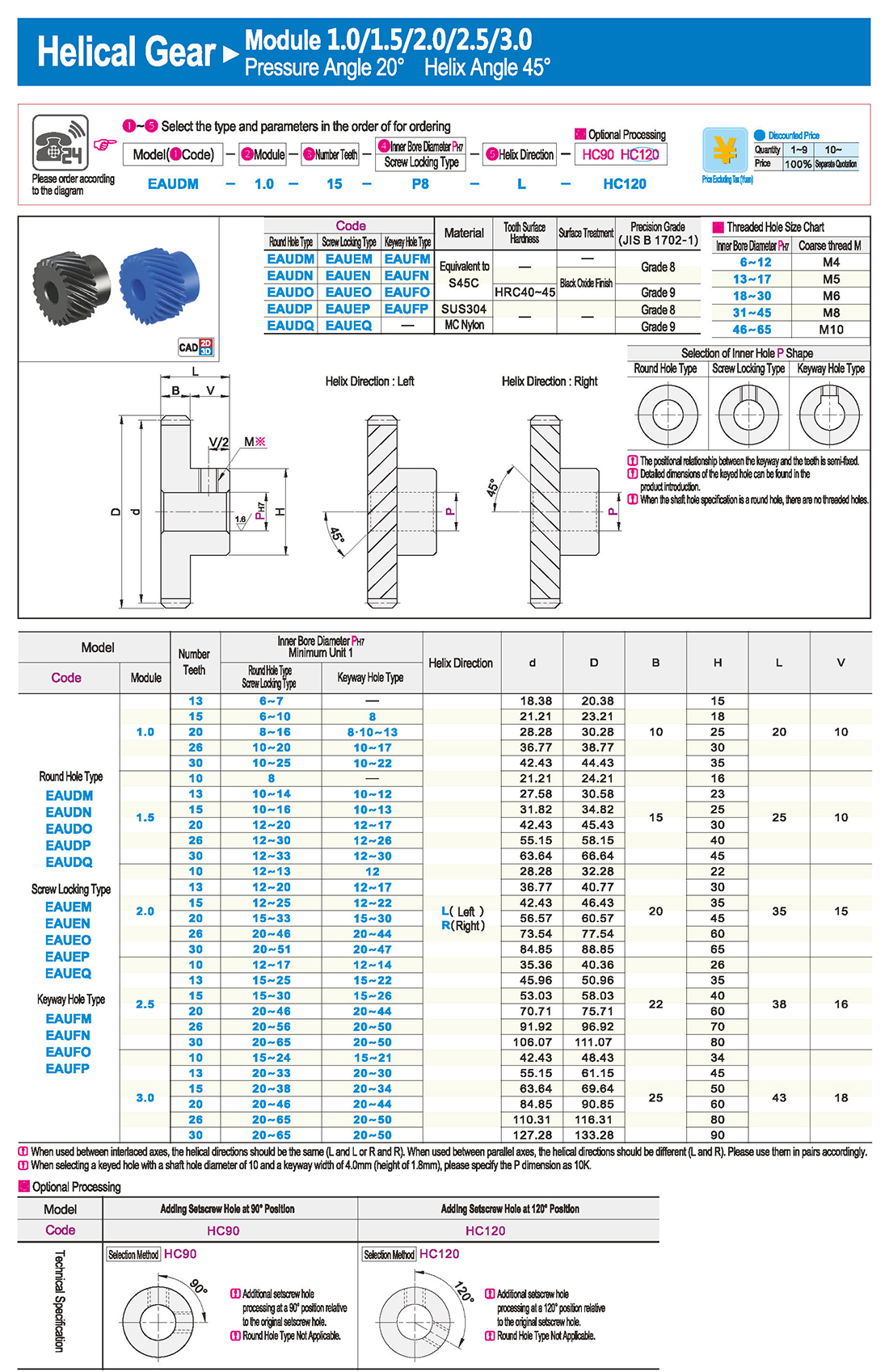

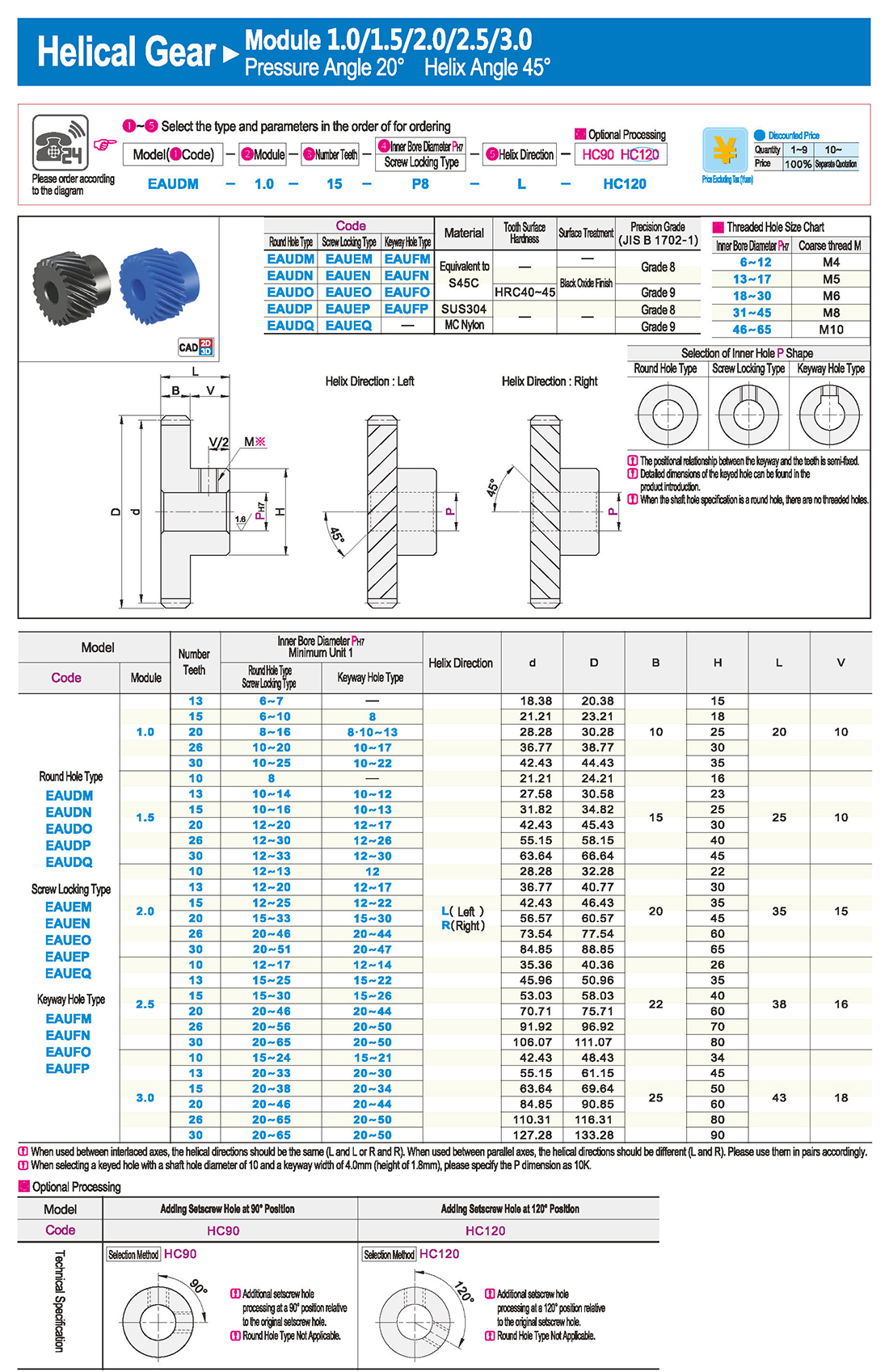

Helical gear, that is, helical tooth cylindrical gear, the tooth line is a cylindrical helix, which is mainly used to transmit the movement between neither intersecting nor parallel axes.

1. Smooth transmission:

The tooth peak and tooth valley of the helical gear are bevelled, and the gear is in a progressive state during meshing, which reduces the impact and vibration and makes the transmission more stable.

2. Low noise:

Due to the number of meshing teeth of the helical gear, the transmission power distribution between the tooth surfaces is smoother, so the noise is relatively small.

This is particularly important in machinery that requires low noise levels.

3. High efficiency:

Helical gear transmission efficiency is usually higher, generally can reach more than 98%, much higher than the traditional vertical gear of about 90%.

High efficiency transmission helps to reduce energy loss and improve the overall performance of the equipment.

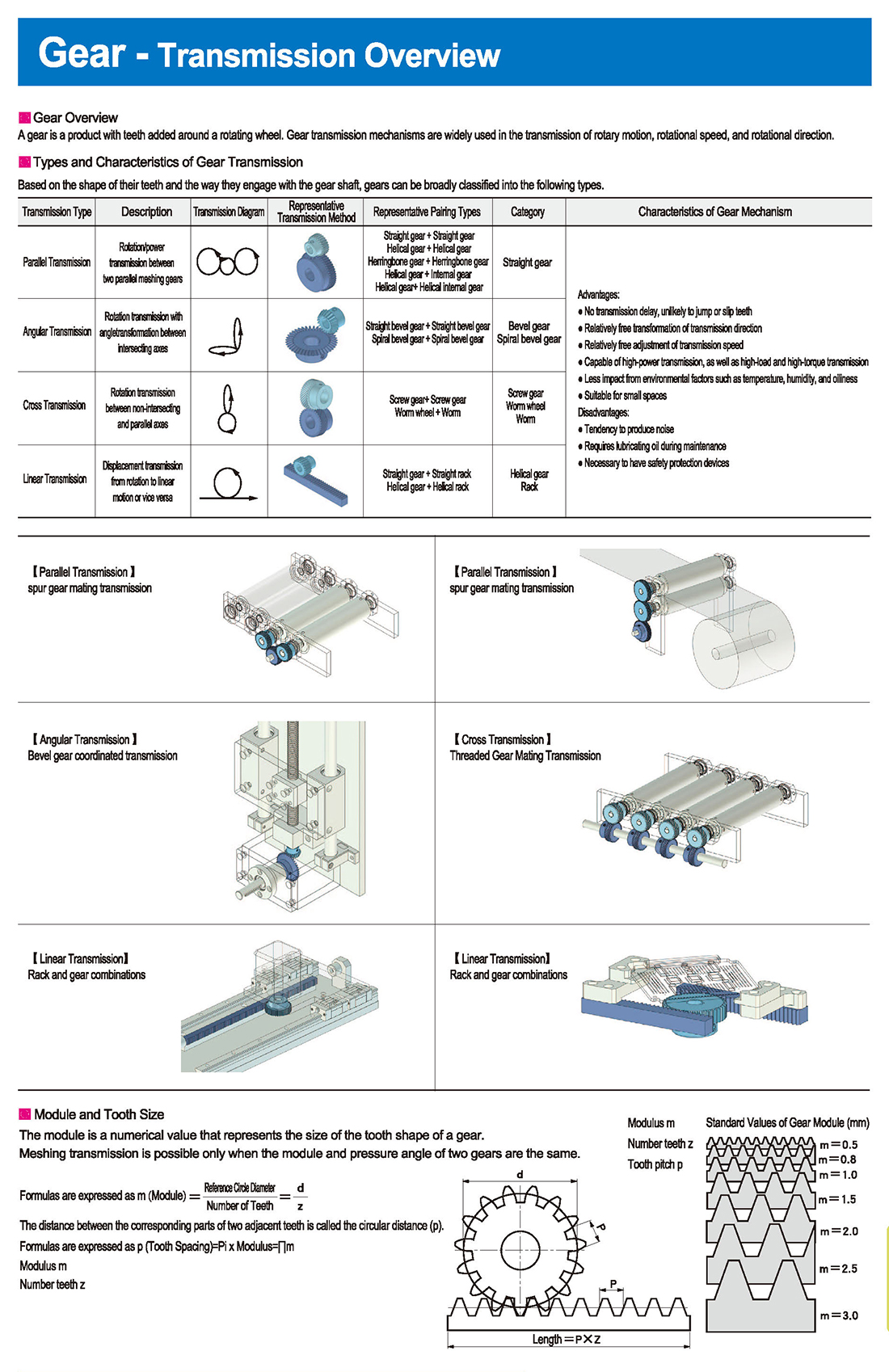

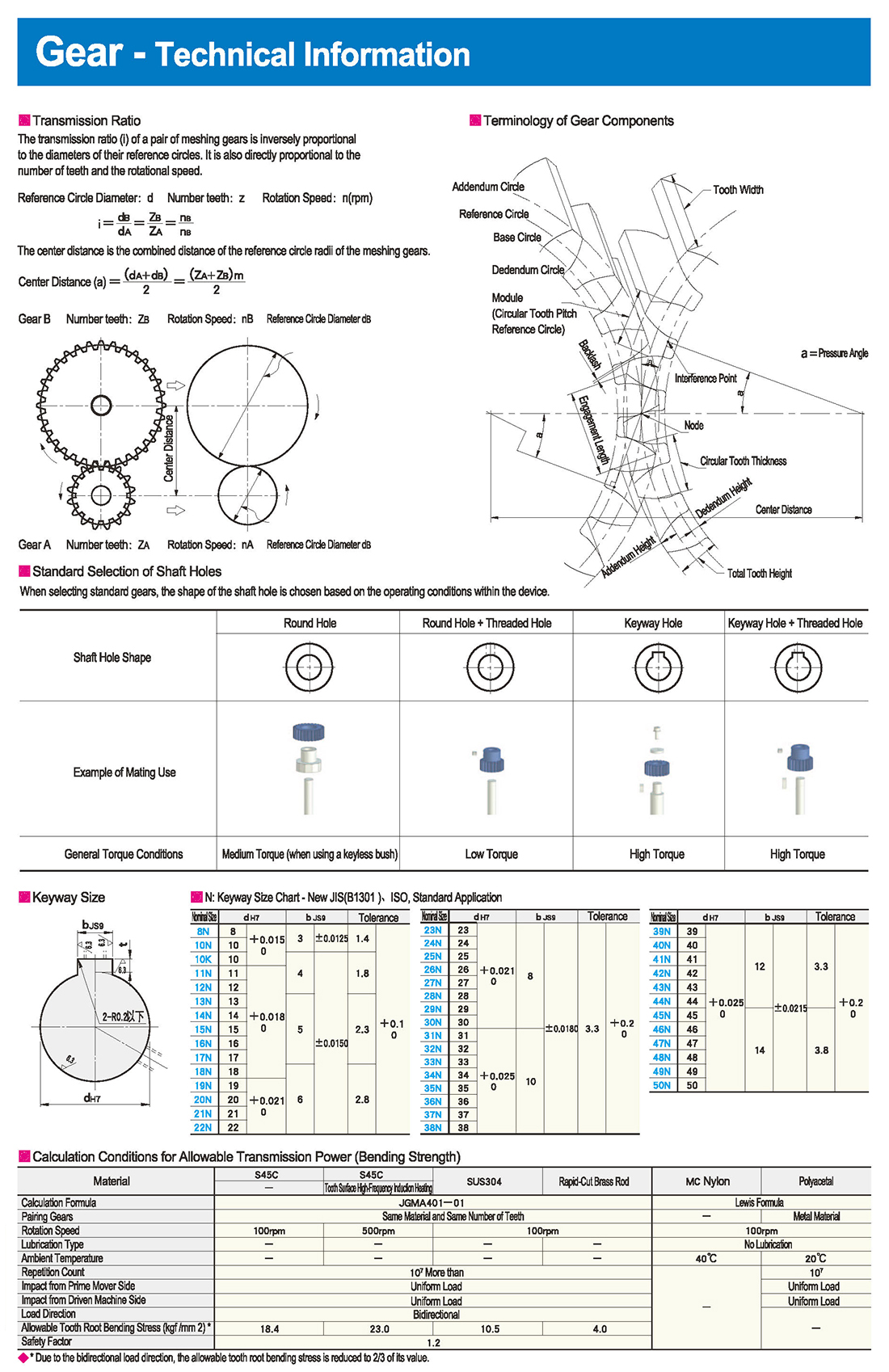

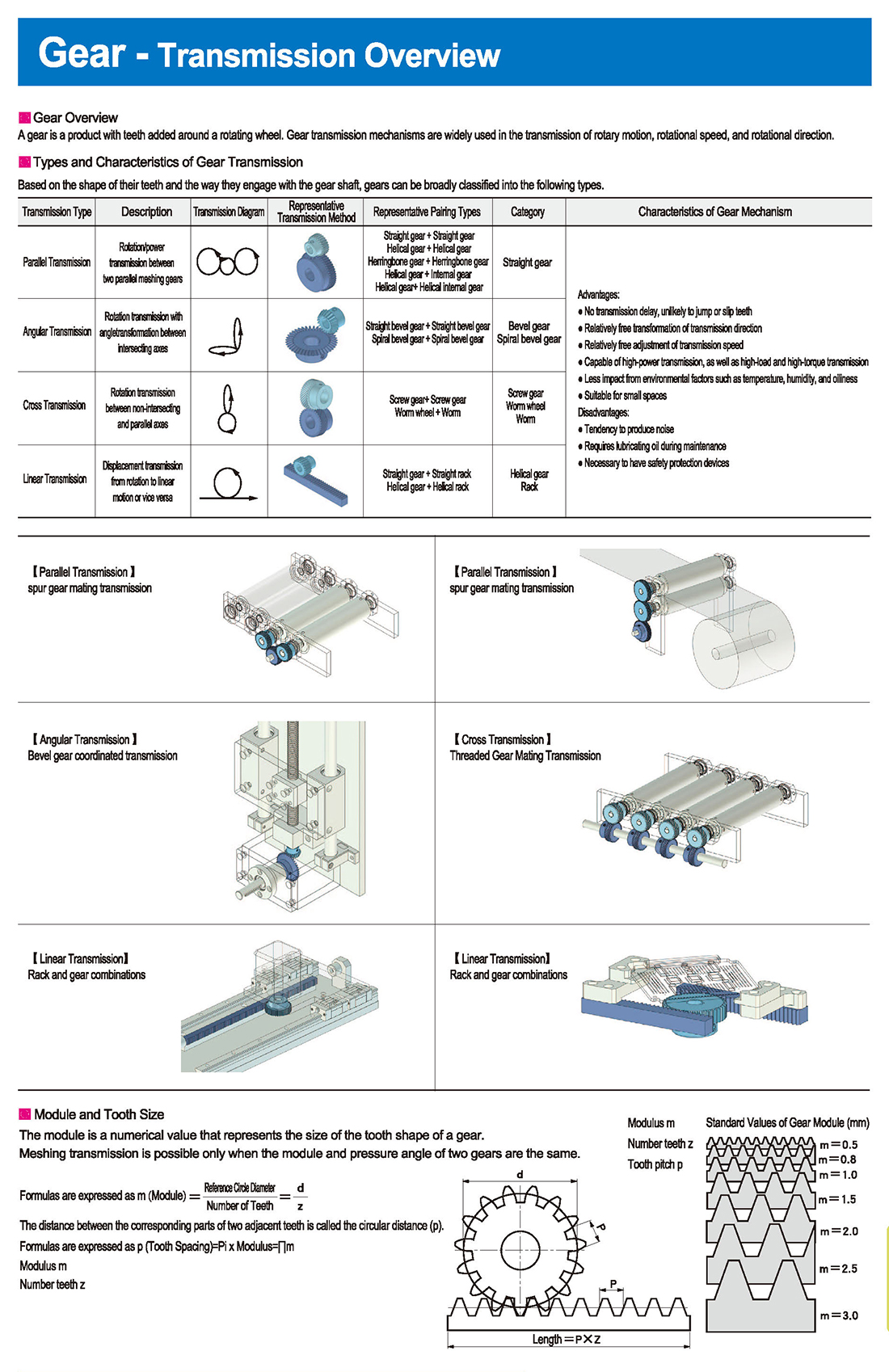

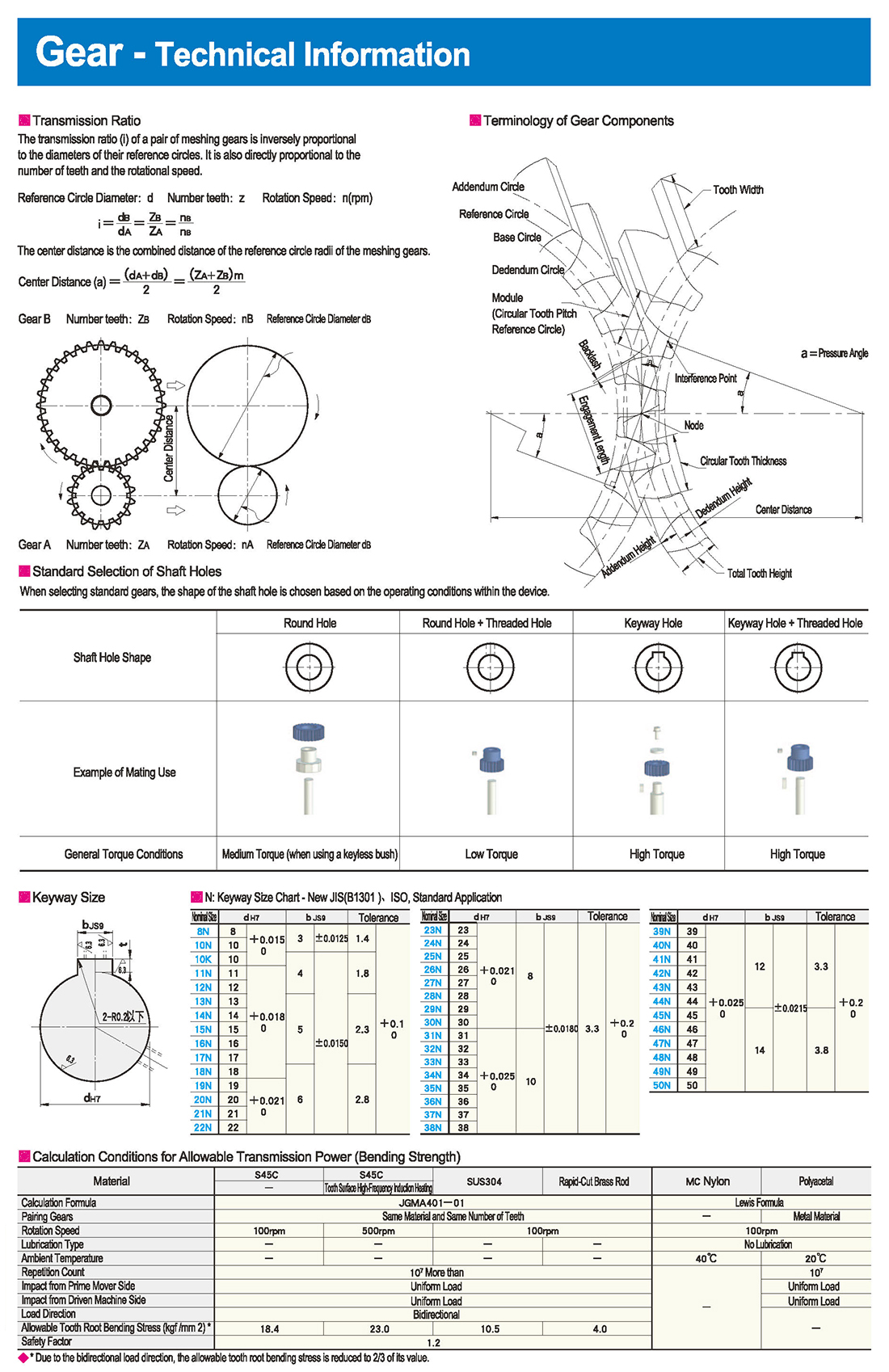

Types and Characteristics of Gear Transmission

①Parallel Transmission Rotation/power transmission between two parallel meshing gears Straight gear + Helical gear + Internal gear + Herringbone gear + Helical internal gear

②Angular Transmission Rotation transmission with angle transformation between intersecting axes Straight bevel gear + Spiral bevel gear Bevel gear

③Cross Transmission Rotation transmission between non-intersecting and parallel axes Screw gear Worm wheel + Worm

④Linear Transmission Displacement transmission from rotation to linear motion or vice versa Straight rack + Helical rack

Advantages:

* No transmission delay, unlikely to jump or slip teeth

*Relatively free transformation of transmission direction

* Relatively free adjustment of transmission speed

*Capable of high-power transmission, as well as high-load and high-torque transmission

* Less impact from environmental factors such as temperature, humidity, and oiliness

* Suitable for small spaces

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

Introduction Specification Table

Specification Table Download

Download