1. Strong carrying capacity

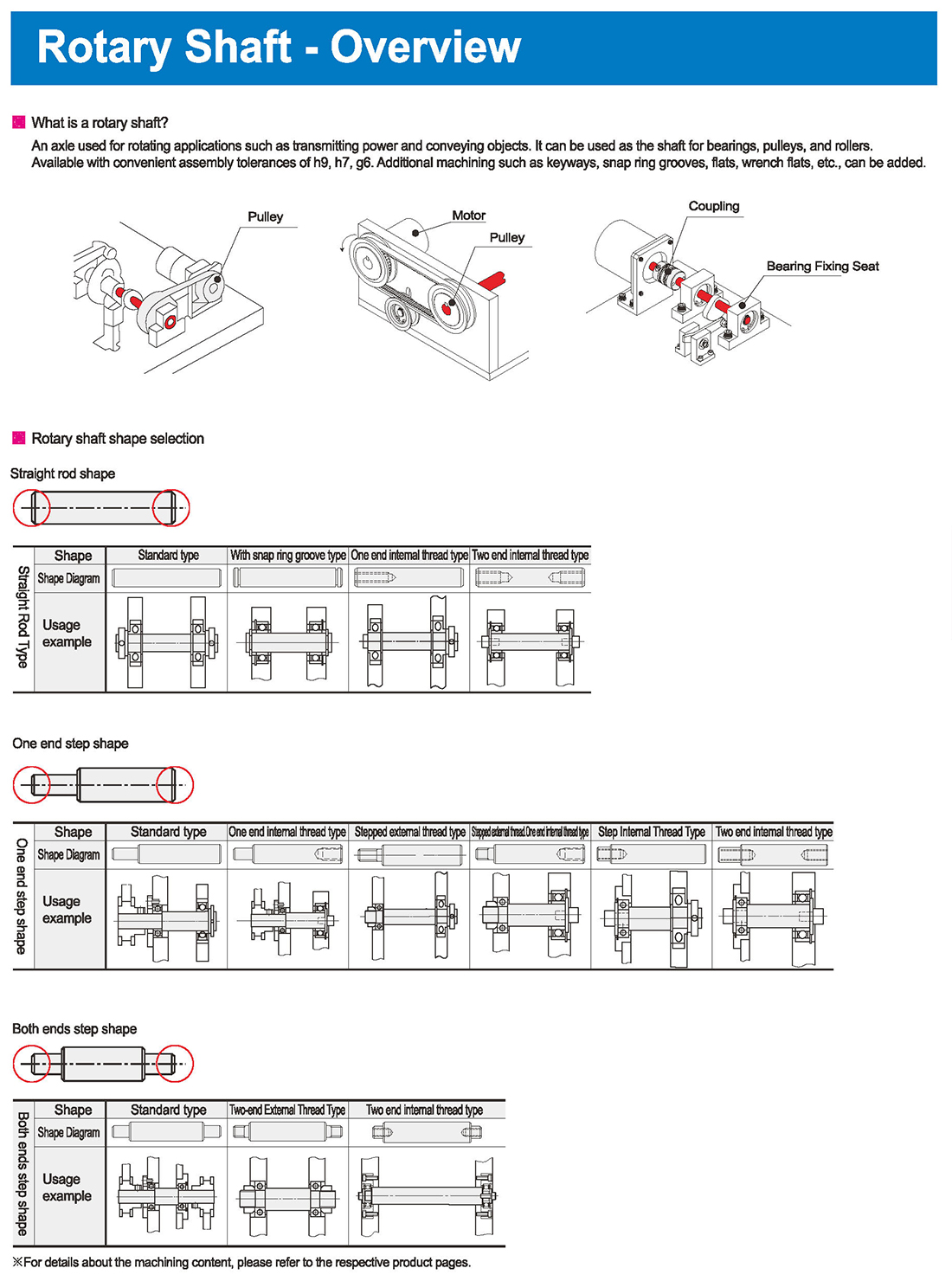

The rotating shaft can carry weight and torque, and is an important bearing part in mechanical equipment. This feature enables the shaft to remain stable when subjected to various loads, ensuring the normal operation of mechanical equipment.

2, high rotation stability

The surface of the shaft is processed by precision machining to ensure its smooth rotation and reduce energy loss. This stability is essential for the operational efficiency and accuracy of mechanical equipment and helps to improve the performance of the overall equipment.

3. High power transmission efficiency

As a transmission component, the rotating shaft is usually combined with other components such as wheels in mechanical equipment to achieve power transmission and speed transformation. This feature enables the shaft to remain efficient during power transmission, reduce energy loss, and improve the operating efficiency of mechanical equipment.

Notes

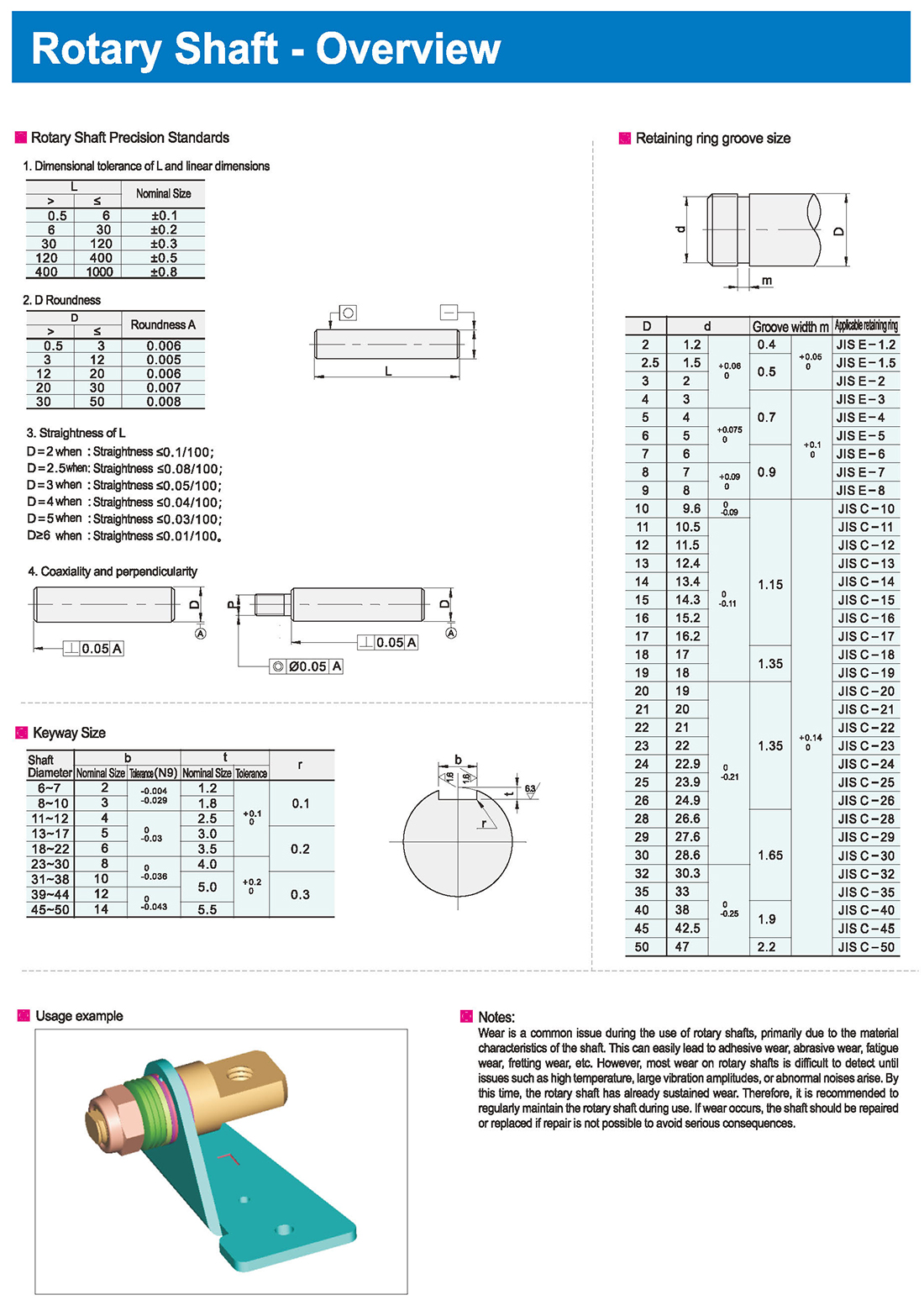

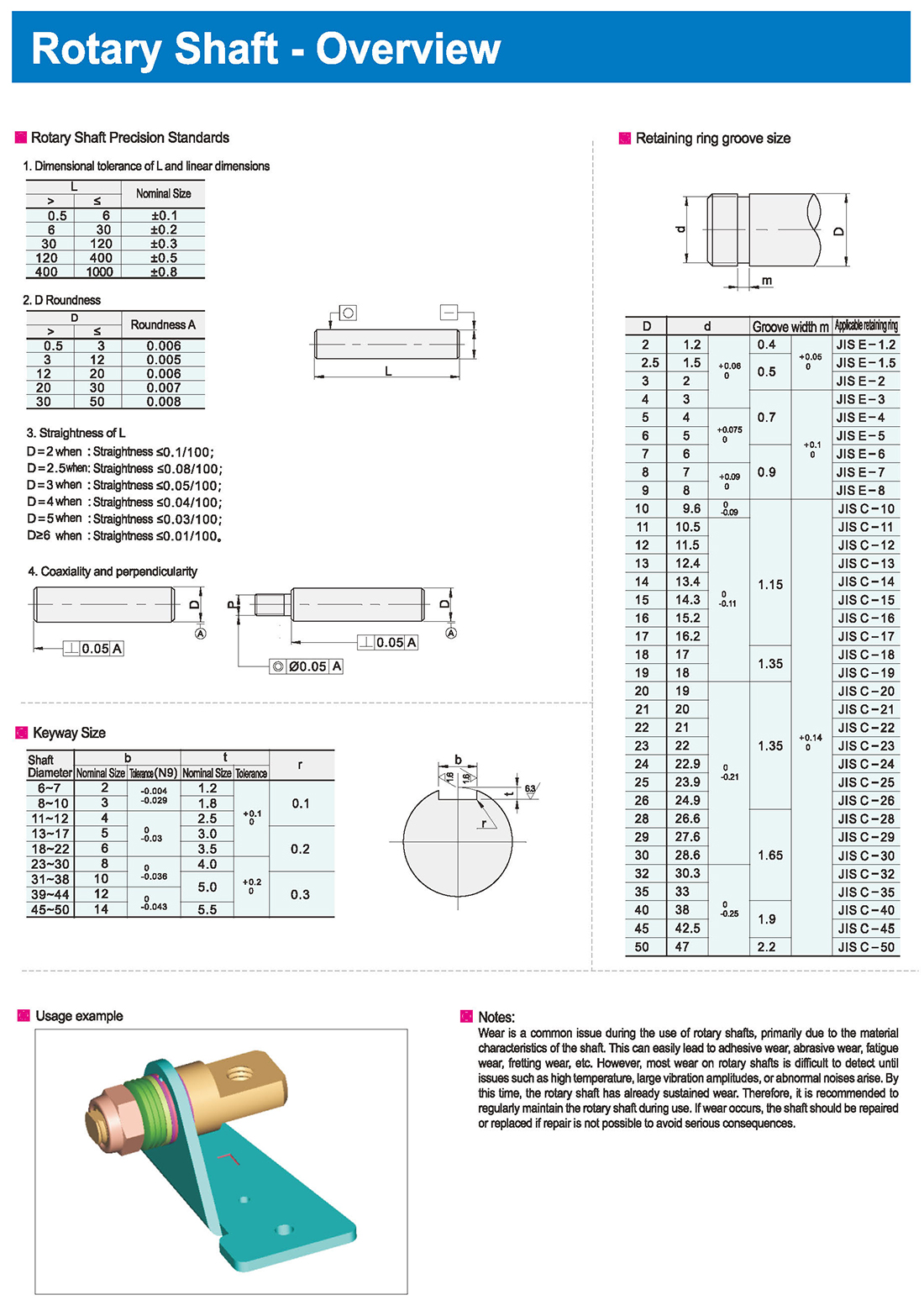

Wear is a common issue during the use of rotary shafts, primarily due to the material characteristics of the shaft. This can easily lead to adhesive wear, abrasive wear, fatigue wear, fretting wear, etc. However, most wear on rotary shafts is difficult to detect until issues such as high temperature, large vibration amplitudes, or abnormal noises arise. By this time, the rotary shaft has already sustained wear. Therefore, it is recommended to regularly maintain the rotary shaft during use. If wear occurs, the shaft should be repaired or replaced if repair is not possible to avoid serious consequences.

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

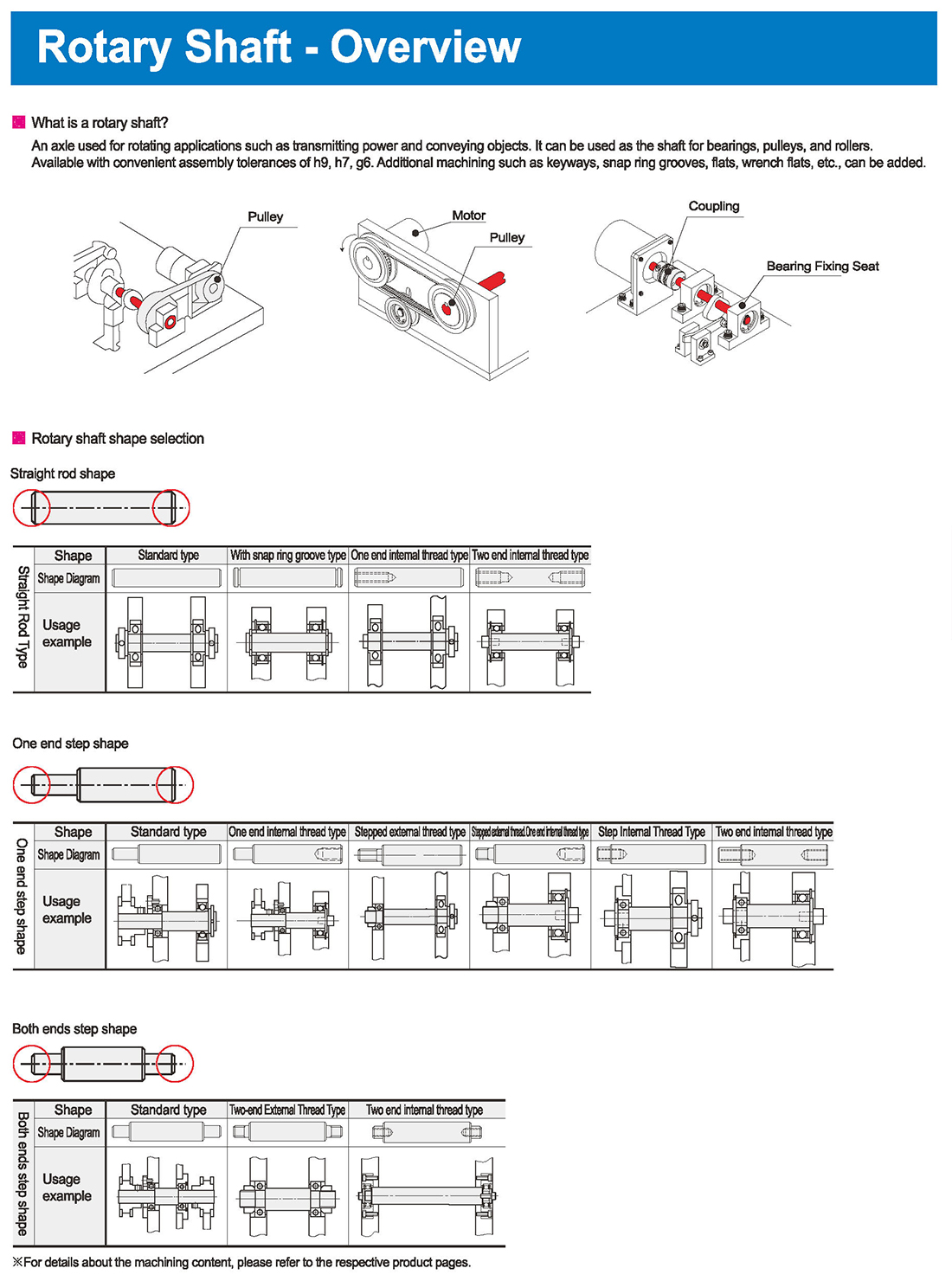

Introduction

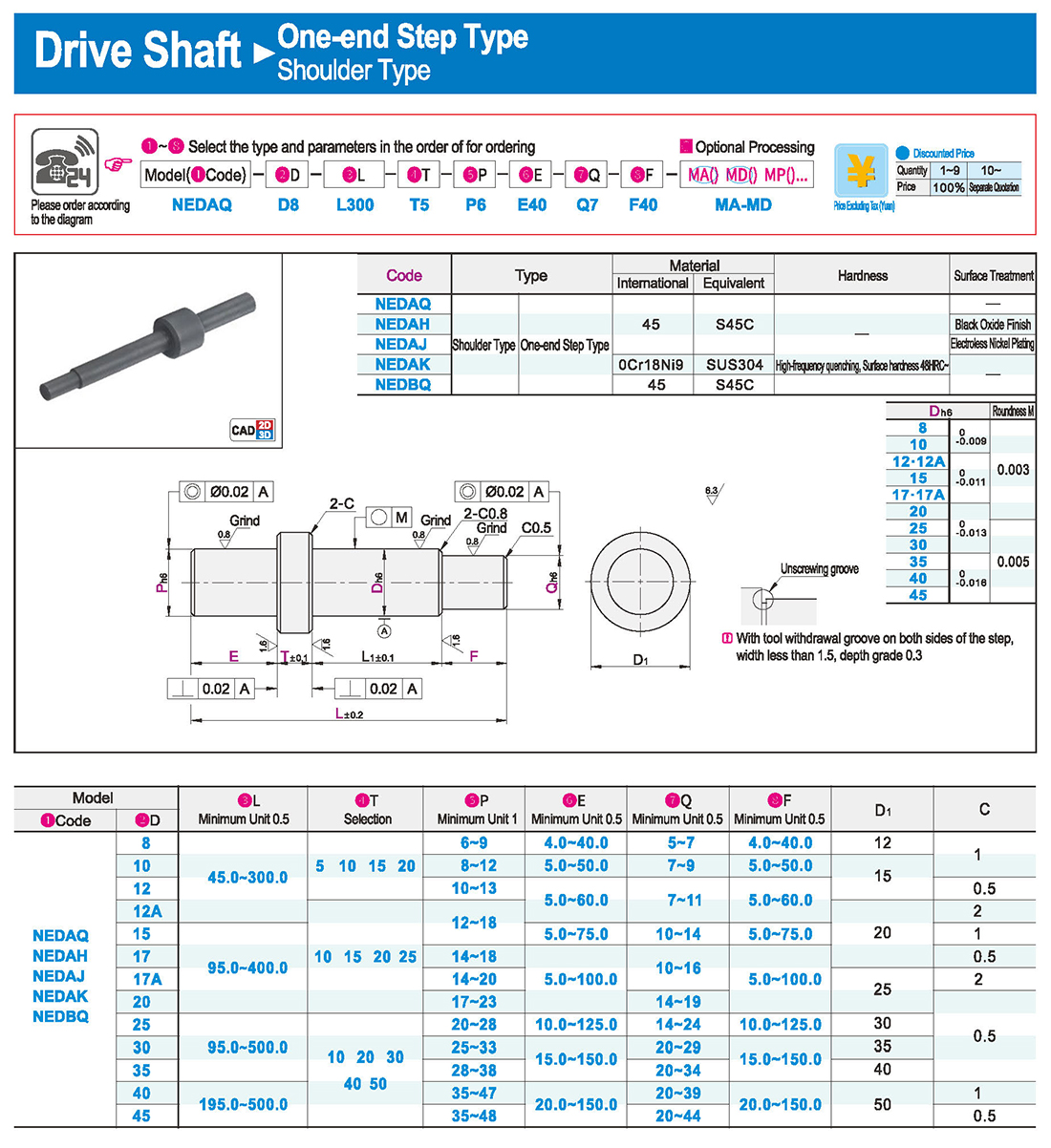

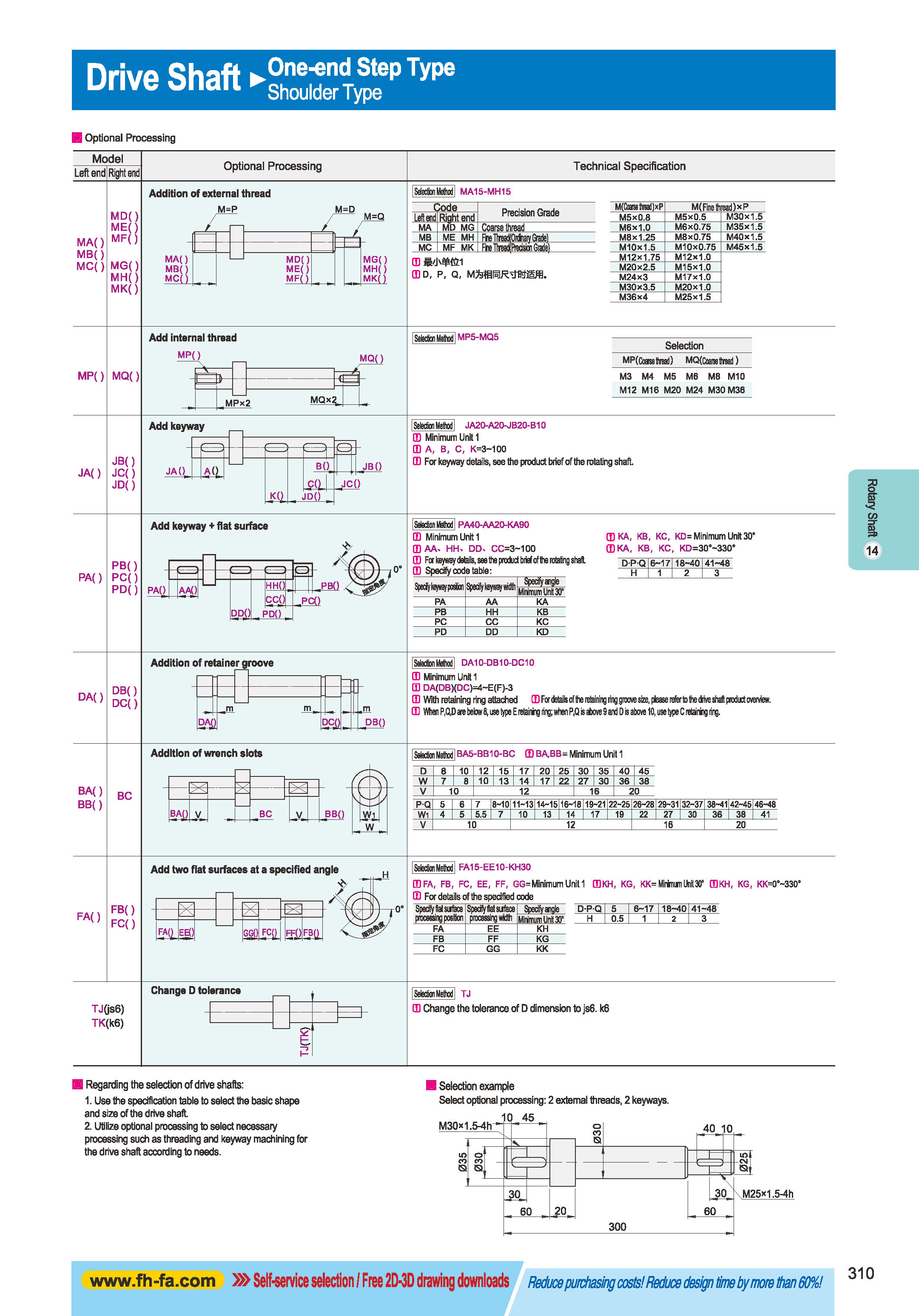

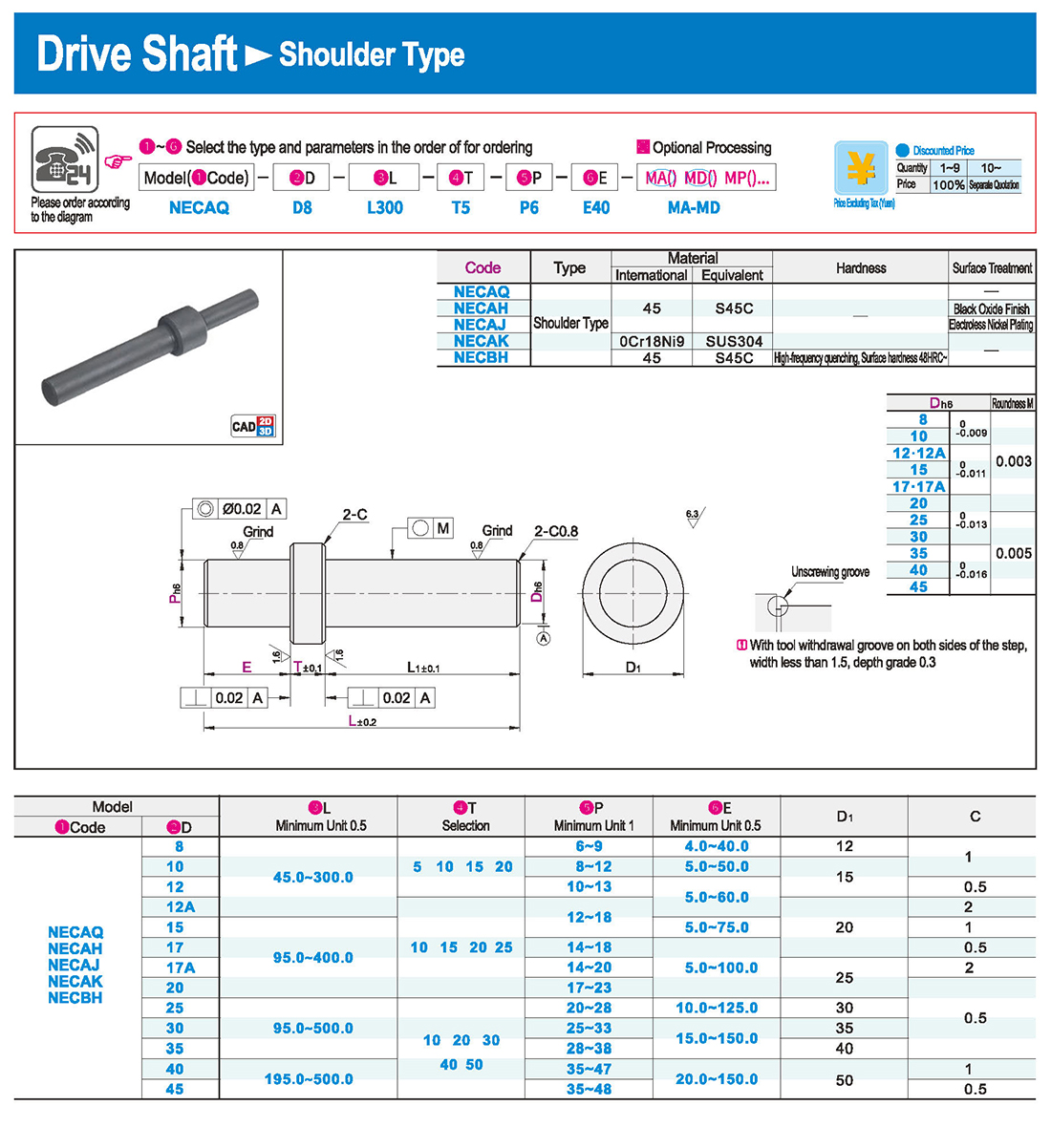

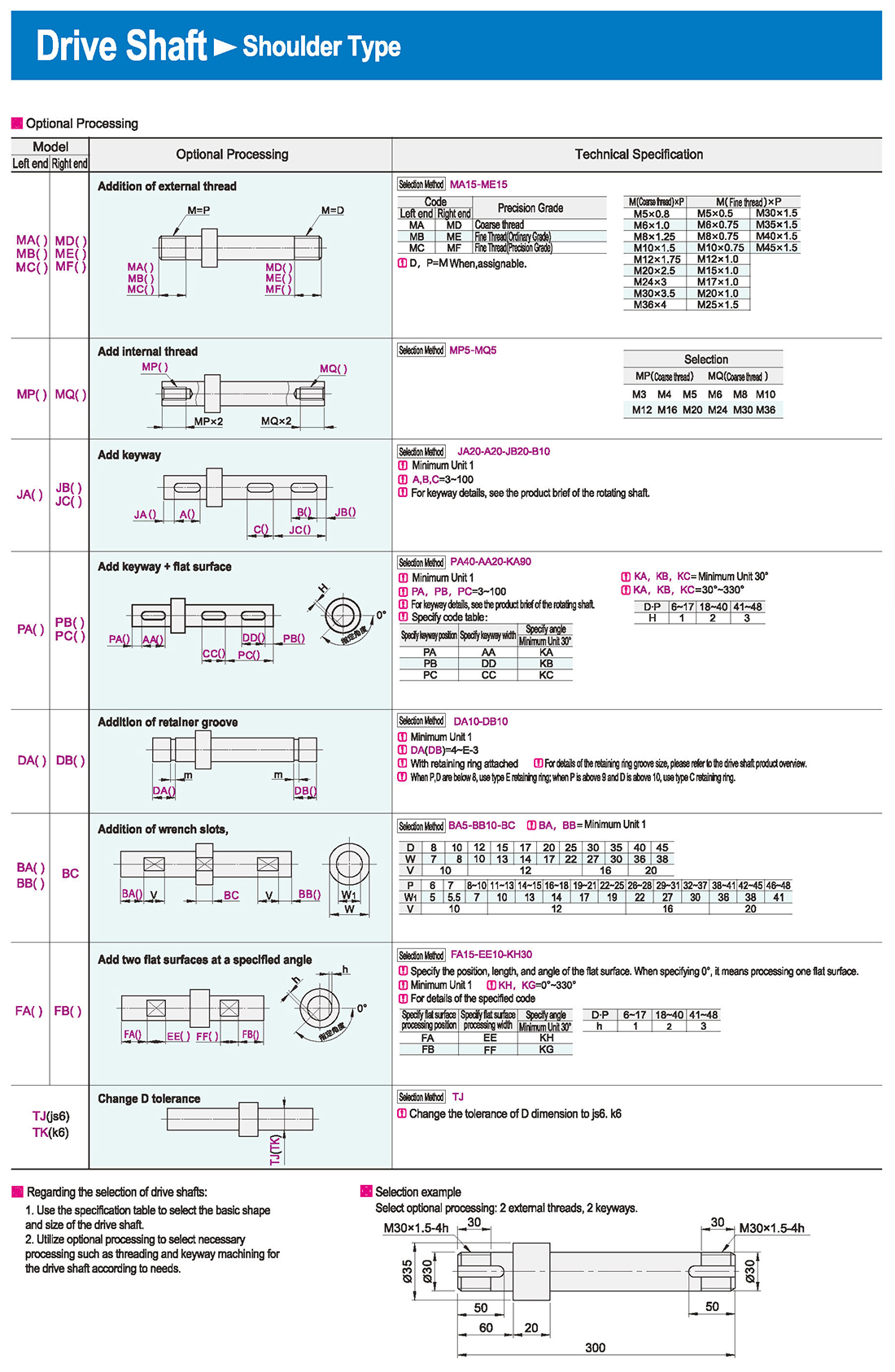

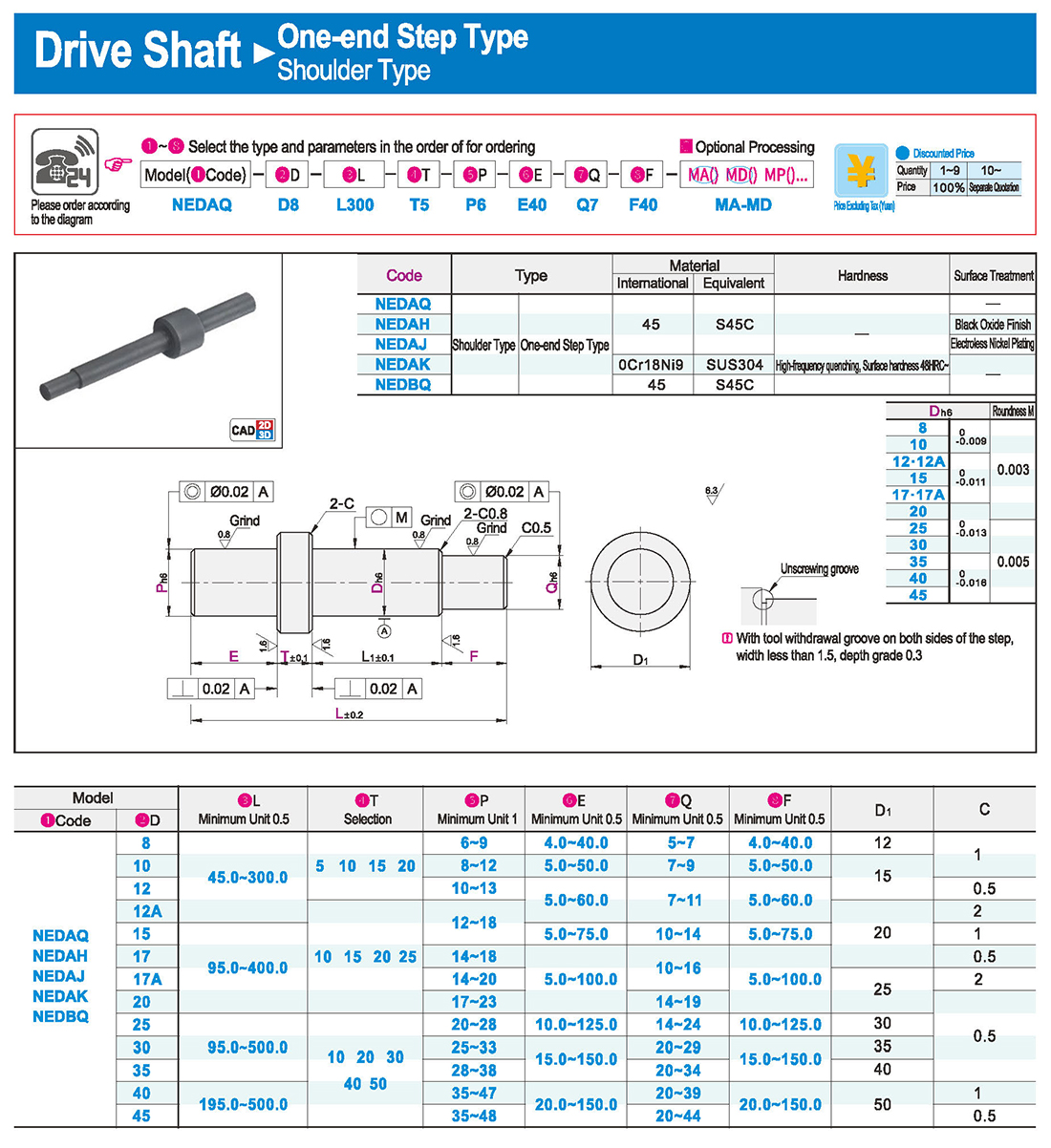

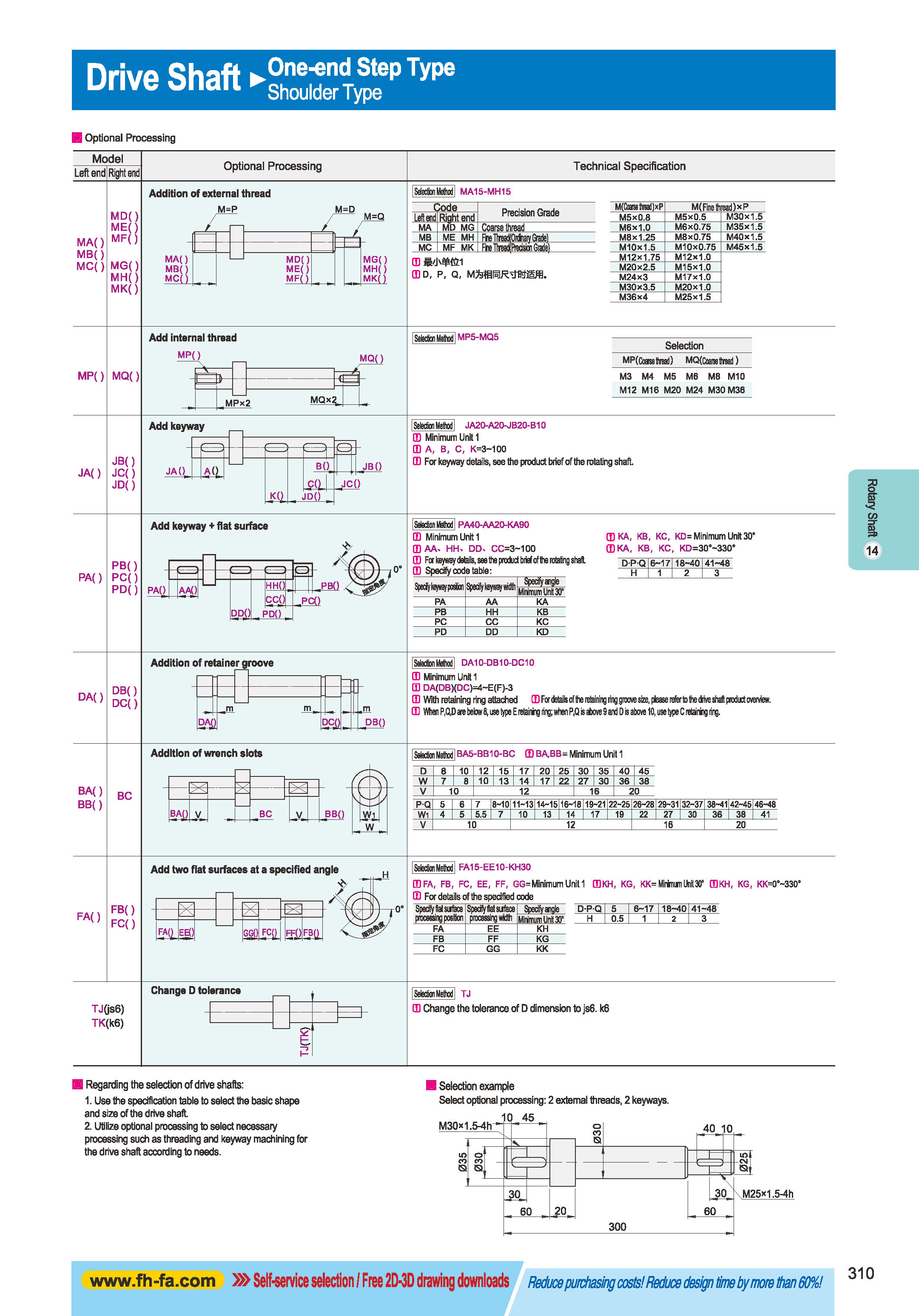

Introduction Specification Table

Specification Table Download

Download