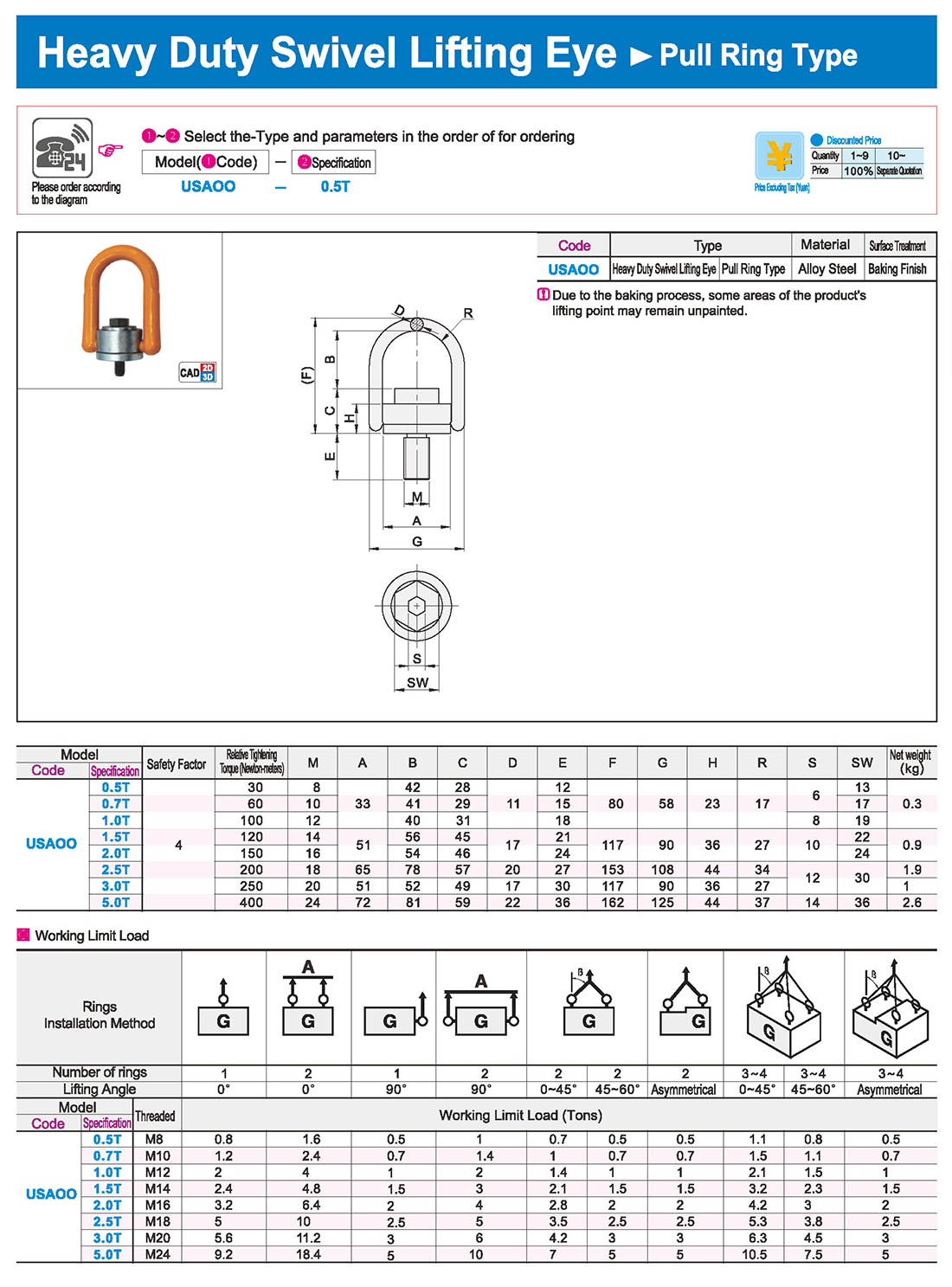

1. High strength and durability

Fastener rings are usually made of high-strength materials, such as carbon steel, alloy steel, etc., to ensure that they can withstand heavy loads and vibration. The selection of these materials makes the rings have excellent durability and fatigue resistance, and can maintain stable connection performance in harsh working environments for long periods of time.

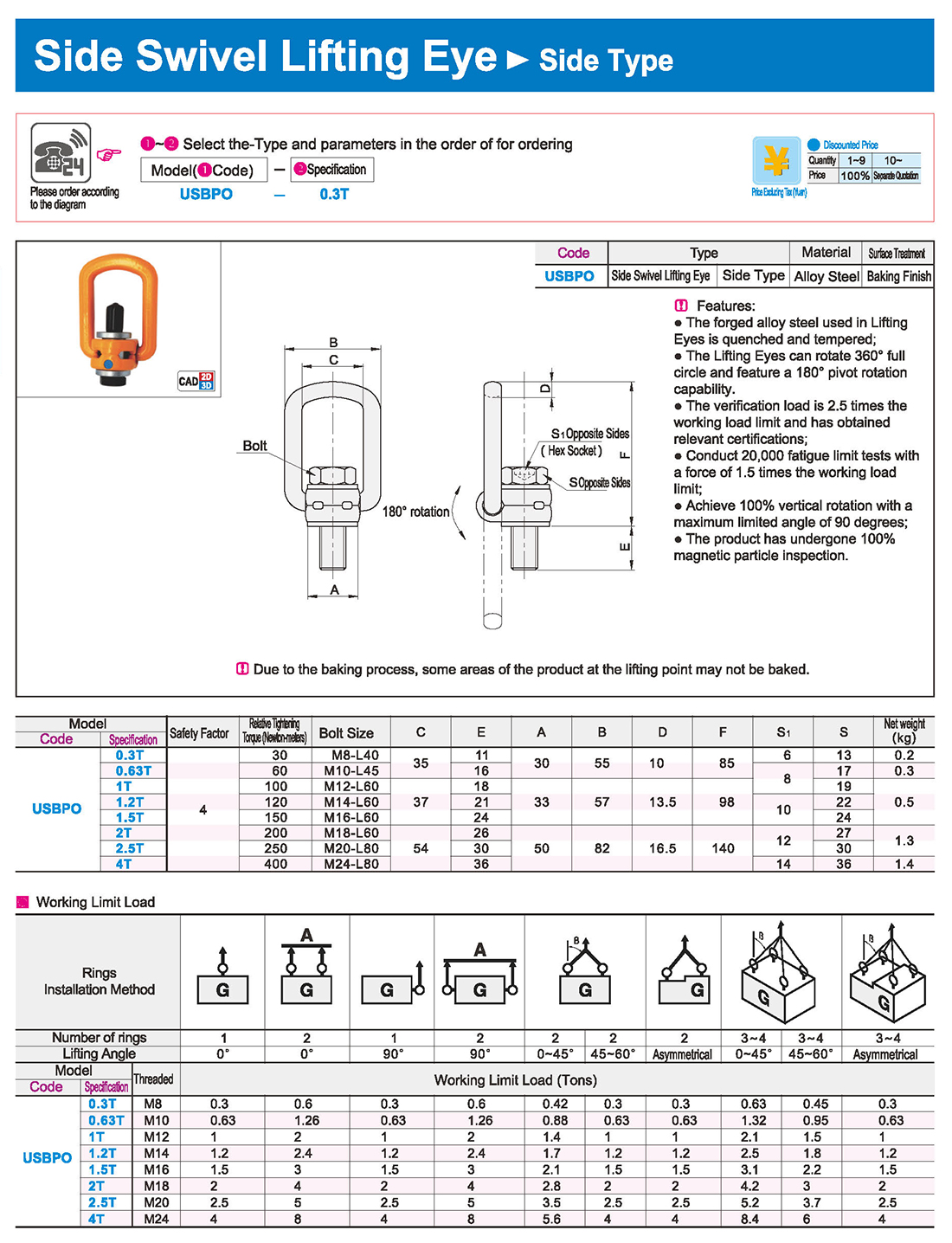

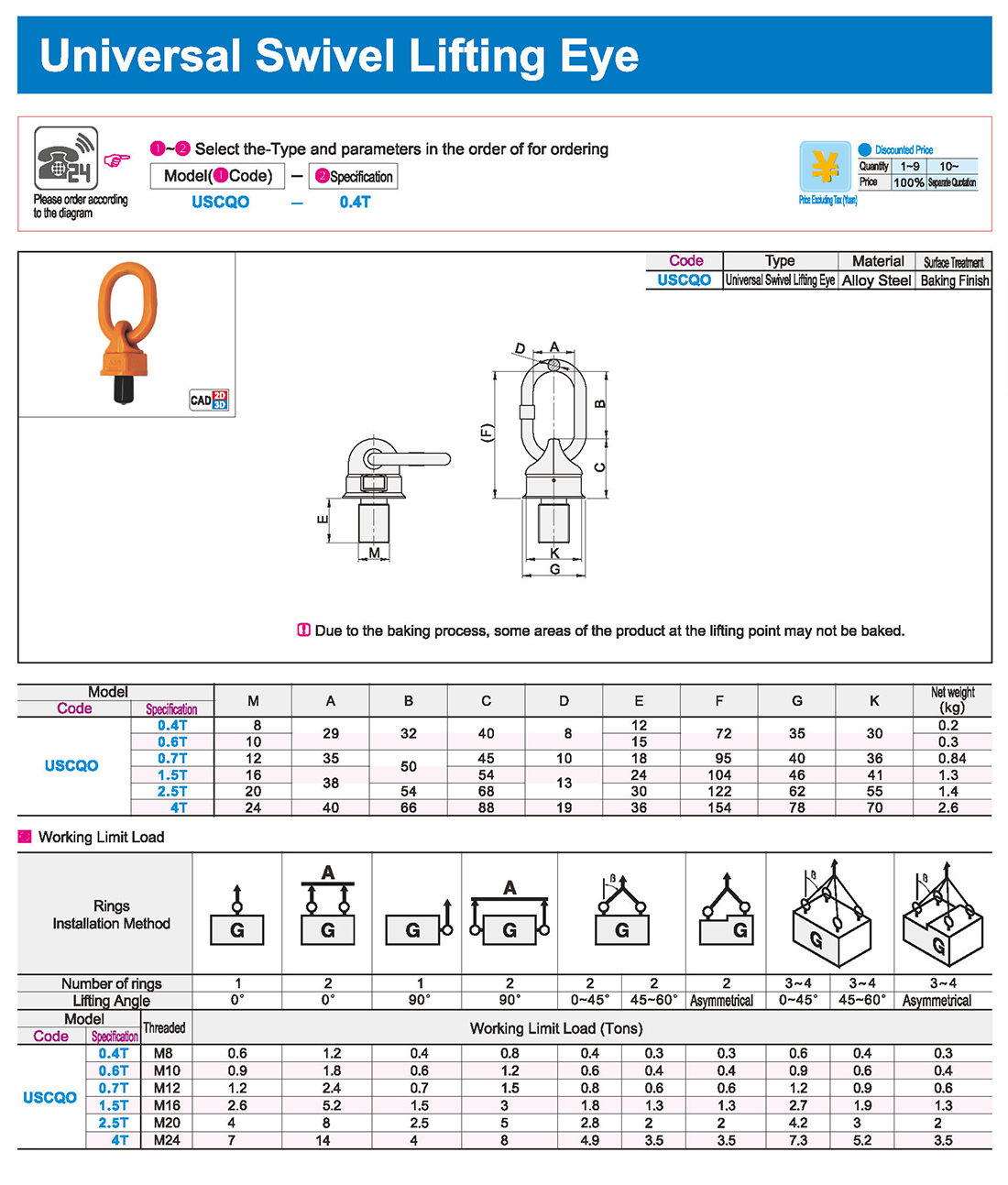

2. Diversified design

The design of fastener rings is diversified to meet different lifting needs. For example, some rings have a rotation function, which can be easily lifted in multiple angles and directions; Some rings have special shapes and sizes to suit specific connection needs. In addition, the surface treatment of the ring is also diversified, such as galvanized, spray paint, etc., to improve its corrosion resistance and beauty.

3. Ease of installation

The installation of fastener rings is usually relatively simple and can be done easily using the appropriate tools. This helps to reduce installation costs and improve work efficiency. At the same time, the connection methods of the ring are also diversified, such as threaded connection, welding, etc., to adapt to different installation environments and requirements.

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

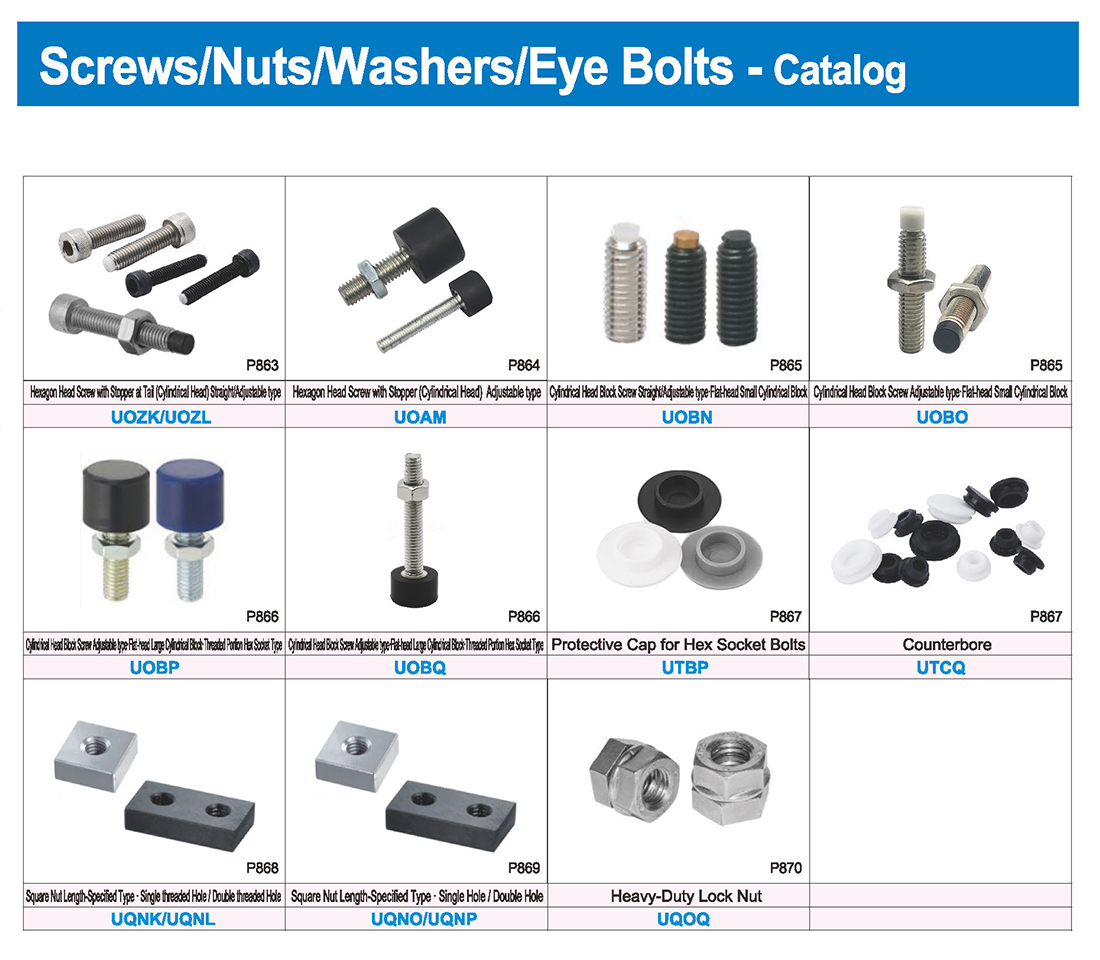

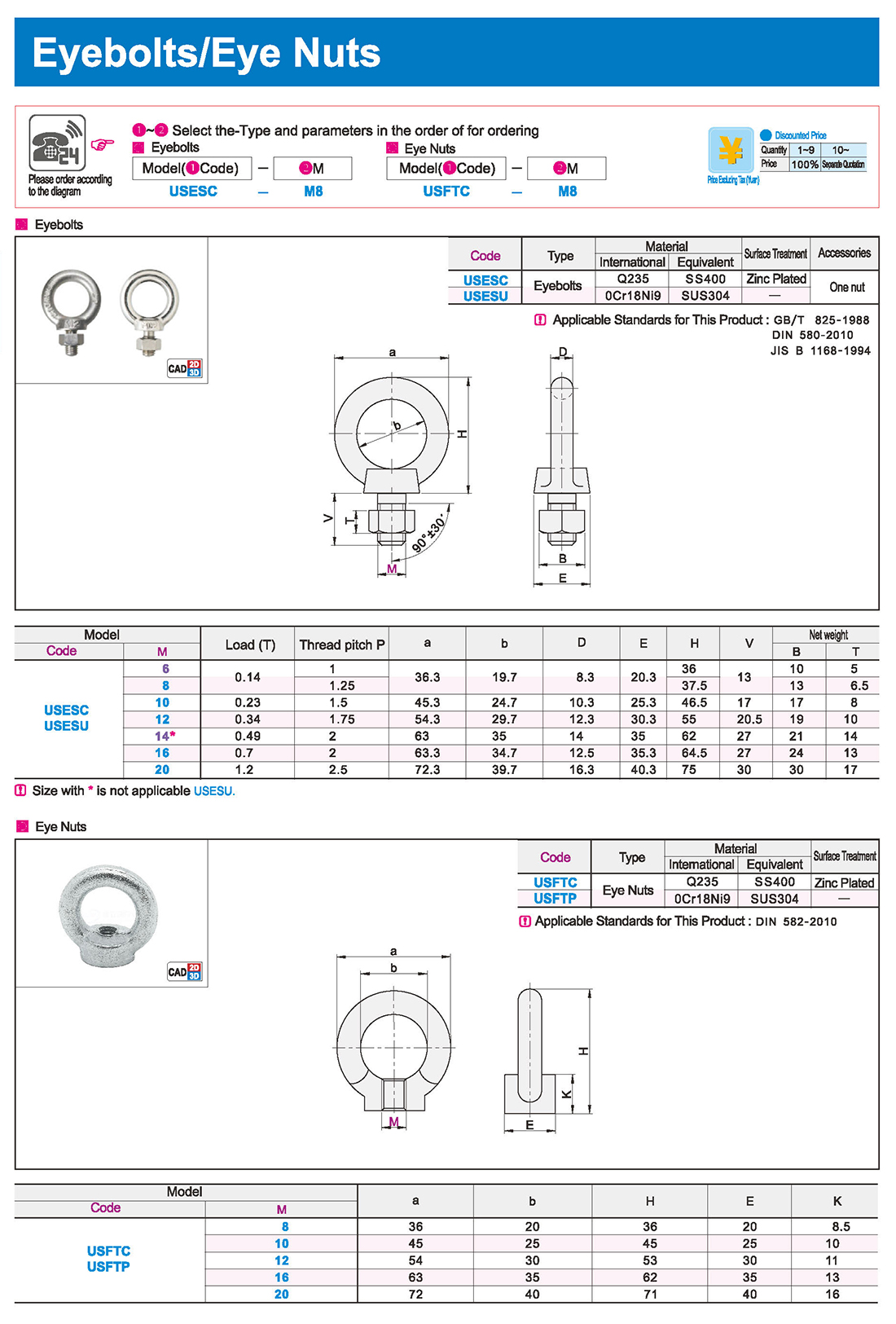

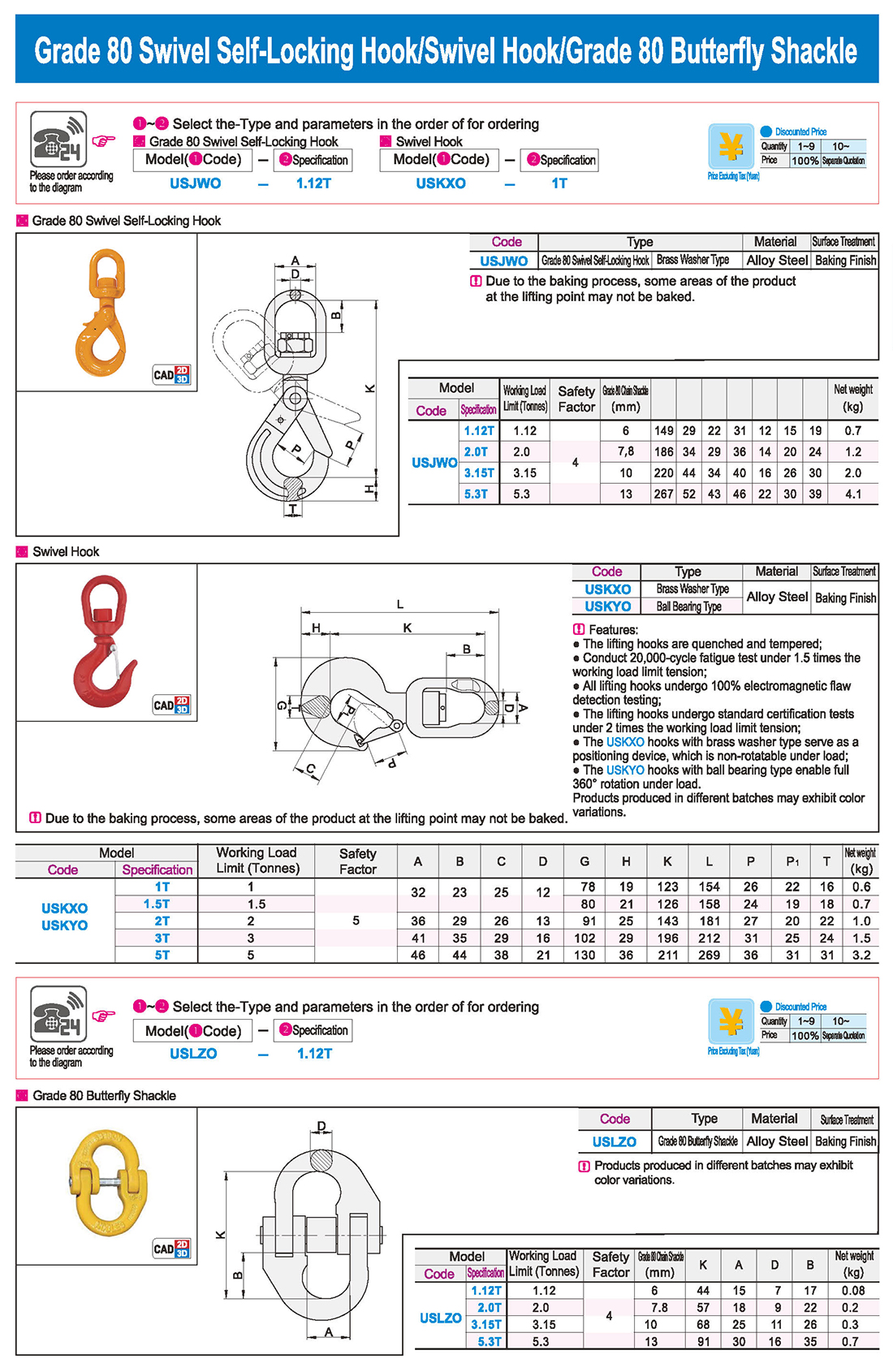

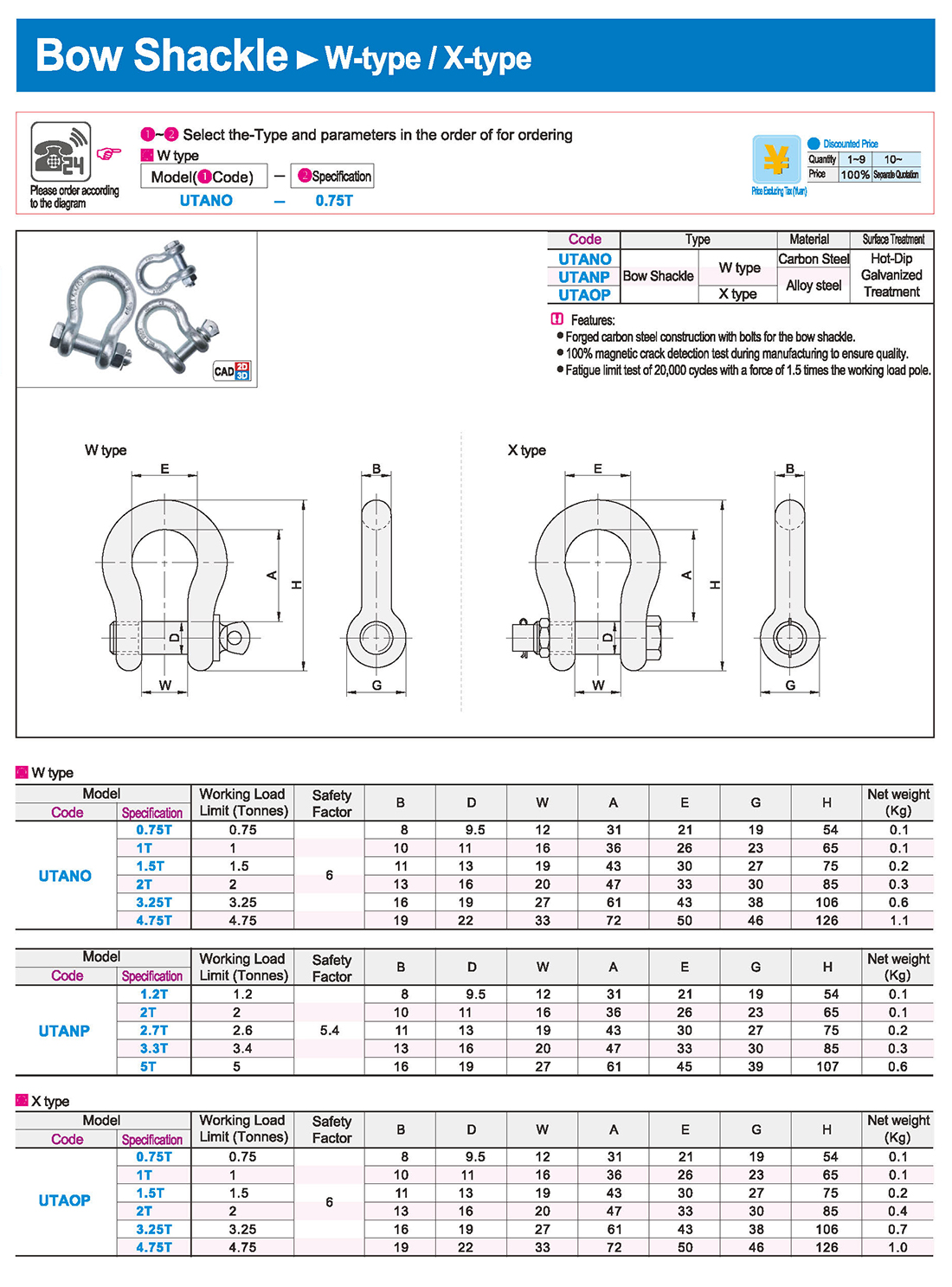

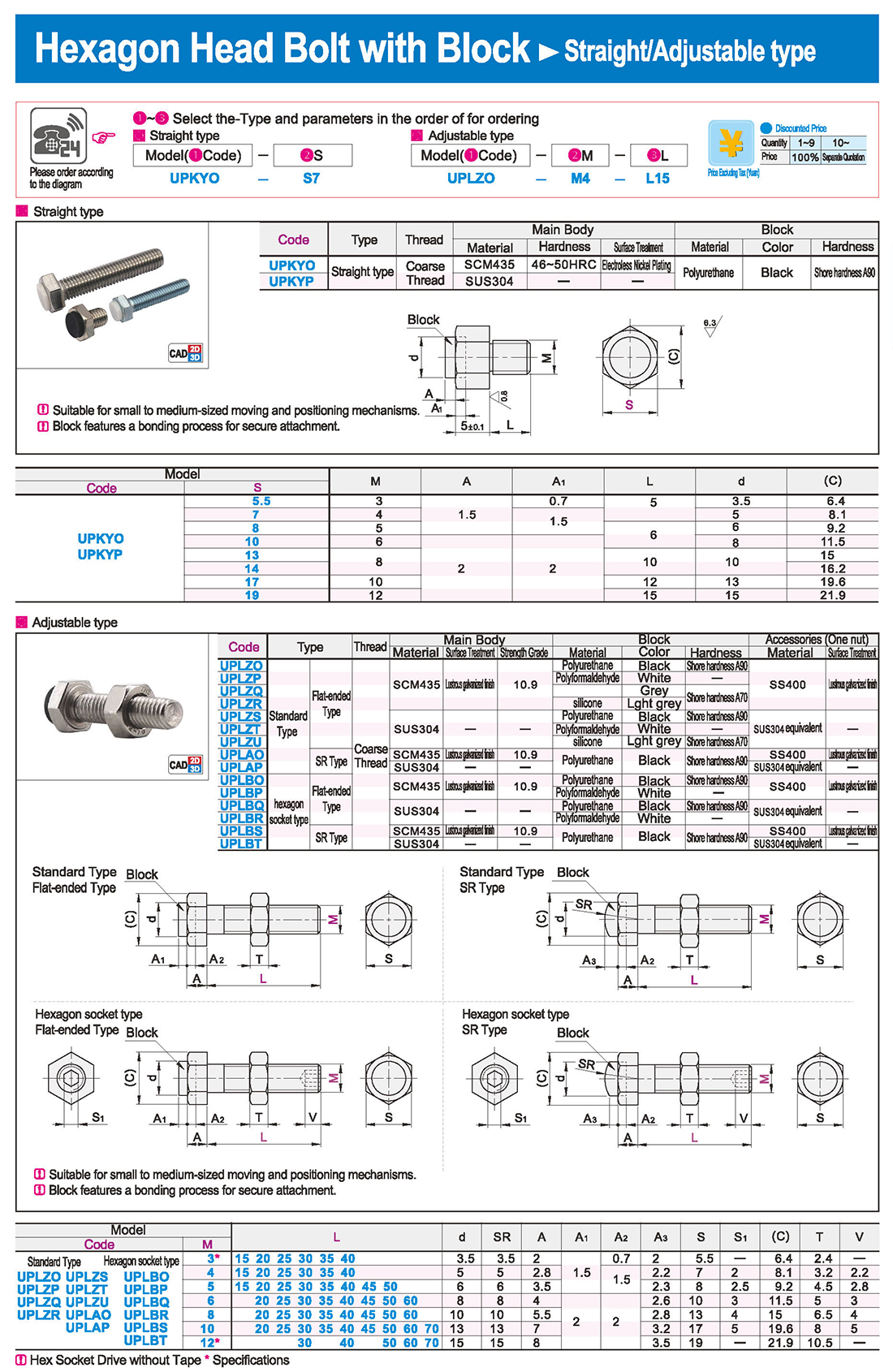

Introduction Specification Table

Specification Table Download

Download