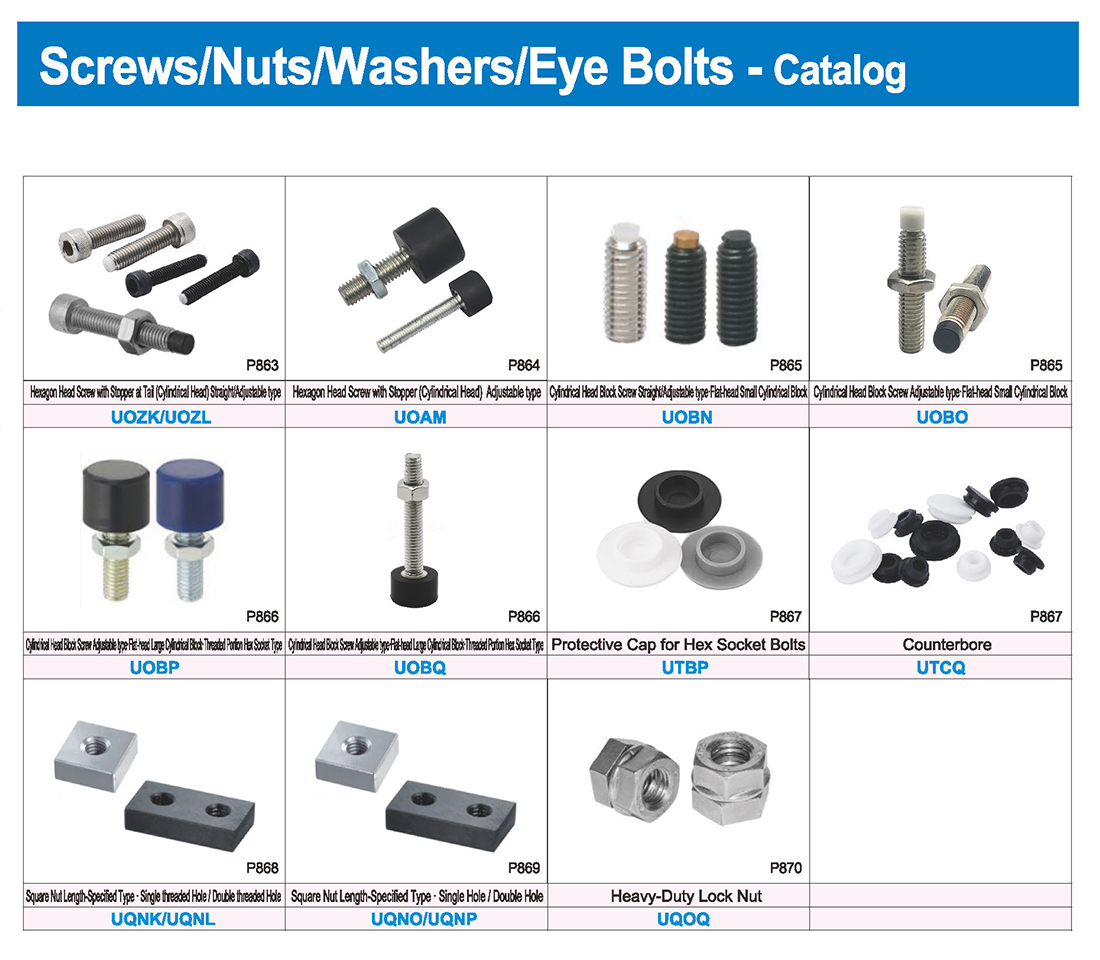

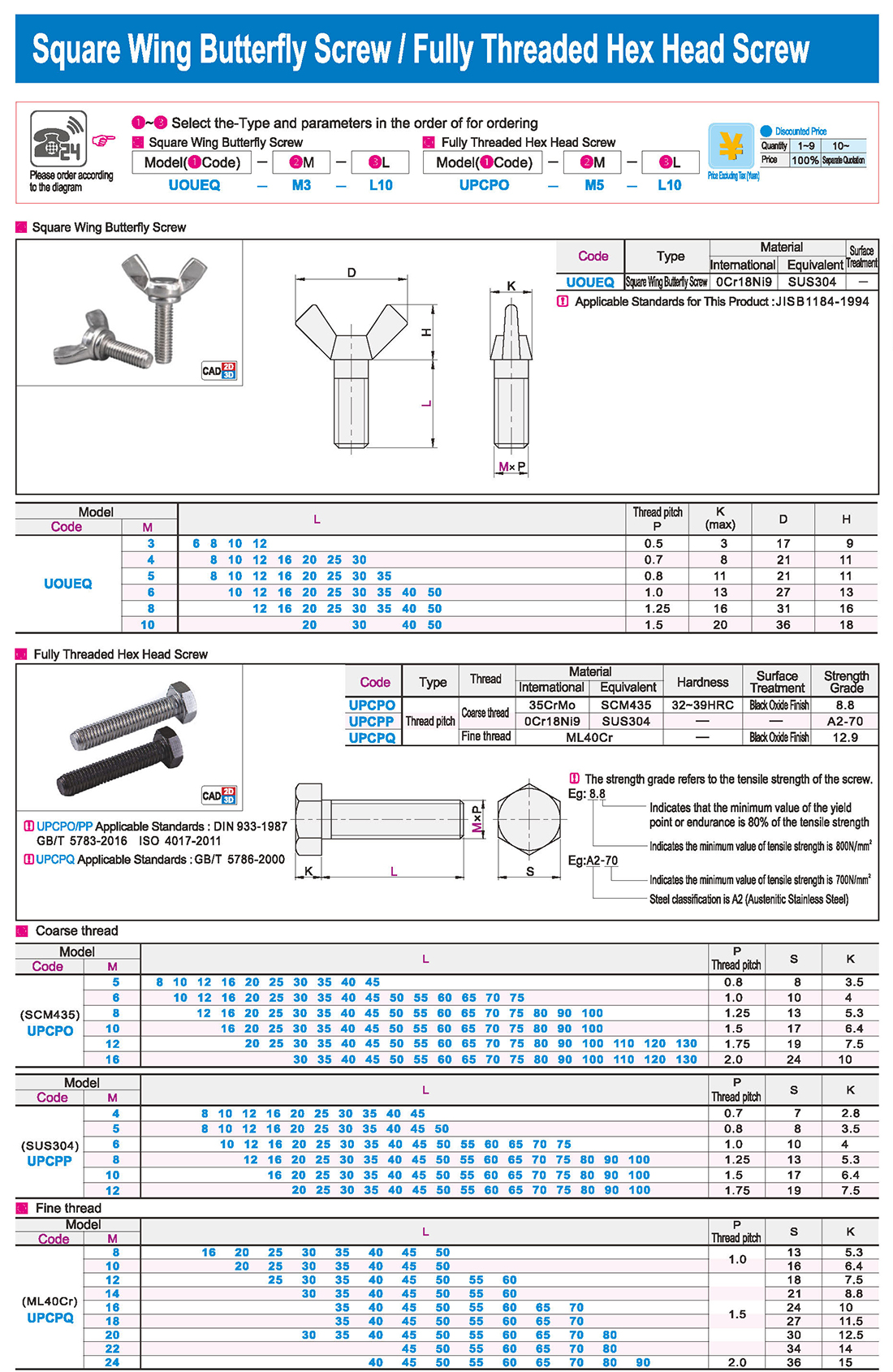

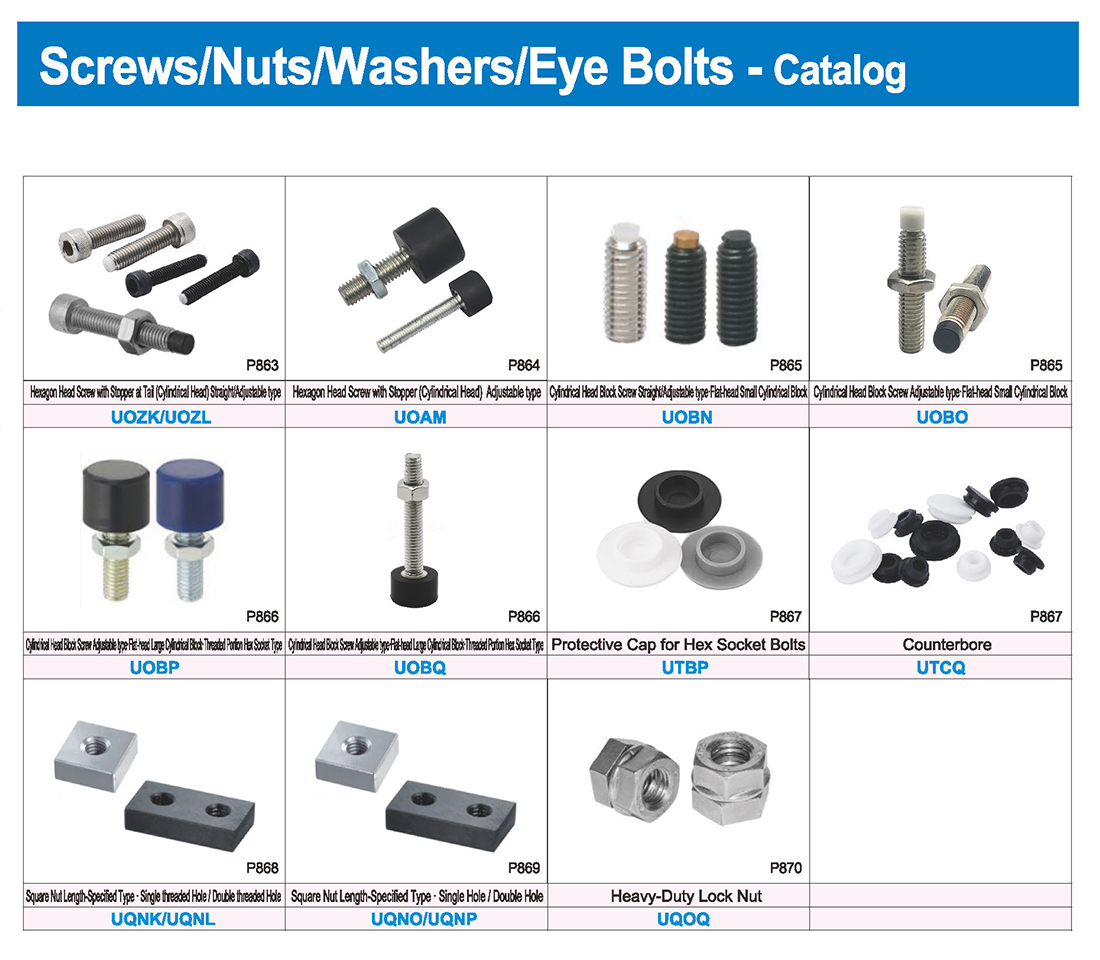

1. Diversity: A wide variety of screws, according to the use of different occasions and functions, there are countersunk screws, cylindrical head screws, outer hexagonal screws and other types. Each type of screw has its specific application scenarios and advantages.

2. Standardization: The specifications and dimensions of screws usually follow international standards or industry standards to ensure that screws produced by different manufacturers can be used interchangeably. This helps simplify the design, production and maintenance processes.

3. High strength: Screws are usually made of high-strength materials, such as stainless steel, alloy steel, etc., to ensure that stable connections can be maintained when subjected to heavy loads or vibration.

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

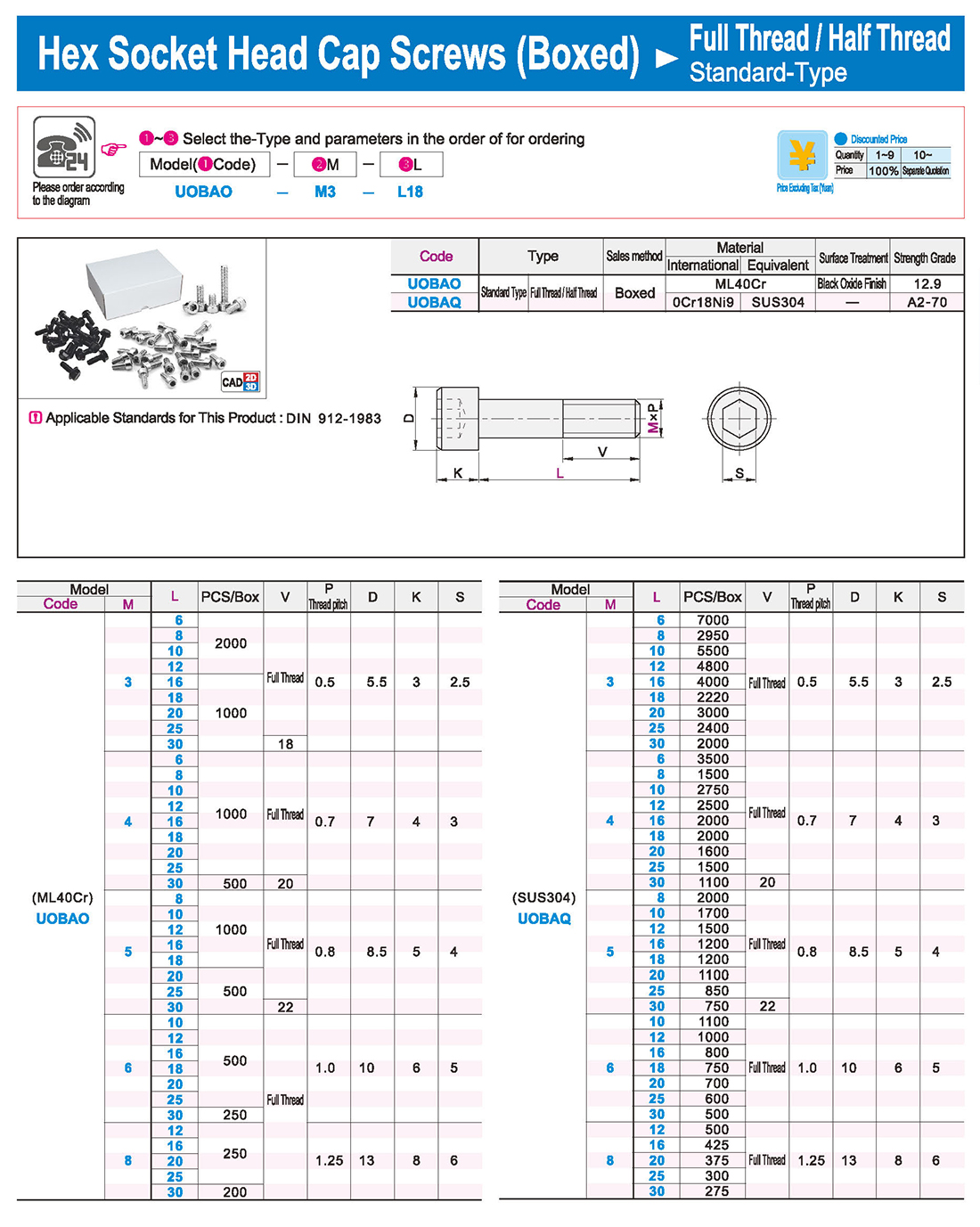

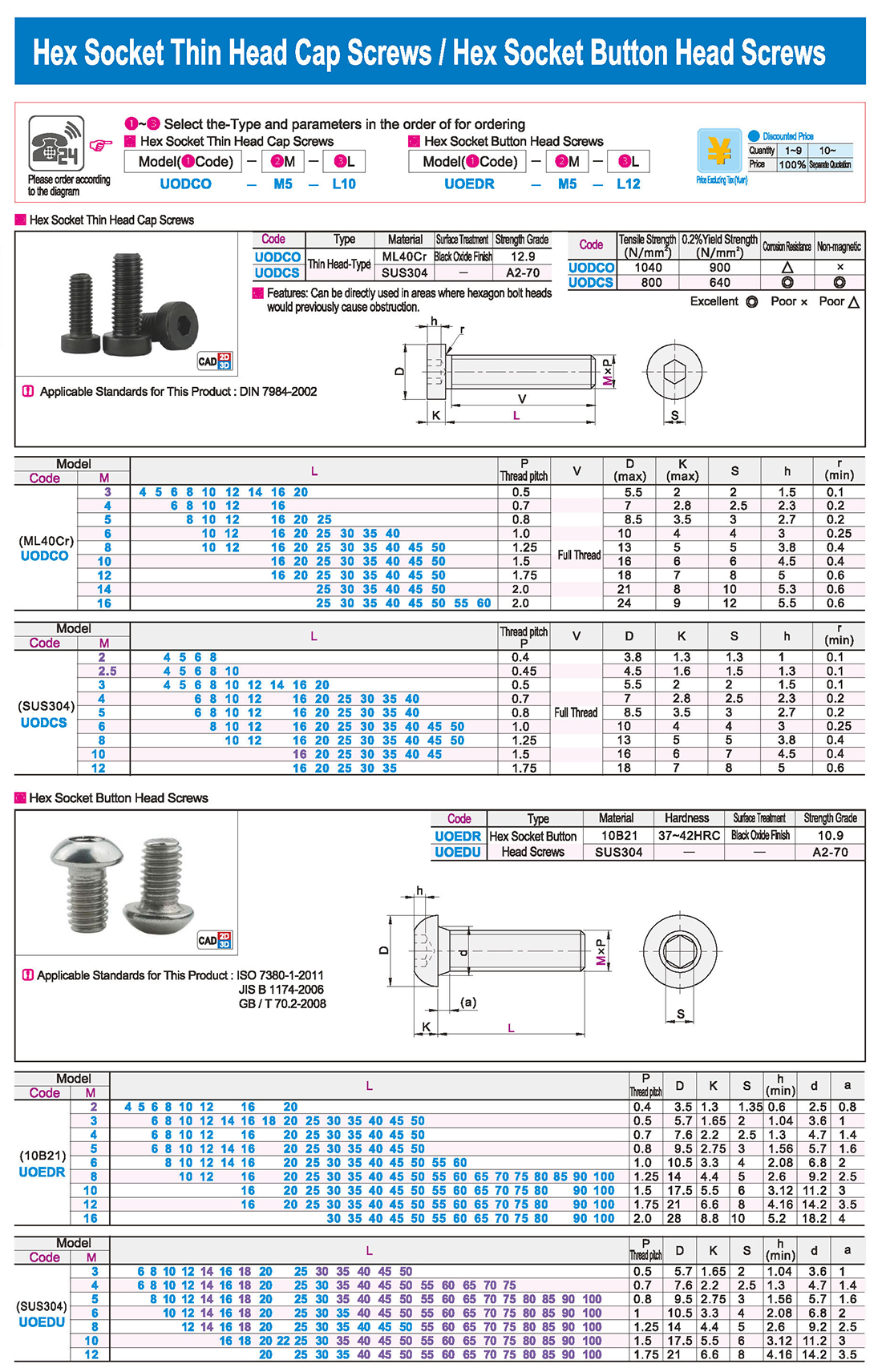

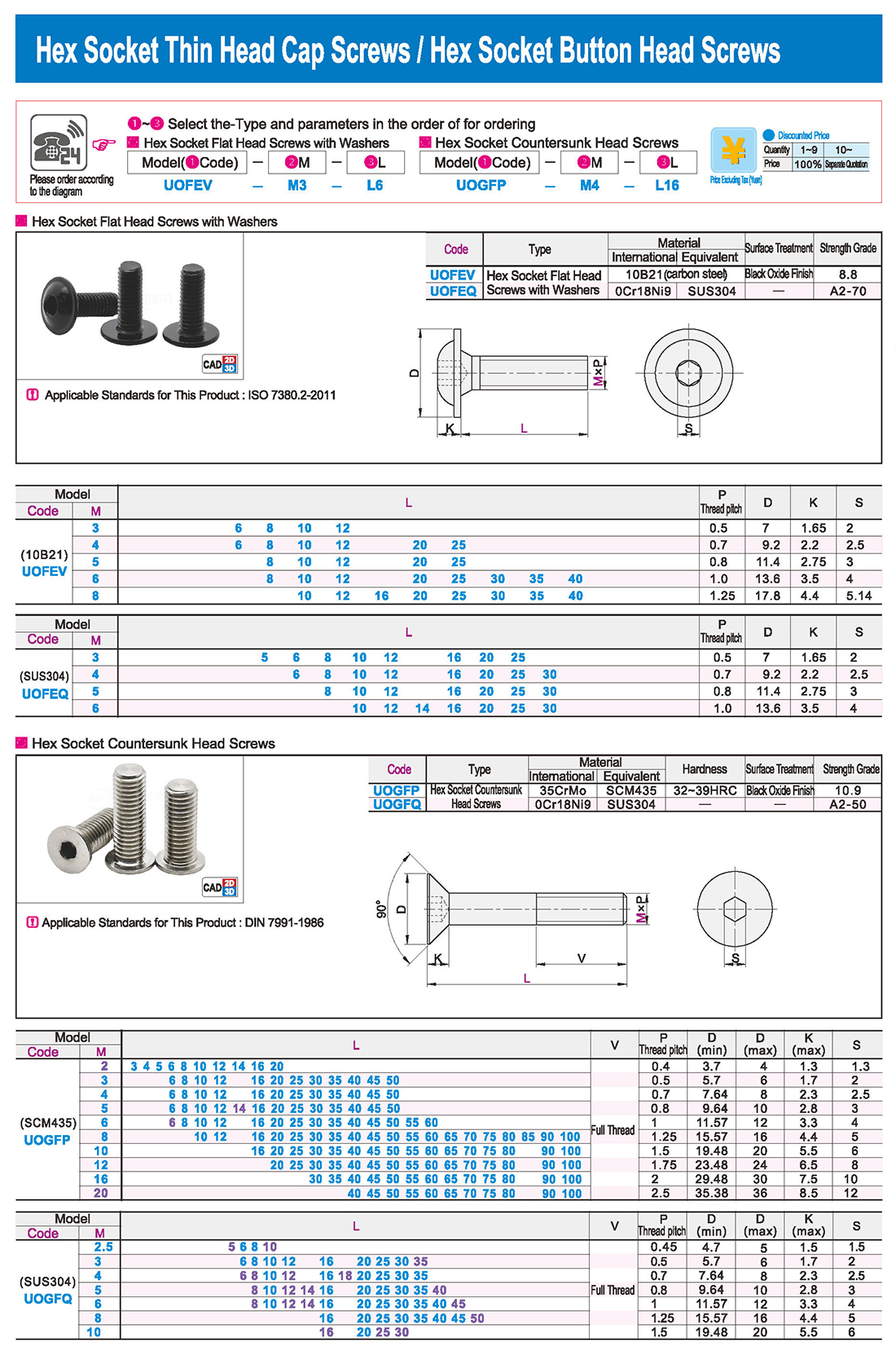

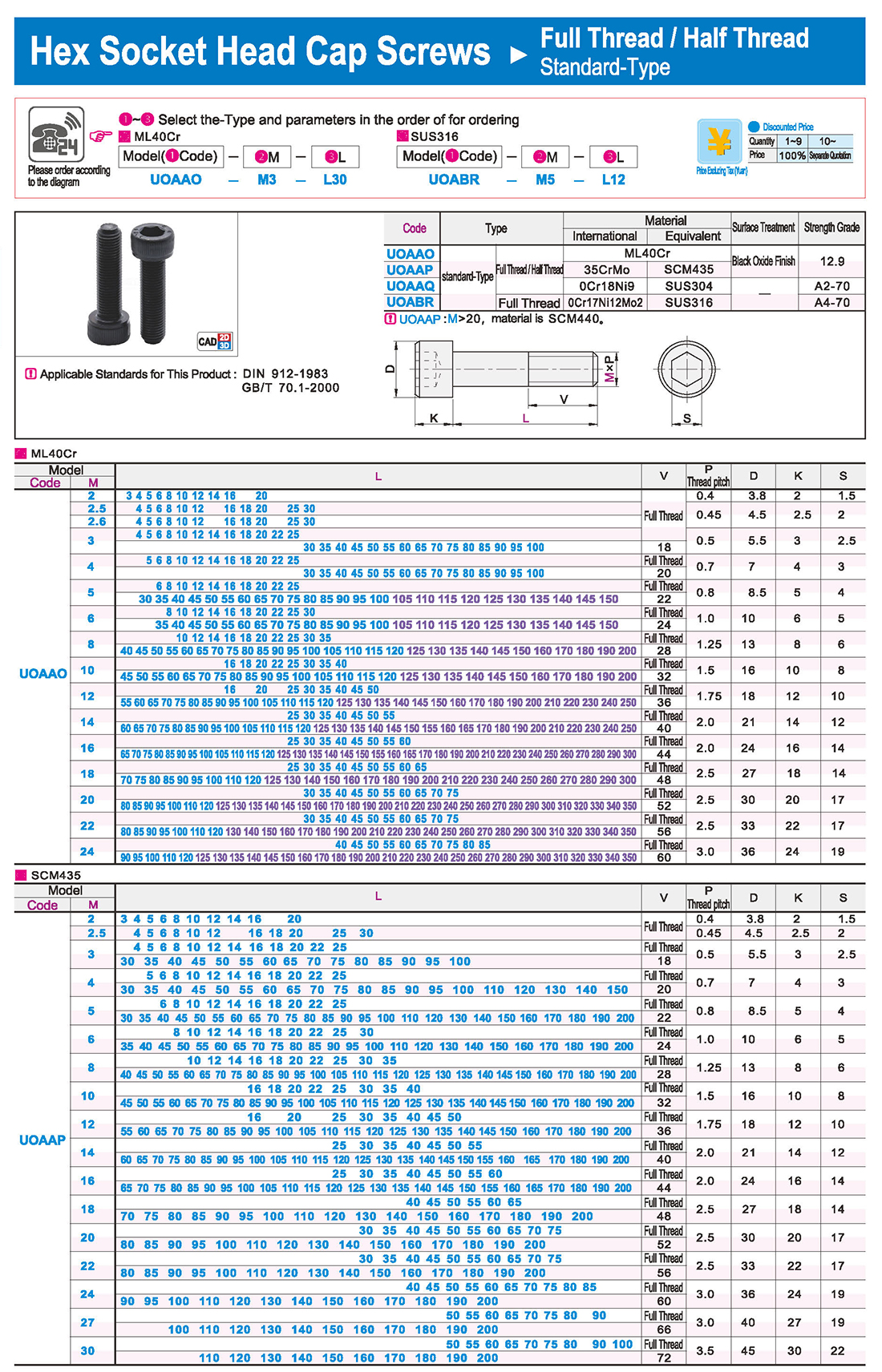

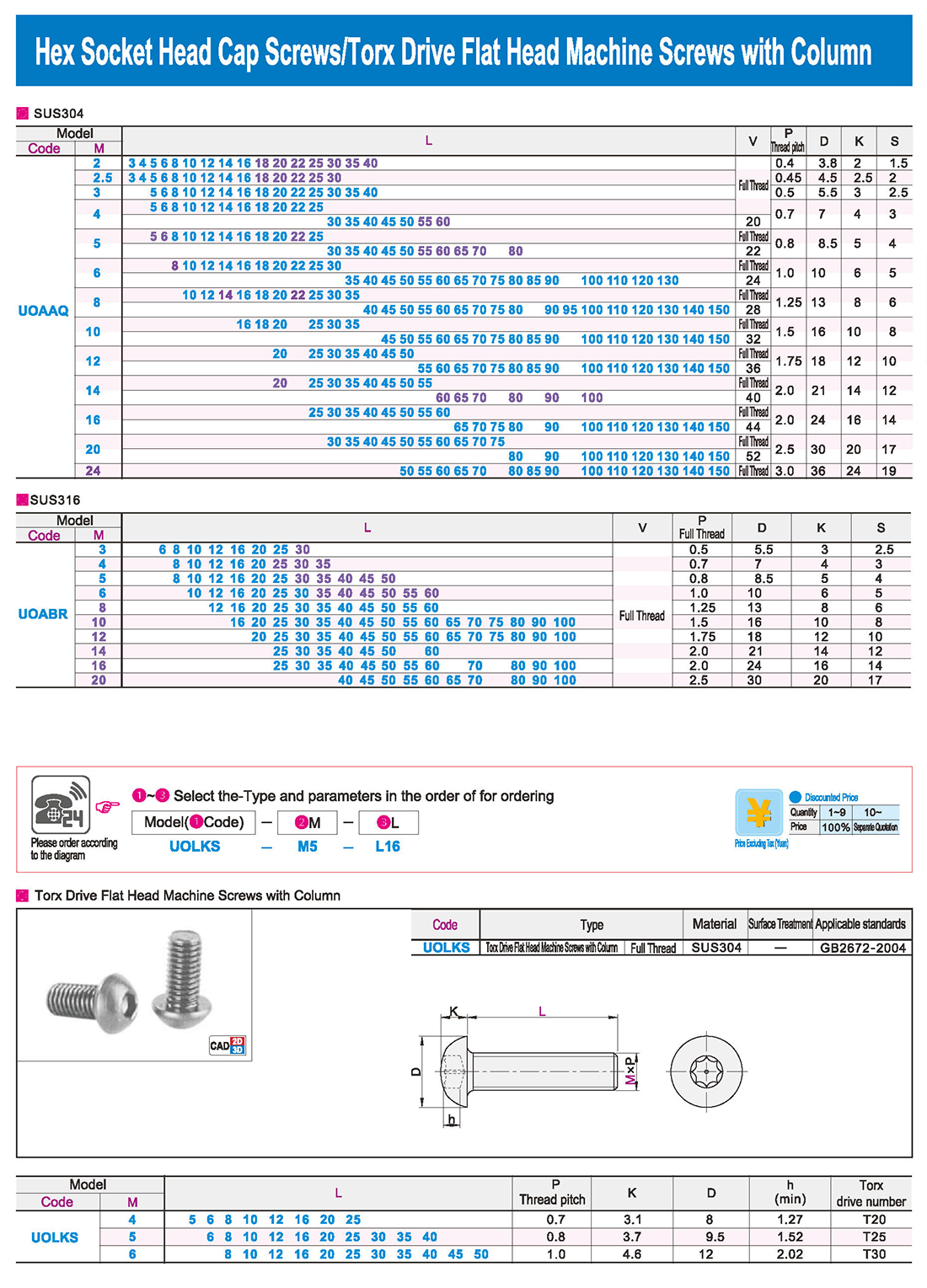

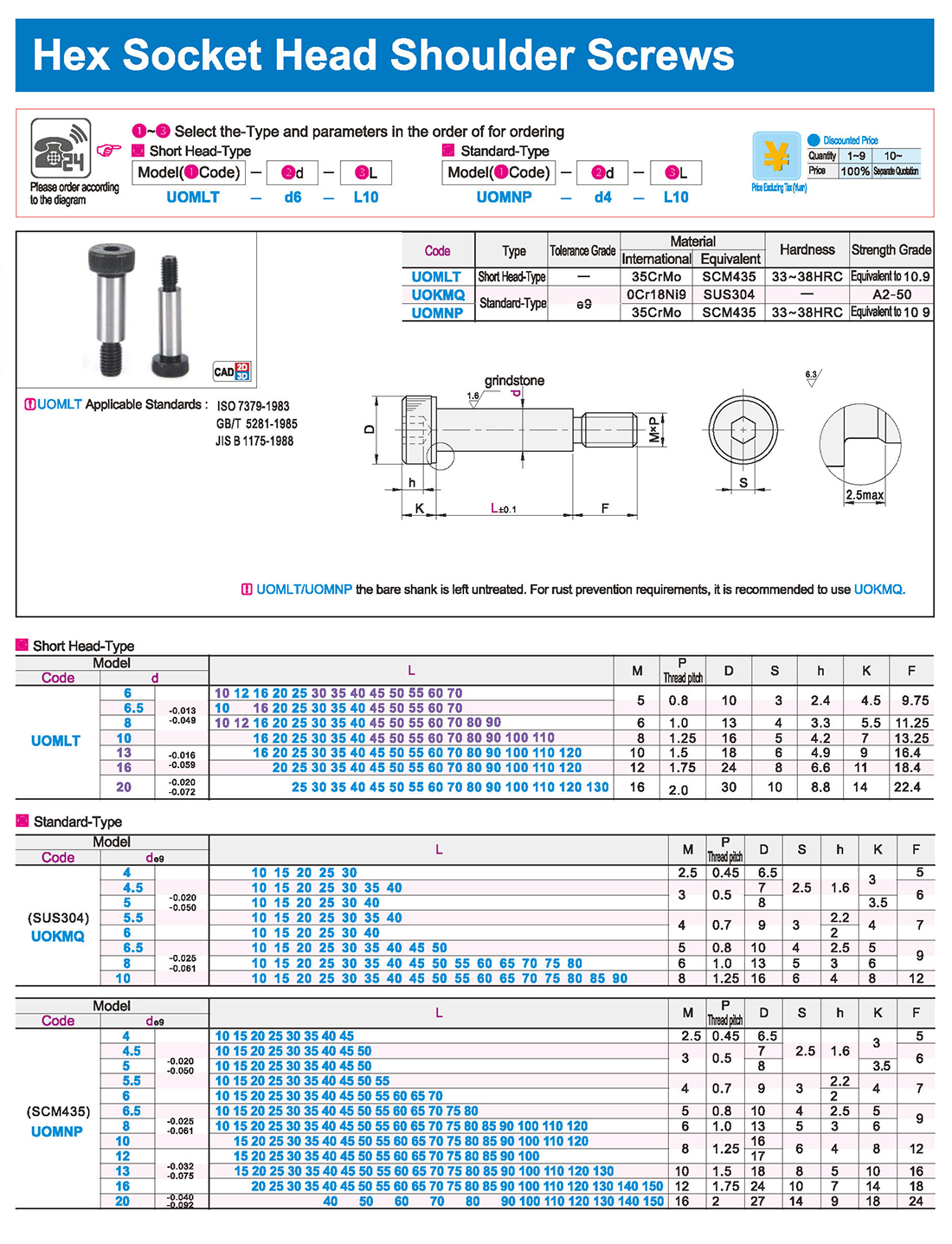

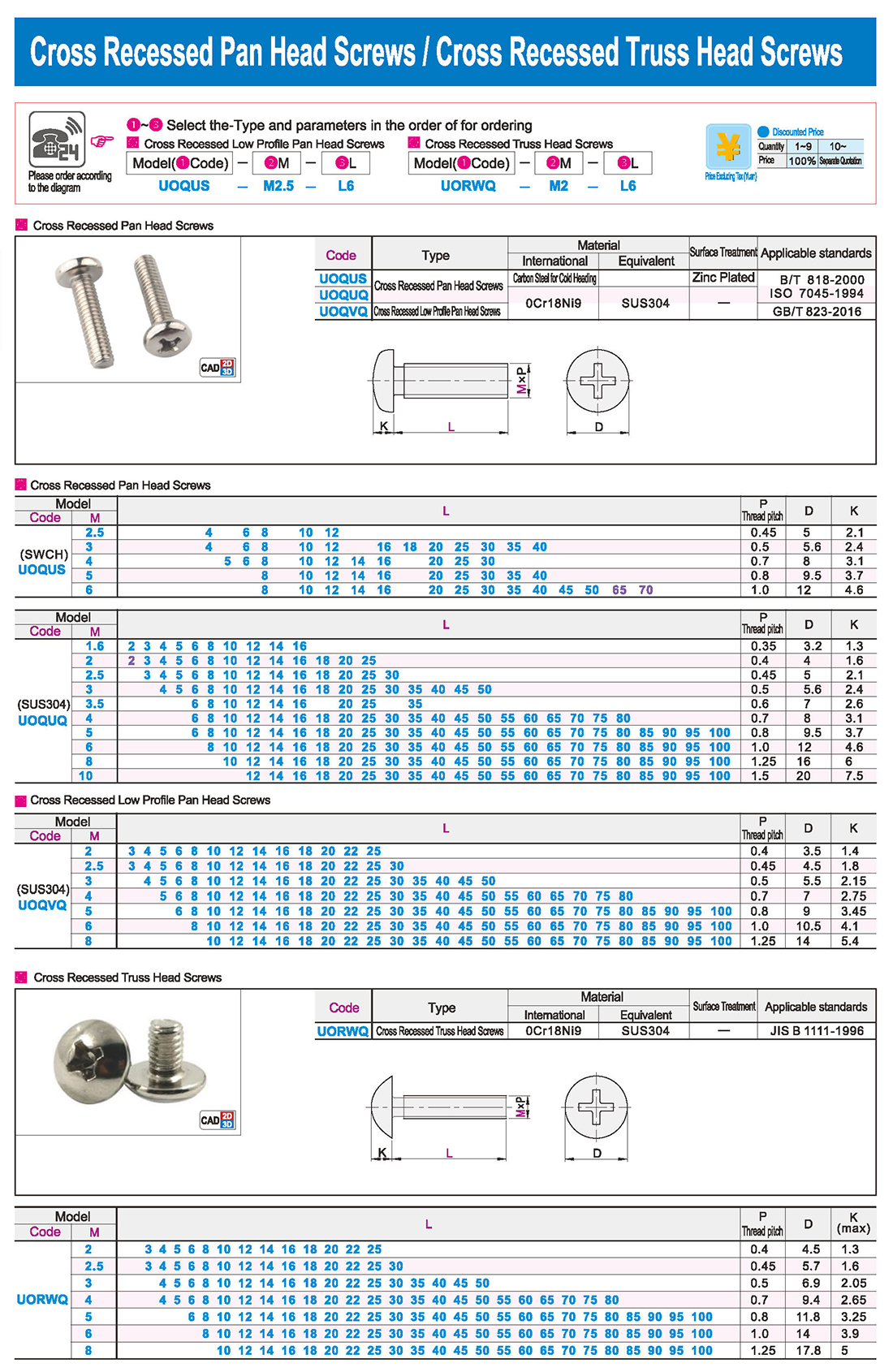

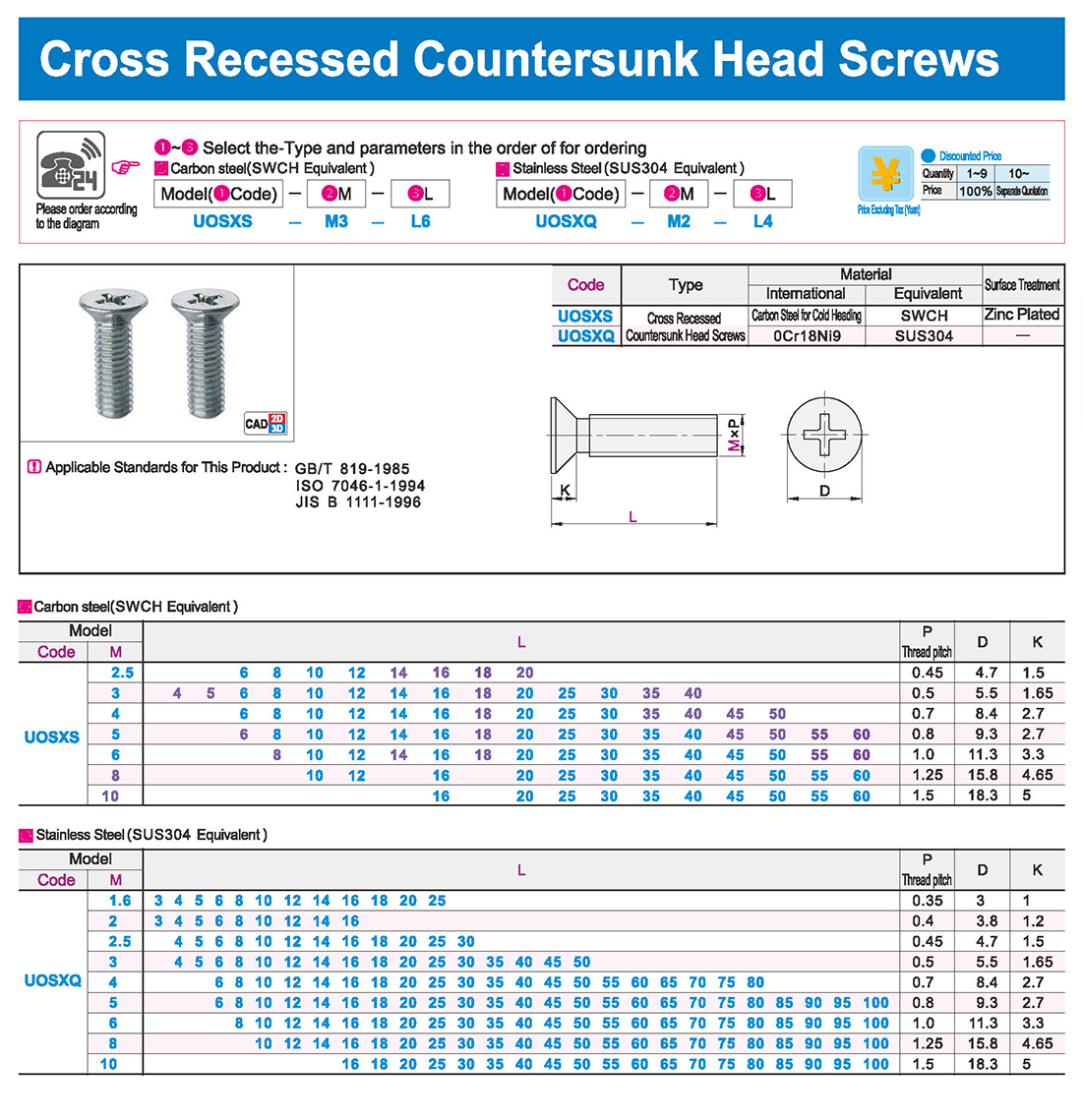

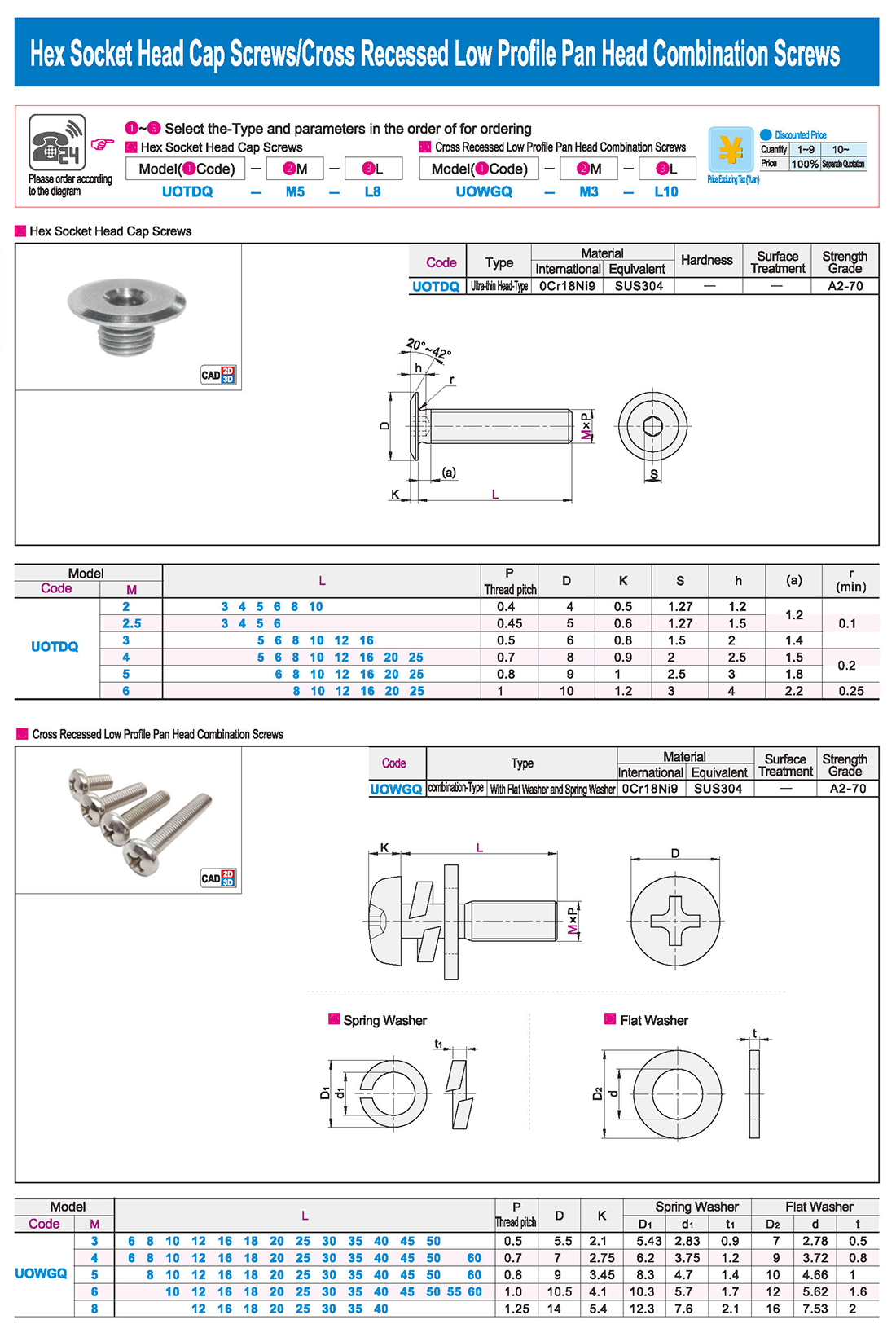

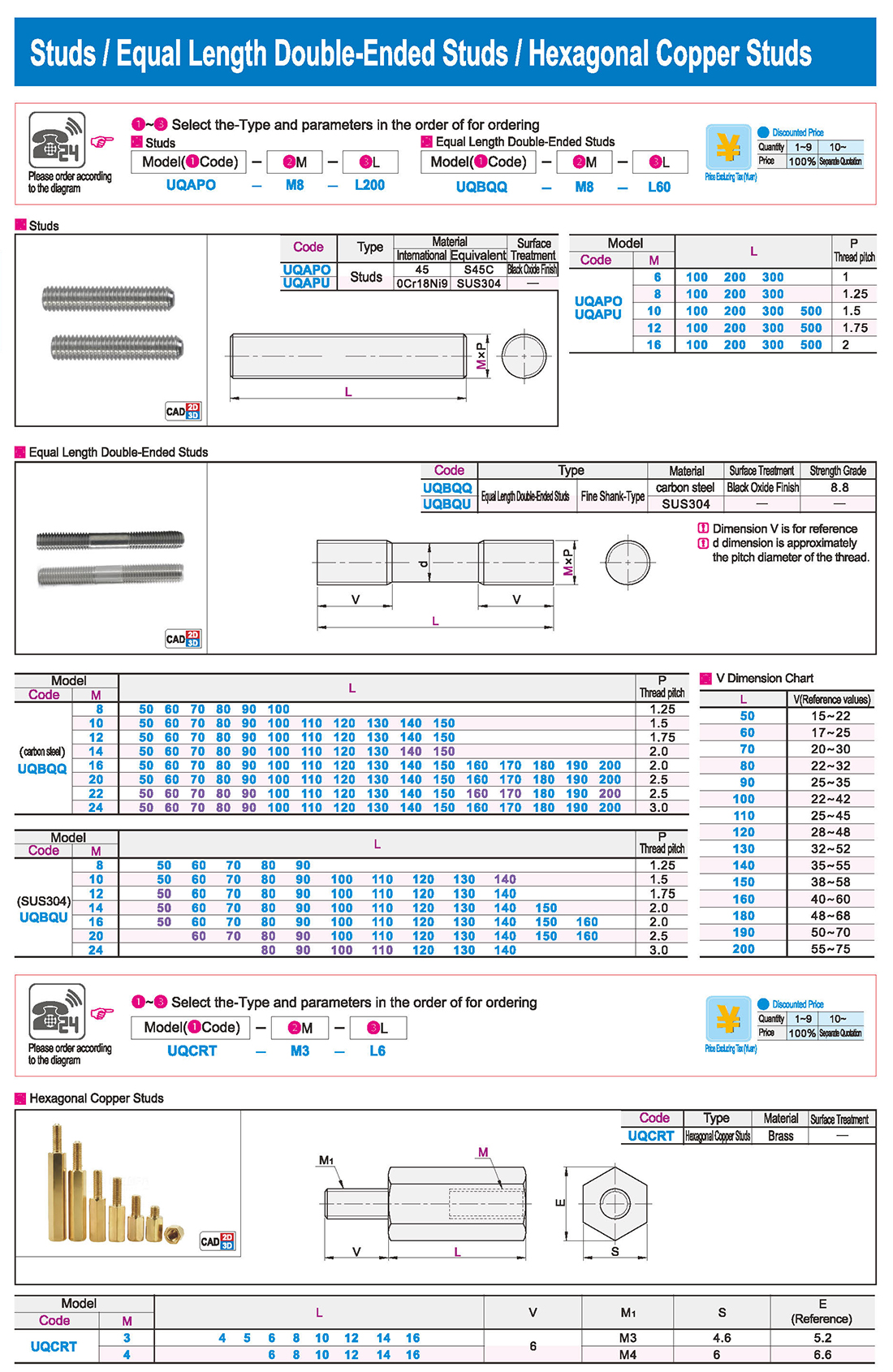

Introduction Specification Table

Specification Table Download

Download