1. High precision adjustment:

The fine-tuning hand wheel can be used to fine-tune the accuracy of the machine equipment, which can fine-tune very small parameters to make the machine reach a more accurate state.

In the case of high precision requirements for machinery and equipment, the use of fine tuning hand wheel can significantly improve the processing accuracy and product quality of equipment.

2. Offset adjustment ability:

When there is a slight deviation in the work of the machine and equipment, the fine-tuning hand wheel can effectively adjust the offset, so that the equipment can achieve a more accurate working state.

This adjustment capability helps to ensure the stability and reliability of the equipment, reducing errors and failures due to deviations.

3. Position adjustment flexibility:

The fine-tuning hand wheel can also be used to adjust the position of the machine, including the position size, shape, etc., so that the machine equipment is more in line with the work needs.

By fine-tuning the position adjustment function of the hand wheel, it is possible to achieve precise control of the machine equipment and optimize the layout.

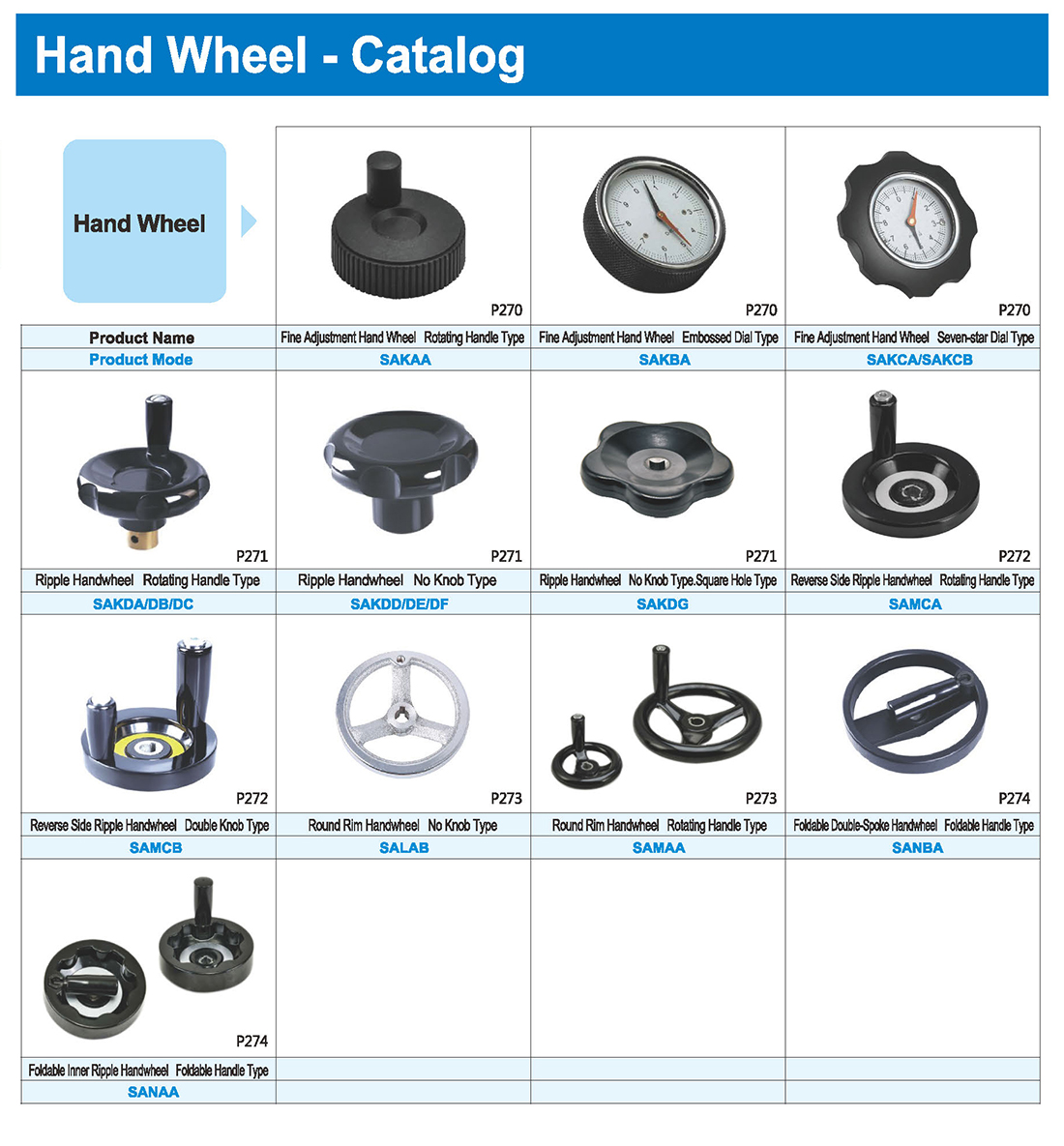

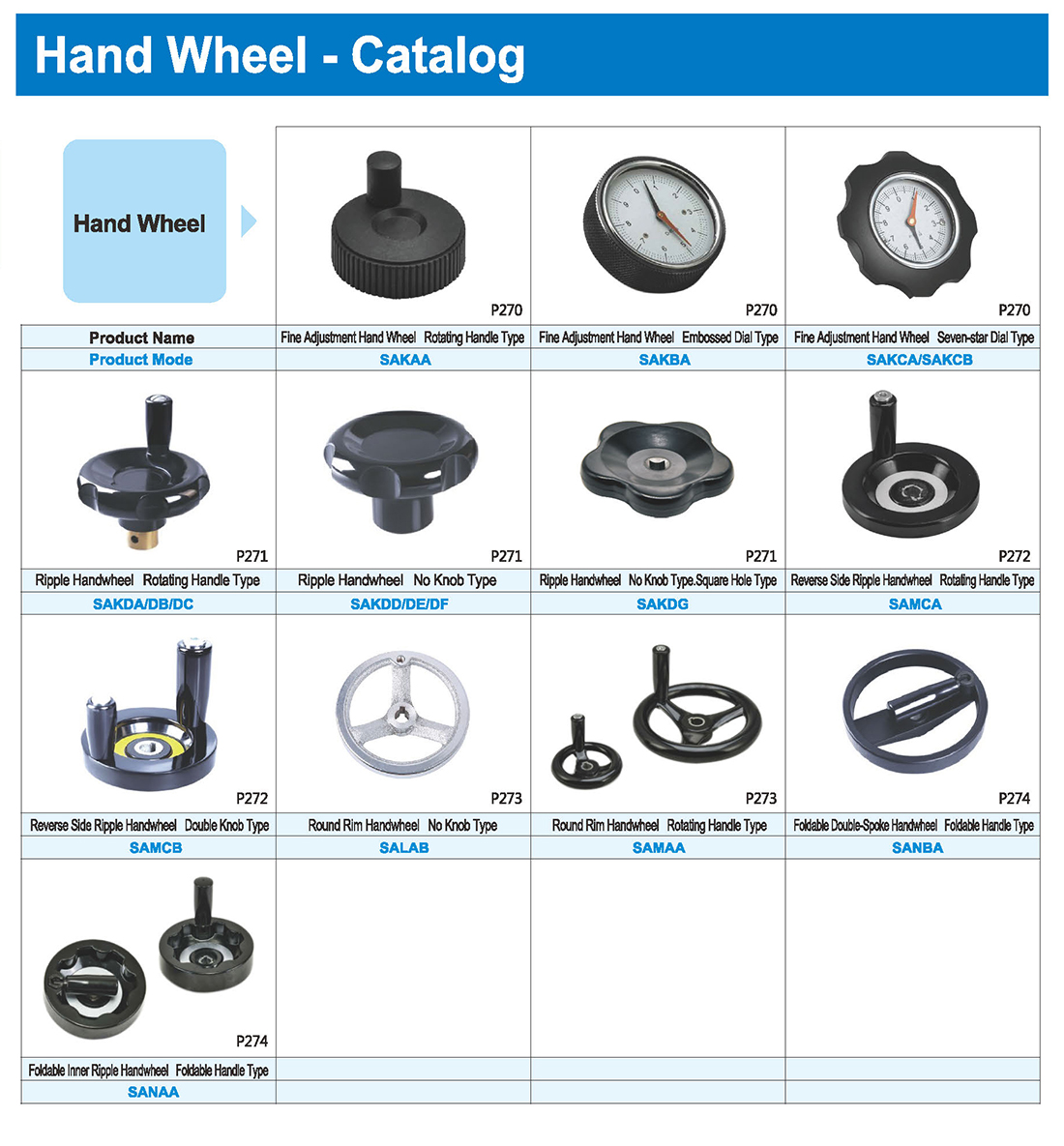

Hand Wheel Fine Adjustment Hand Wheel

Rotating Handle Type Embossed Dial Type Seven-star Dial Type

Coupling Portion Hand Wheel Body Brass Color Screw Locking Type Reference Weight Clockwise Increment Counterclockwise Increment

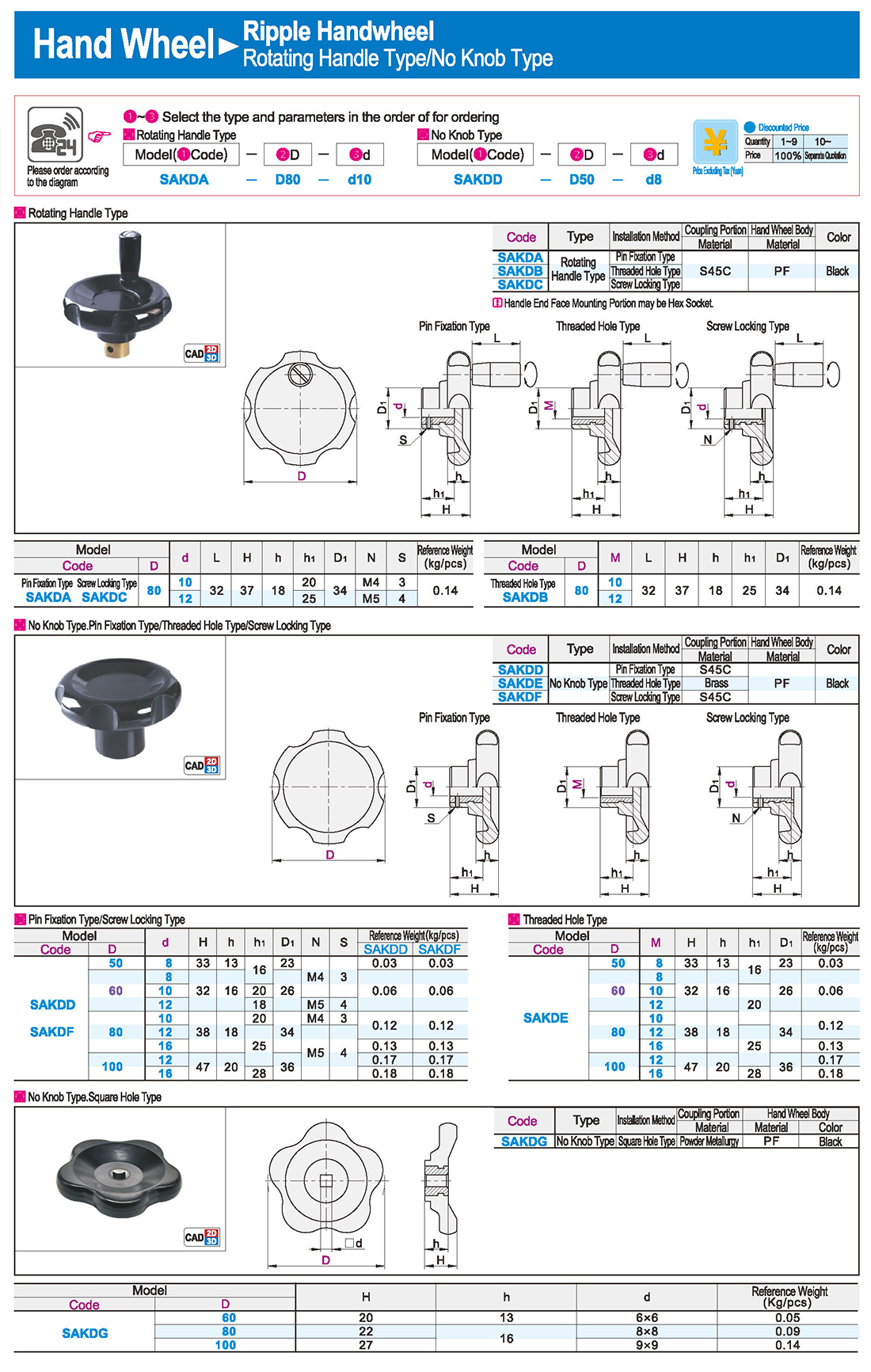

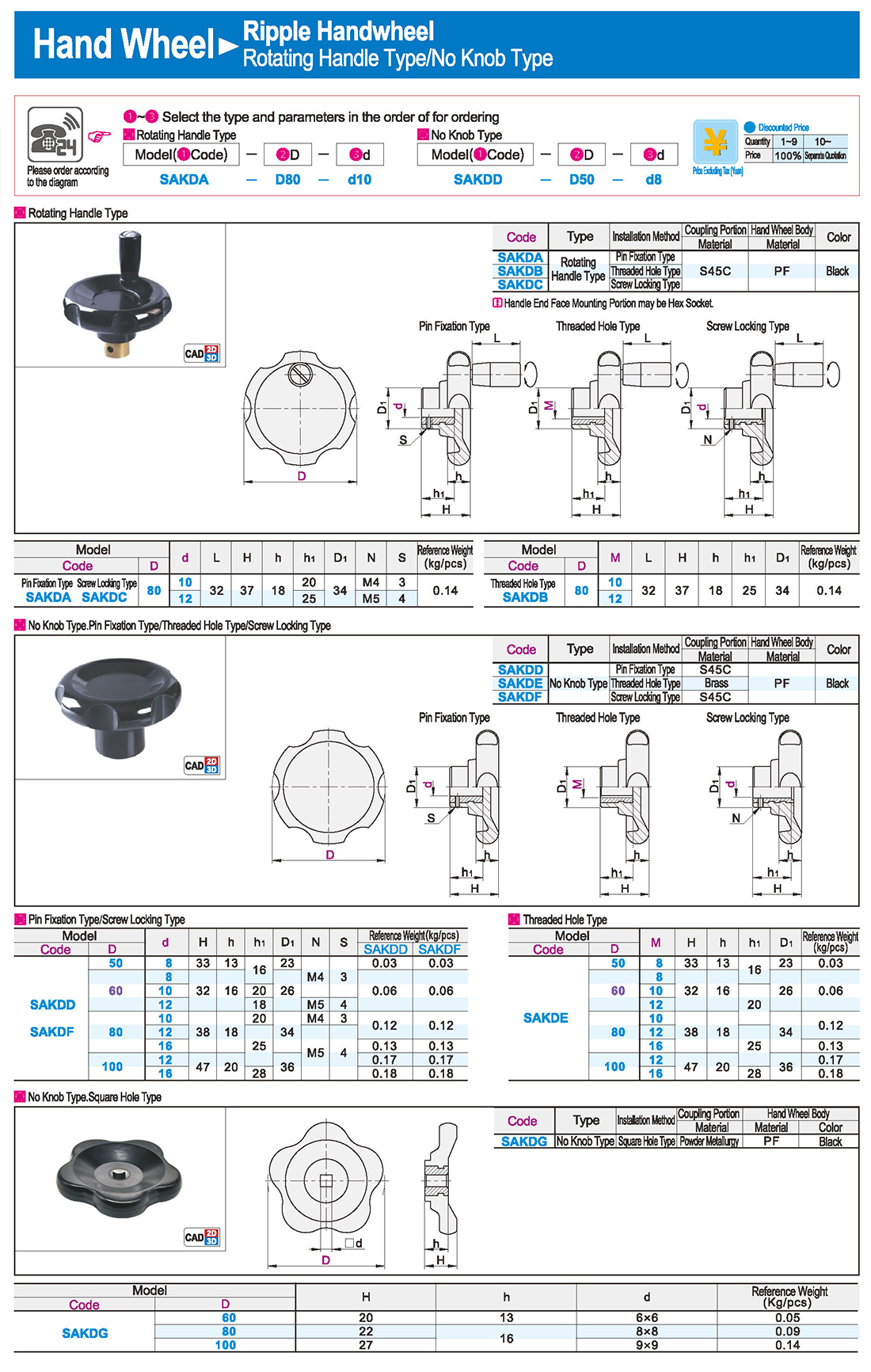

Ripple Handwheel - Knob Type / No Knob Type

Pin Fixation Type - Threaded Hole Type

Handle End Face Mounting Portion may be Hex Socket - Square Hole Type - Powder Metallurgy

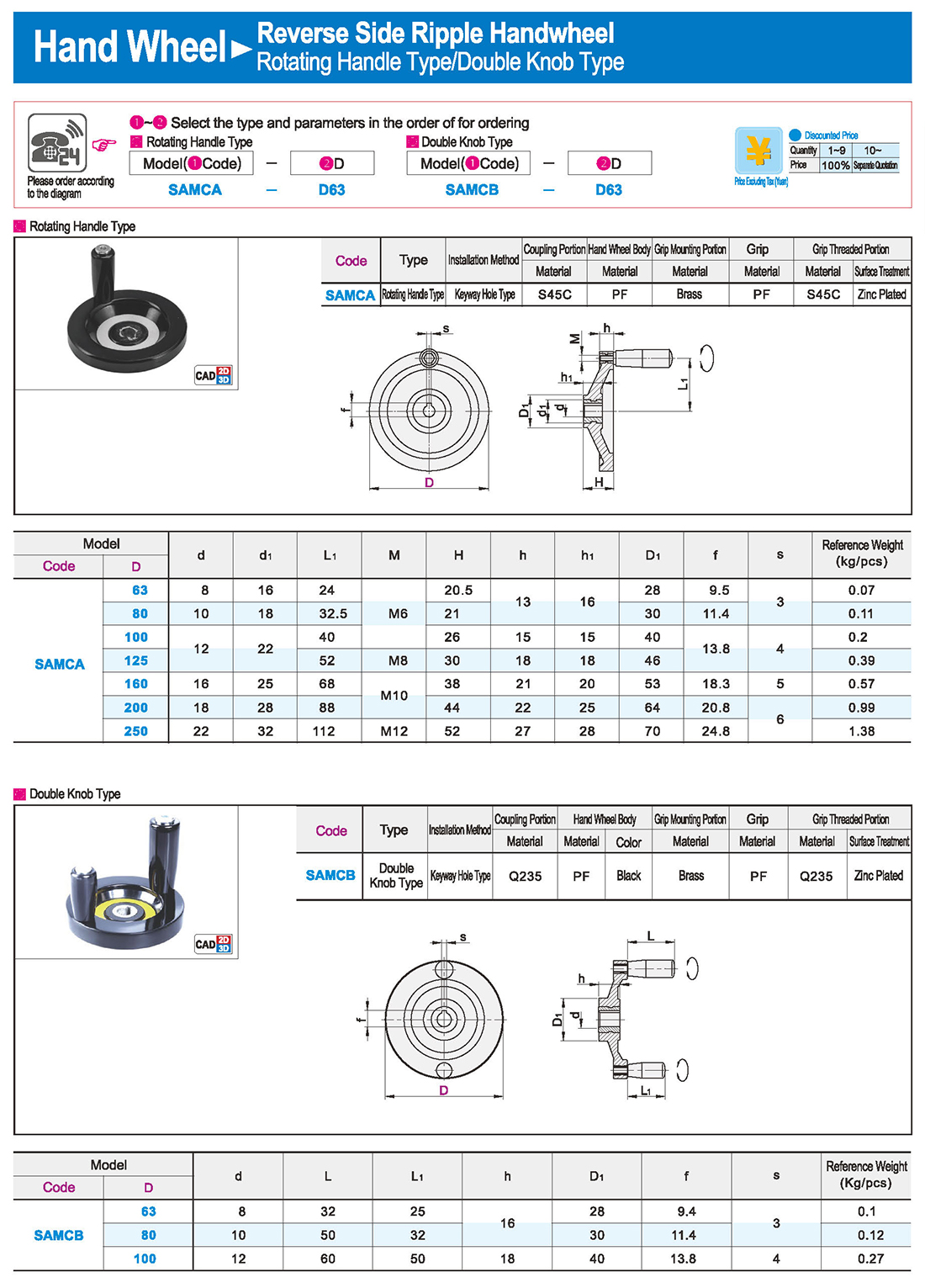

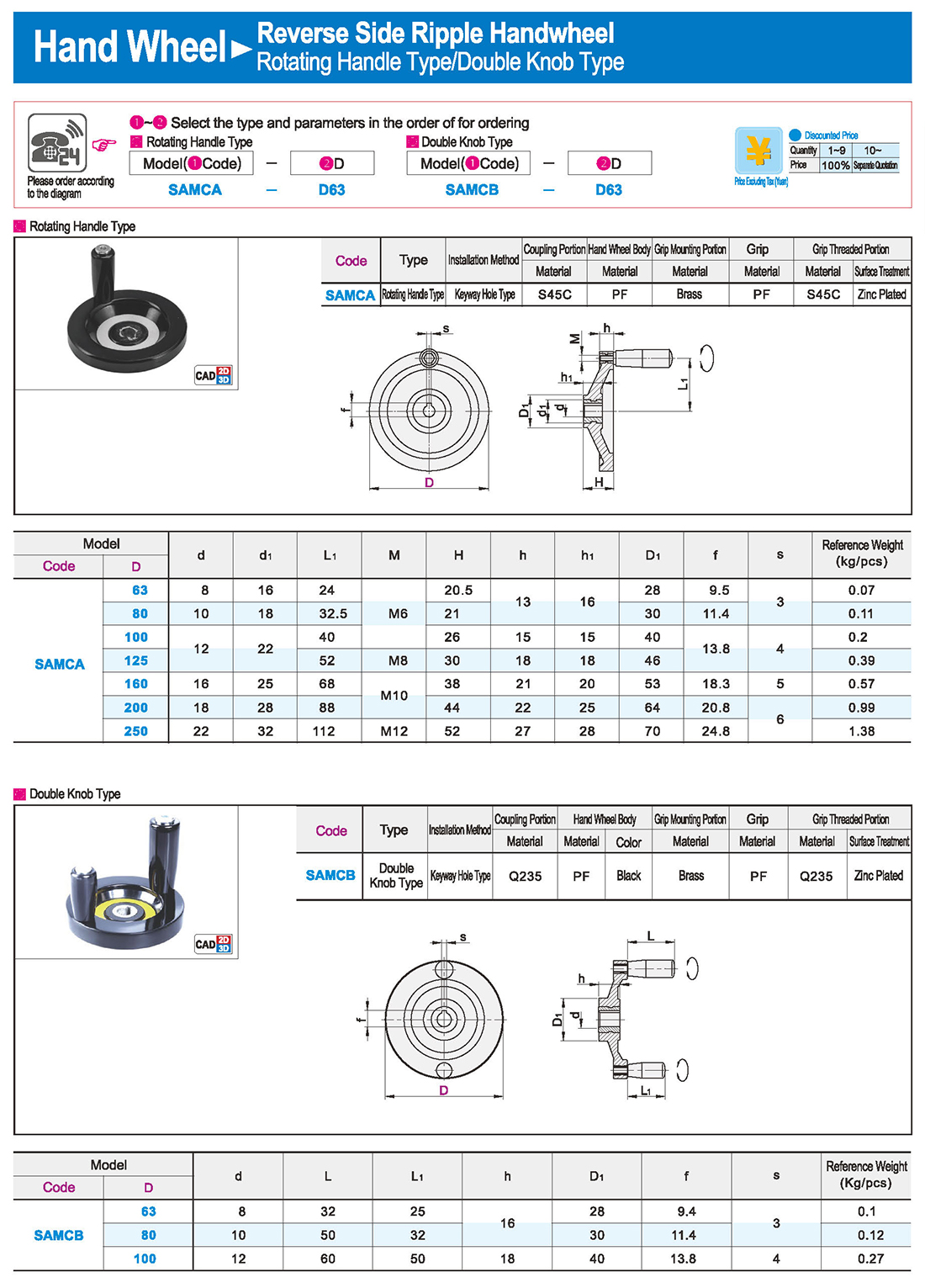

Reverse Side Ripple Handwheel - Double Knob Type - Keyway Hole Type - Grip Mounting Portion - Grip - Grip Threaded Portion - Zinc Plated

Round Rim Handwheel - Inner Hole Shape d Selection

Foldable Double-Spoke Handwheel - Foldable Inner Ripple Handwheel - Foldable Handle Type

Nylon / Aluminum Alloy

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

Introduction Specification Table

Specification Table Download

Download