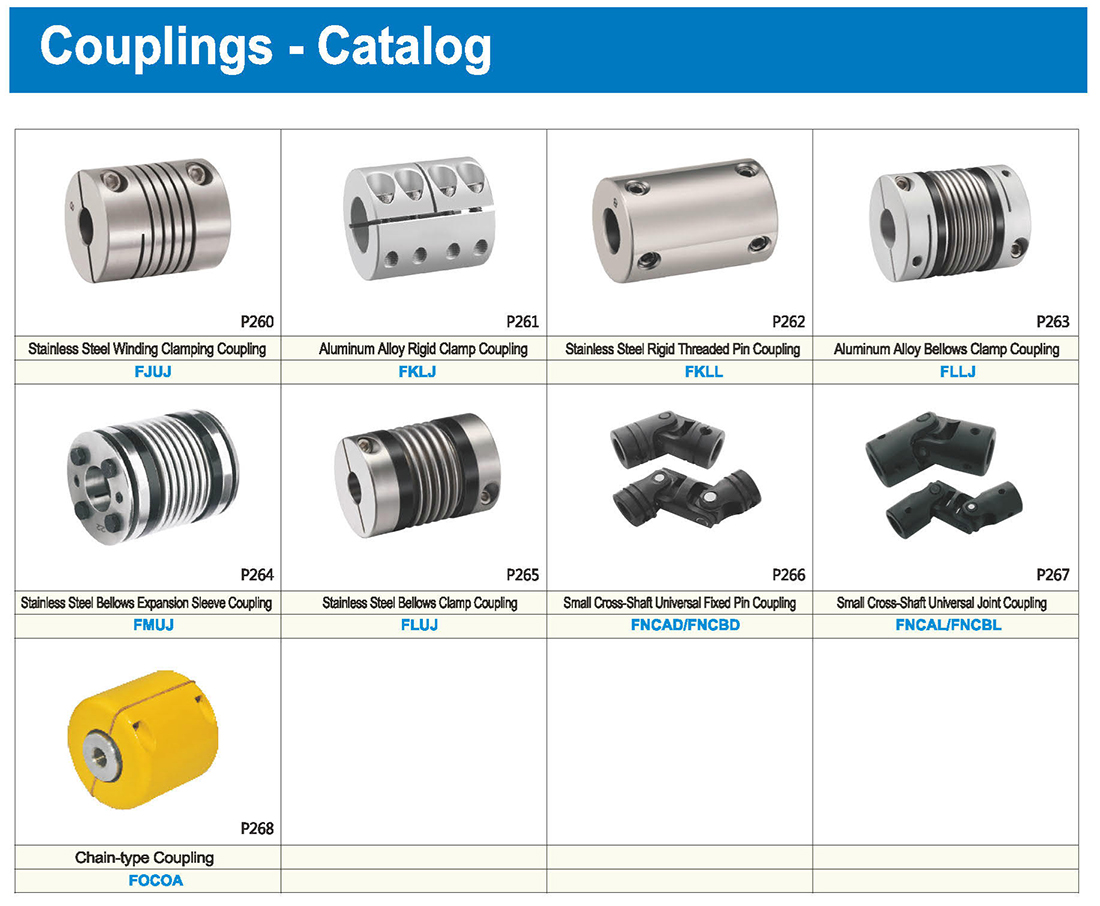

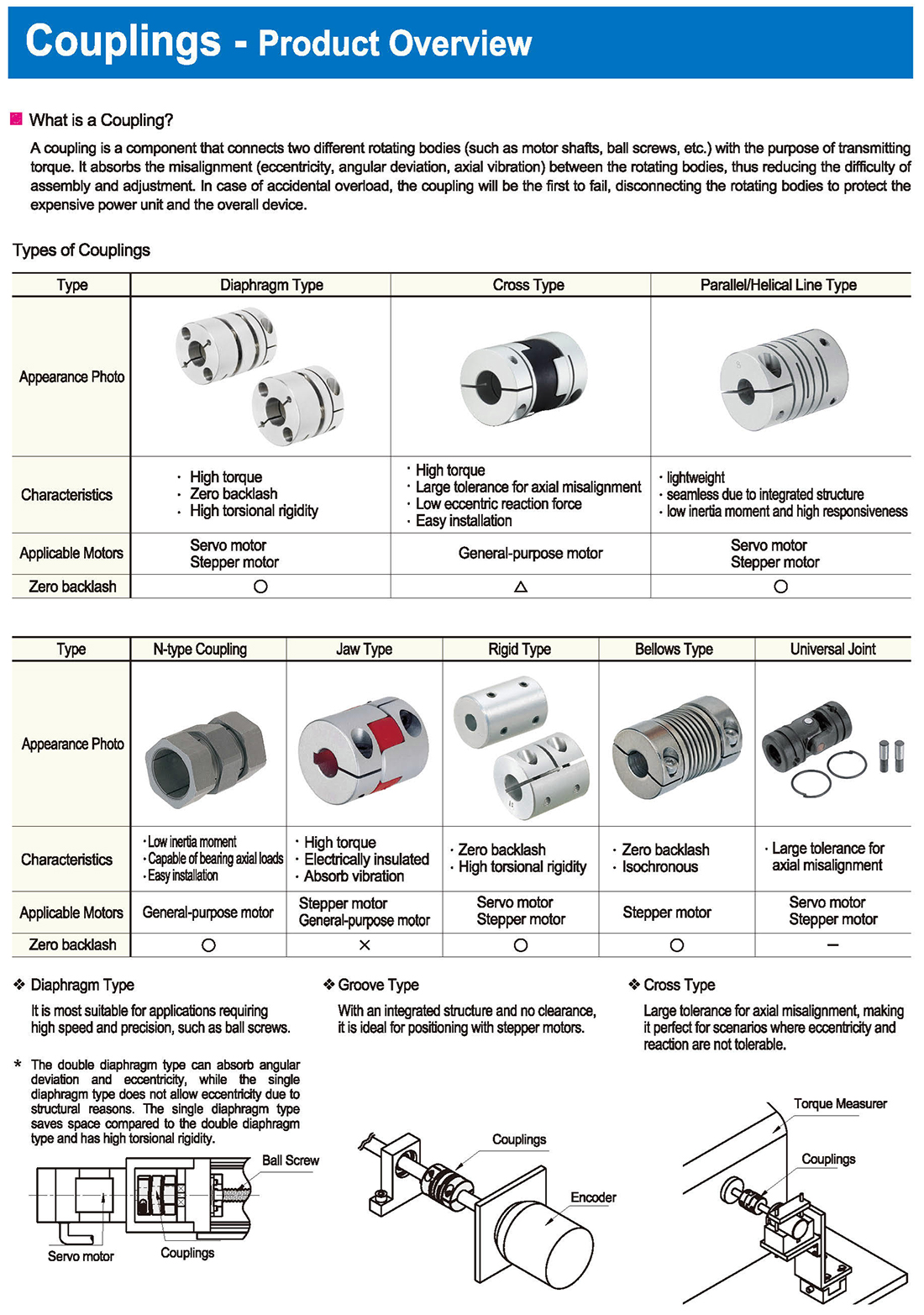

Types of Couplings

Type: Diaphragm Type, Cross Type, Parallel/Helical Line Type

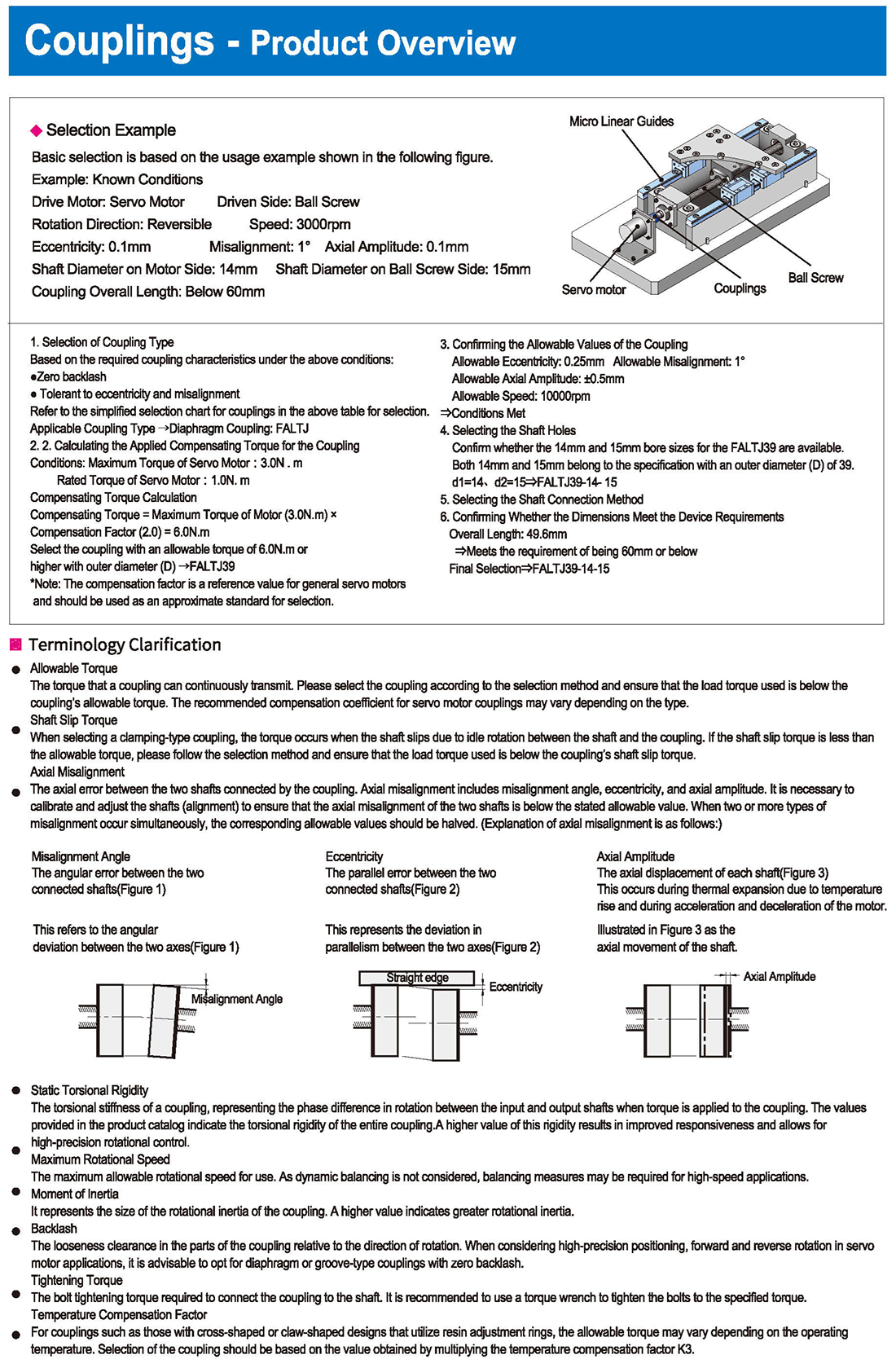

Appearance Photo: Characteristics - High torque, zero backlash, high torsional rigidity, large tolerance for axial misalignment, low eccentric reaction force, easy installation, lightweight, seamless due to integrated structure, low inertia moment, and high responsiveness

Applicable Motors: Servo motor, stepper motor, general-purpose motor.

N-type Coupling: Jaw Type, Rigid Type, Bellows Type, Universal Joint

Appearance Photo: Characteristics - Low inertia moment, capable of bearing axial loads, electrically insulated. N-type coupling features seamless operation, simple installation, and requires no lubrication.

Applicable Scenarios: Jaw type is suitable for low-speed applications, easy disassembly/assembly, easy alignment adjustment, wear-resistant. Rigid type tolerates large axial misalignment, lightweight, shock-resistant, and low noise. Bellows type has low backlash, easy alignment adjustment, suitable for high-speed applications, and corrosion-resistant。

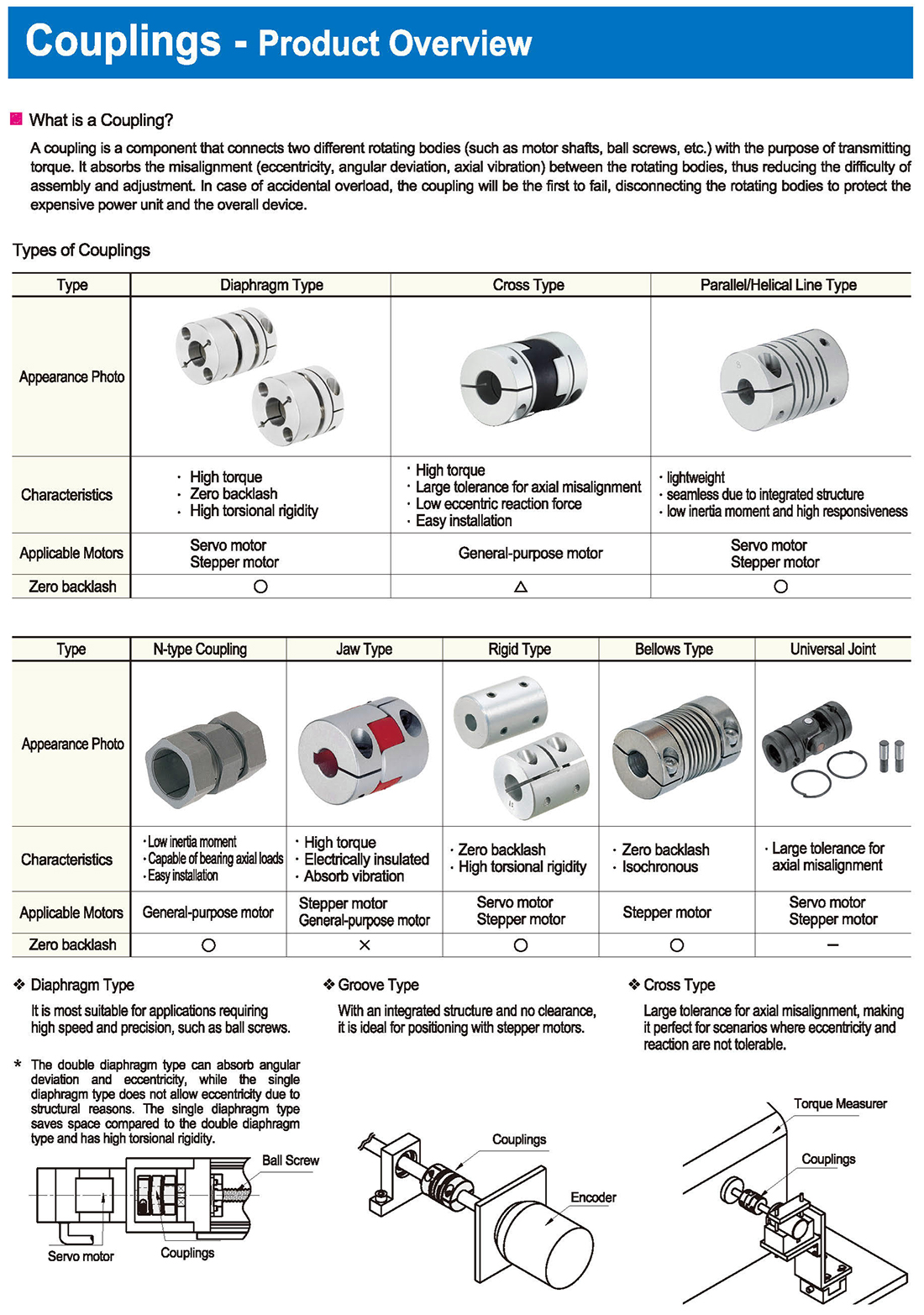

It is most suitable for applications requiring high speed and precision, such as ball screws.

Groove Type

With an integrated structure and no clearance, it is ideal for positioning with stepper motors.

Large tolerance for axial misalignment, making it perfect for scenarios where eccentricity and reaction are not tolerable.

* The double diaphragm type can absorb angular deviation and eccentricity, while the single diaphragm type does not allow eccentricity due to structural reasons. The single diaphragm type saves space compared to the double diaphragm type and has high torsional rigidity.

Encoder & Torque Measurer

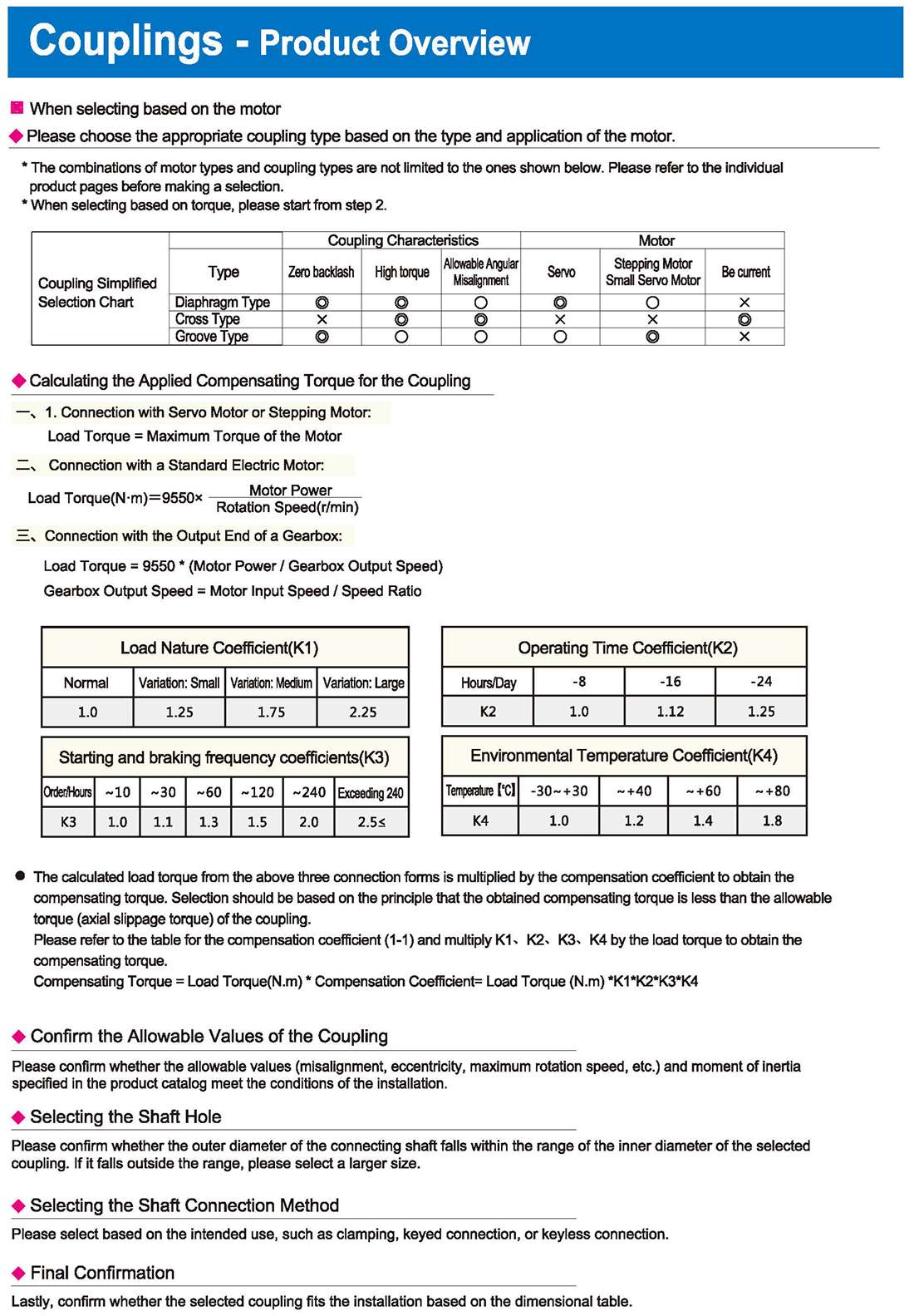

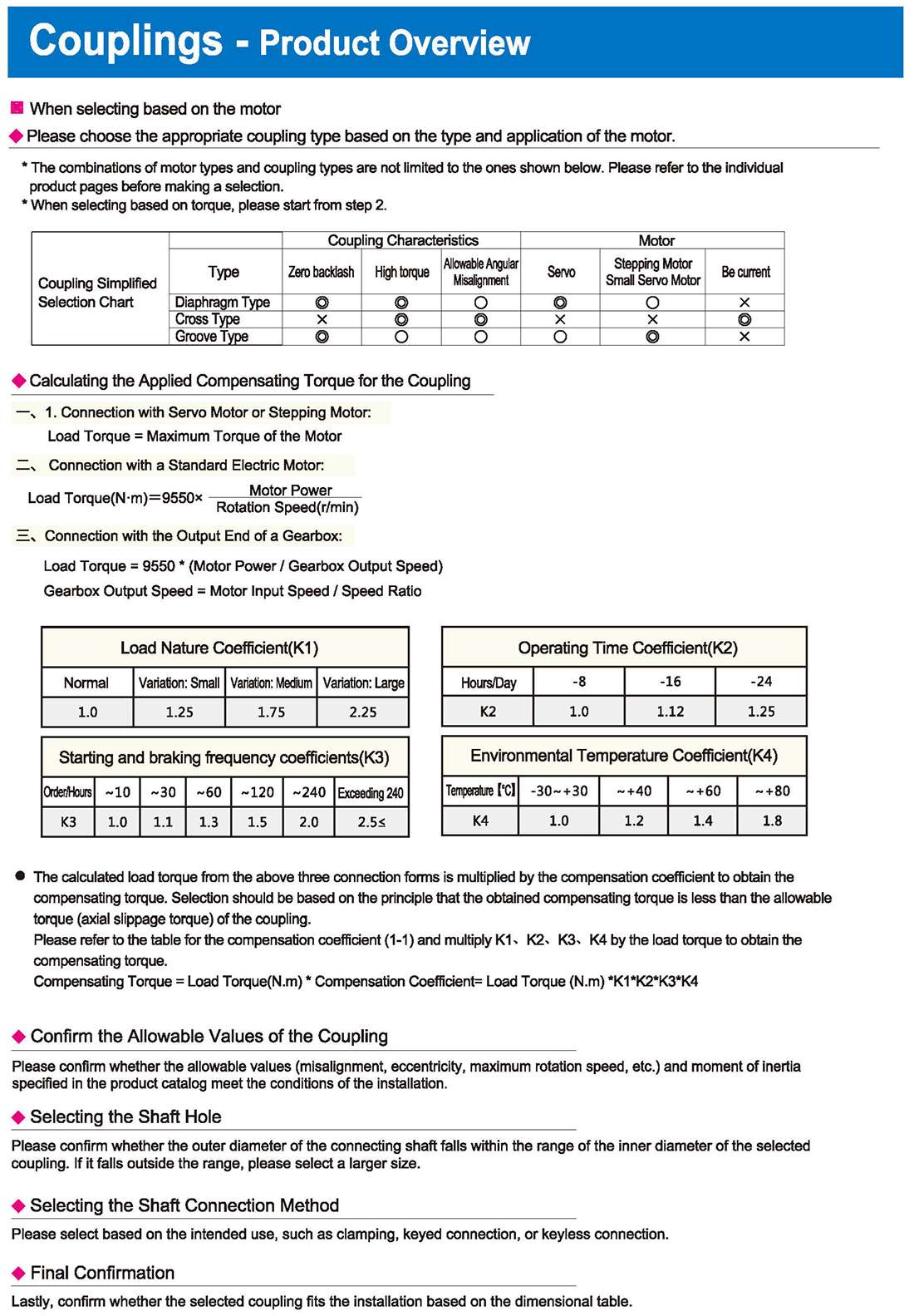

When selecting based on the motor, please choose the appropriate coupling type based on the type and application of the motor.

* The combinations of motor types and coupling types are not limited to the ones shown below. Please refer to the individual product pages before making a selection.

* When selecting based on torque, please start from step 2.

Types of Couplings

Type: Diaphragm Type, Cross Type, Parallel/Helical Line Type

Appearance Photo: Characteristics - High torque, zero backlash, high torsional rigidity, large tolerance for axial misalignment, low eccentric reaction force, easy installation, lightweight, seamless due to integrated structure, low inertia moment, and high responsiveness

Applicable Motors: Servo motor, stepper motor, general-purpose motor.

N-type Coupling: Jaw Type, Rigid Type, Bellows Type, Universal Joint

Appearance Photo: Characteristics - Low inertia moment, capable of bearing axial loads, electrically insulated. N-type coupling features seamless operation, simple installation, and requires no lubrication.

Applicable Scenarios: Jaw type is suitable for low-speed applications, easy disassembly/assembly, easy alignment adjustment, wear-resistant. Rigid type tolerates large axial misalignment, lightweight, shock-resistant, and low noise. Bellows type has low backlash, easy alignment adjustment, suitable for high-speed applications, and corrosion-resistant。

It is most suitable for applications requiring high speed and precision, such as ball screws.

Groove Type

With an integrated structure and no clearance, it is ideal for positioning with stepper motors.

Large tolerance for axial misalignment, making it perfect for scenarios where eccentricity and reaction are not tolerable.

* The double diaphragm type can absorb angular deviation and eccentricity, while the single diaphragm type does not allow eccentricity due to structural reasons. The single diaphragm type saves space compared to the double diaphragm type and has high torsional rigidity.

Encoder & Torque Measurer

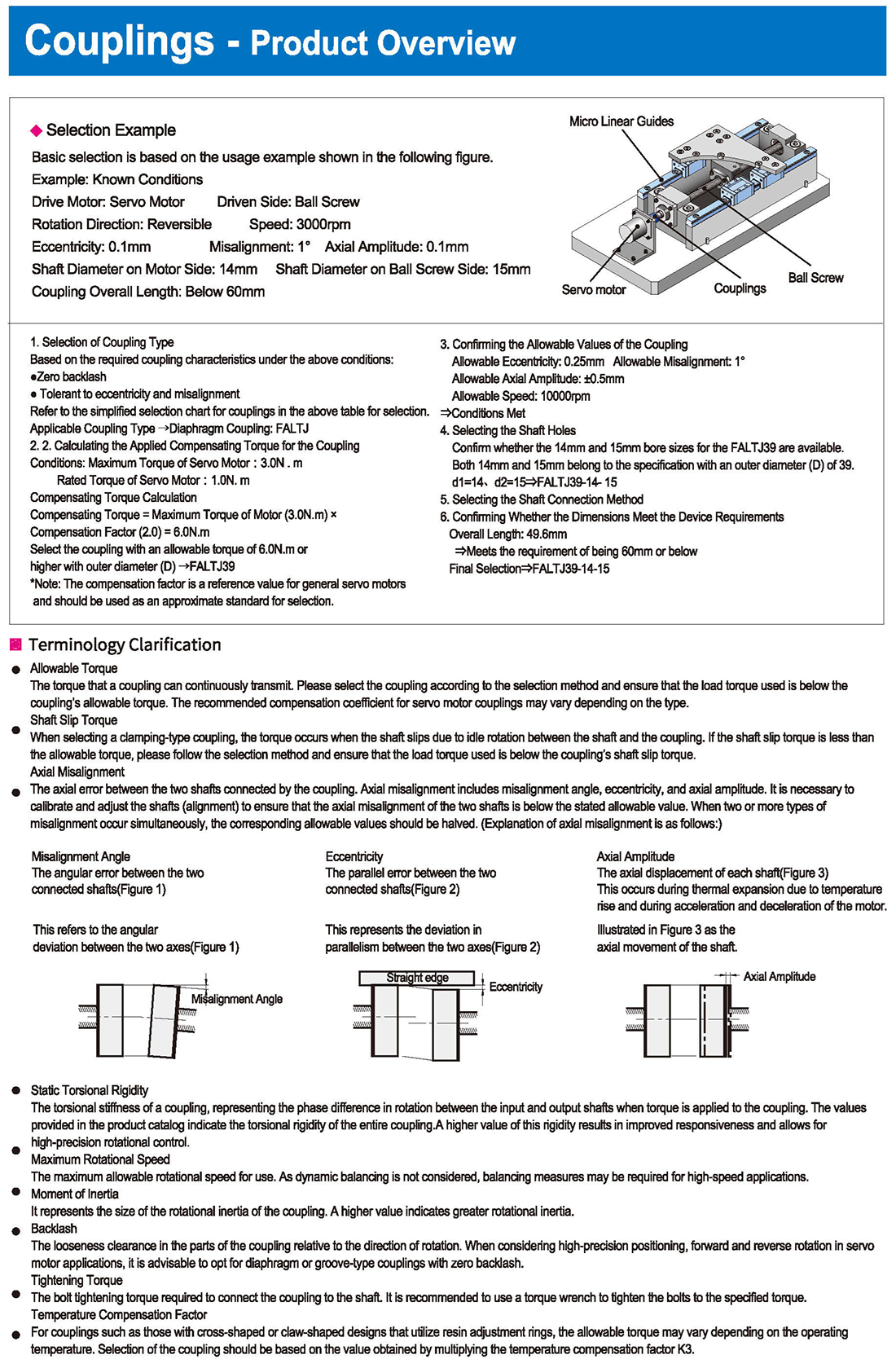

When selecting based on the motor, please choose the appropriate coupling type based on the type and application of the motor.

* The combinations of motor types and coupling types are not limited to the ones shown below. Please refer to the individual product pages before making a selection.

* When selecting based on torque, please start from step 2.

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

Introduction Specification Table

Specification Table Download

Download