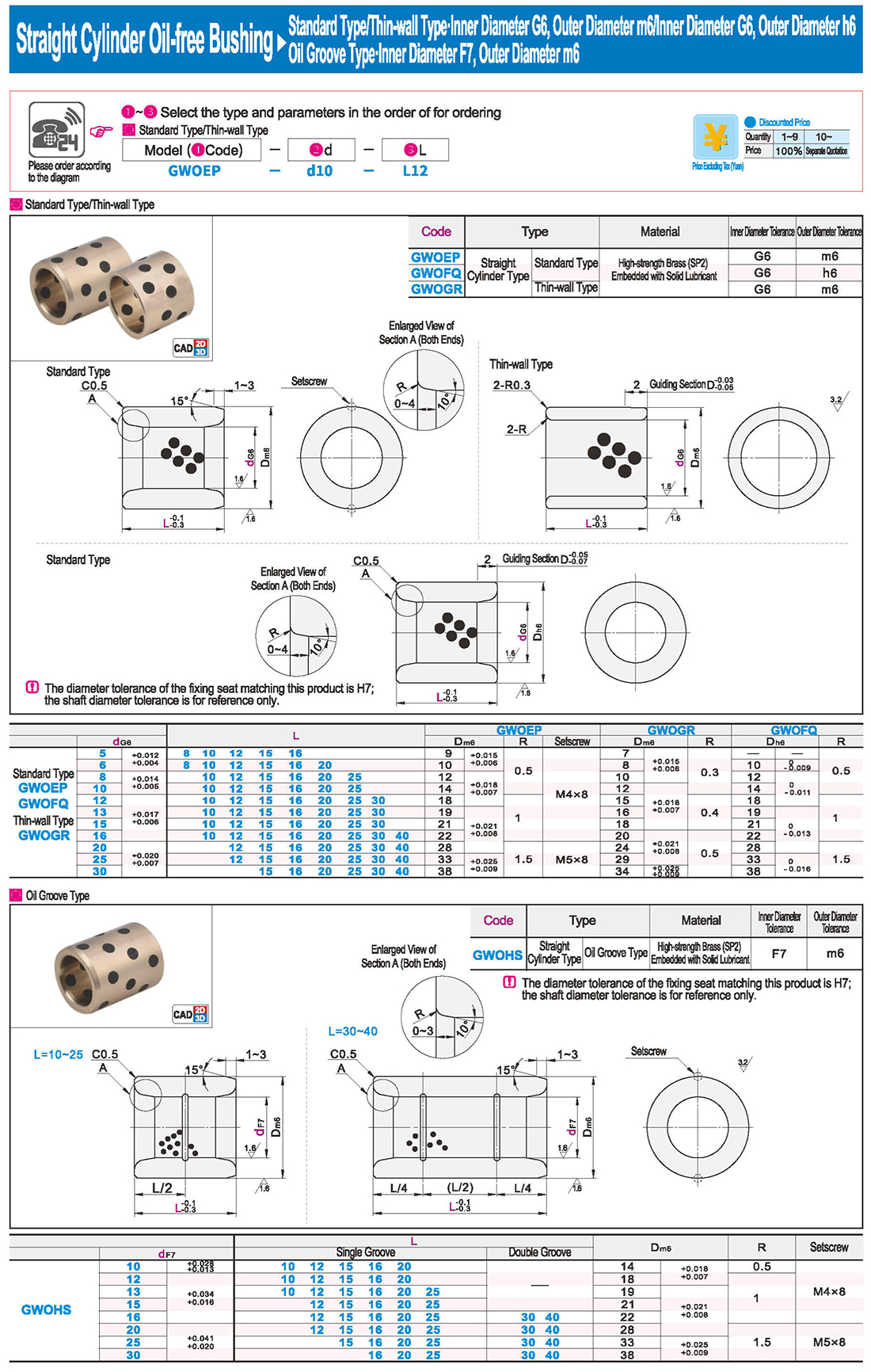

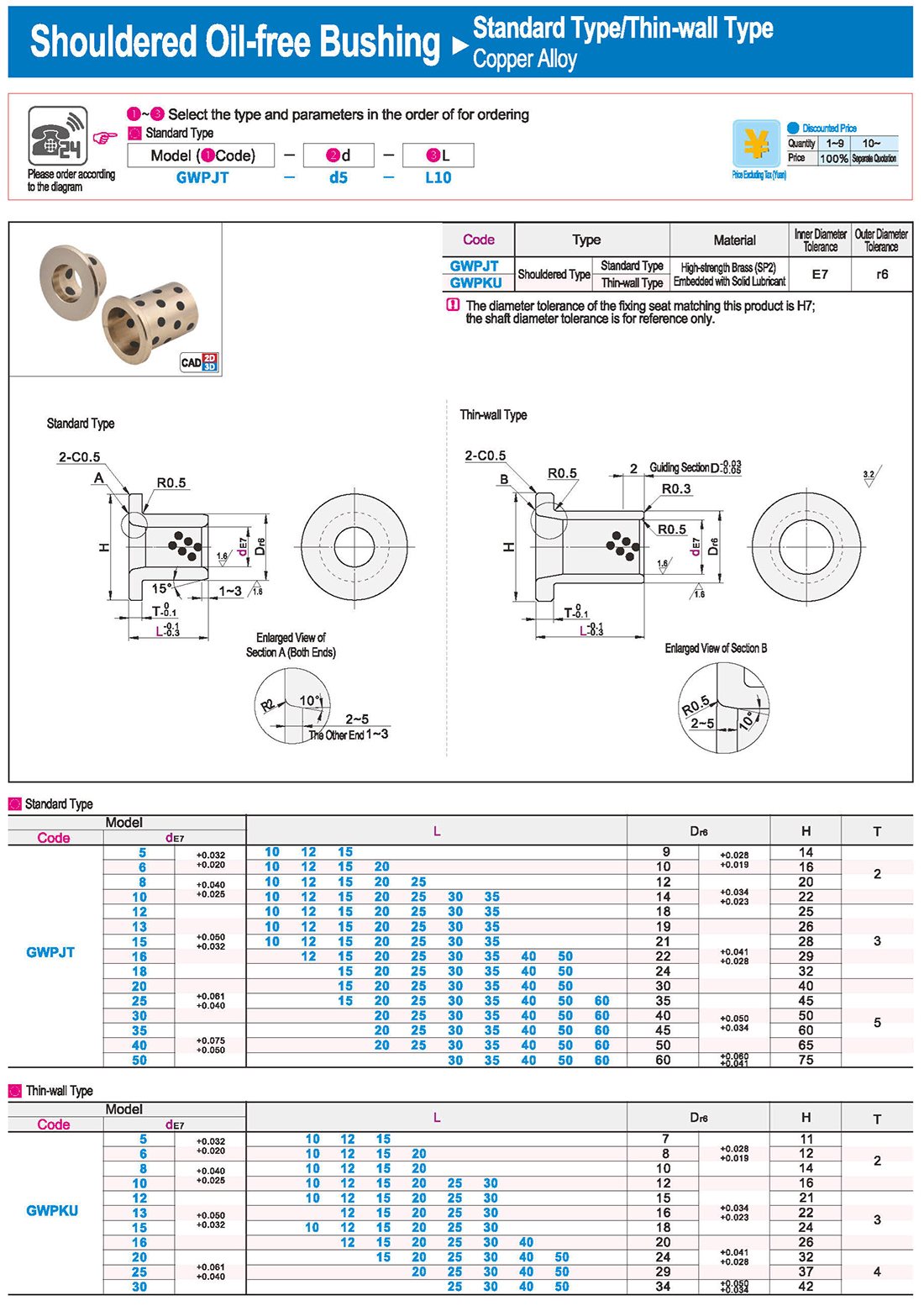

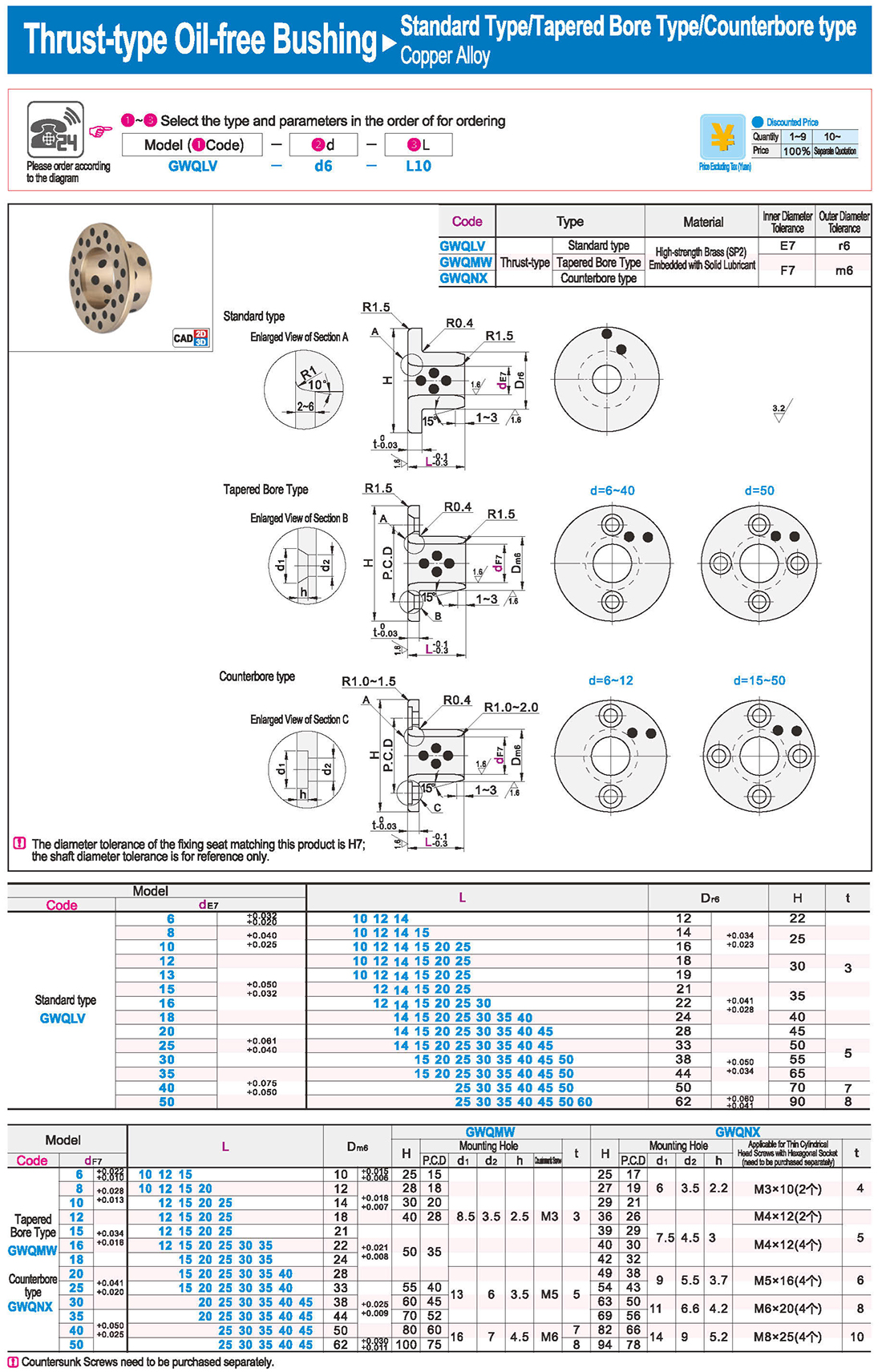

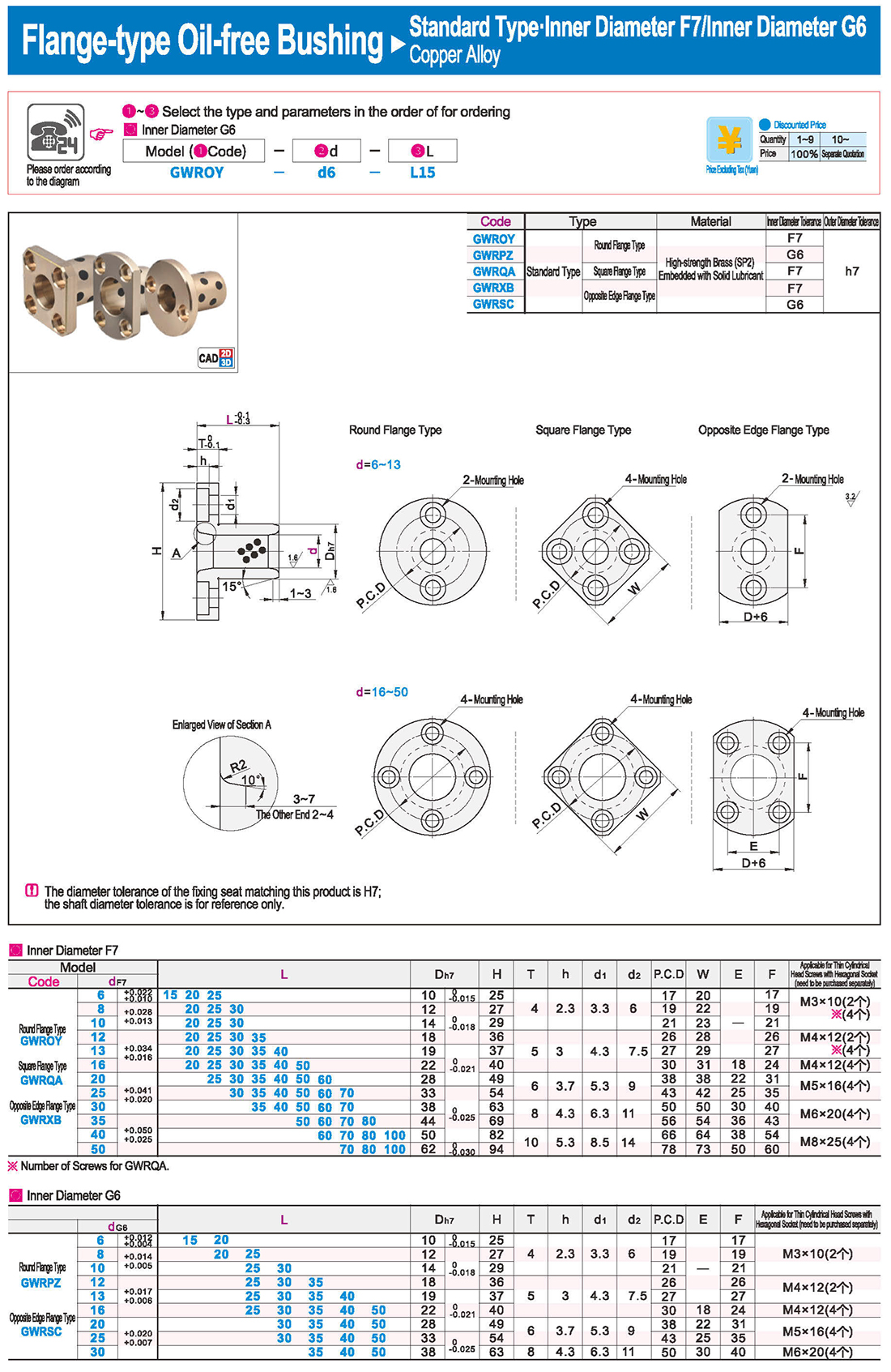

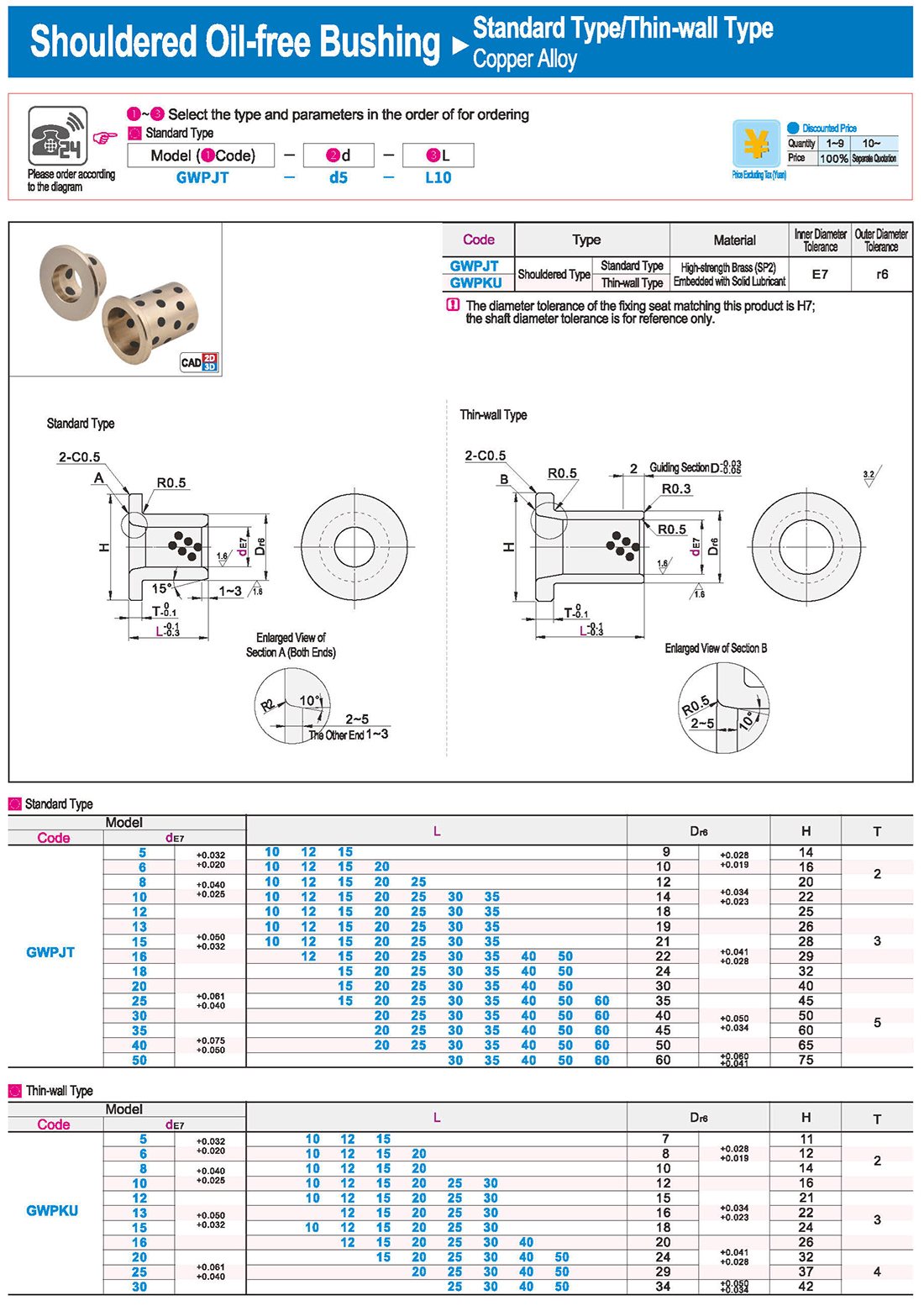

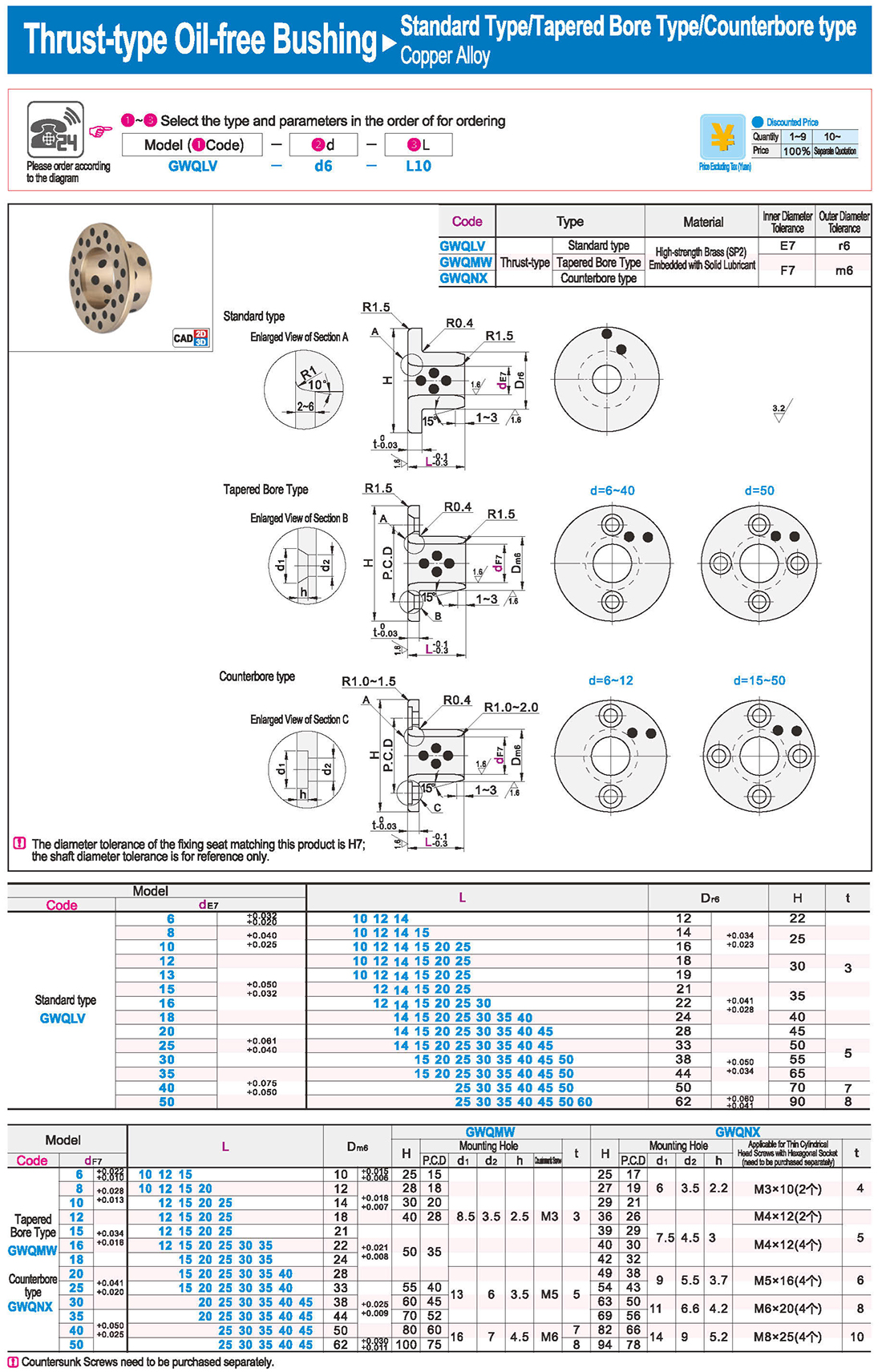

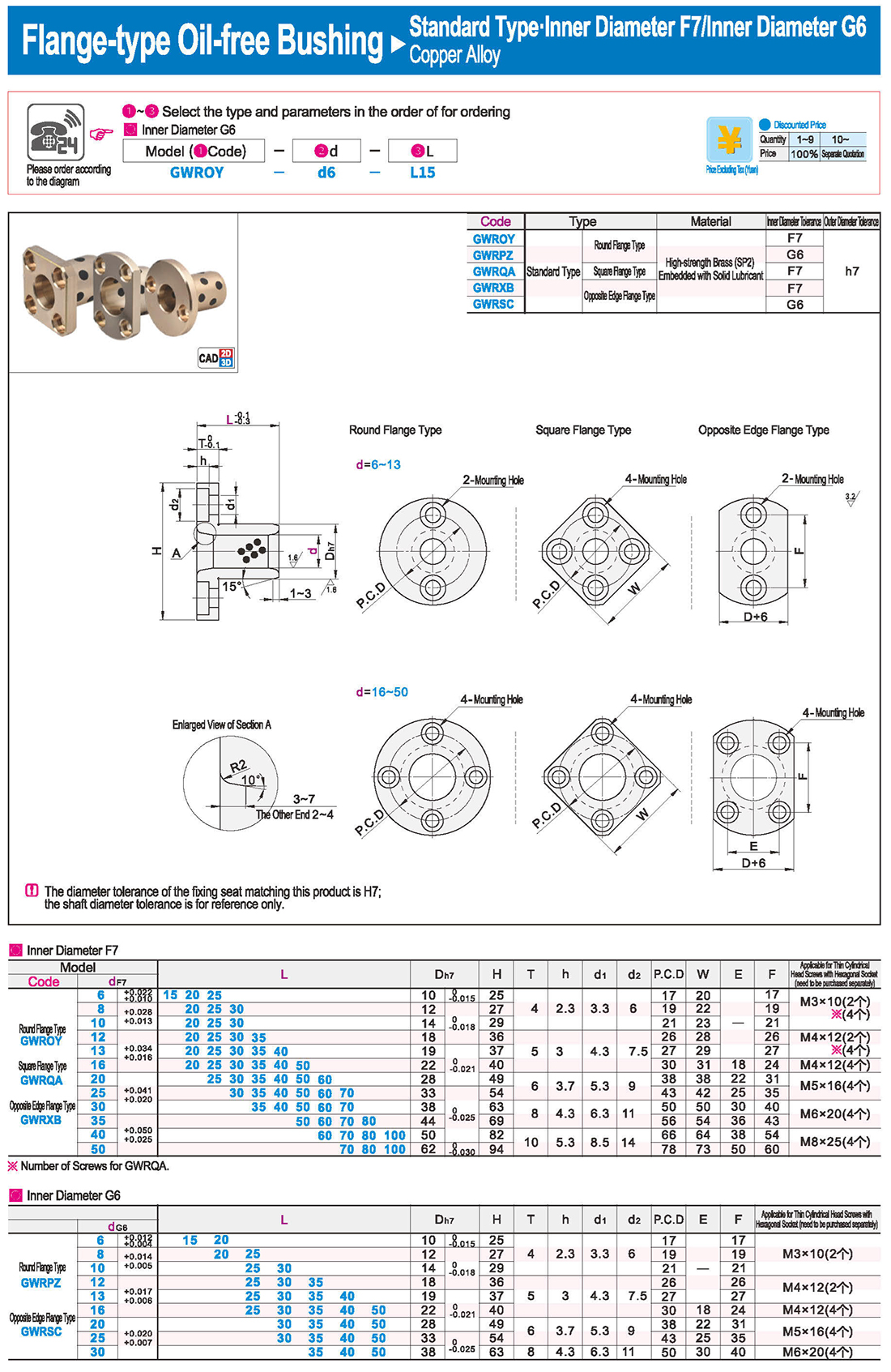

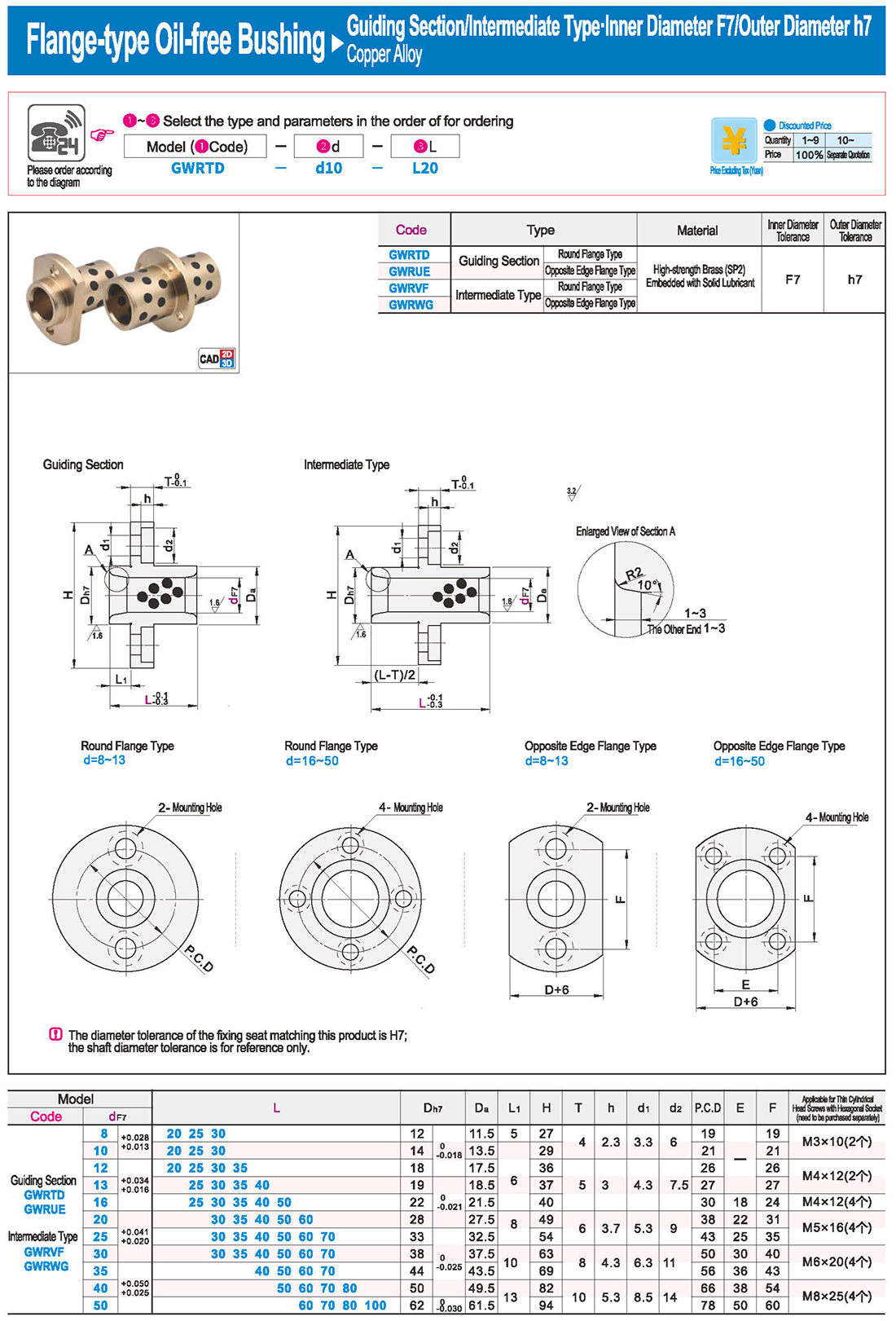

Select the appropriate type such as straight pillar or shoulder-type. Pre-select the specification and size based on the design conditions.

Maximum Allowable Load: Please confirm that the load is within the maximum allowable load limit.

Maximum Allowable Speed: Please verify that the moving speed is within the maximum allowable speed limit.

Lifespan (Wear Calculation): Calculate the approximate wear amount and confirm that the necessary lifespan can be ensured.

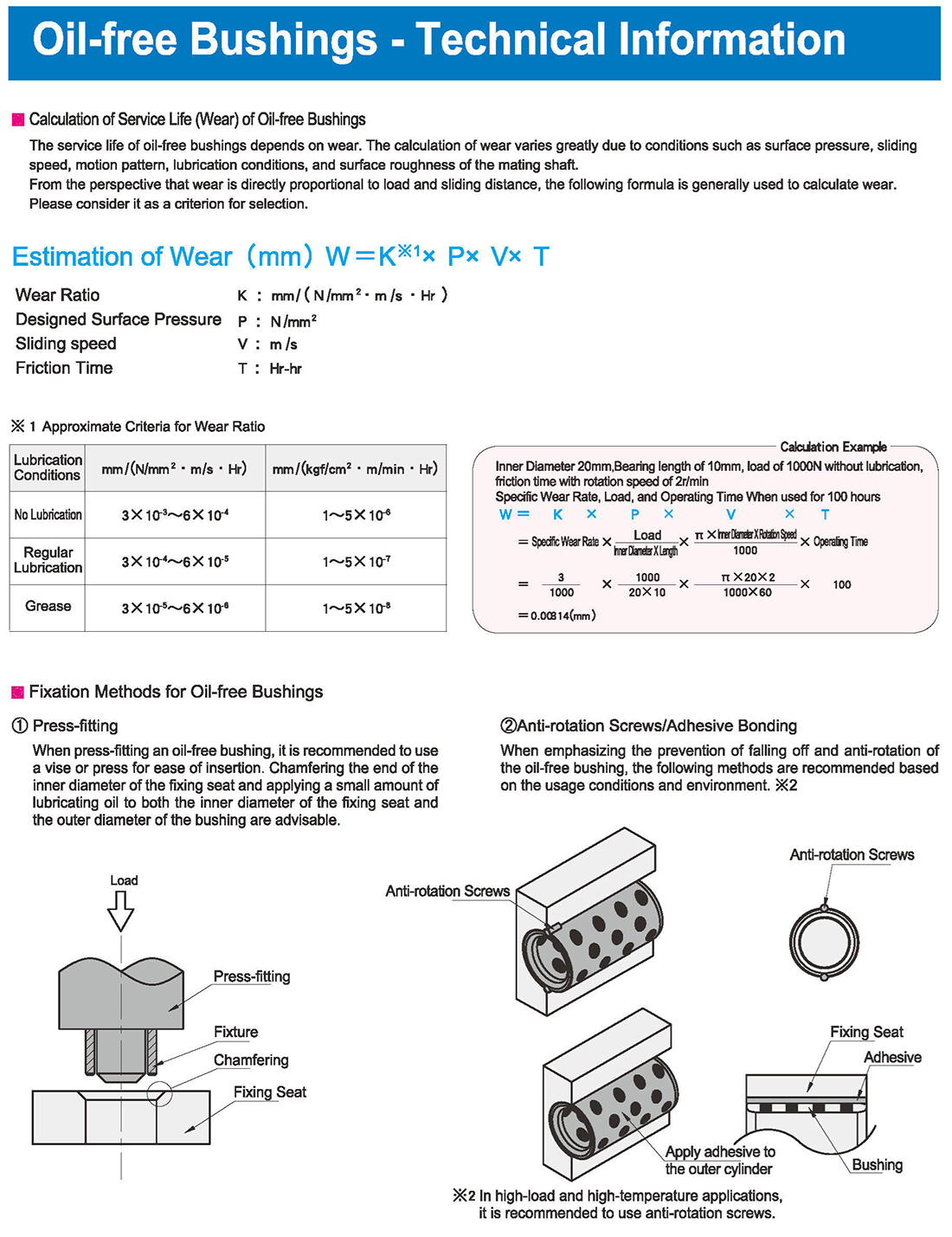

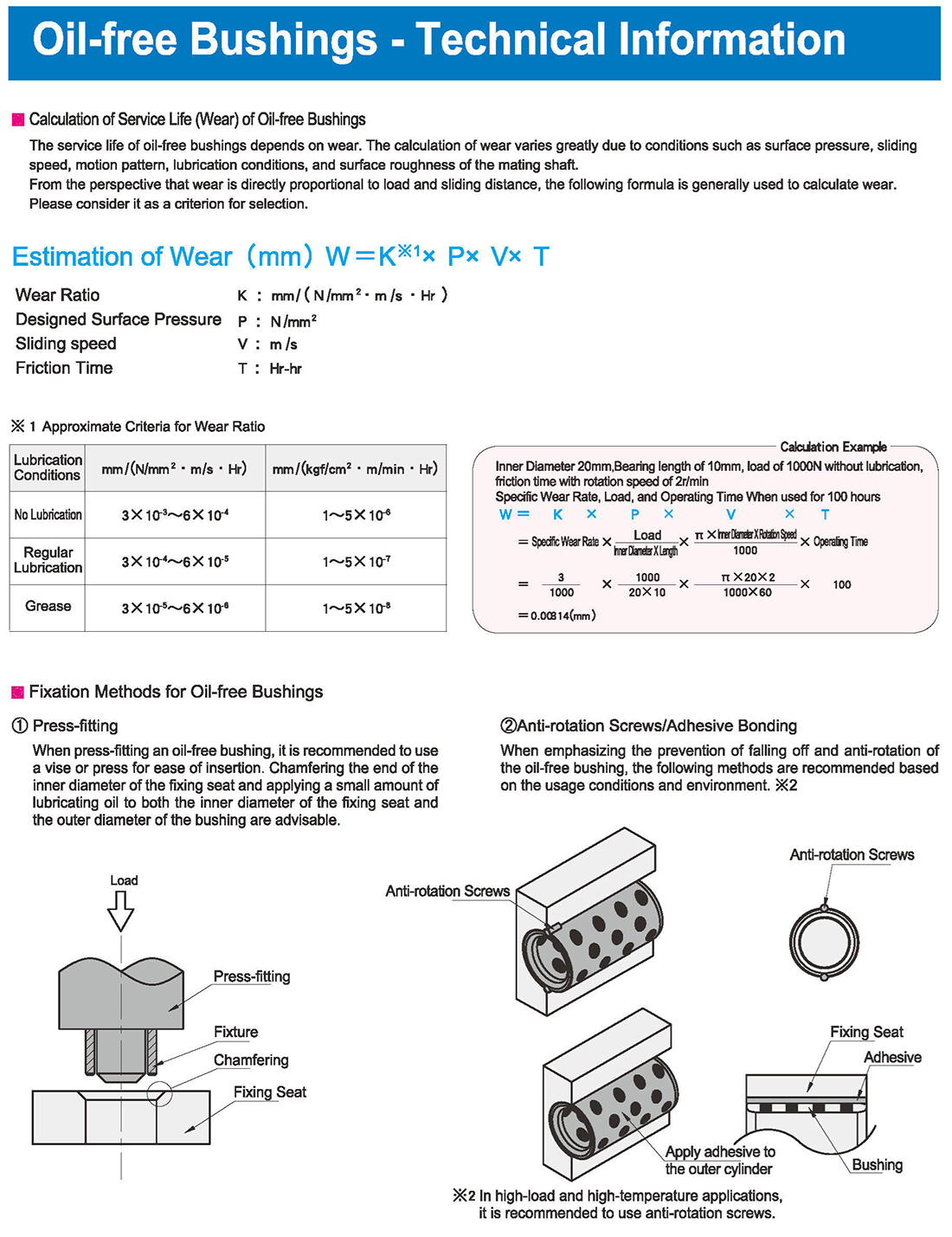

Fixation Methods for Oil-free Bushings

Press-fitting

When press-fitting an oil-free bushing, it is recommended to use a vise or press for ease of insertion. Chamfering the end of the inner diameter of the fixing seat and applying a small amount of lubricating oil to both the inner diameter of the fixing seat and the outer diameter of the bushing are advisable.

Anti-rotation Screws/Adhesive Bonding

When emphasizing the prevention of falling off and anti-rotation of the oil-free bushing, the following methods are recommended based on the usage conditions and environment. ※2

Press-fitting Fixture, Bushing, Chamfering, Anti-rotation Screws, Adhesive, Apply adhesive to the outer cylinder

In high-load and high-temperature applications, it is recommended to use anti-rotation screws.

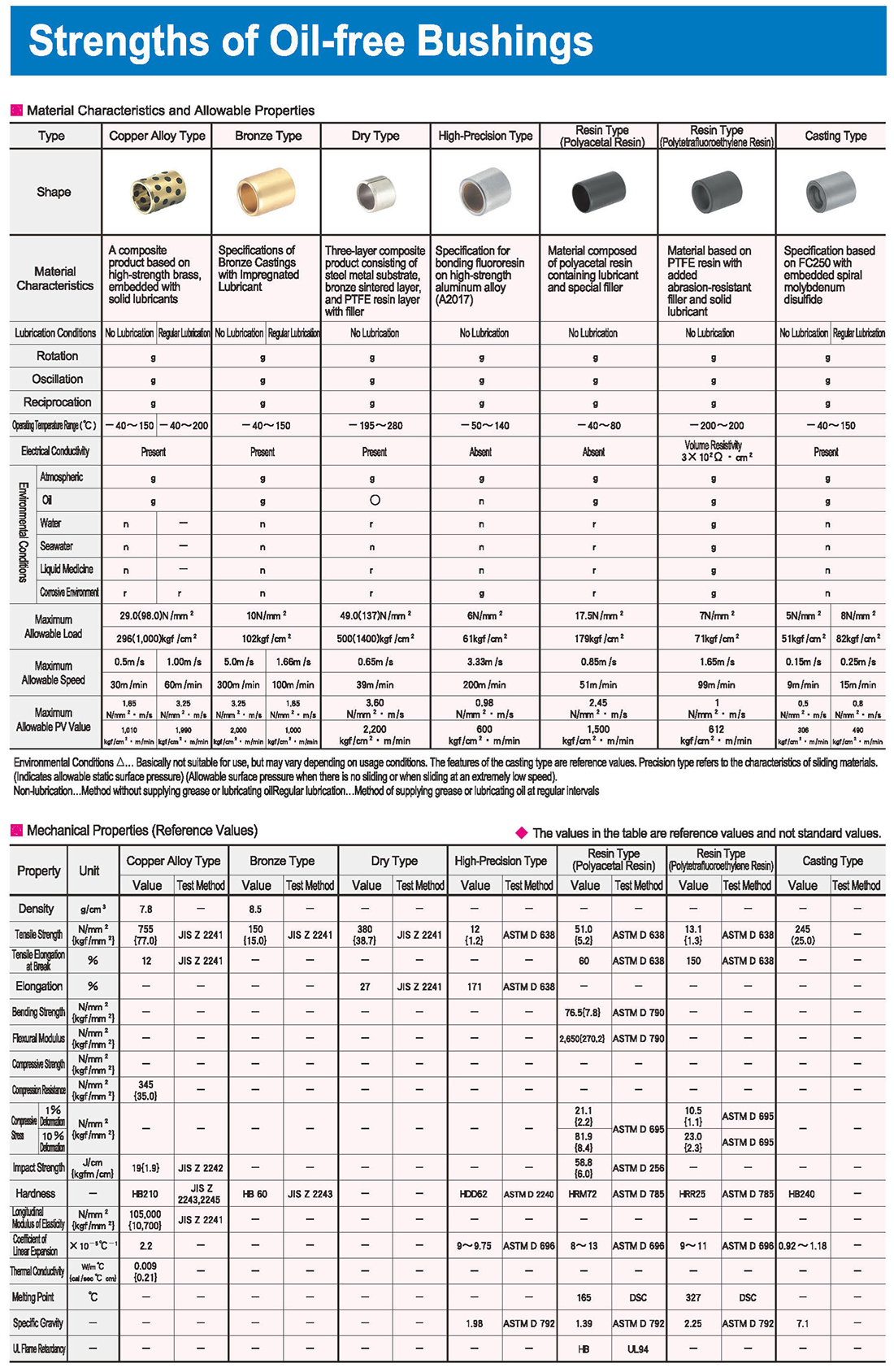

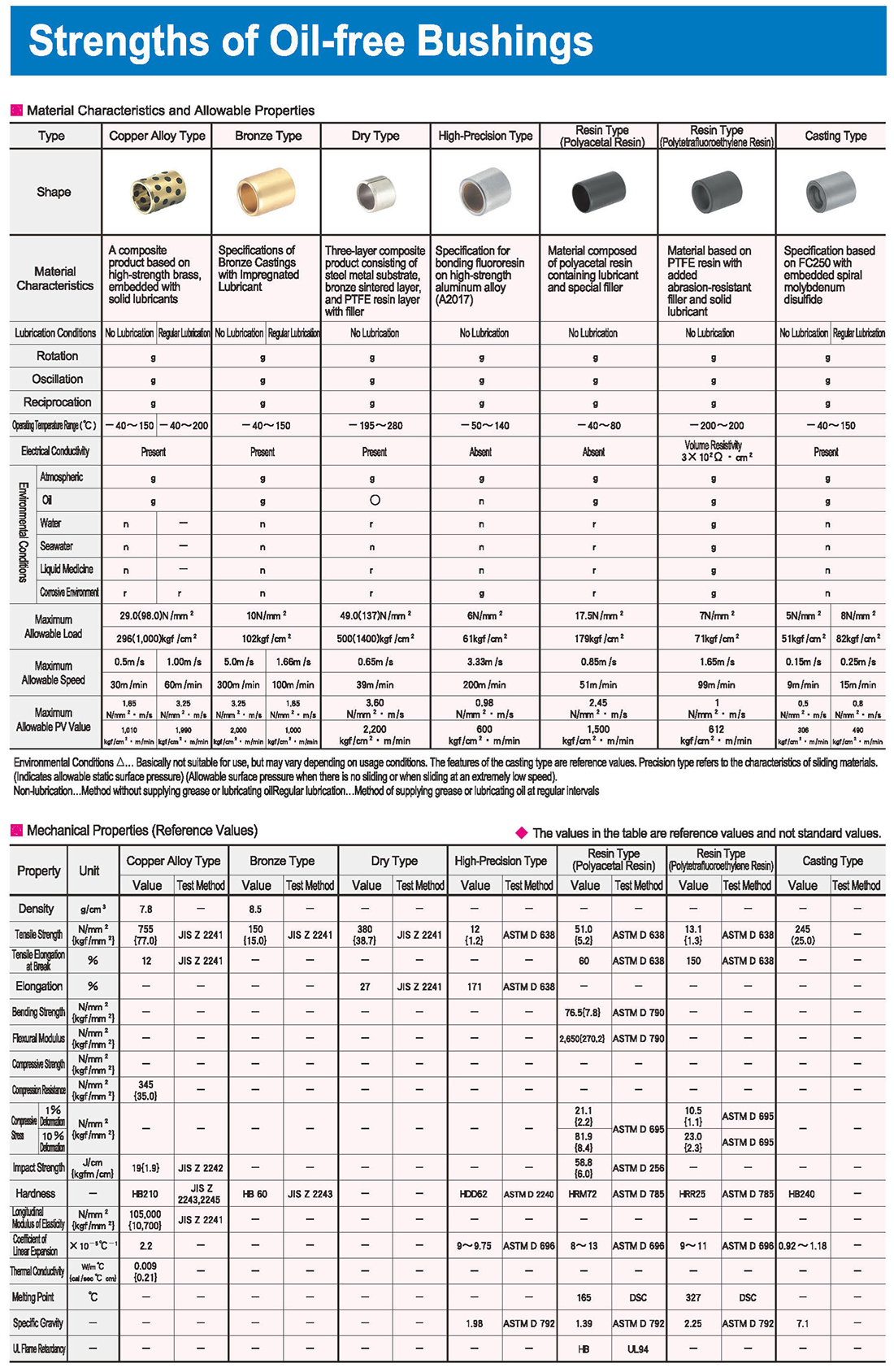

Strengths of Oil-free Bushings

Material Characteristics and Allowable Properties

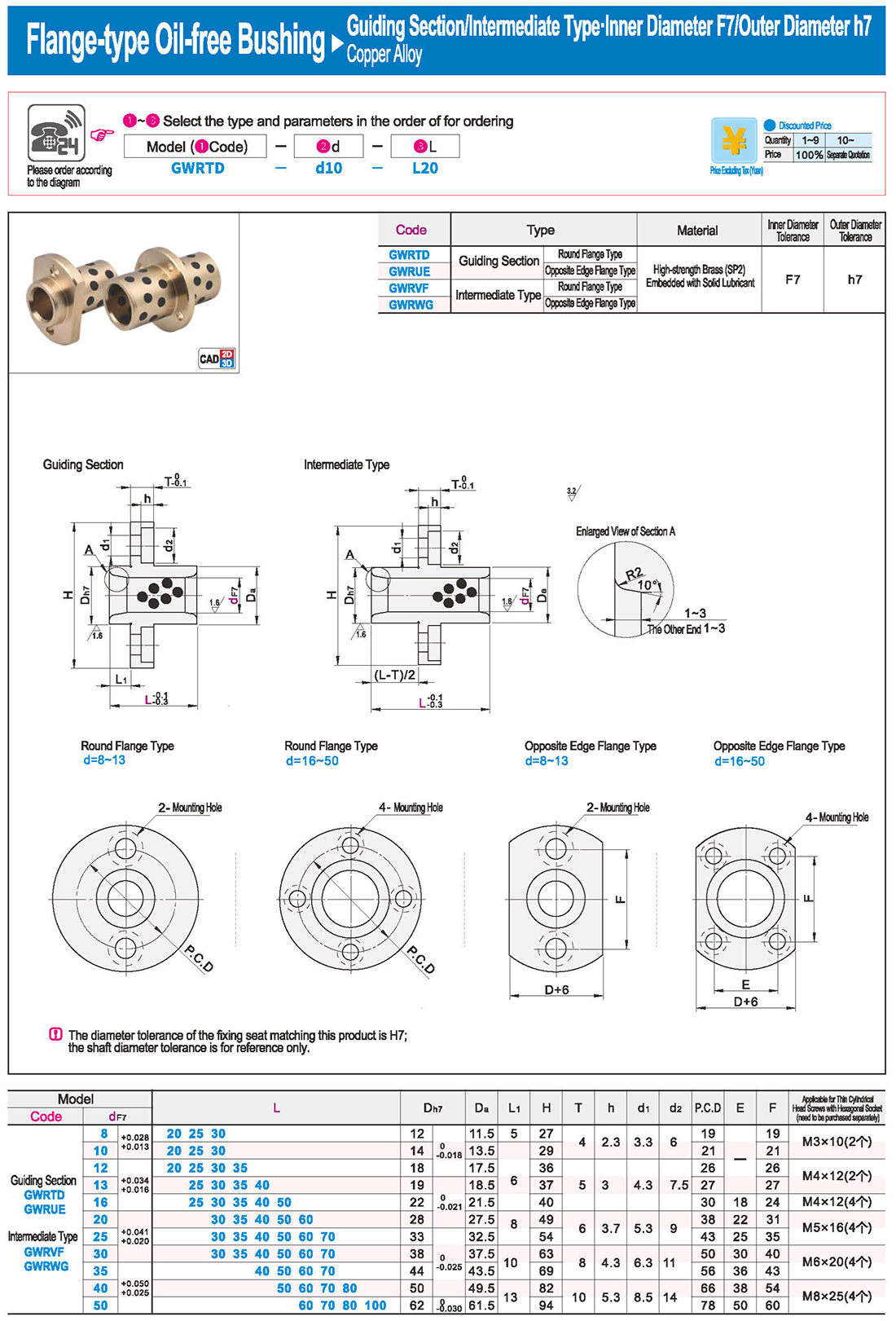

Copper Alloy Type, Bronze Type, Dry Type, High-Precision Type

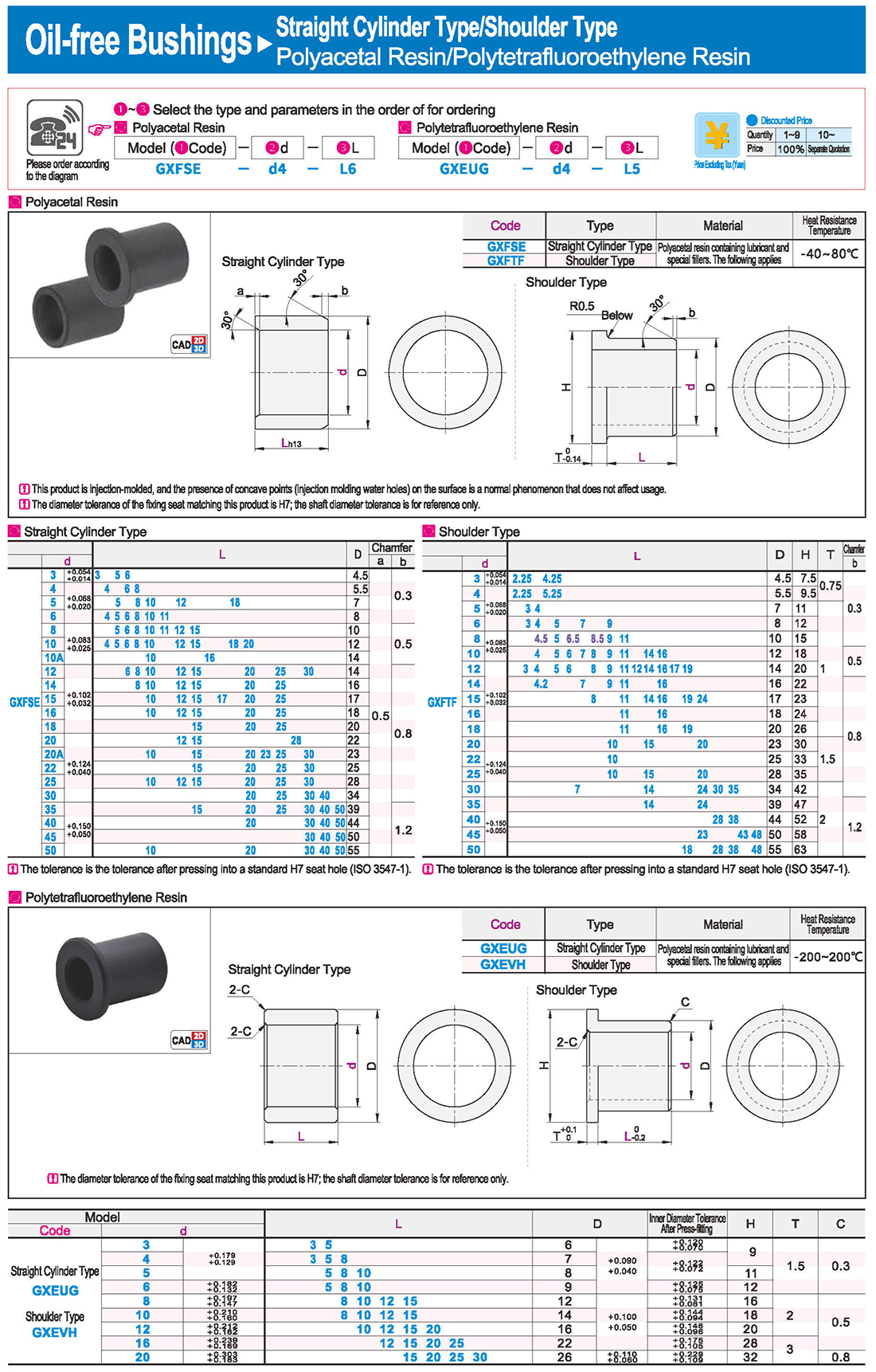

Resin Type (Polyacetal Resin), Polytetrafluoroethylene Resin, Casting Type

Material Characteristics

A composite product based on high-strength brass, embedded with solid lubricants

Specifications of Bronze Castings with Impregnated Lubricant

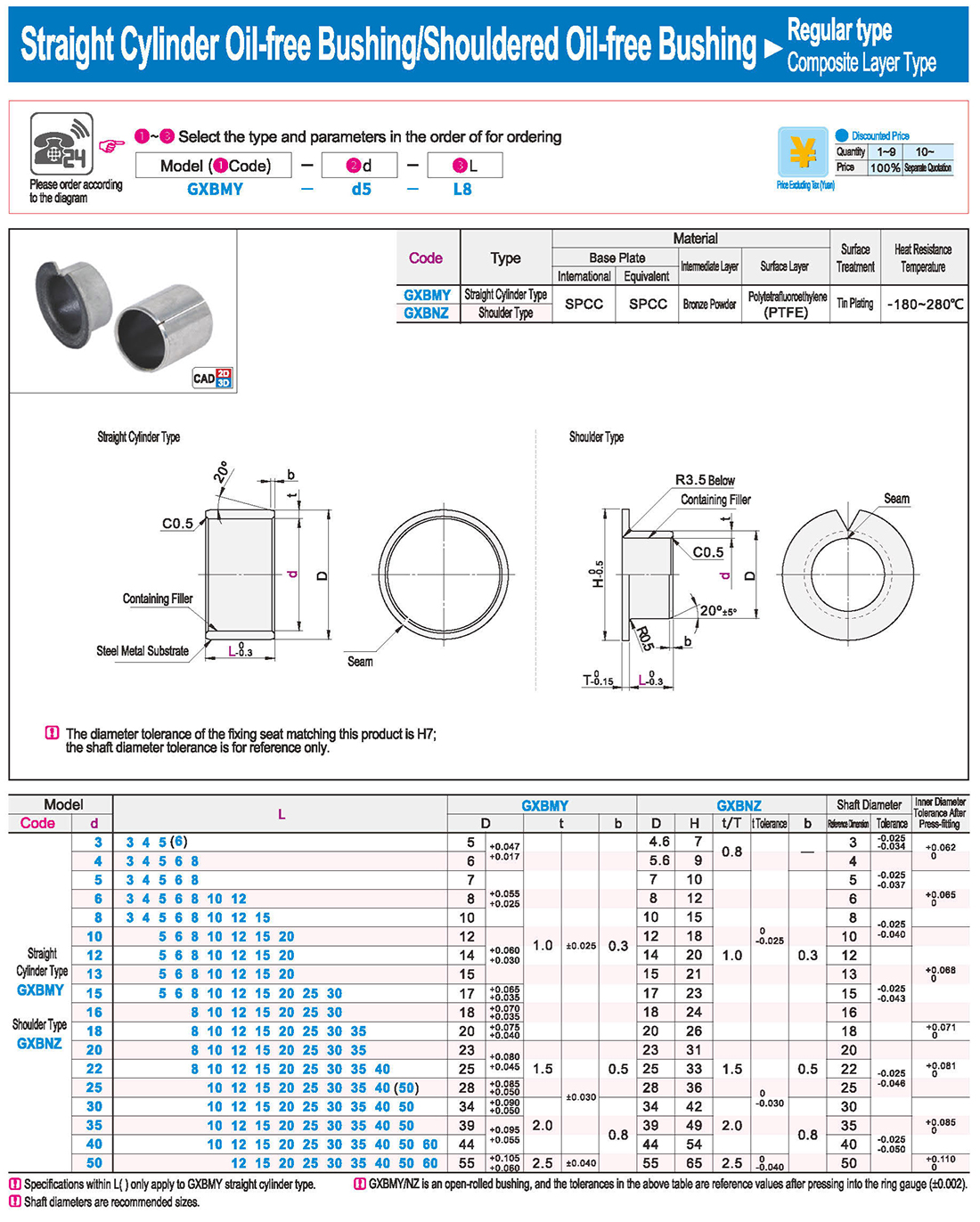

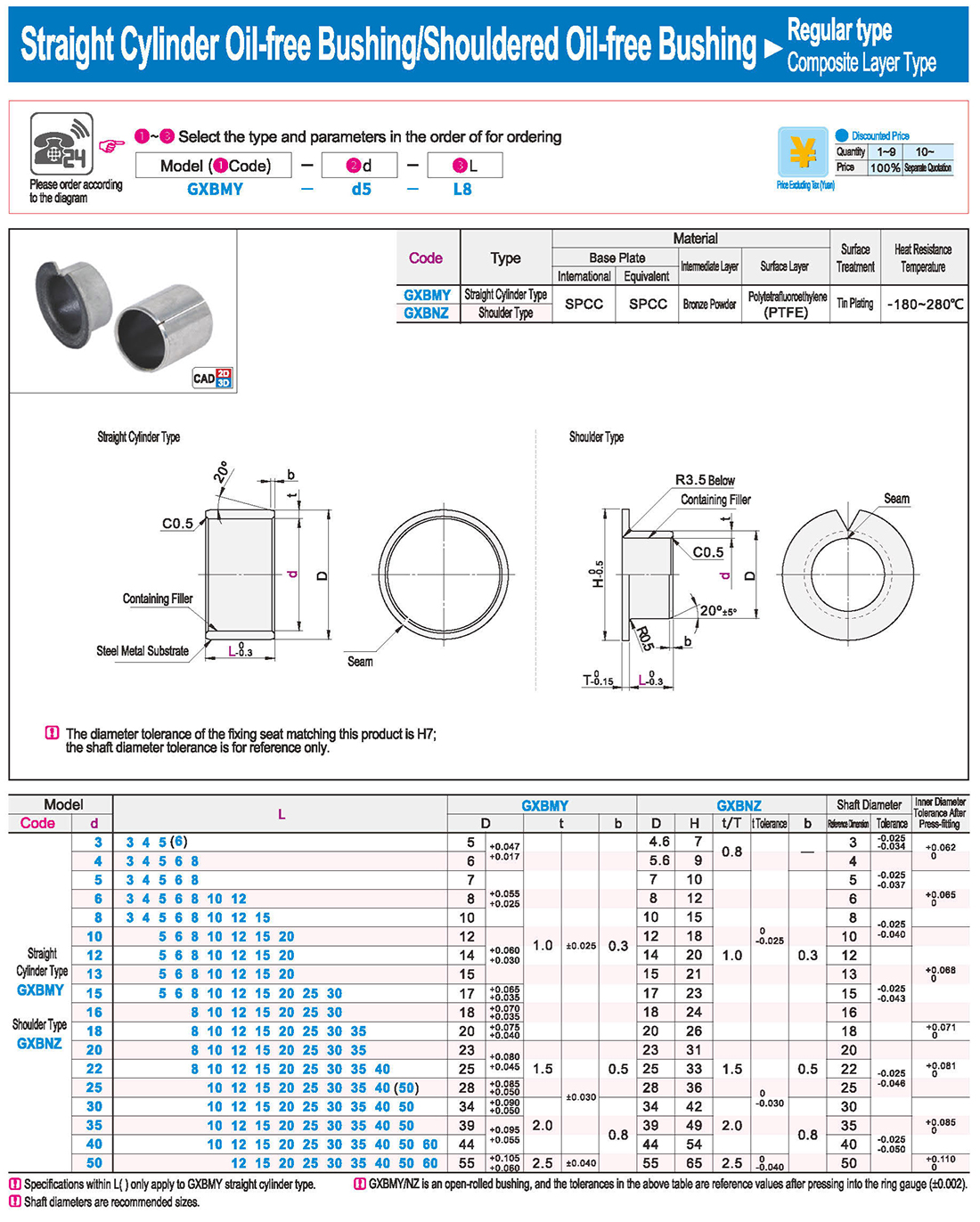

Three-layer composite product consisting of steel metal substrate, bronze sintered layer, and PTFE resin layer with filler

Specifications of High-strength Aluminum Alloy

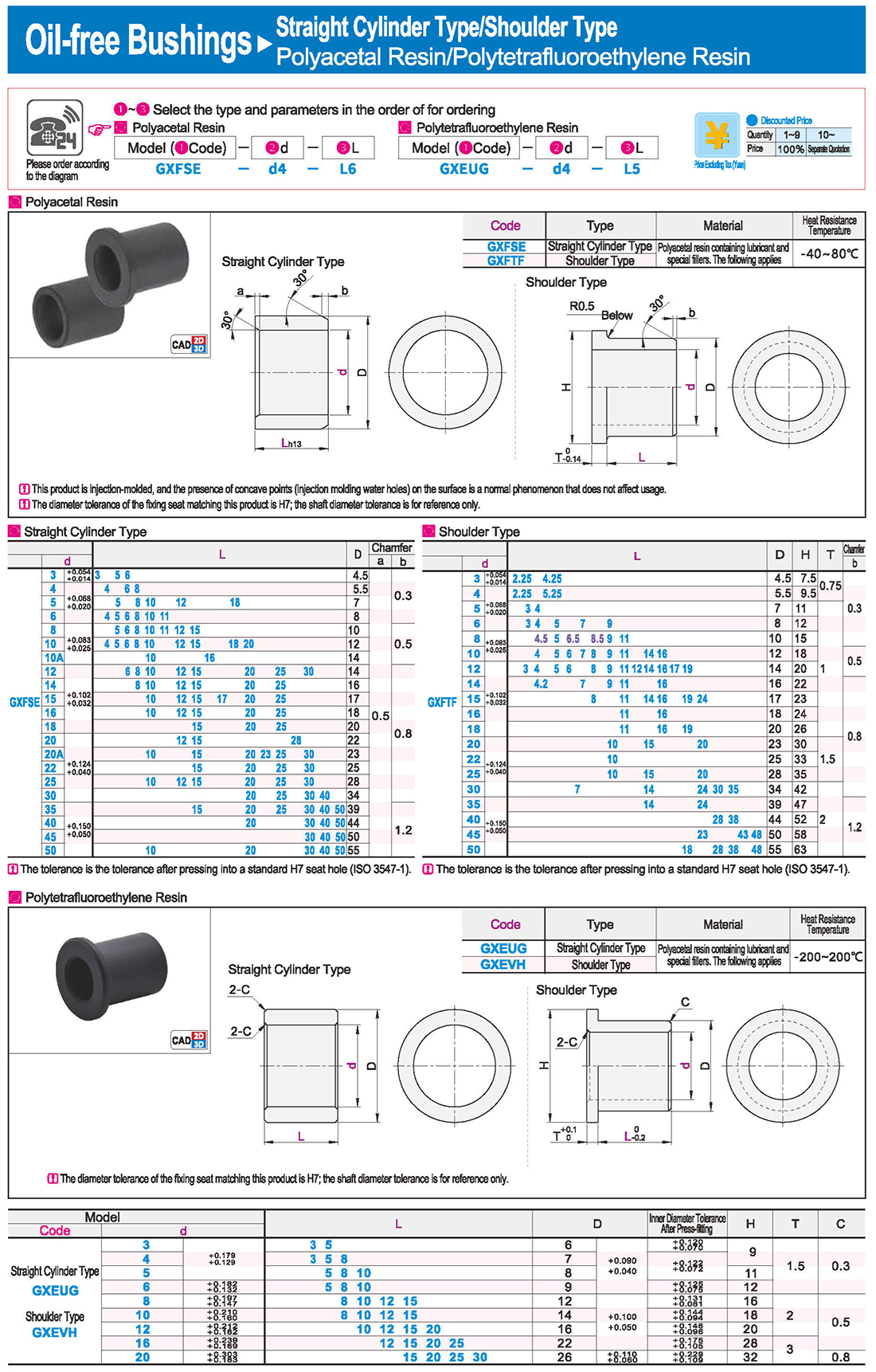

Material composed of polyacetal resin containing lubricant and special filler

Material based on PTFE resin with added abrasion-resistant filler and solid lubricant

Specification based on FC250 with embedded spiral molybdenum disulfide

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

Introduction Specification Table

Specification Table Download

Download