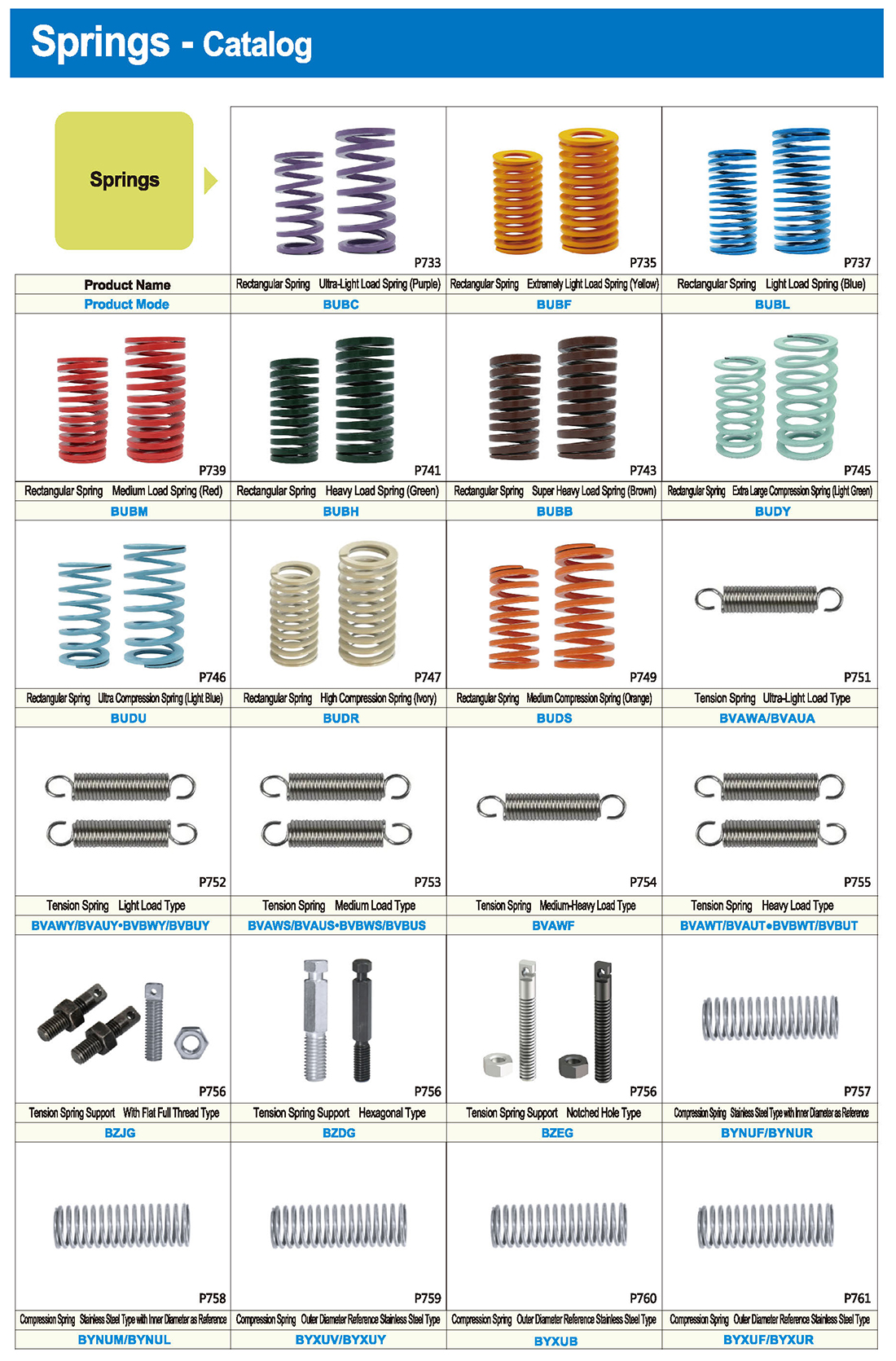

Types and characteristics of springs

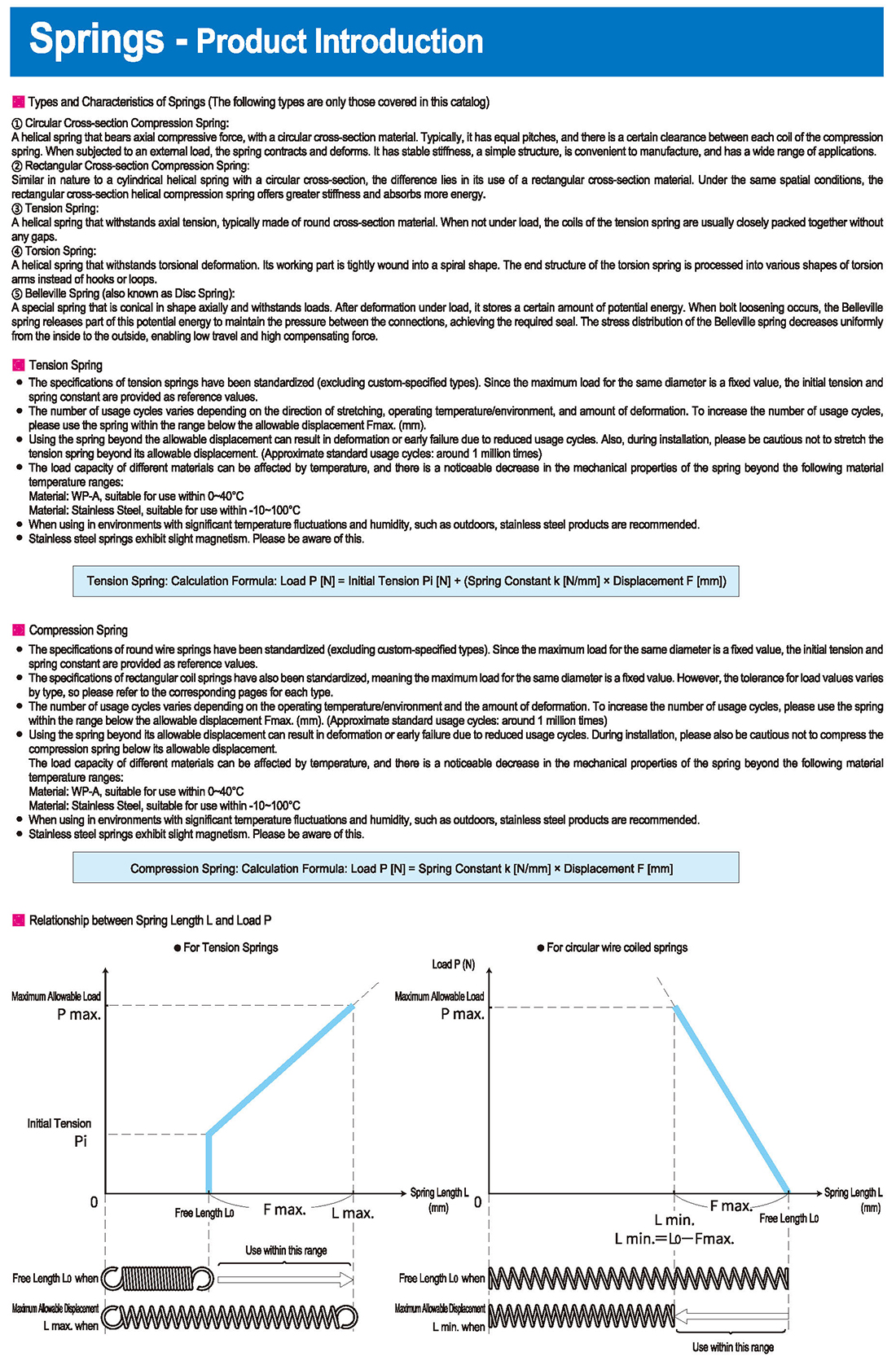

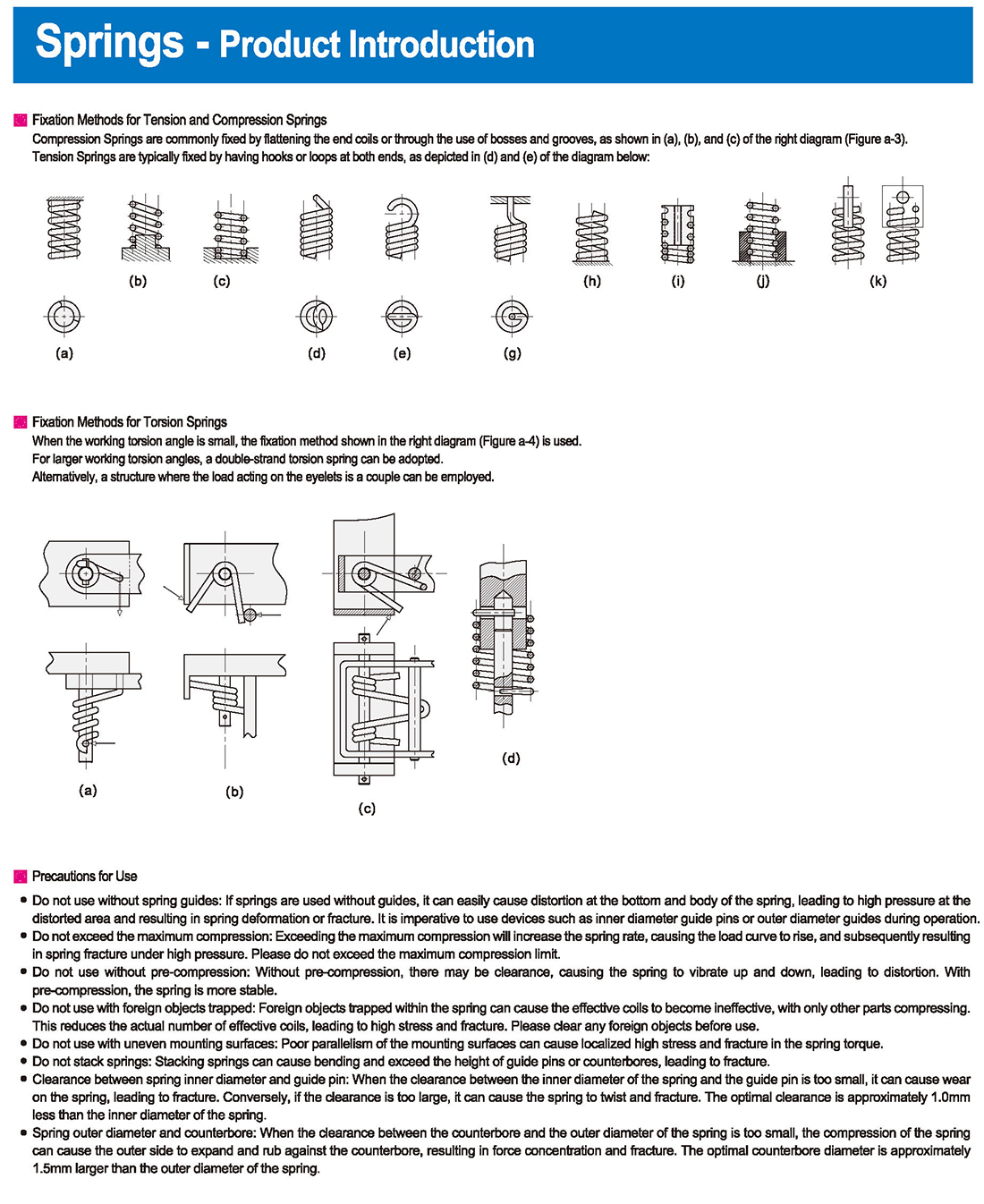

1. Circular compression spring: It is a helical spring that bears axial pressure, and the cross-section of the material used is circular. Generally equal pitch, there is a certain gap between the ring and the ring of the compression spring, and the spring will shrink and deform when subjected to external load. The stiffness is stable, the structure is simple, the manufacture is convenient, and the application is wide.

2. Rectangular section compression spring: the nature and circular section of cylindrical helical spring are similar, the difference is that the material used is rectangular. Under the same space condition, the rectangular section helical compression spring has higher stiffness and more energy absorption.

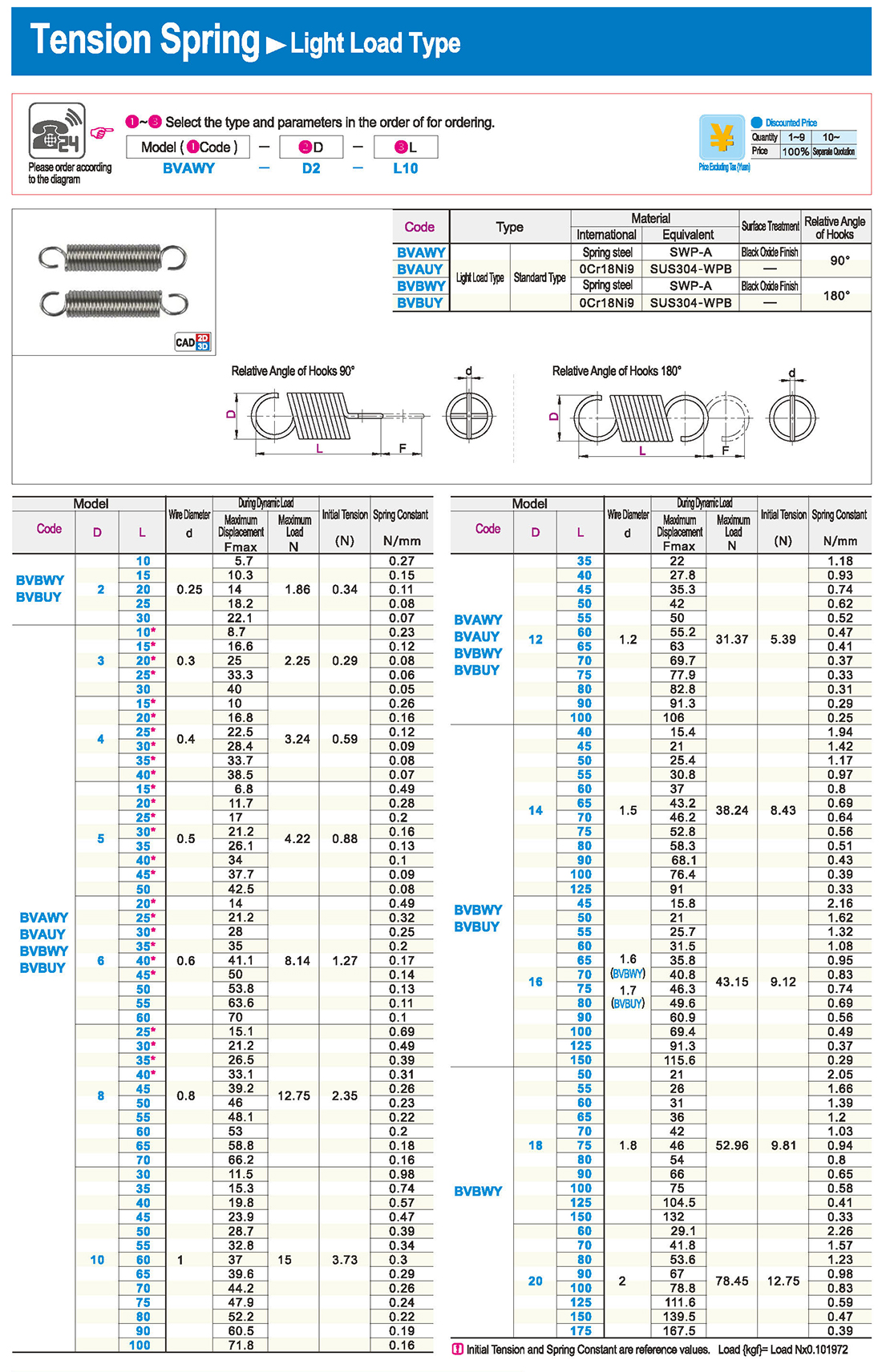

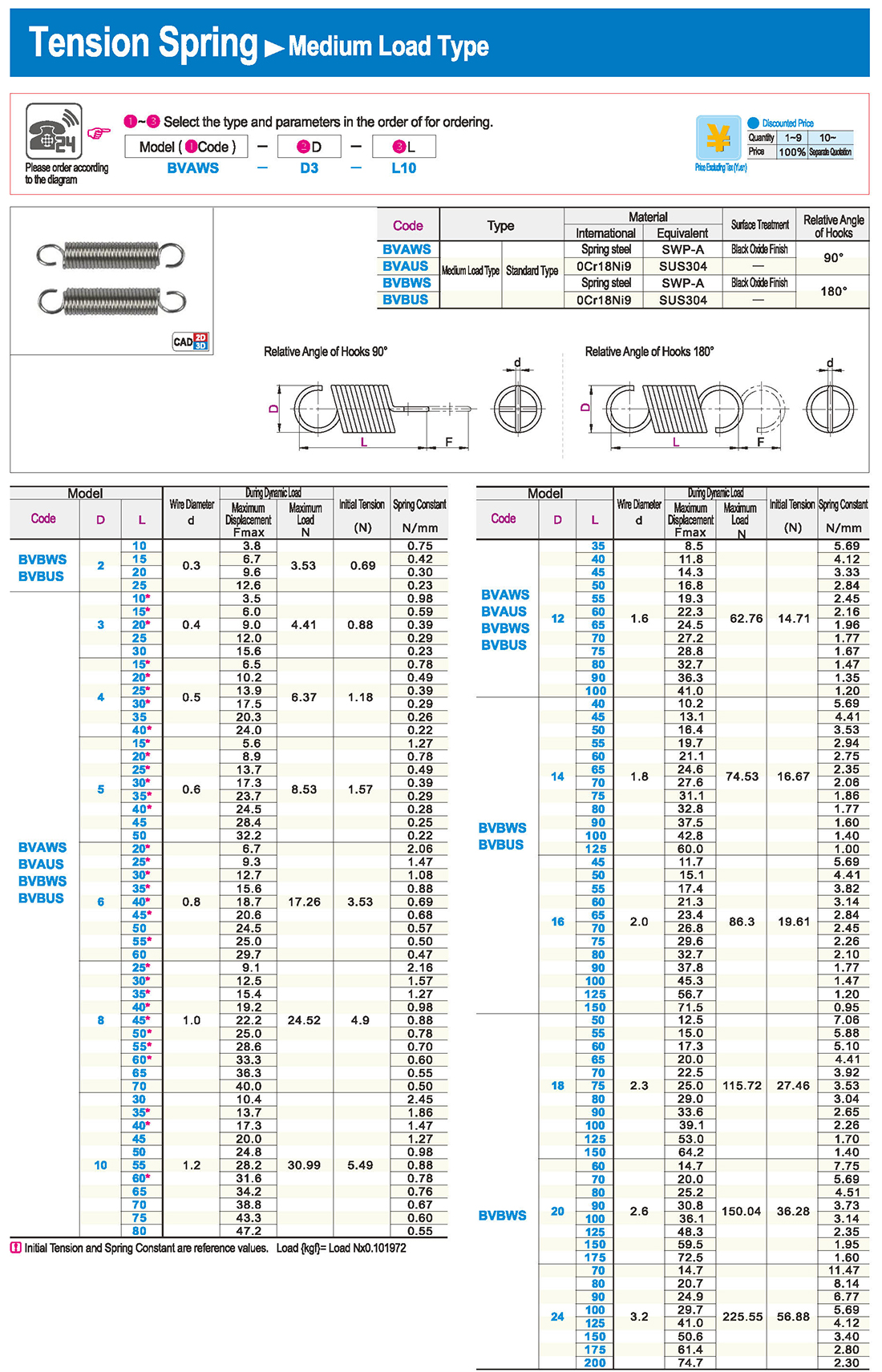

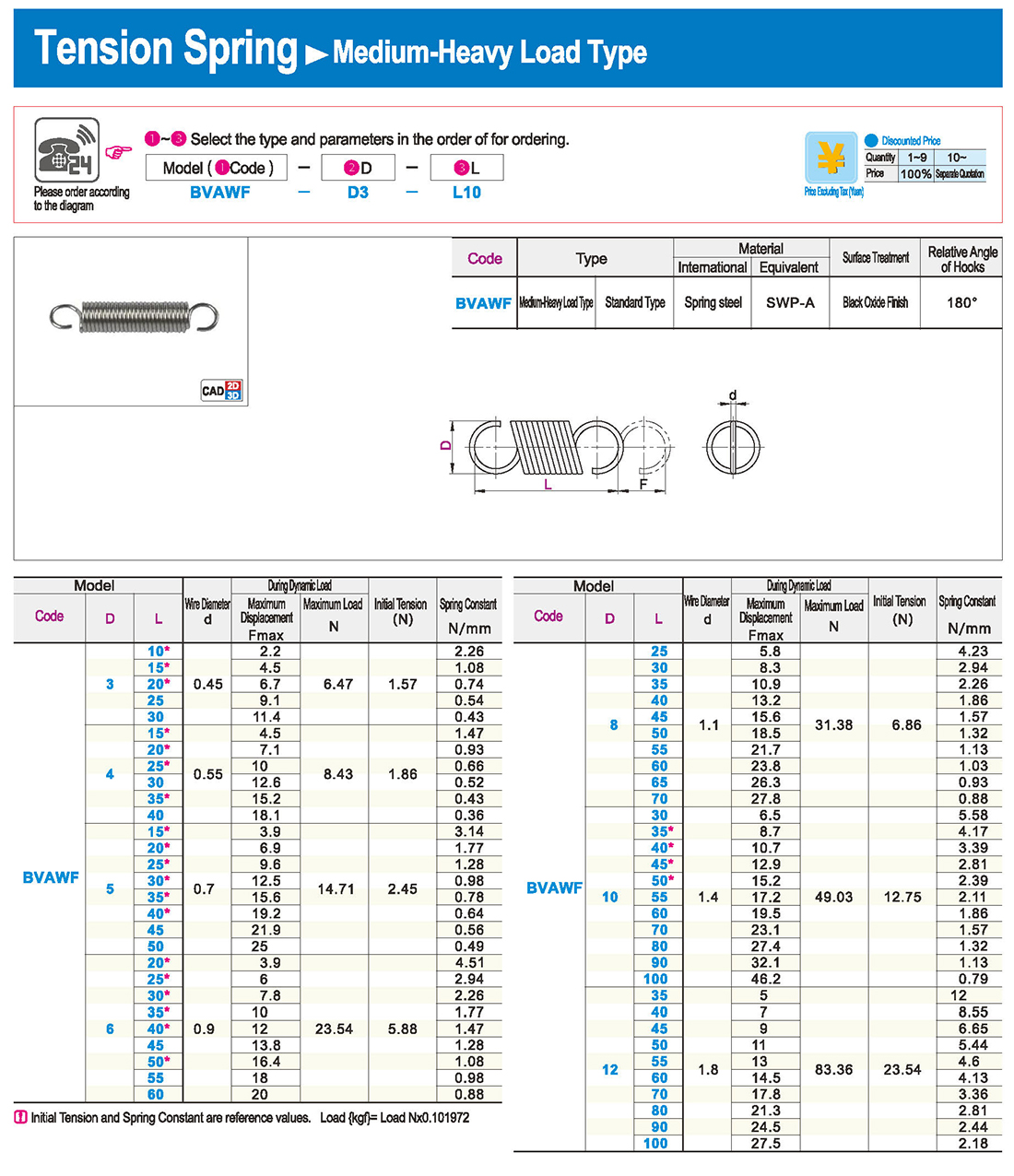

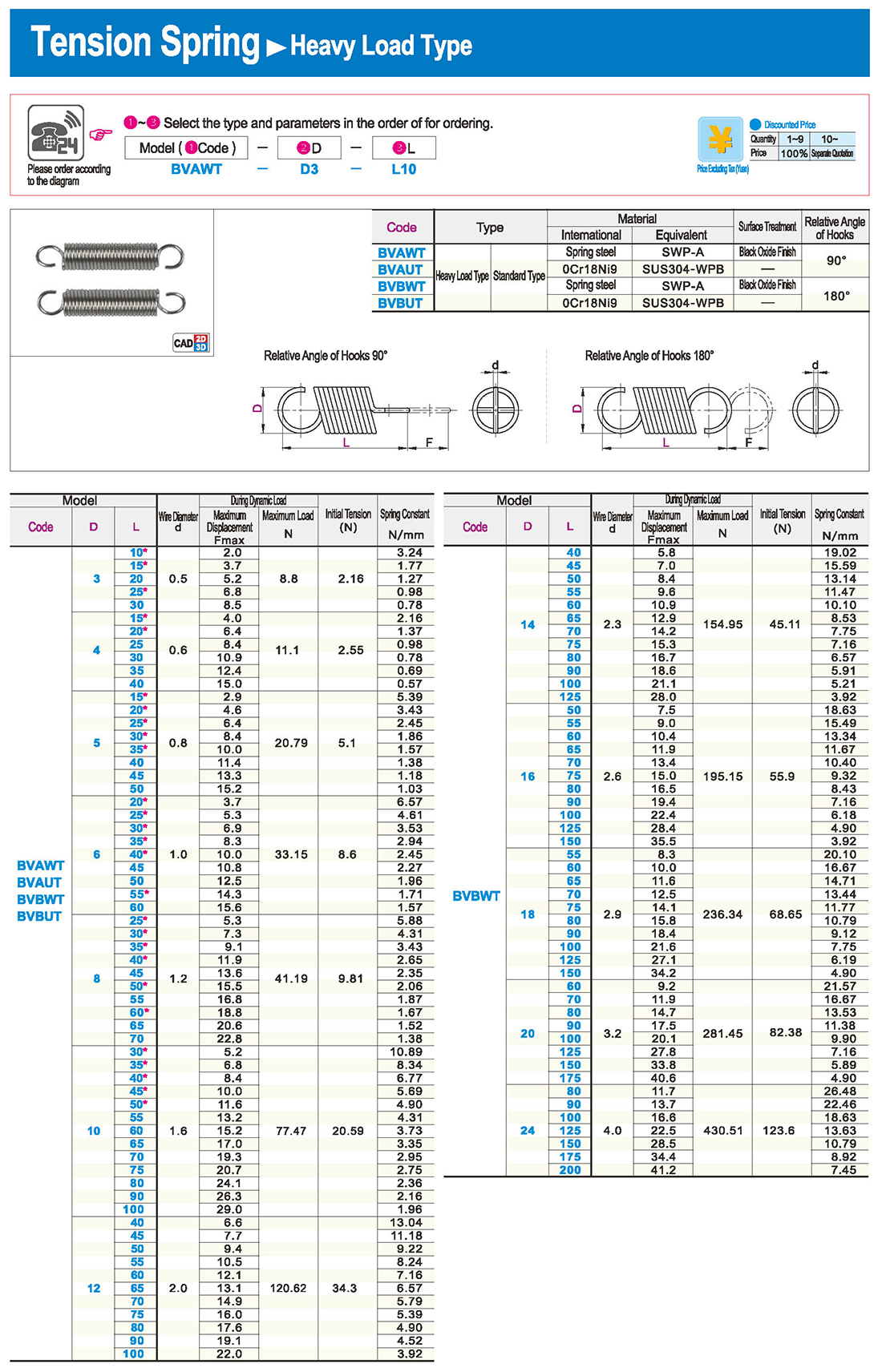

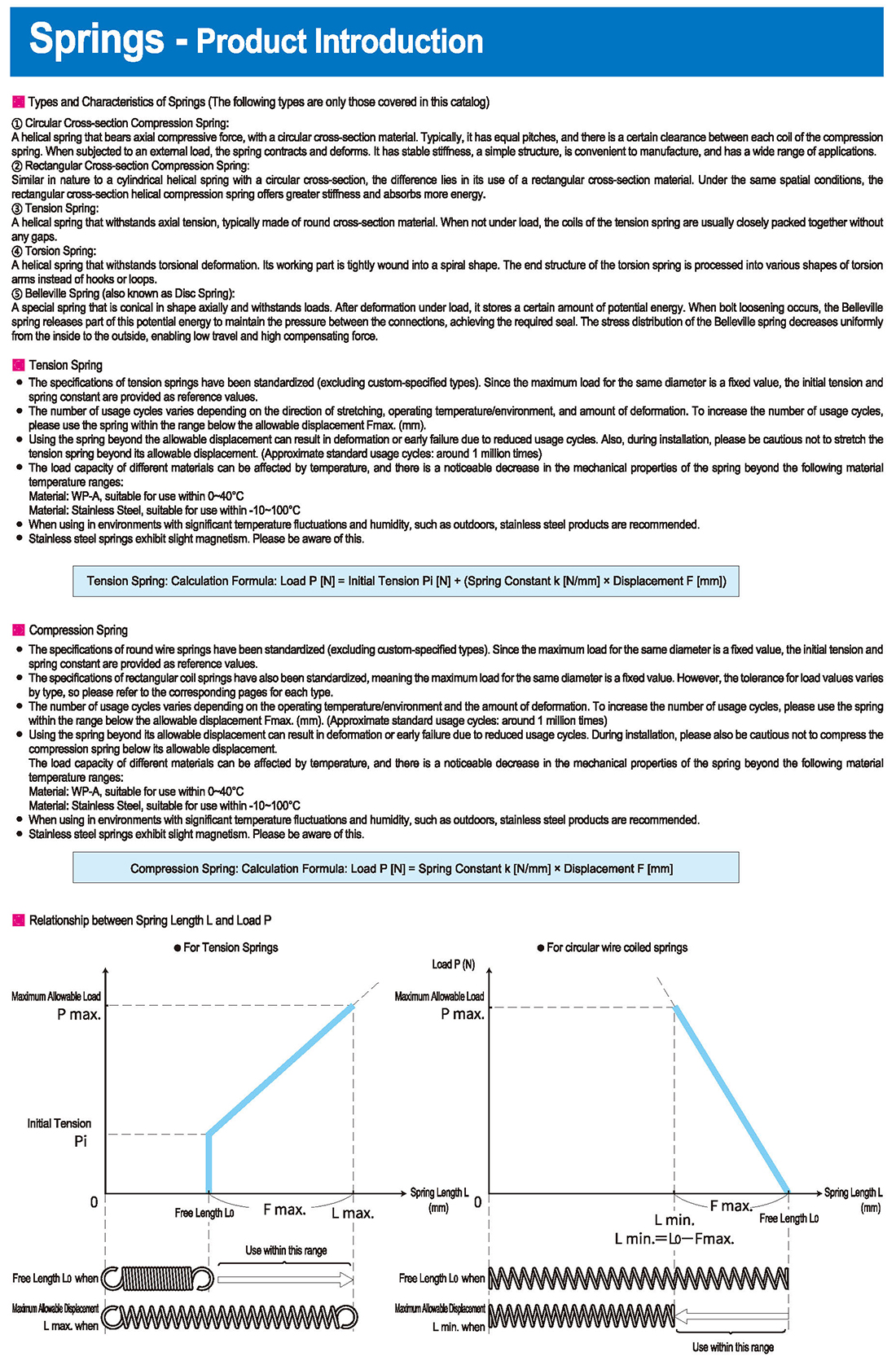

3. Tensile spring: It is a helical spring that withstands axial tension, generally made of a circular cross-section material. When the load is not borne, the tension spring between the ring and the ring are generally tight, there is no gap.

4. Torsion spring: It is a spiral spring that bears torsion deformation, and its working part is tightly wound into a spiral shape. The end structure of the torsion spring is machined into twisting arms of various shapes instead of carabiners.

5. Dish spring: It is a special spring that is conical in the axis and bears the load. After bearing the load deformation, it saves a certain potential energy. When the bolt relaxes, the dish spring releases part of the potential energy to keep the pressure between the blue connection to meet the sealing requirements.

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

Introduction Specification Table

Specification Table Download

Download