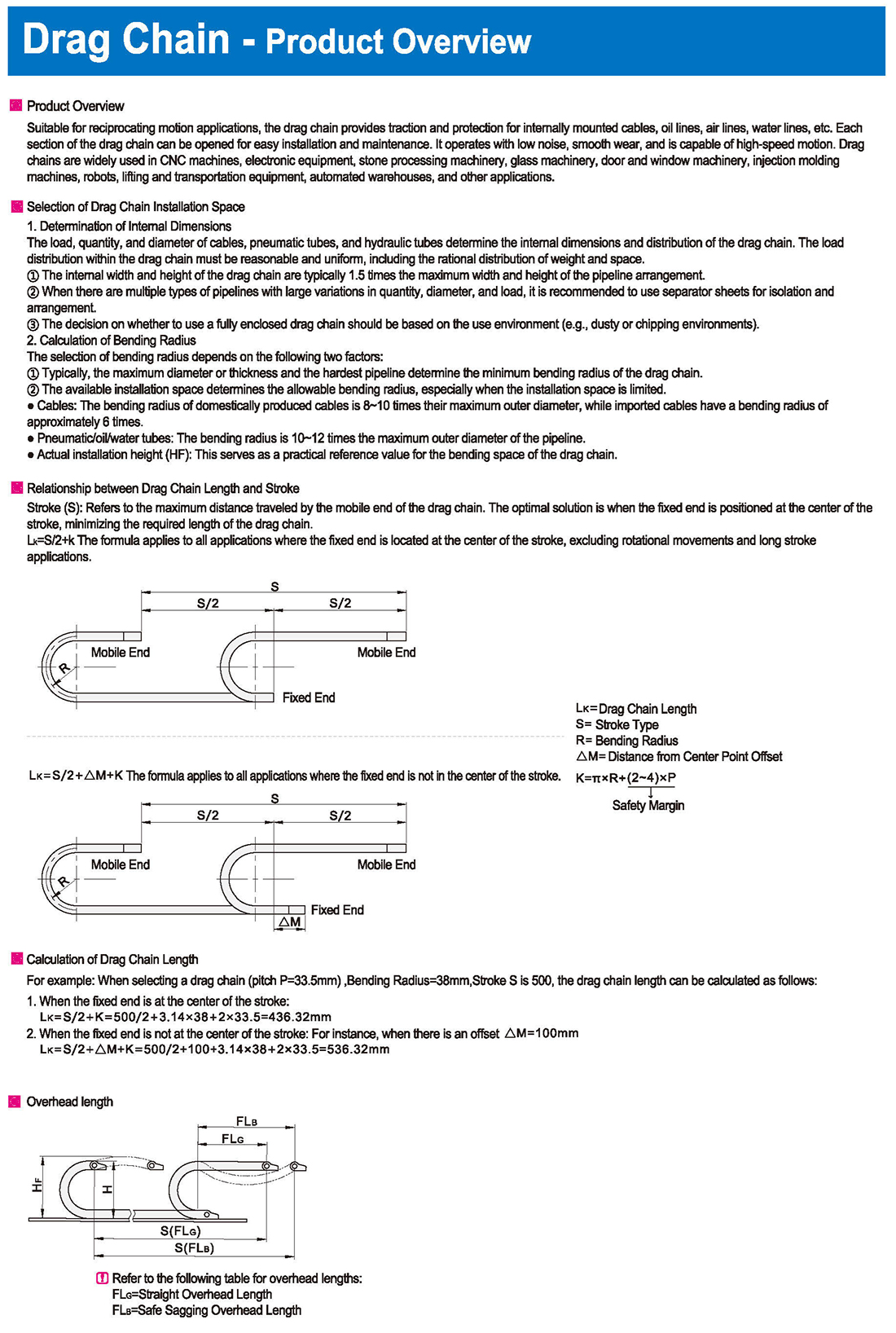

Selection of Drag Chain Installation Space

1. Determination of Internal Dimensions

The load, quantity, and diameter of cables, pneumatic tubes, and hydraulic tubes determine the internal dimensions and distribution of the drag chain. The load distribution within the drag chain must be reasonable and uniform, including the rational distribution of weight and space.

① The internal width and height of the drag chain are typically 1.5 times the maximum width and height of the pipeline arrangement.

② When there are multiple types of pipelines with large variations in quantity, diameter, and load, it is recommended to use separator sheets for isolation and arrangement.

③ The decision on whether to use a fully enclosed drag chain should be based on the use environment (e.g., dusty or chipping environments).

2. Calculation of Bending Radius

The selection of bending radius depends on the following two factors:

① Typically, the maximum diameter or thickness and the hardest pipeline determine the minimum bending radius of the drag chain.

② The available installation space determines the allowable bending radius, especially when the installation space is limited.

● Cables: The bending radius of domestically produced cables is 8~10 times their maximum outer diameter, while imported cables have a bending radius of approximately 6 times.

● Pneumatic/oil/water tubes: The bending radius is 10~12 times the maximum outer diameter of the pipeline.

● Actual installation height (HF): This serves as a practical reference value for the bending space of the drag chain.

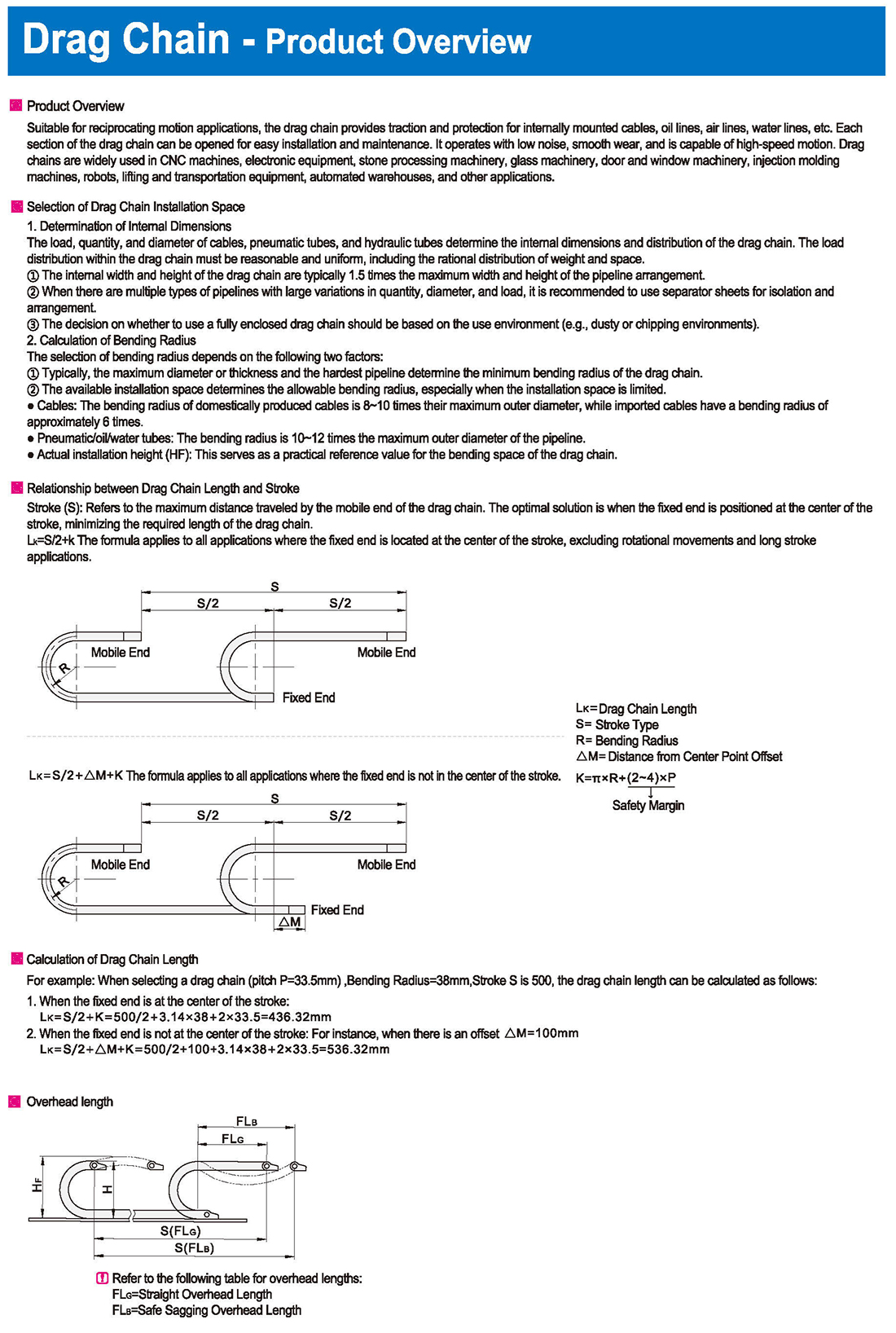

Relationship between Drag Chain Length and Stroke

Stroke (S): Refers to the maximum distance traveled by the mobile end of the drag chain. The optimal solution is when the fixed end is positioned at the center of the stroke, minimizing the required length of the drag chain.

The formula applies to all applications where the fixed end is located at the center of the stroke, excluding rotational movements and long stroke applications.

Small Semi-closed Drag Chain, Non-openable 10 Series, Semi-closed

Press-to-Open 10 Series with Convenient Operation, Convenient Press-to-Open Type

Small Bridge-type Drag Chain, Outward-opening 15 Series, Vertical Hole, Horizontal Hole

Small Semi-closed Drag Chain, Side-opening 15 Series, Side-opening, Data

Small Press-to-Open 15 Series with Convenient Operation

Small Semi-closed Drag Chain, Internal-opening 18 Series, Compatible with Divider Plates

Bridge-type Drag Chain, Outward-opening 18 Series

Small Press-to-Open 18 Series with Convenient Operation

Small Bridge-type Drag Chain, Double-side Opening 25 Series

Small Closed Drag Chain, Double-side Opening 25 Series, Closed

Reinforced Bridge-type Drag Chain, Double-side Opening 25 Series, Colorful Bridge-type, Special for Crossbeam, N indicates Universal, Y indicates Divider Block

Reinforced Closed Drag Chain, Double-side Opening 25 Series, Colorful Closed

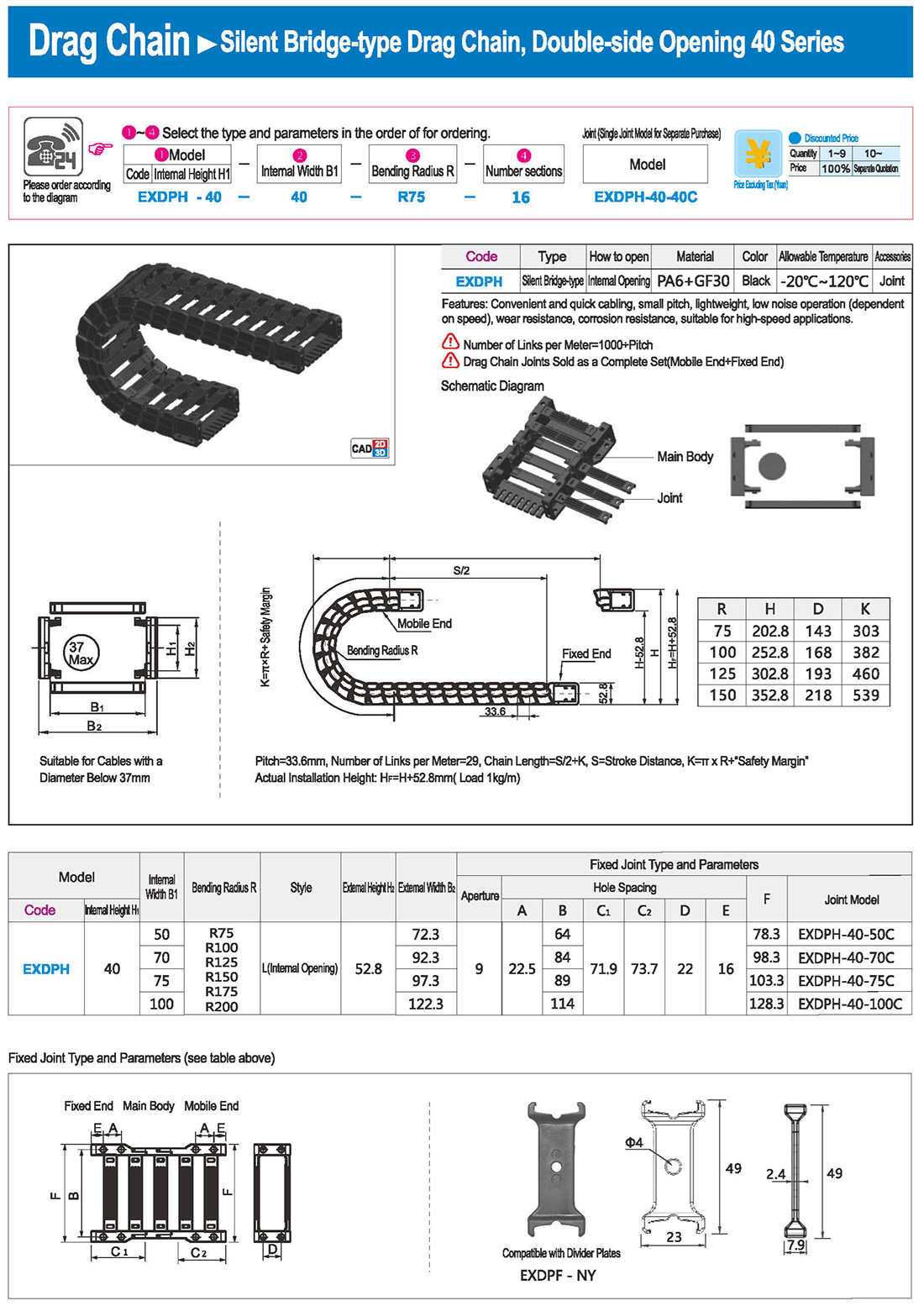

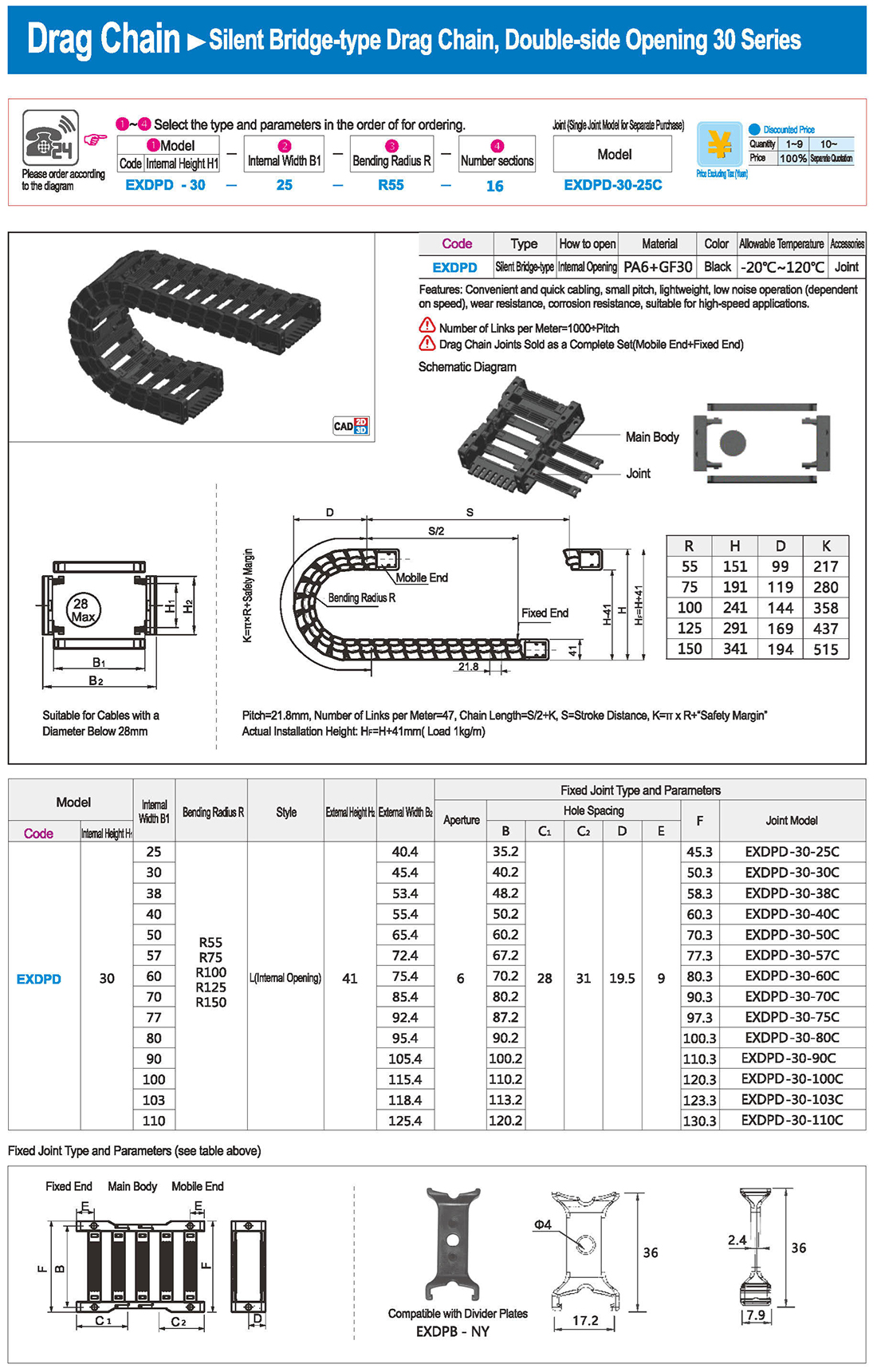

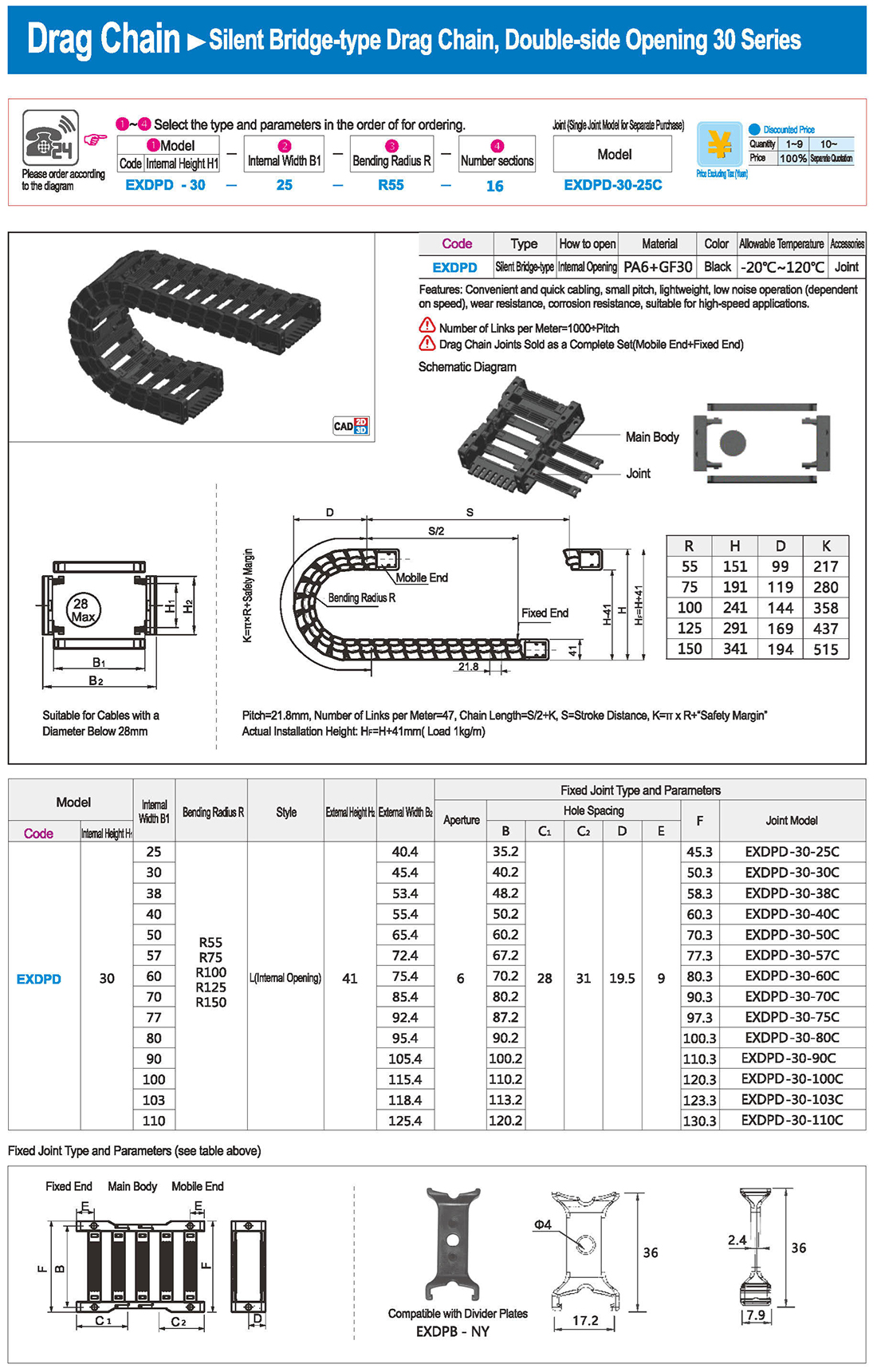

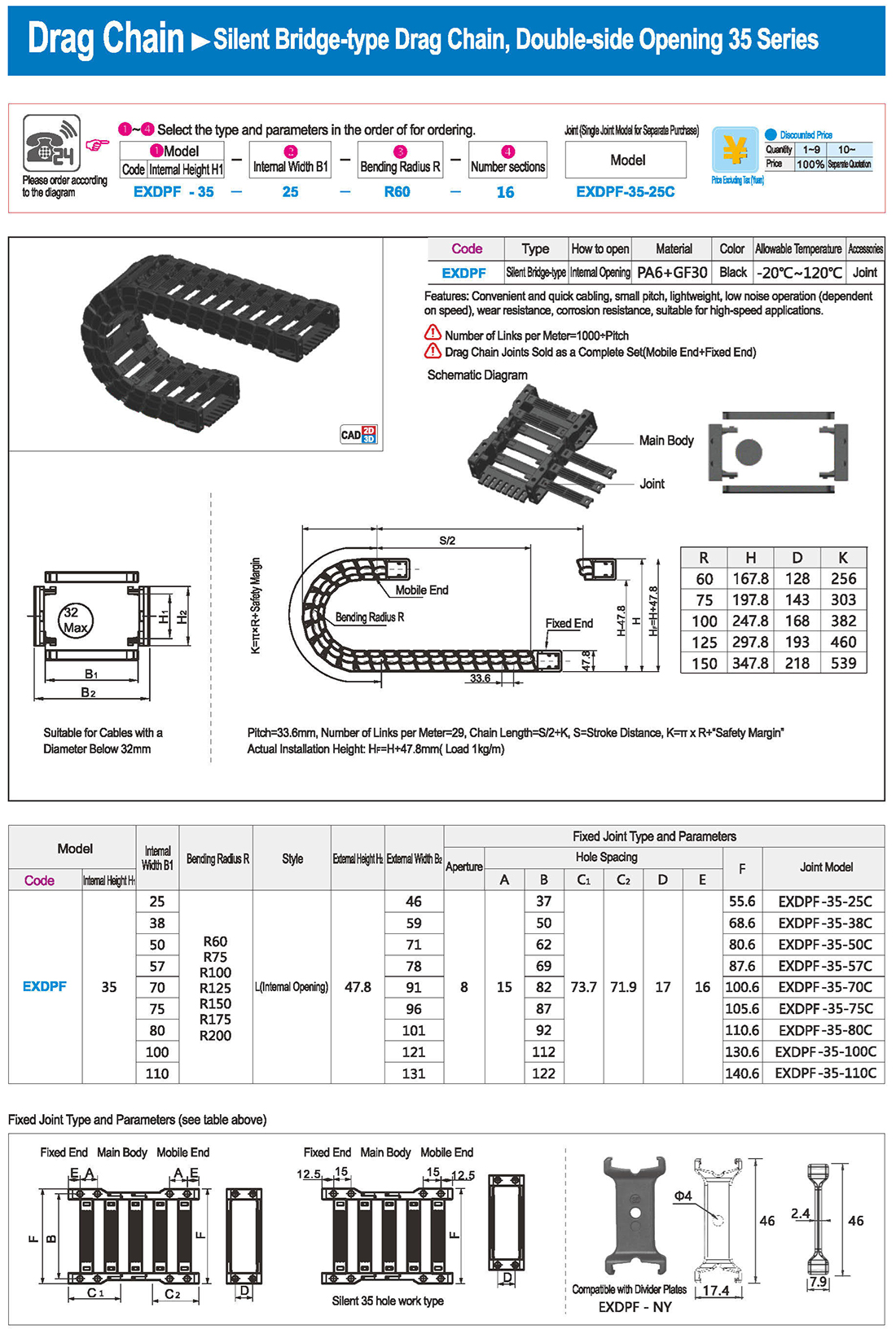

Heavy-duty Bridge-type Drag Chain, Double-side Opening 35 Series

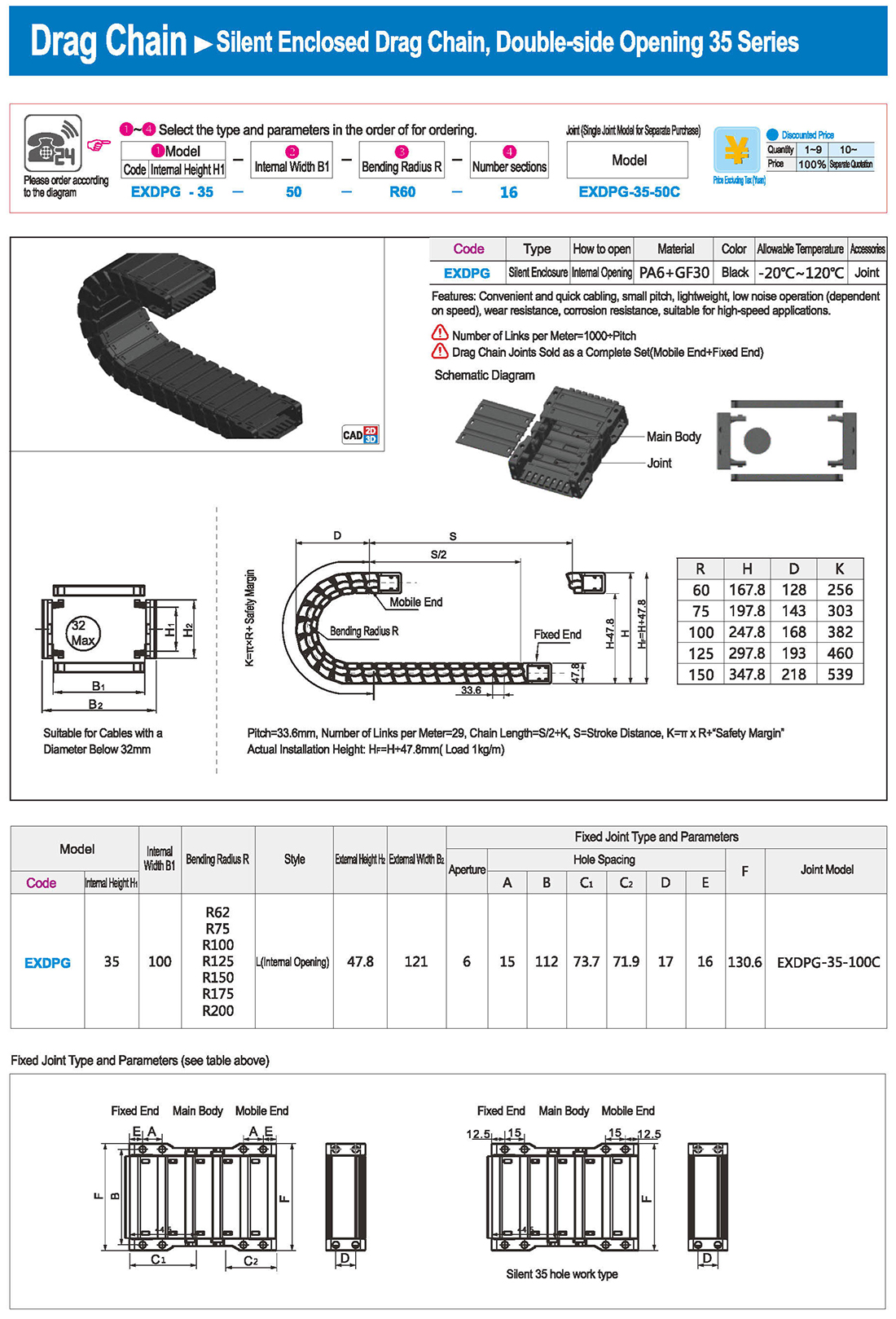

Heavy-duty Closed Drag Chain, Double-side Opening 35 Series

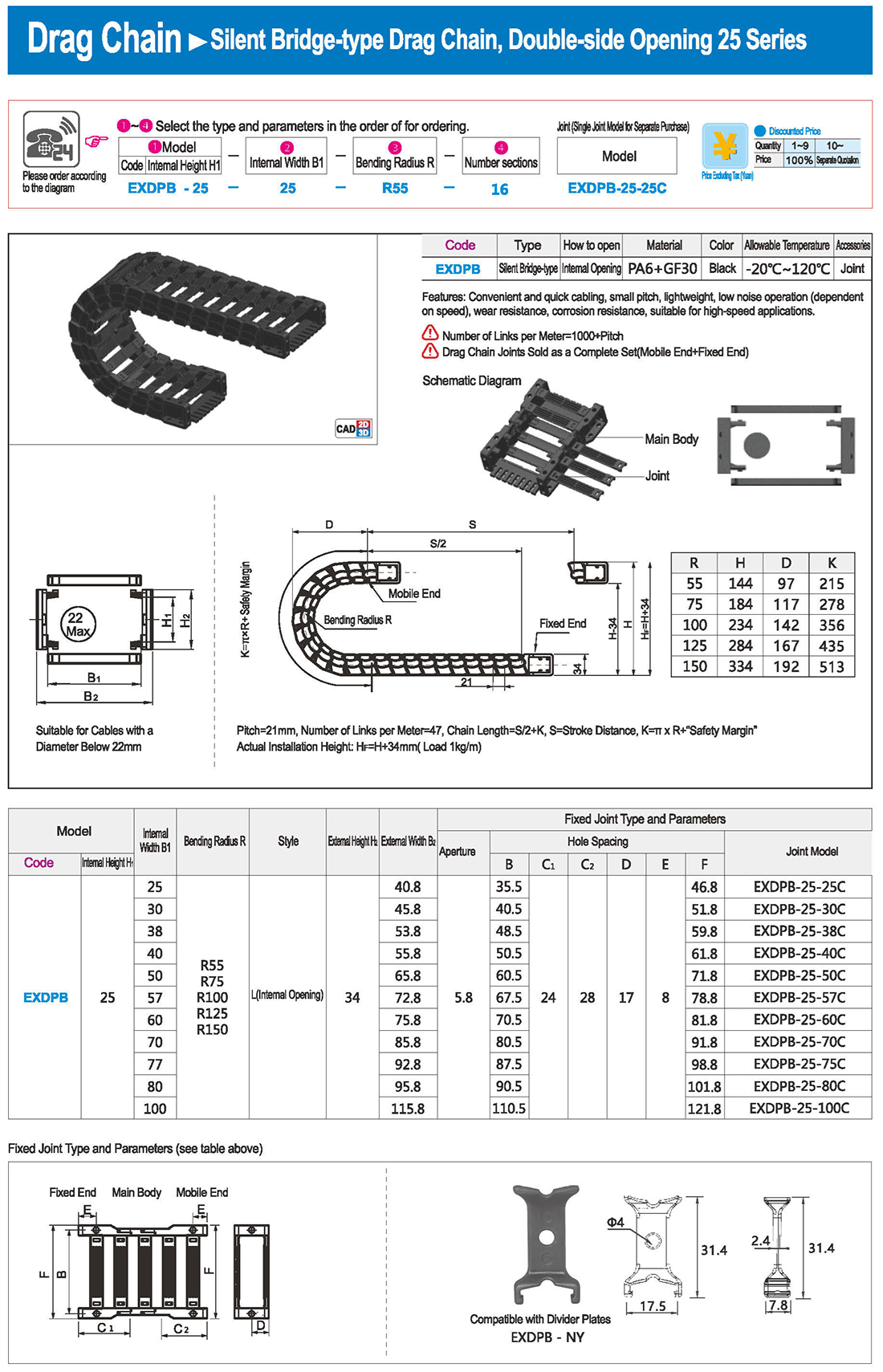

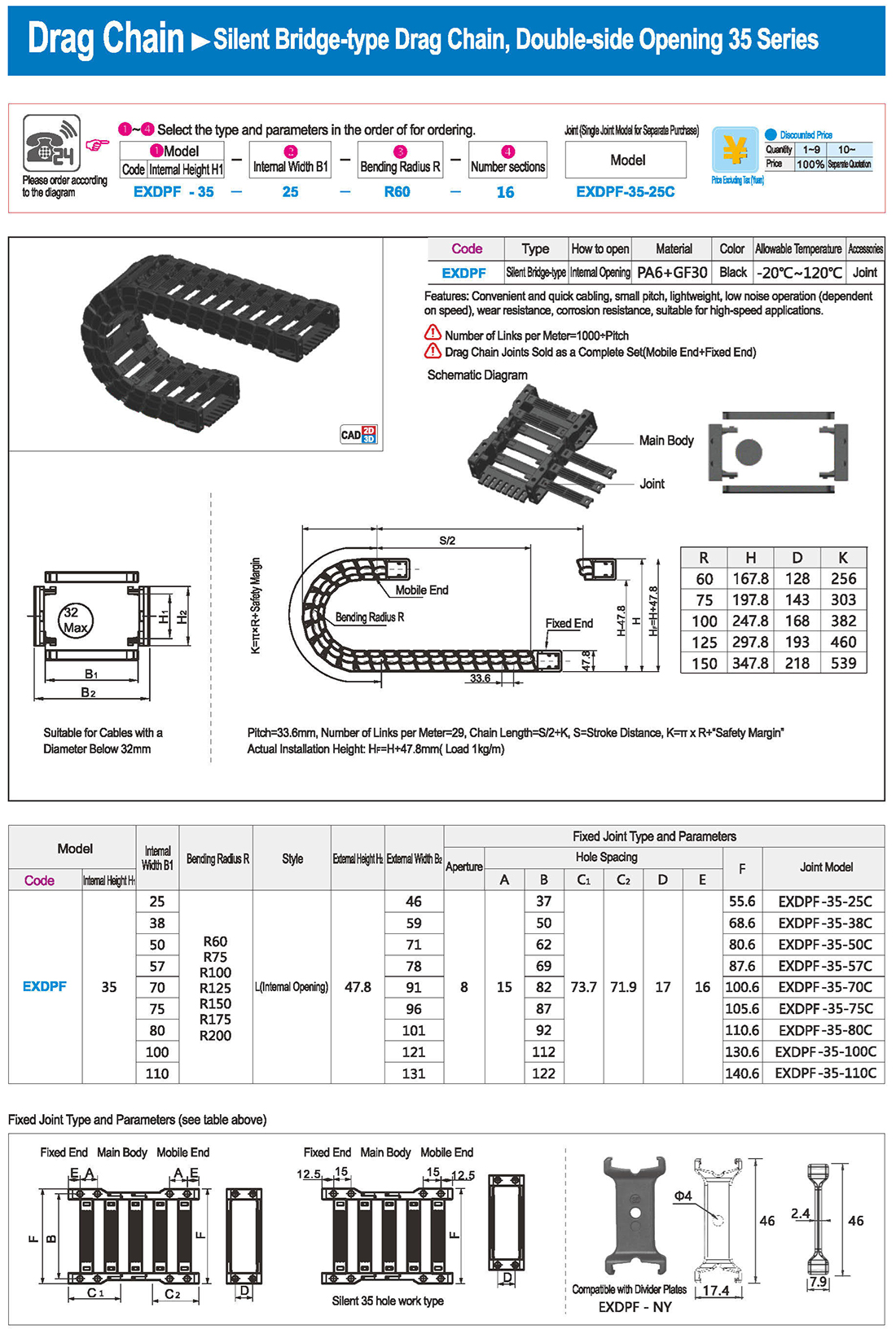

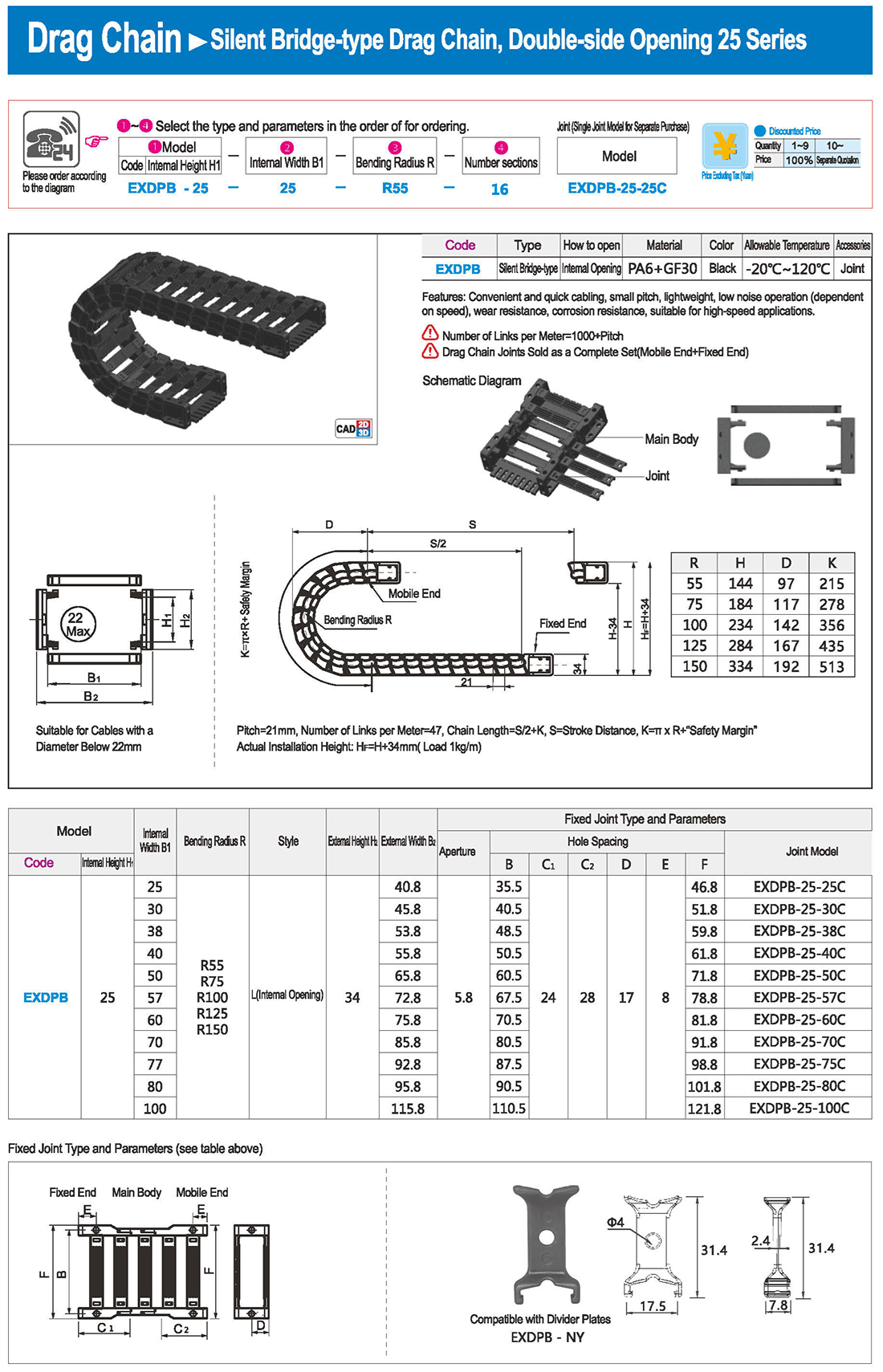

Silent Bridge-type Drag Chain, Double-side Opening 25 Series, Silent Bridge-type

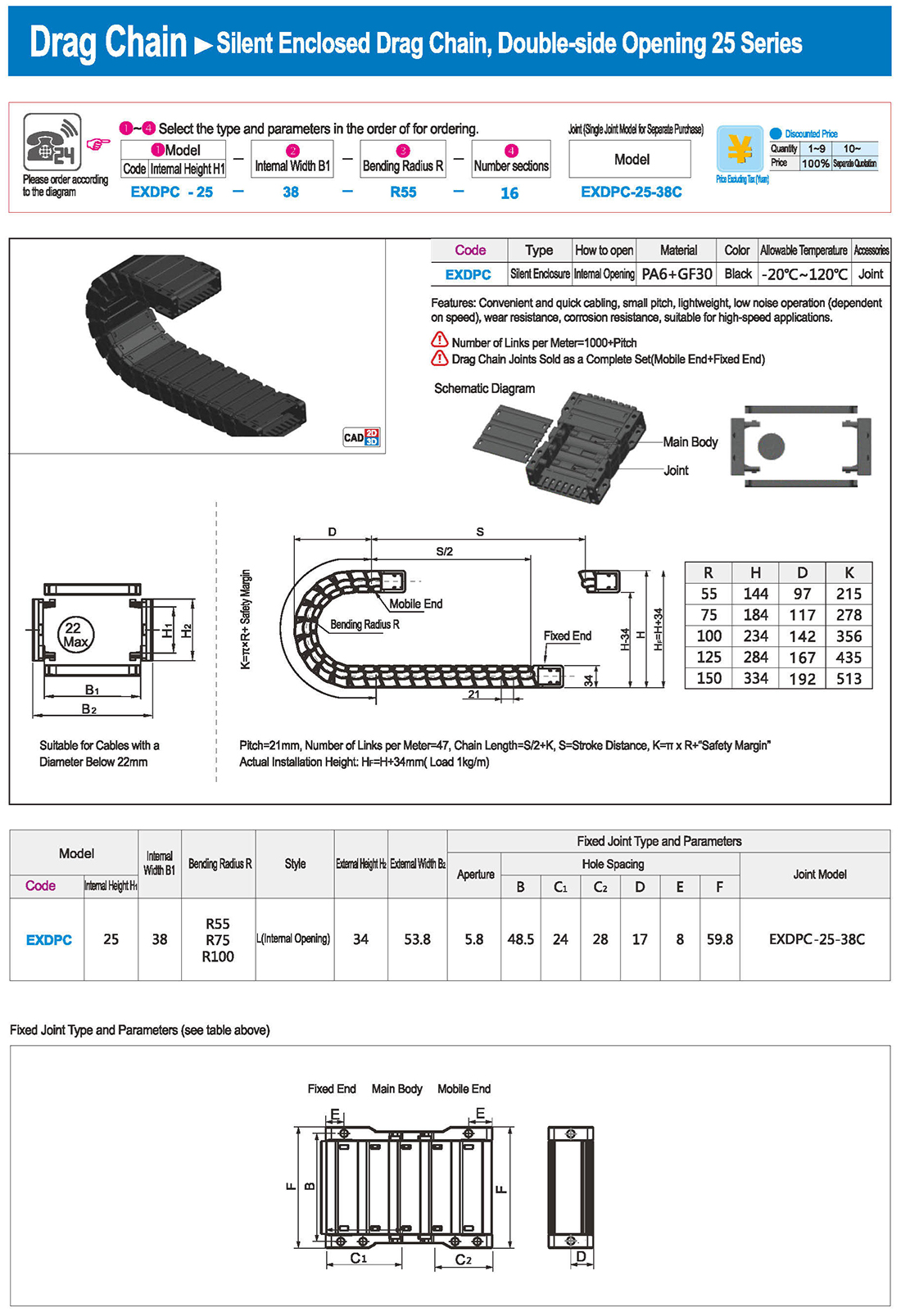

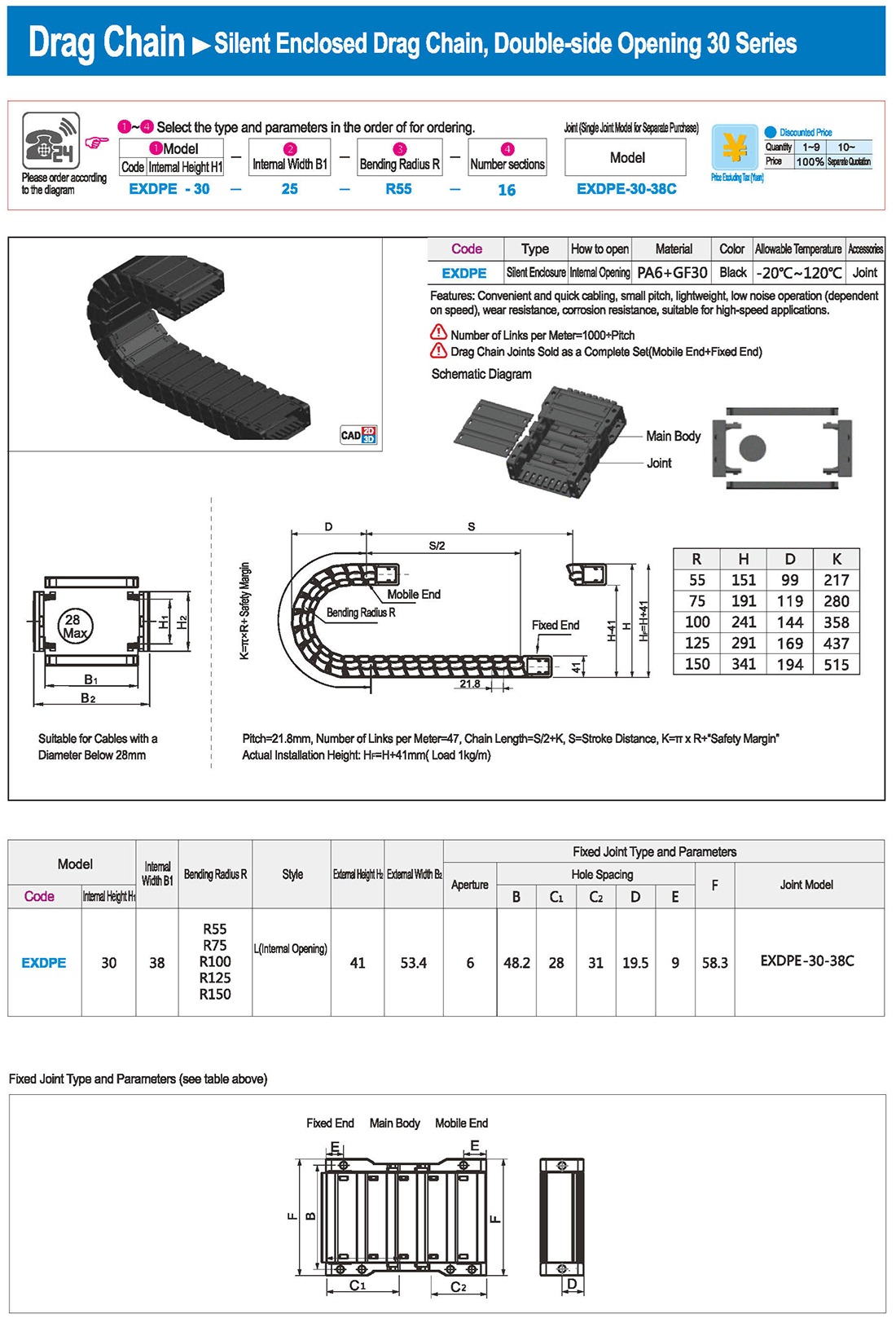

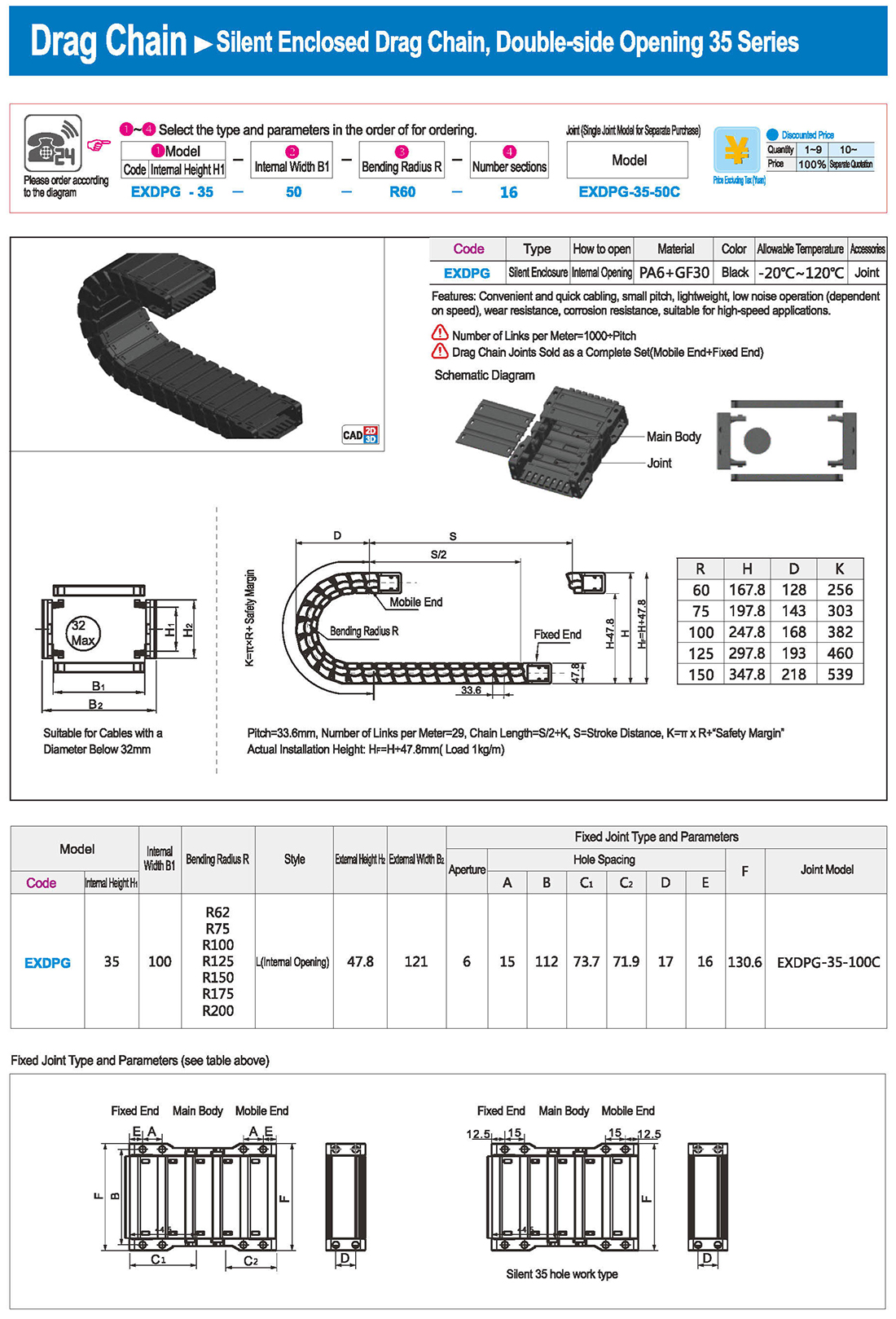

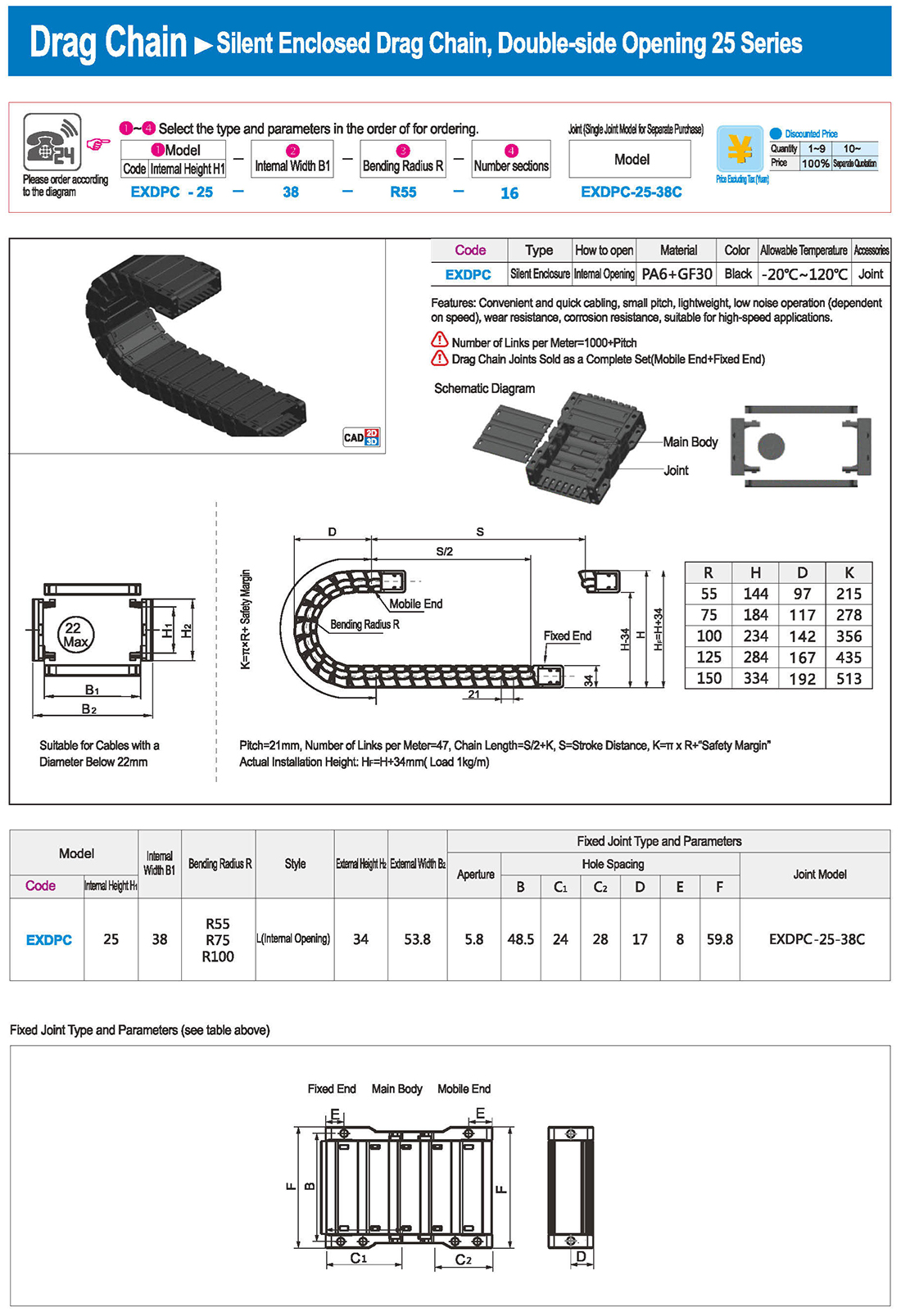

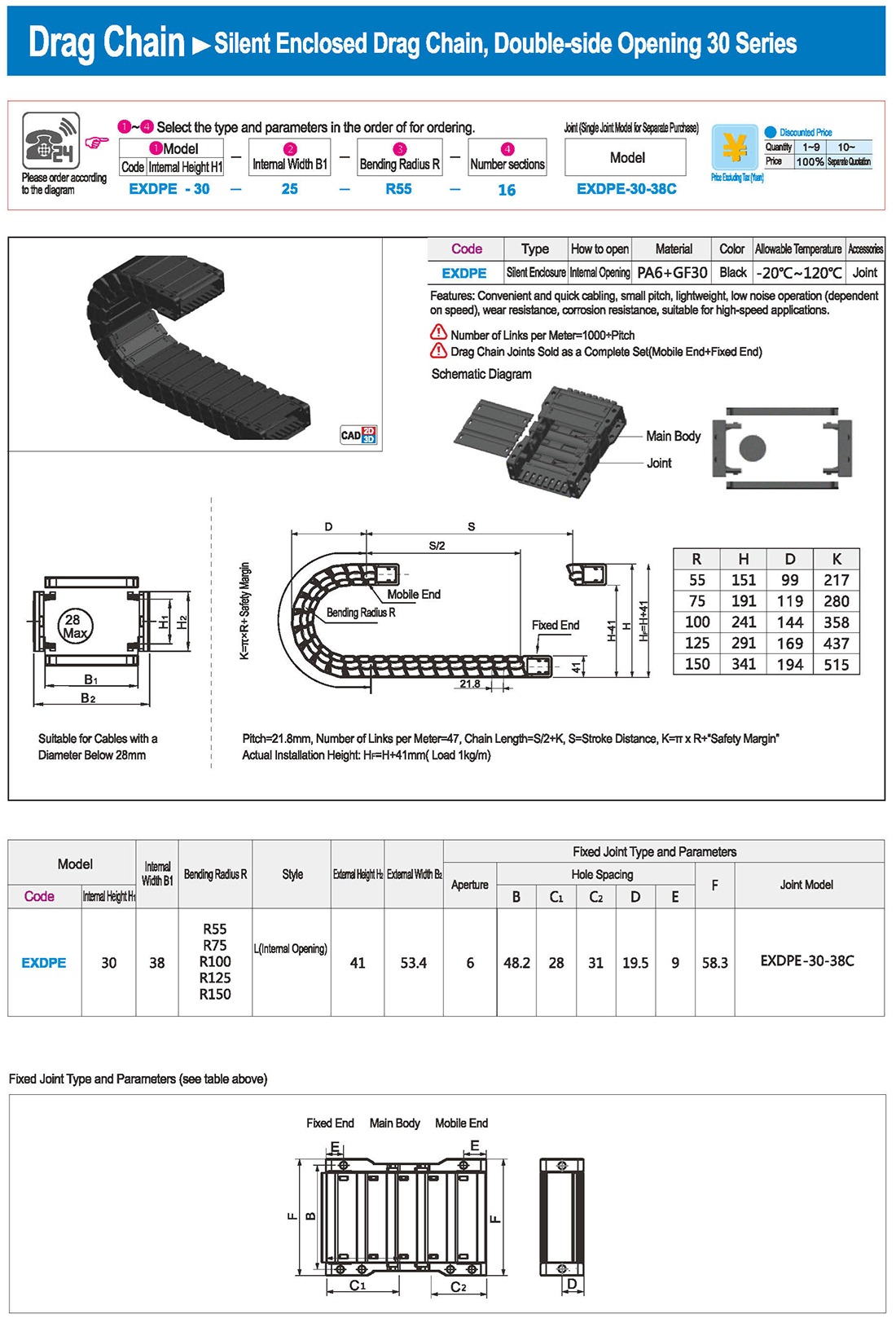

Silent Enclosed Drag Chain, Double-side Opening 25 Series, Silent Enclosure

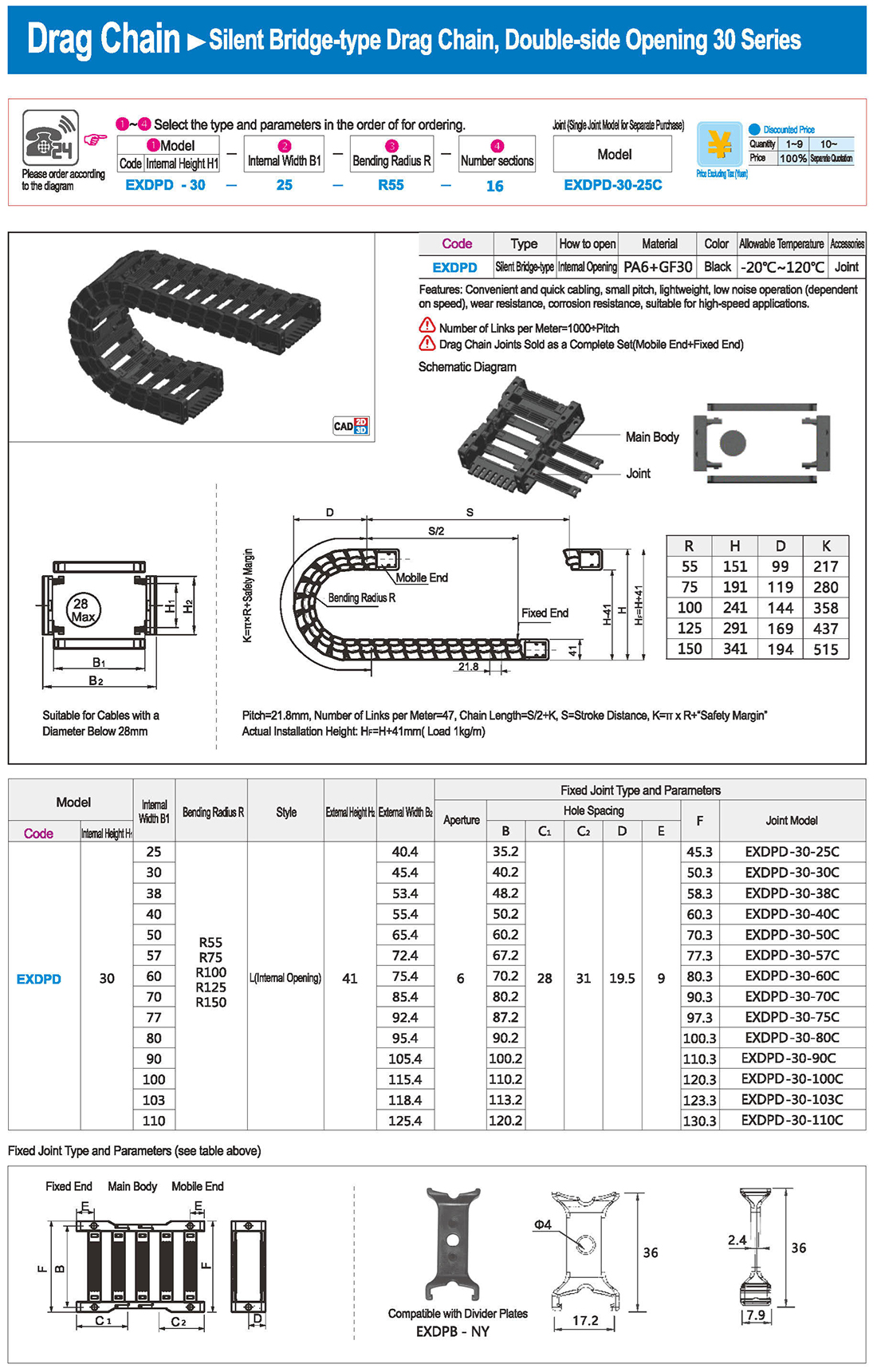

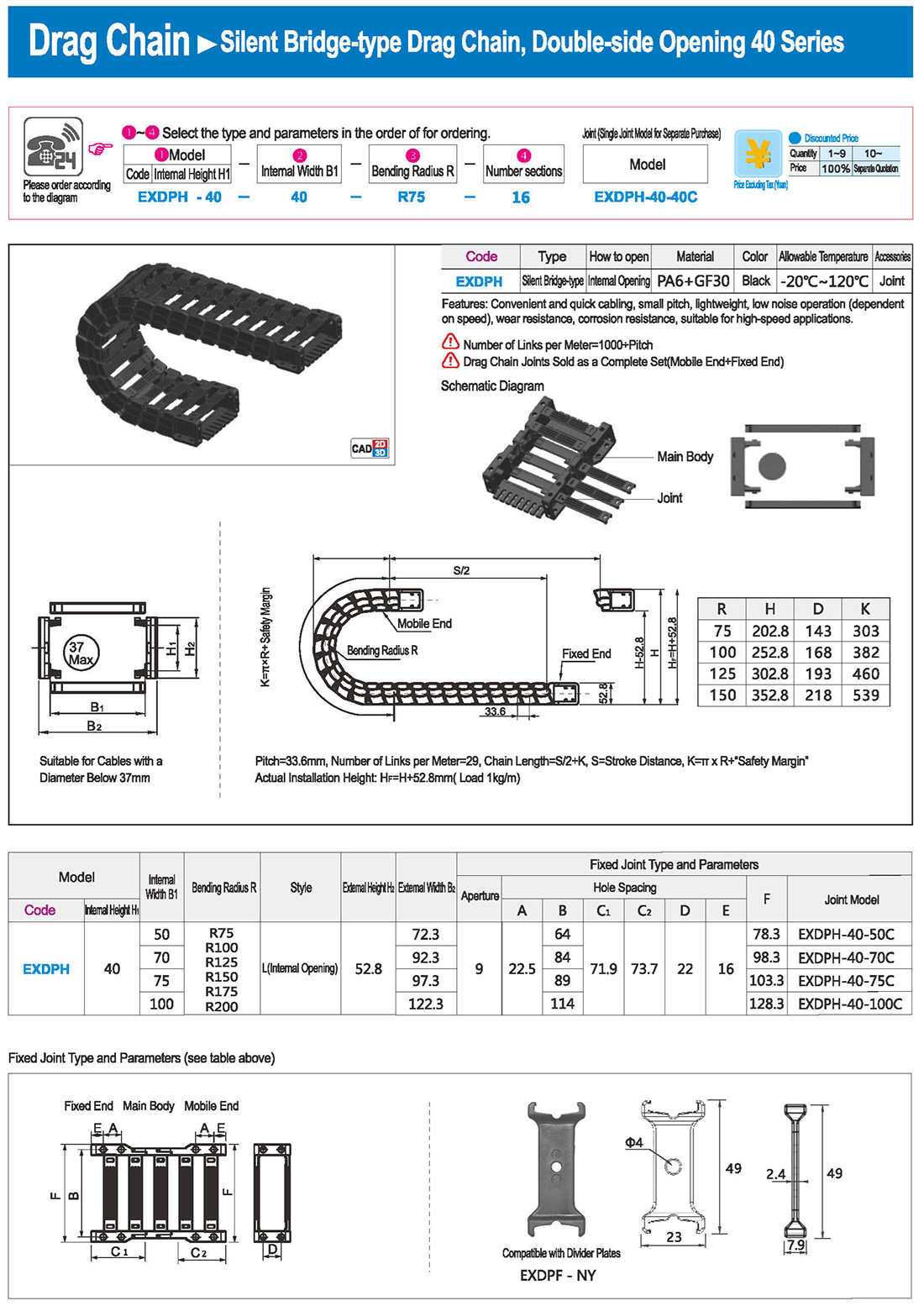

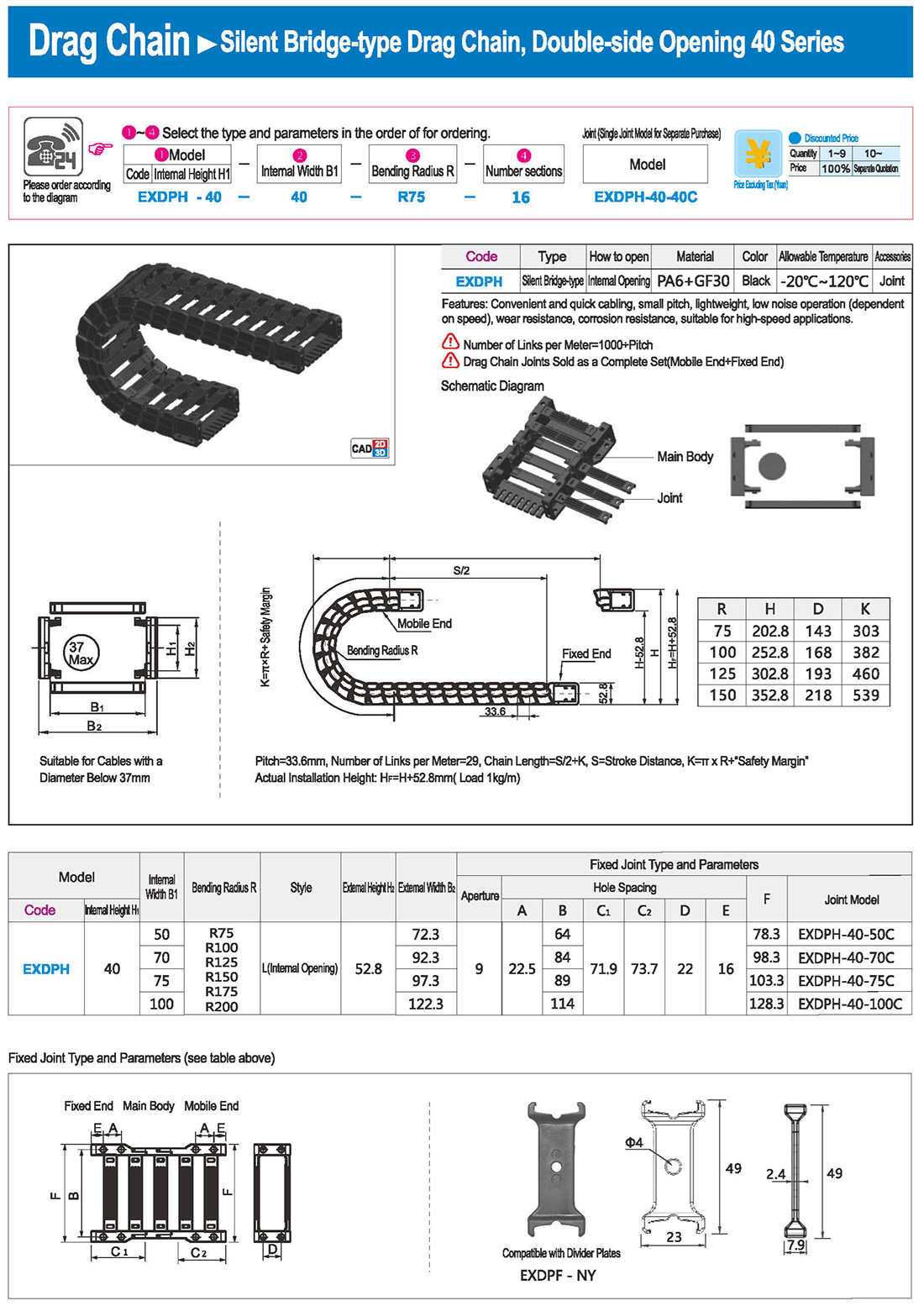

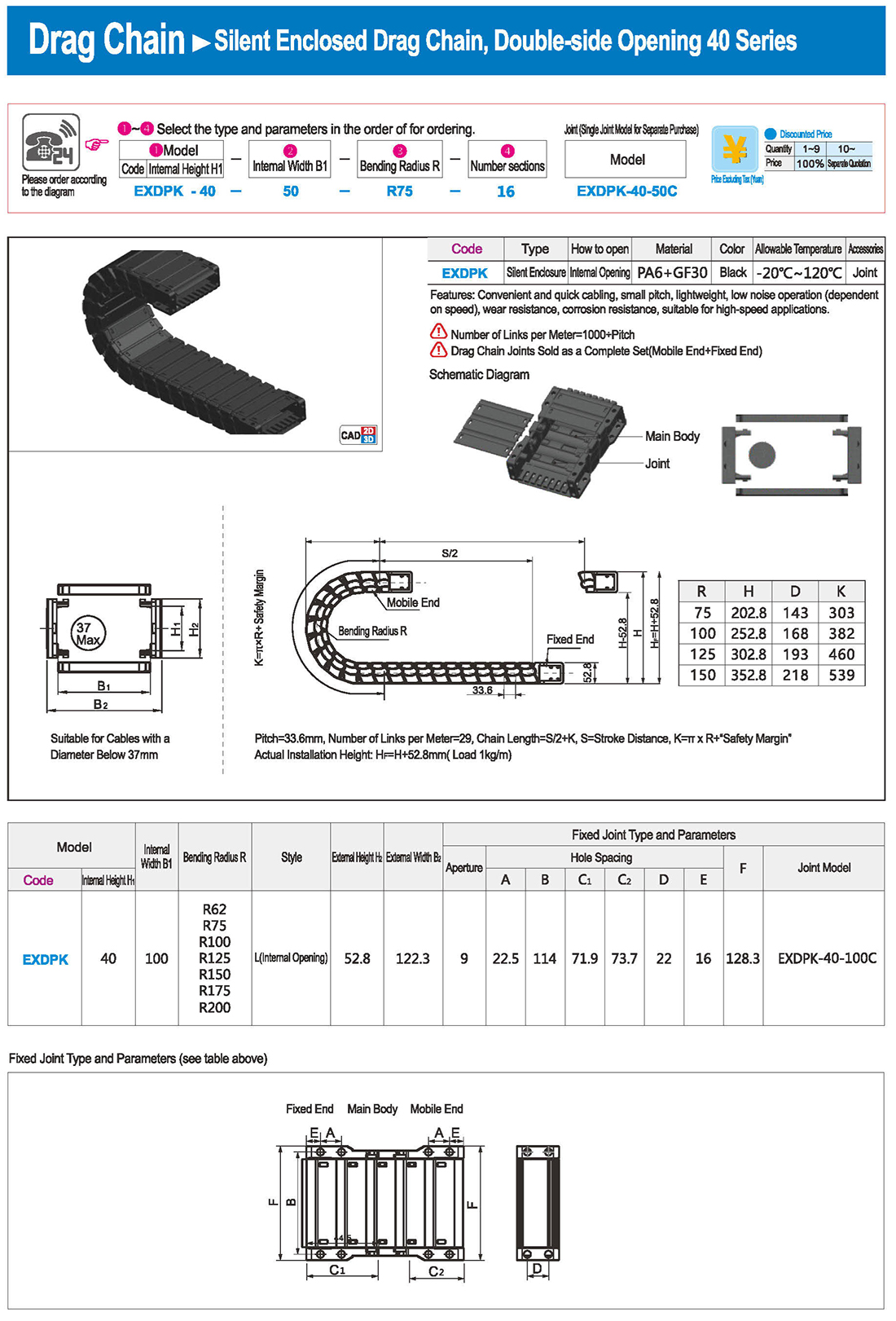

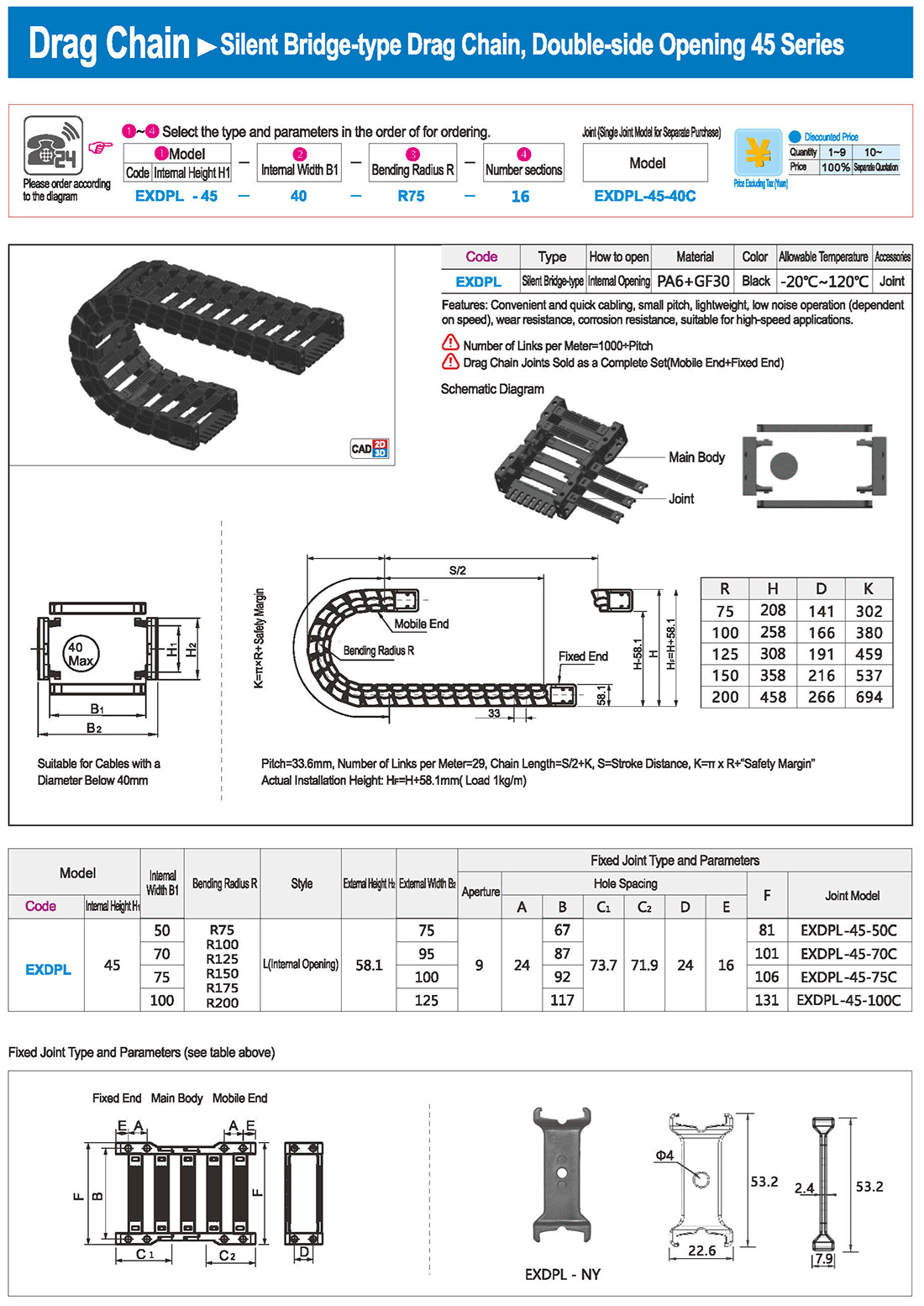

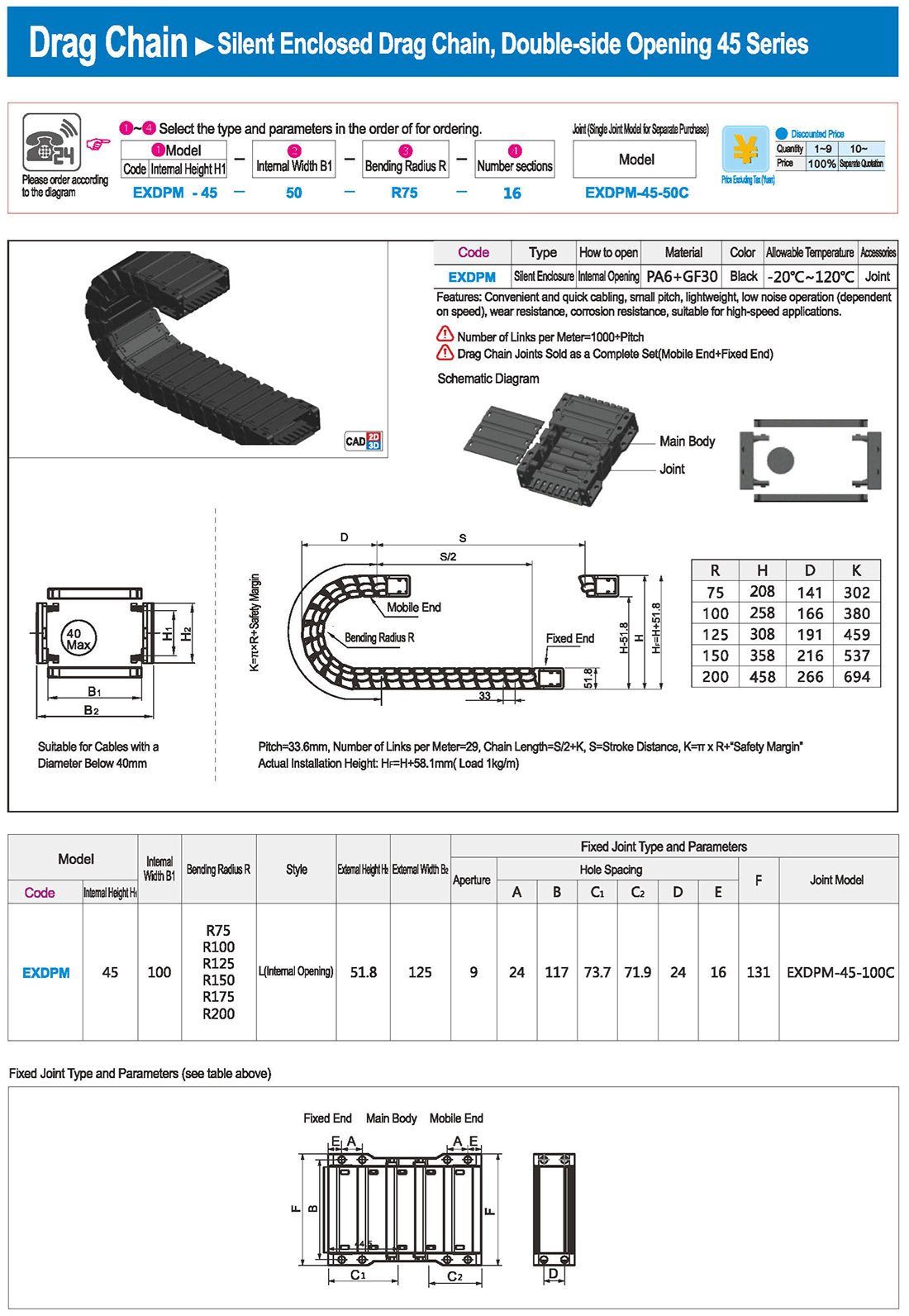

Features: Convenient and quick cabling, small pitch, lightweight, low noise operation (dependent on speed), wear resistance, corrosion resistance, suitable for high-speed applications.

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

Introduction Specification Table

Specification Table Download

Download