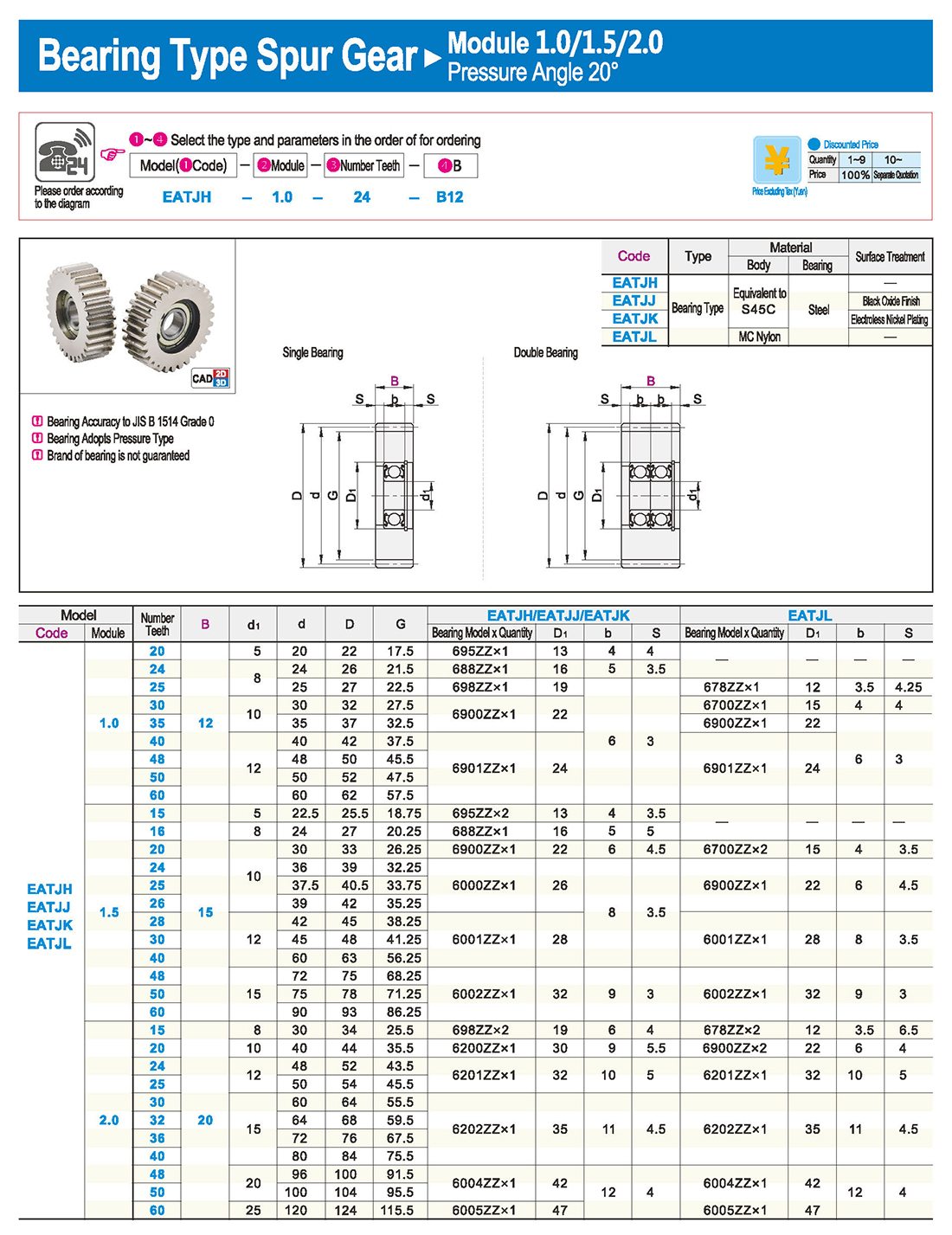

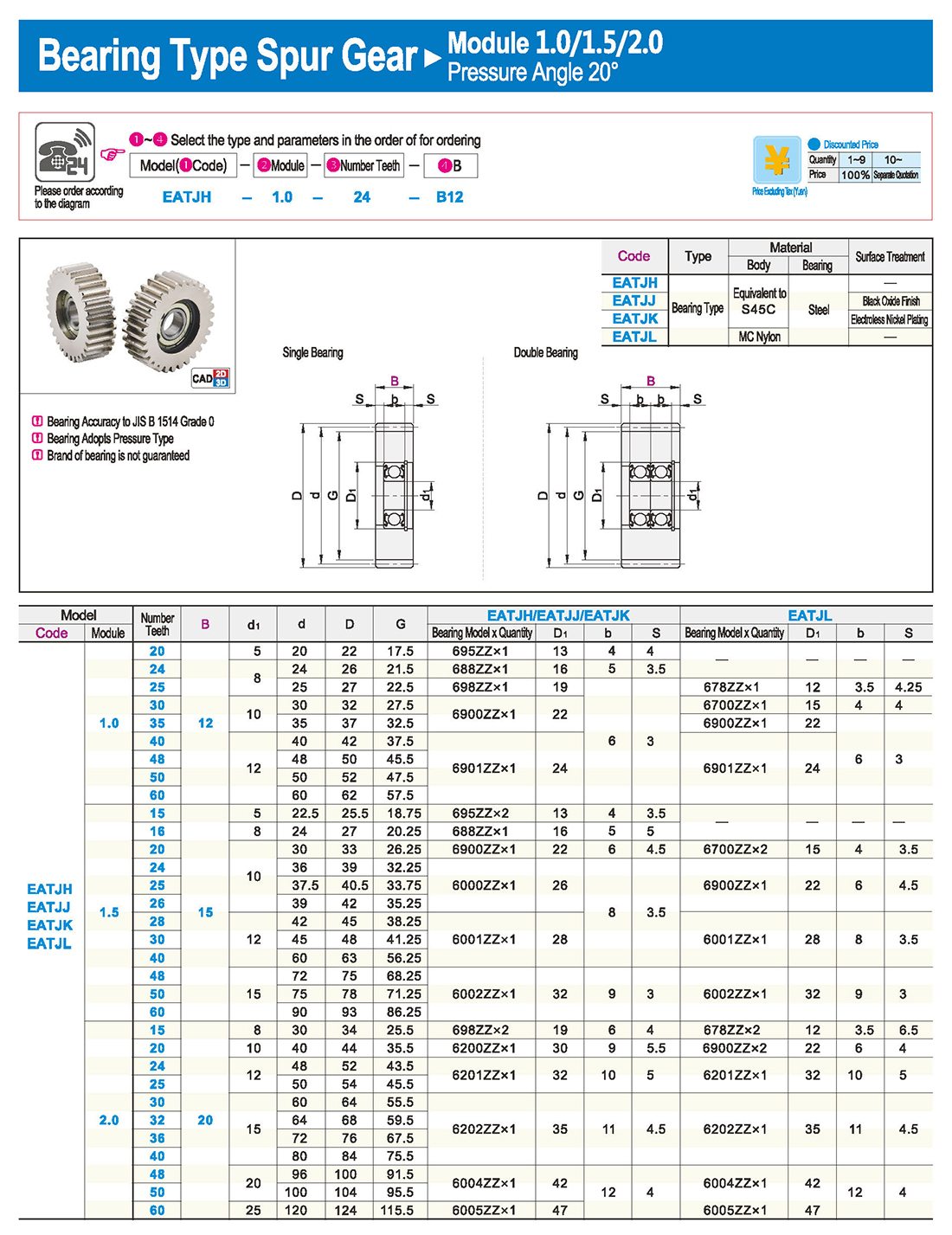

1. Integrated design:

Bearing type gears combine the functions of gears and bearings into one, achieving compact structure and space saving.

This integrated design simplifies the mechanical structure and reduces the complexity and weight of the equipment.

2. High torque transmission capacity:

Due to the involvement of the gear, the bearing type gear can transmit higher torque.

This makes it excellent in applications that require high torque transmission, such as heavy machinery equipment and high-speed transmission systems.

Bearing type gears combine bearing rotation and shift functions with gear ratio control to provide precise motion control.

This is essential for mechanical devices that require high precision positioning and motion control

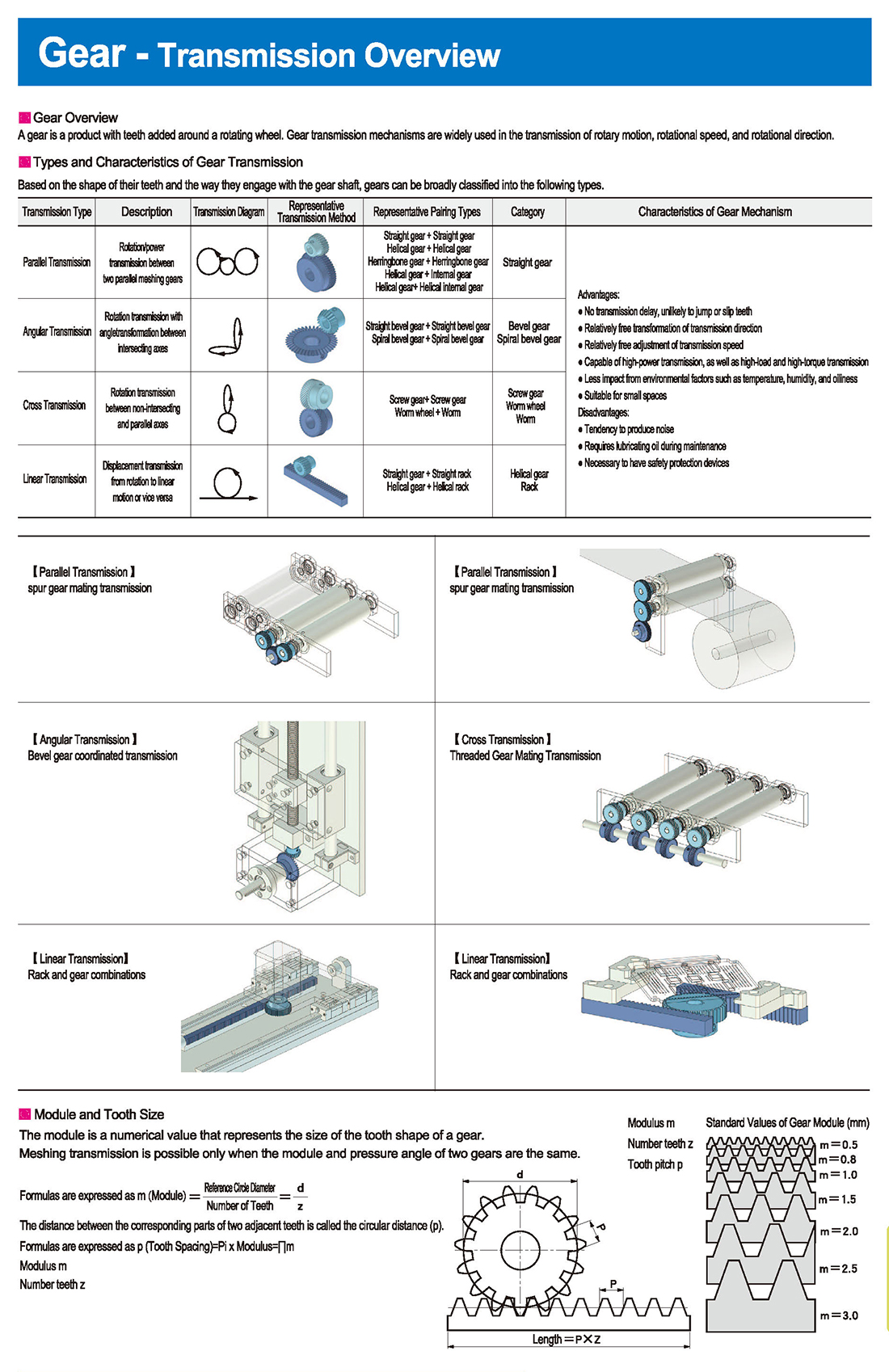

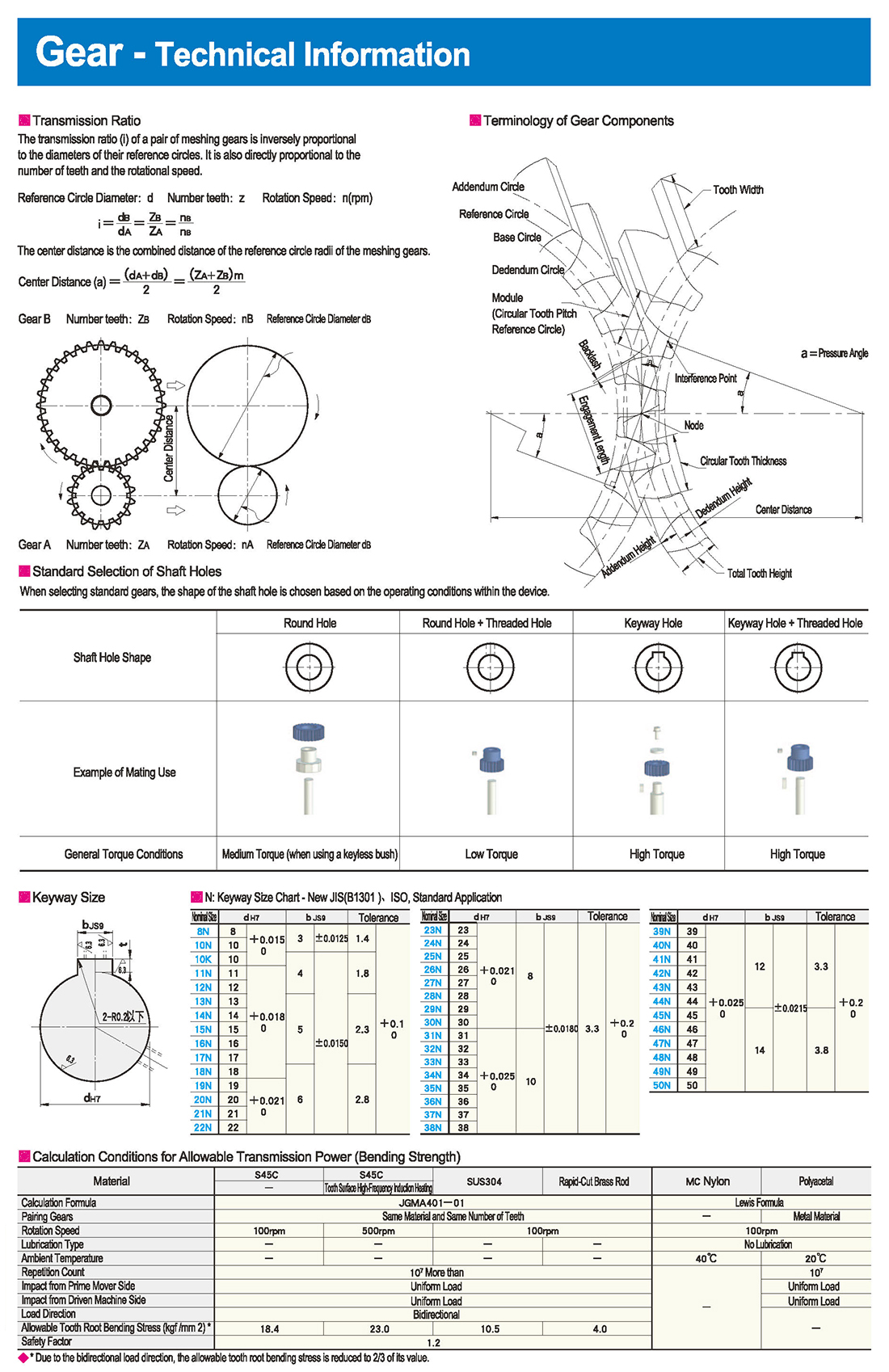

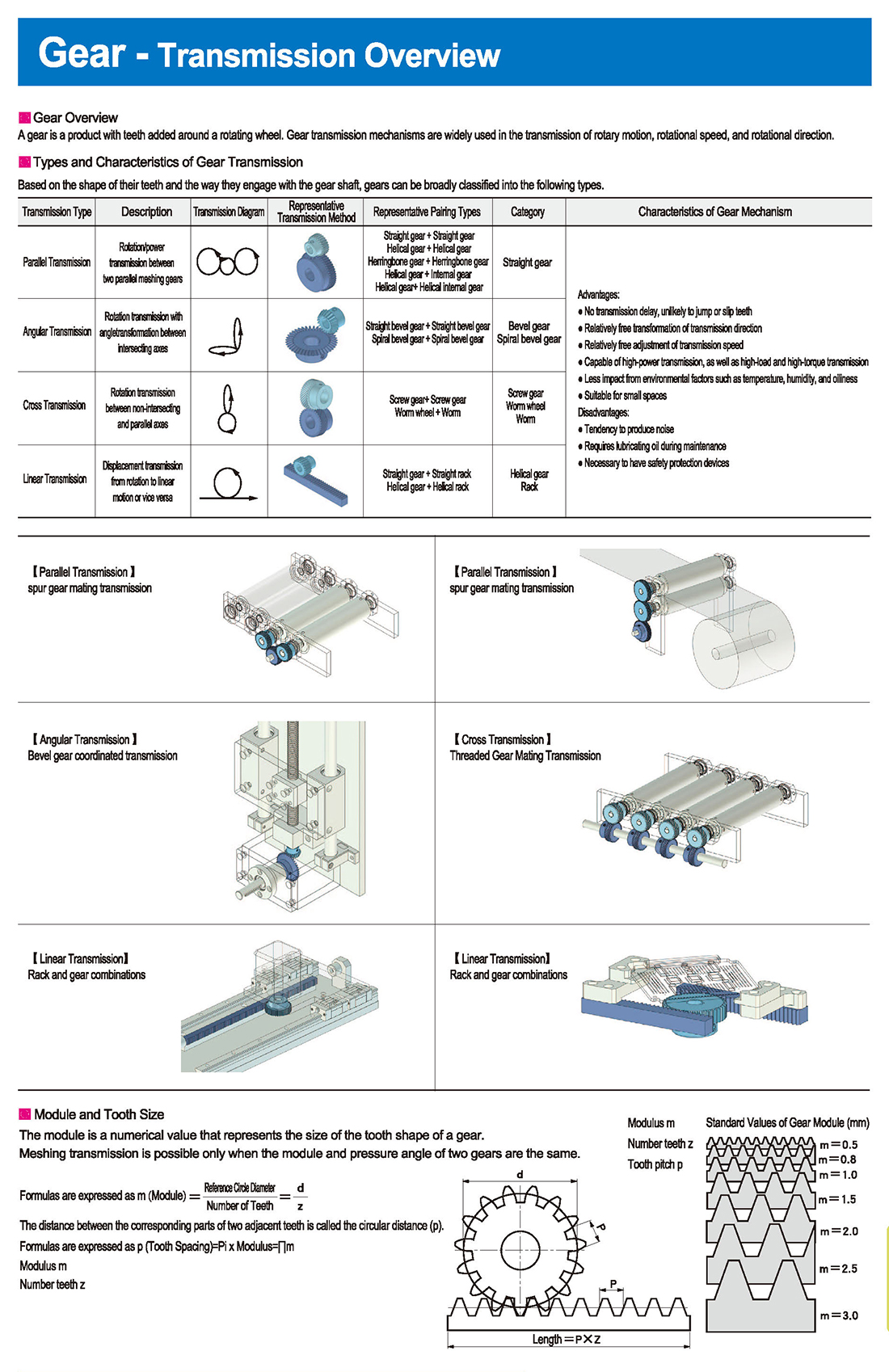

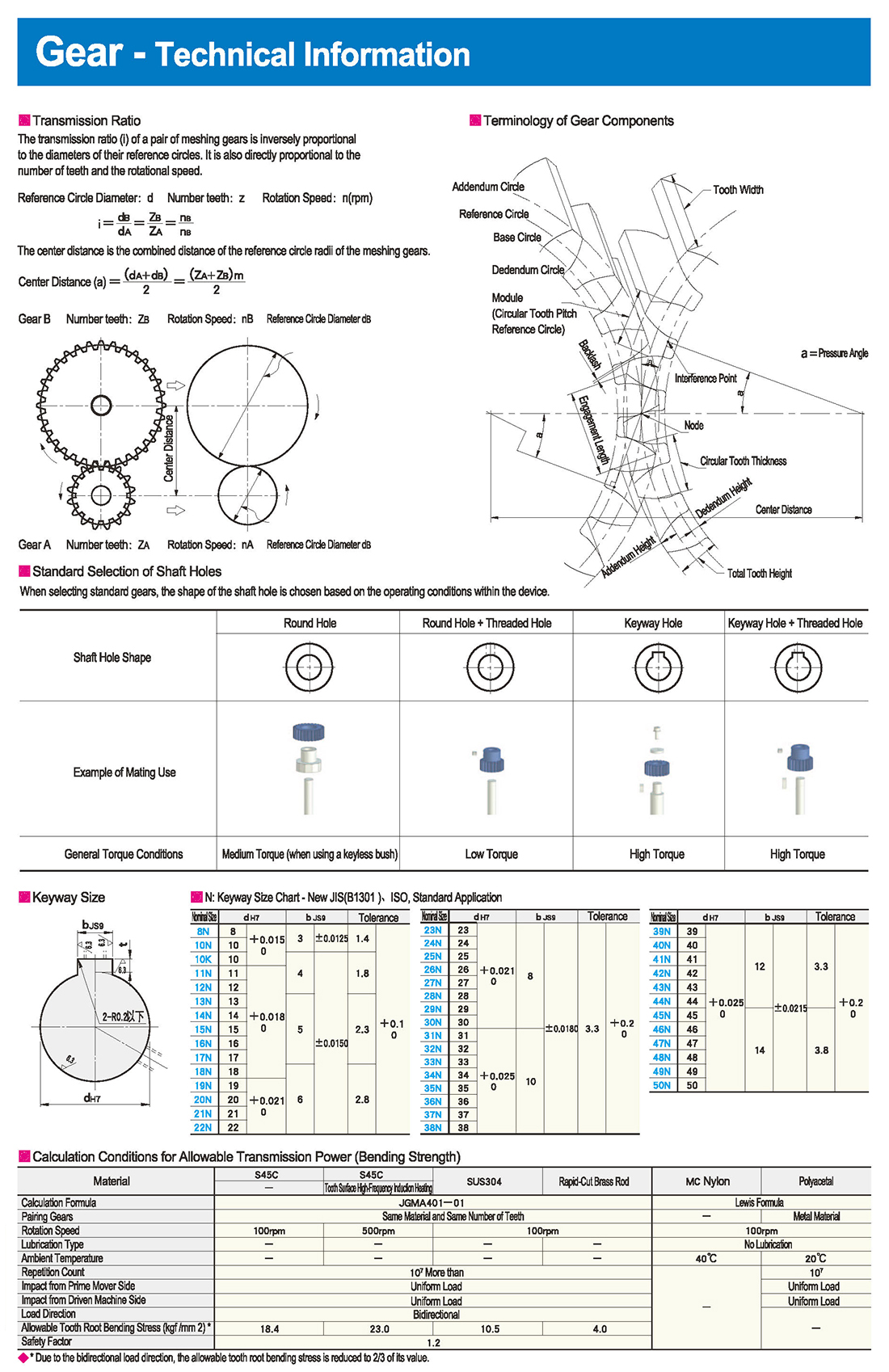

Types and Characteristics of Gear Transmission

①Parallel Transmission Rotation/power transmission between two parallel meshing gears Straight gear + Helical gear + Internal gear + Herringbone gear + Helical internal gear

②Angular Transmission Rotation transmission with angle transformation between intersecting axes Straight bevel gear + Spiral bevel gear Bevel gear

③Cross Transmission Rotation transmission between non-intersecting and parallel axes Screw gear Worm wheel + Worm

④Linear Transmission Displacement transmission from rotation to linear motion or vice versa Straight rack + Helical rack

Advantages:

* No transmission delay, unlikely to jump or slip teeth

*Relatively free transformation of transmission direction

* Relatively free adjustment of transmission speed

*Capable of high-power transmission, as well as high-load and high-torque transmission

* Less impact from environmental factors such as temperature, humidity, and oiliness

* Suitable for small spaces

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

Introduction Specification Table

Specification Table Download

Download