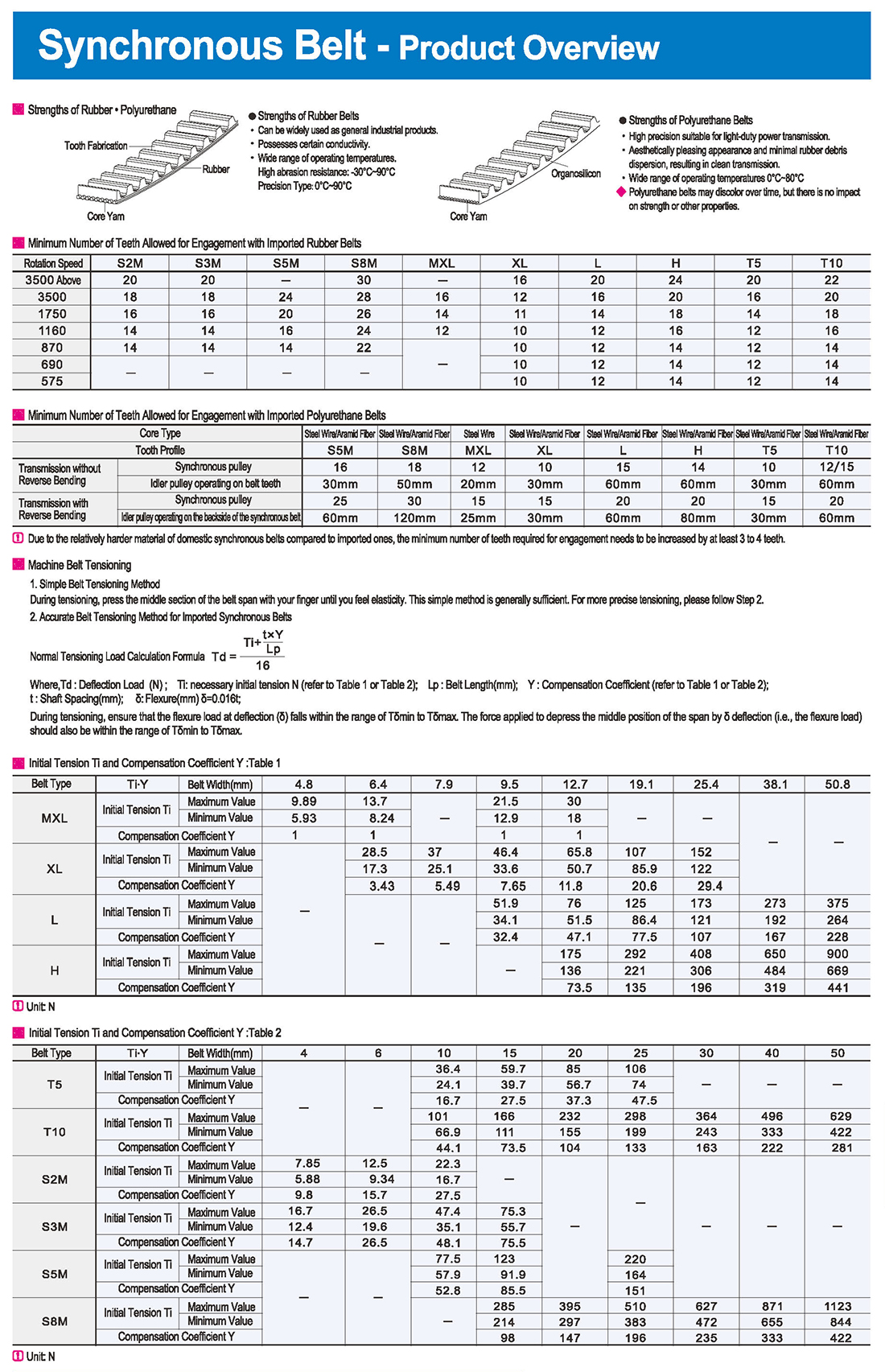

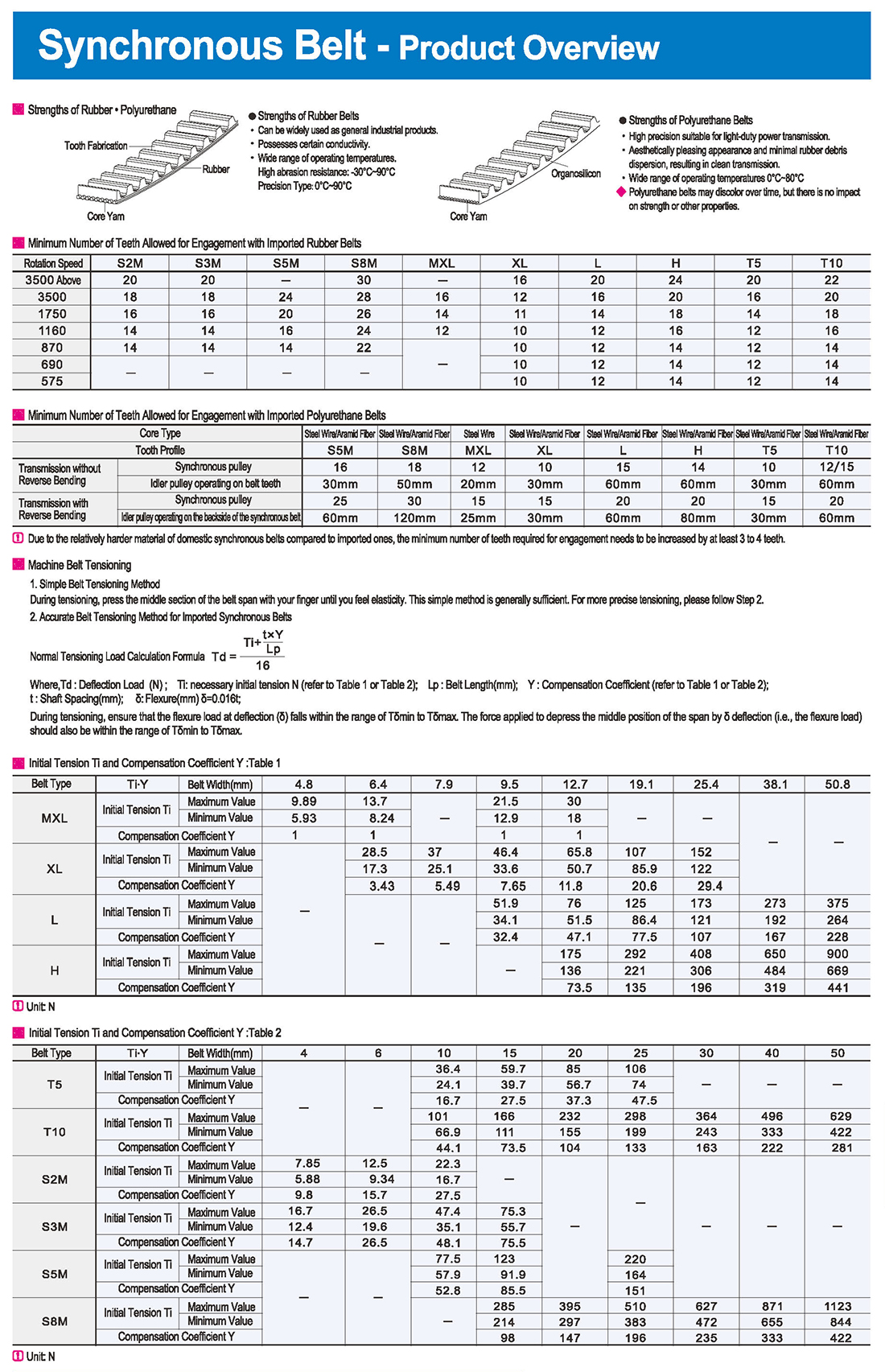

The specialty of rubber and polyurethane

Advantages of rubber belt: It can be widely used as general industrial products and has certain electrical conductivity.

Use temperature range High wear-resistant type :-30℃~90℃, economic type :0℃~90℃.

Polyurethane belt features

High precision as a light power transmission product. Beautiful appearance, little rubber debris flying, so it can achieve clean transmission.

The use temperature range of 0~80℃ polyurethane belt may change color with time, but the strength has no effect.

Due to the relatively harder material of domestic synchronous belts compared to imported ones, the minimum number of teeth required for engagement needs to be increased by at least 3 to 4 teeth.

Machine Belt Tensioning

1. Simple Belt Tensioning Method

During tensioning, press the middle section of the belt span with your finger until you feel elasticity. This simple method is generally sufficient. For more precise tensioning, please follow Step 2.

2. Accurate Belt Tensioning Method for Imported Synchronous Belts

Normal Tensioning Load Calculation Formula

Where: Deflection Load is the necessary initial tension N (refer to Table 1 or Table 2); Belt Length; Compensation Coefficient; Shaft Spacing; Flexure

During tensioning, ensure that the flexure load at deflection (δ) falls within the range of Tδmin to Tδmax. The force applied to depress the middle position of the span by δ deflection (i.e., the flexure load) should also be within the range of Tδmin to Tδmax.

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

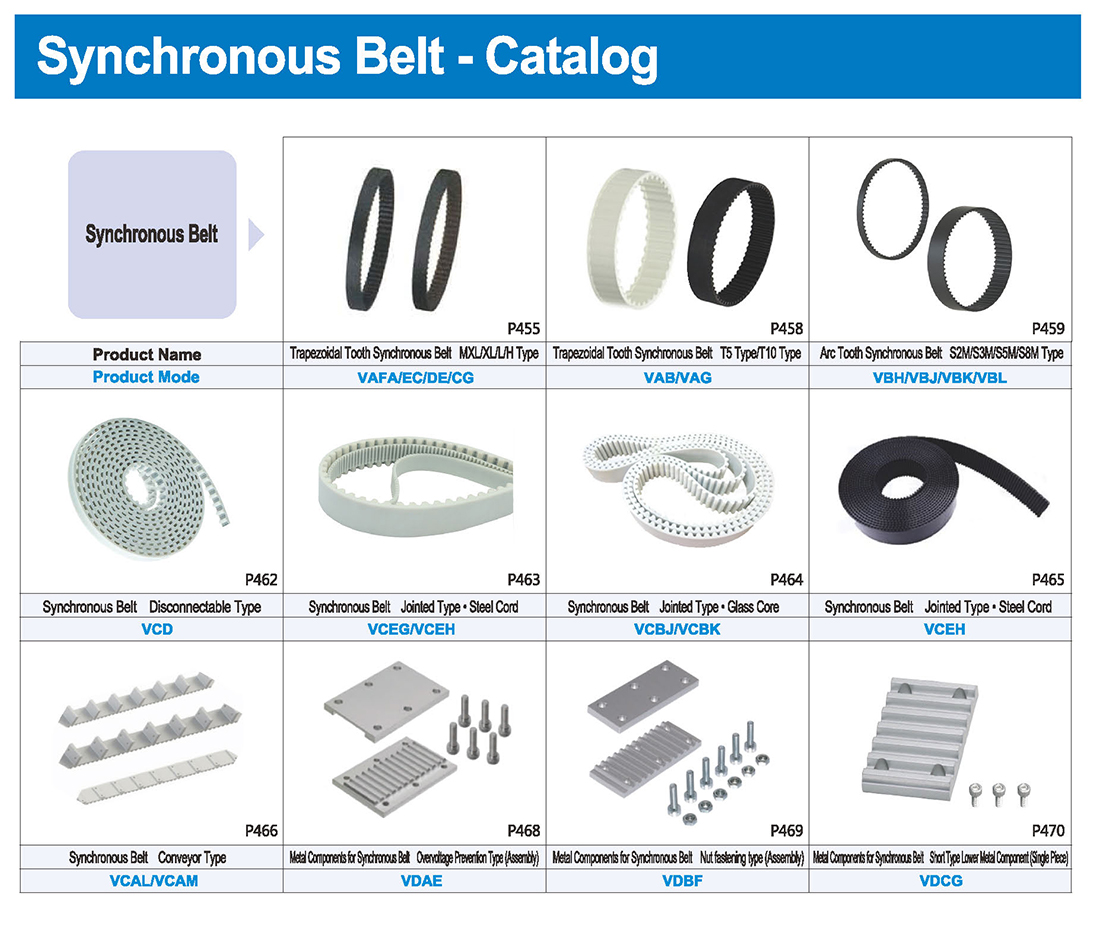

Introduction

Introduction Specification Table

Specification Table Download

Download