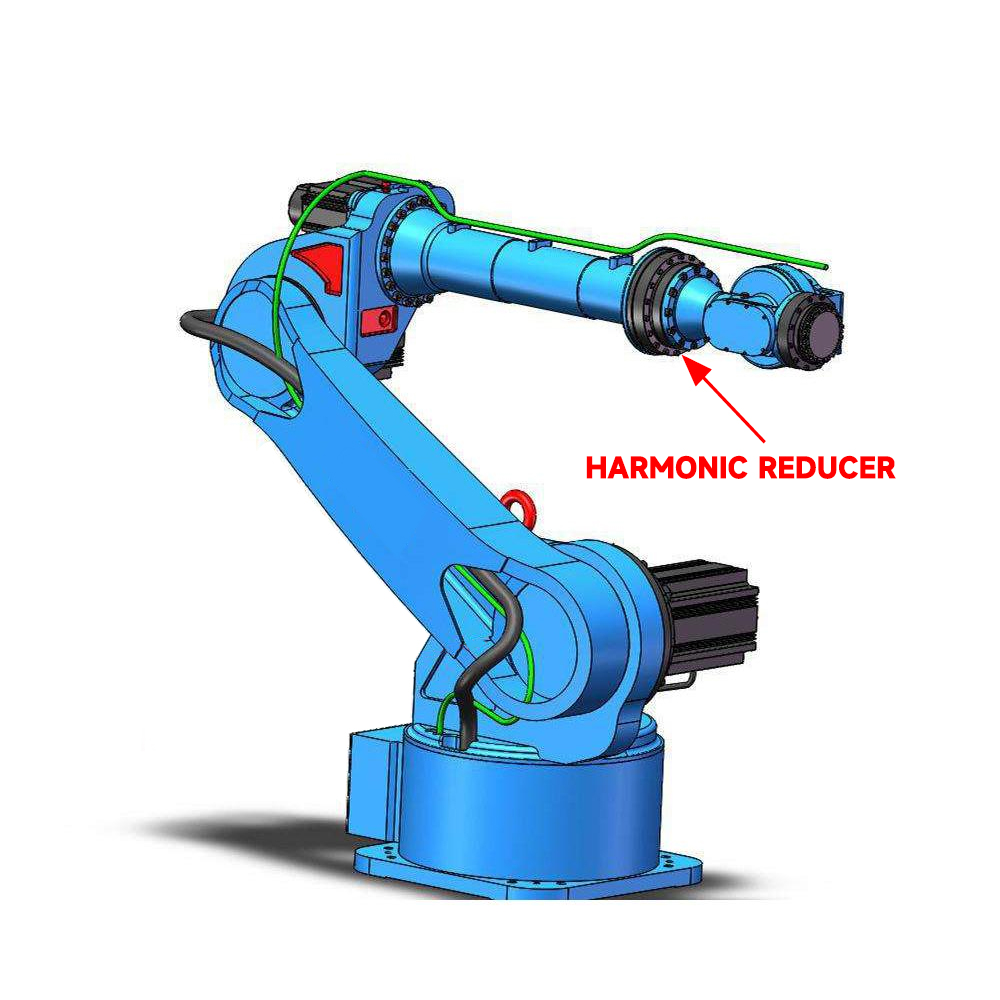

Industry professionals in the field of industrial robotics are well aware of one of the three core components of industrial robots — the harmonic reducer. This crucial component, sometimes no larger than a palm, consists primarily of four basic parts: the wave generator, flexible gear, flexible bearing, and rigid gear. It is a type of gear transmission that relies on the wave generator fitted with a flexible bearing to cause controlled elastic deformation of the flexible gear, which then meshes with the rigid gear to transmit motion and power.

With the development of Industry 4.0, many traditional manufacturing factories have begun transforming into smart factories. Industrial robots are now widely used in enterprises, not only saving labor but also effectively increasing work efficiency, reducing production costs, and improving product quality and output.

As a critical component of industrial robots, the demand for harmonic reducers has significantly increased with the rapid development of smart factories. Industries such as mobile phone manufacturing, semiconductors, and LCD production machinery have shown a growing need for small robots.

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish