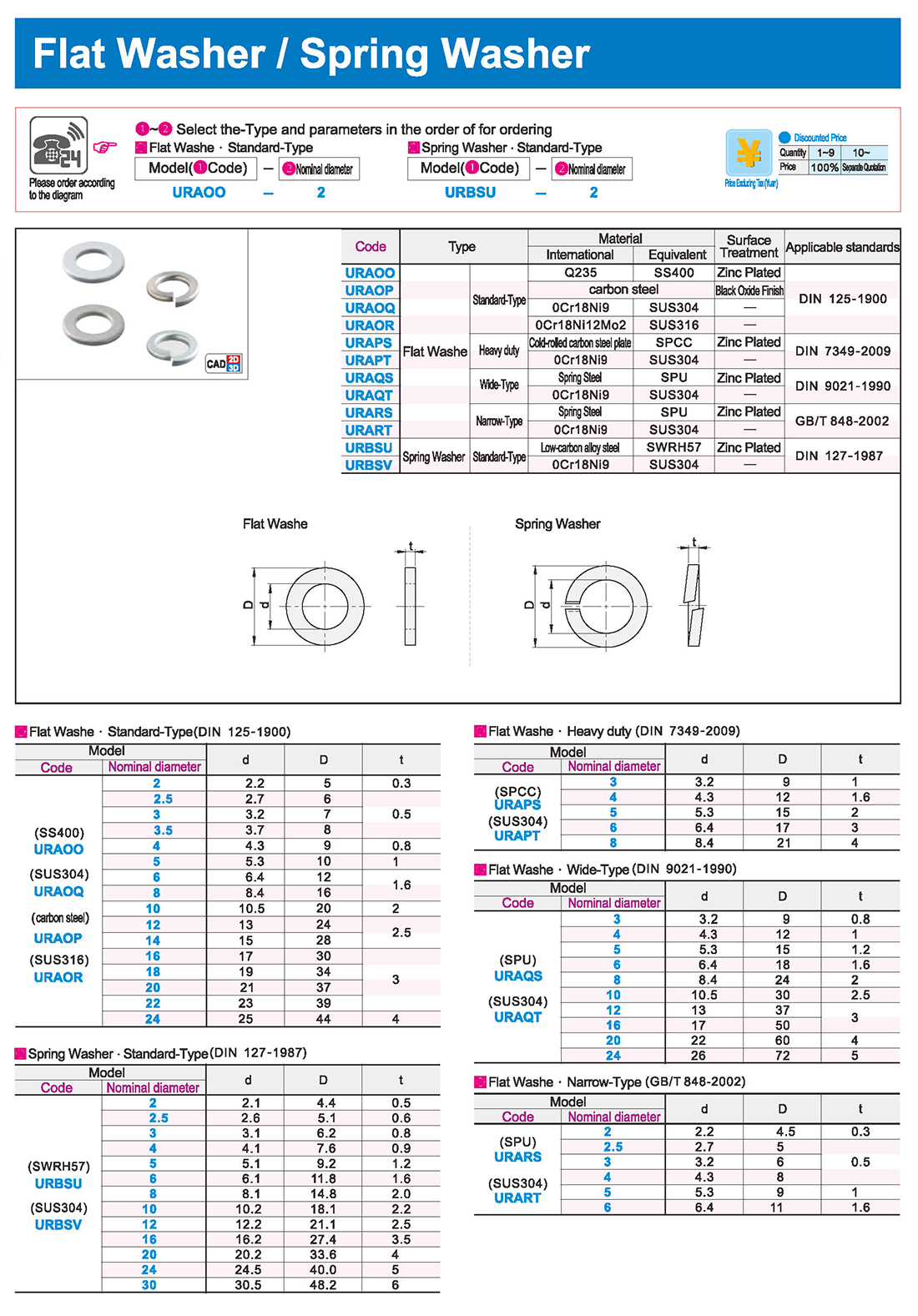

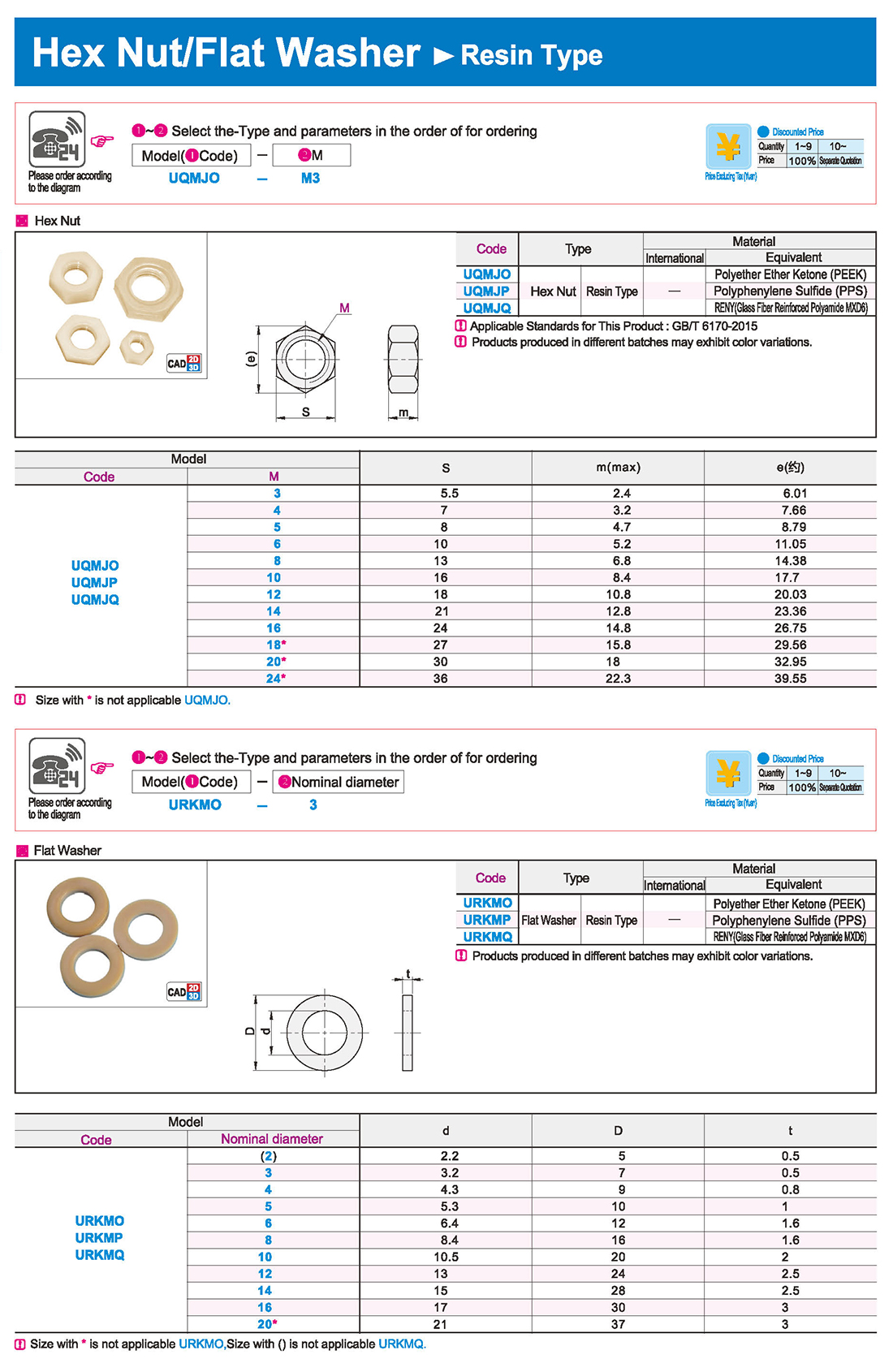

1. Flat washer: mainly by increasing the contact surface area of the connected parts, reducing the unit area pressure, so as to protect the surface of the connected parts from being damaged. It also has the function of reducing pressure, increasing friction, sealing, damping and fixing.

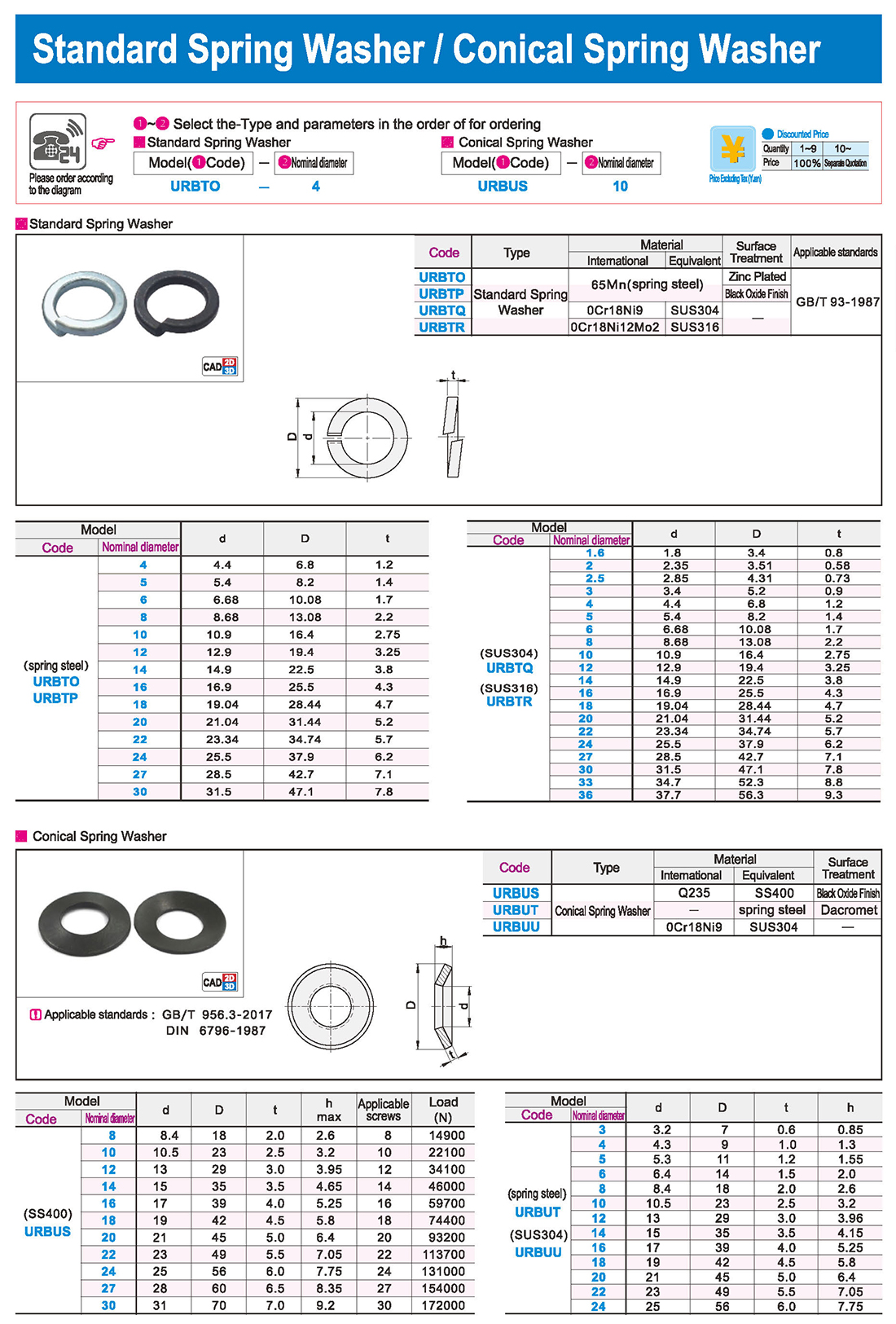

2. Spring washer: The main function is to increase the friction between the nut and the bolt to prevent the loosening of the fastening bolt due to vibration of the equipment in operation. Spring washers have anti-seismic, anti-loose effect, especially suitable for equipment with vibration.

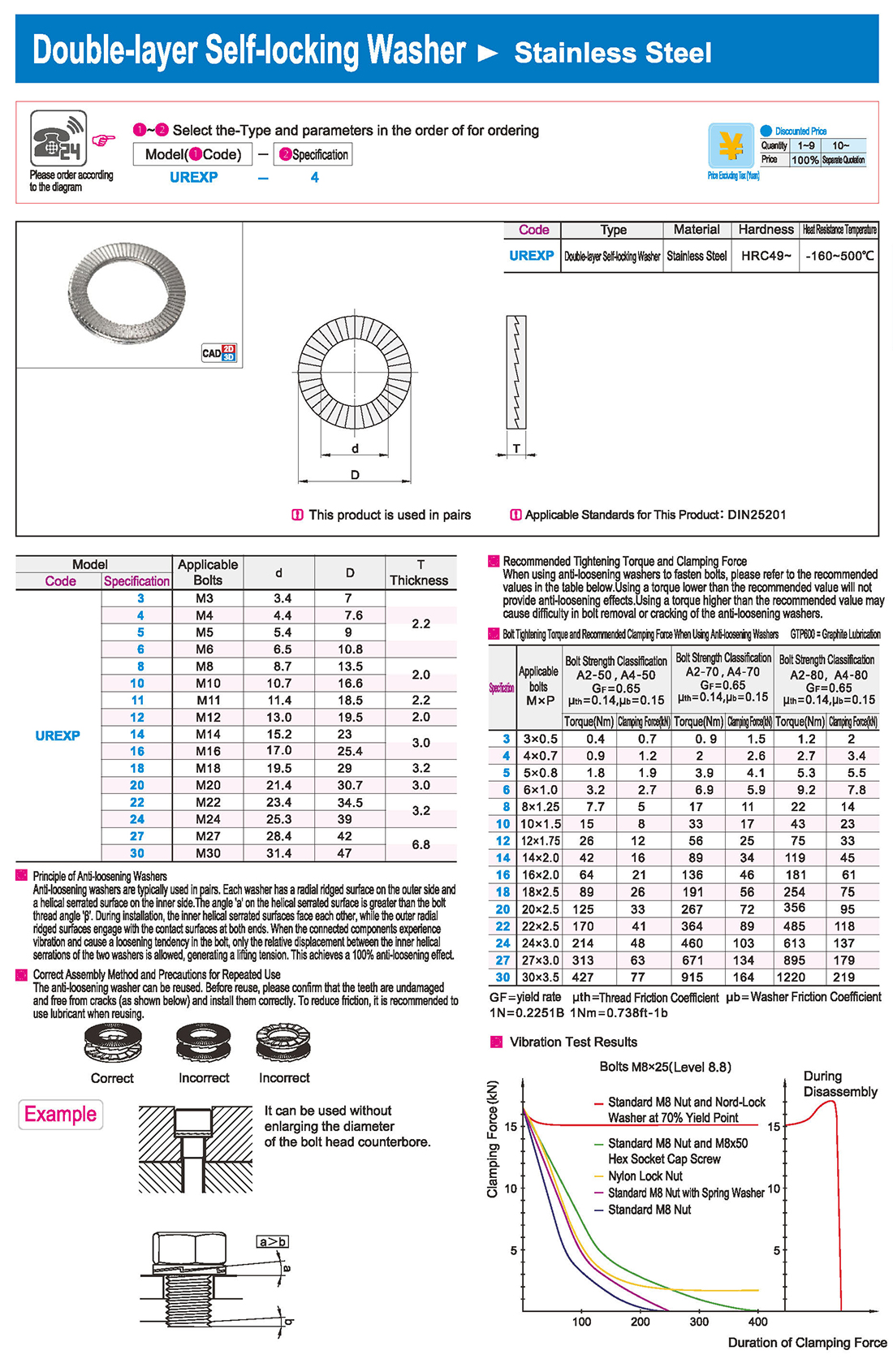

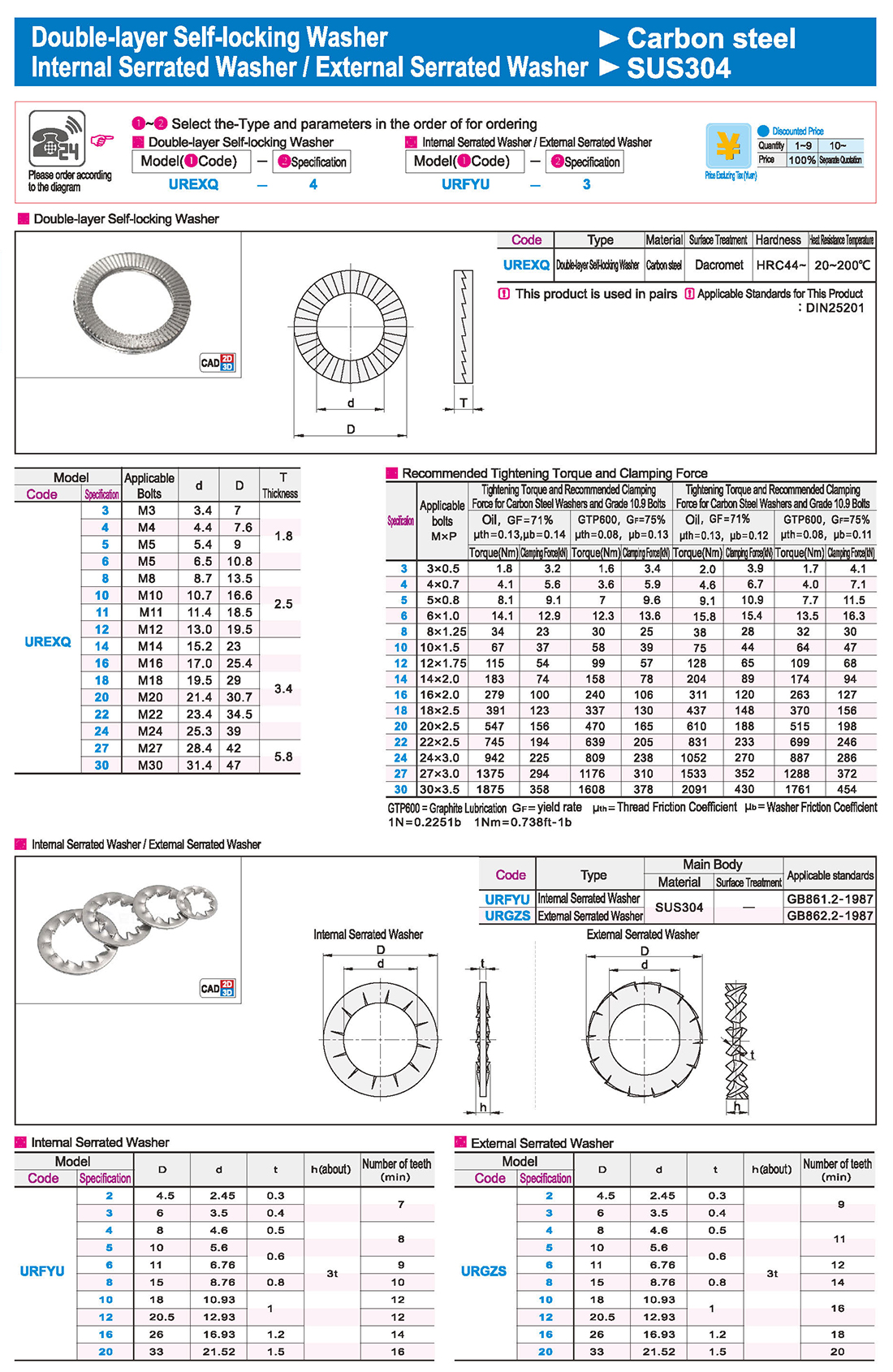

3. Lock washer: By increasing friction to achieve the purpose of locking, prevent the thread connection loosening. For example, the inner/outer tooth lock washer relies on the biting force and small elasticity of the tooth tip and the plane of the connected piece to prevent the threaded connection from loosening.

4. Special purpose gaskets: such as sealing gaskets are used to seal joints to prevent liquid or gas leakage; Spherical and square bevel washers may be used to adjust the Angle or position of the connector.

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

Introduction Specification Table

Specification Table Download

Download