1. High carrying capacity:

The rolling pin transmits force and motion through rolling contact, which can withstand large radial load and axial load, as well as a certain bending moment.

Rolling contact can disperse stress and reduce the pressure on the contact area, thereby increasing the load carrying capacity.

2. Low friction resistance:

The resistance of rolling friction is much less than that of sliding friction, so the rolling pin can significantly reduce the friction loss in mechanical systems.

This helps to reduce energy consumption, reduce heat generation, and improve the efficiency of mechanical systems.

3. High precision:

The rolling pin usually has high precision, ensuring accurate alignment and relative motion between mechanical components.

High precision helps to improve the stability and reliability of mechanical systems.

1.Internal Thread Type, External Thread Type

Change N-part external thread to fine thread, Change to a four-sided wrench slot, Only applicable to stepped type

In this table, the N dimension in parentheses refers to the fine thread. When selecting, please change N to NC. Above

Add a guide section, Add the guide section at the position indicated in the left figure

Internal thread mounting type. When selecting Y and F, ensure that the t dimension in the figure is not less than the value shown in the previous table. If the bottom holes interfere with each other, they should be through holes.

2.Guided External Thread Mounting Type

One end with internal thread and one end with external thread type, Add guiding flat, Flange type

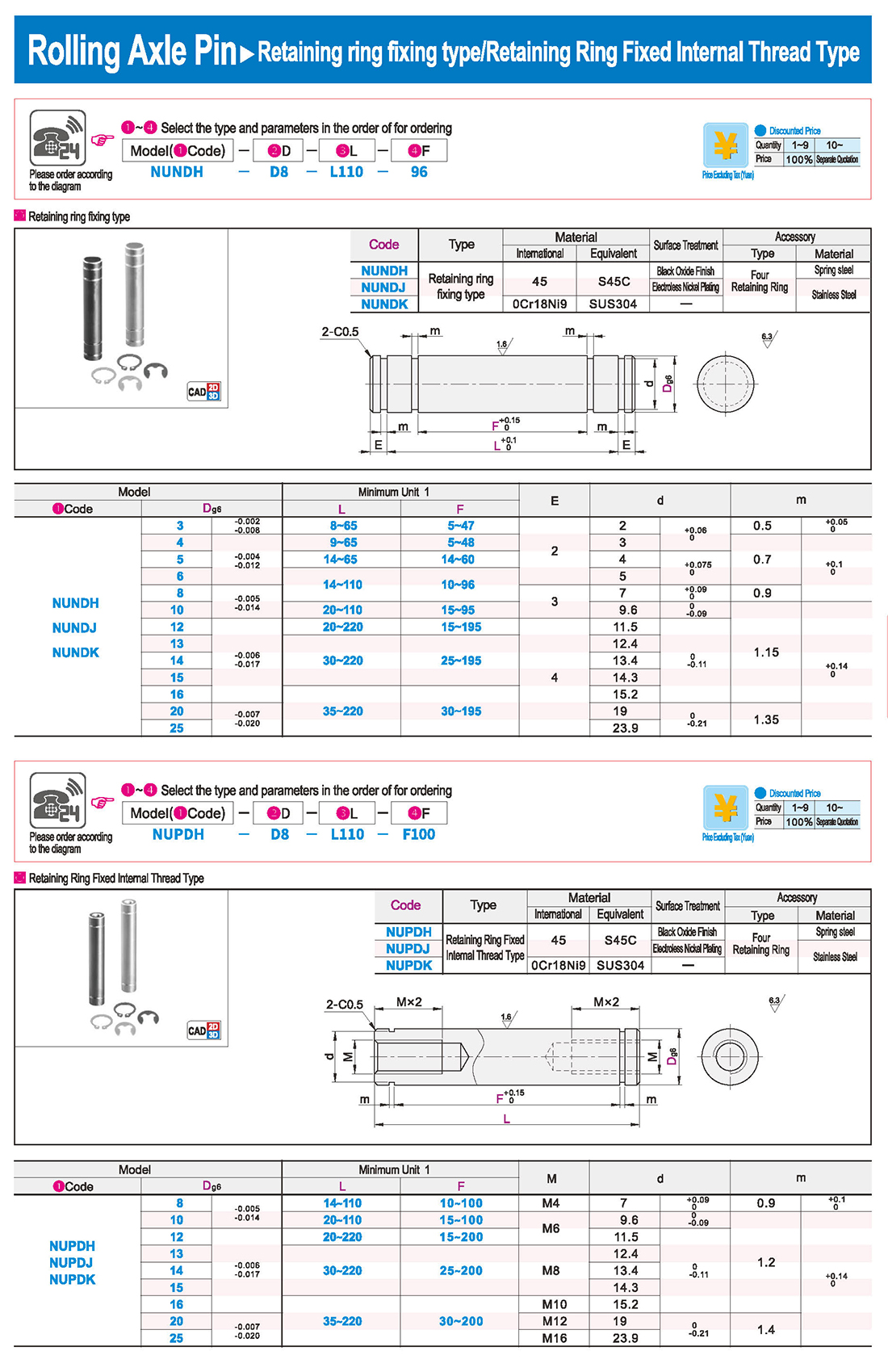

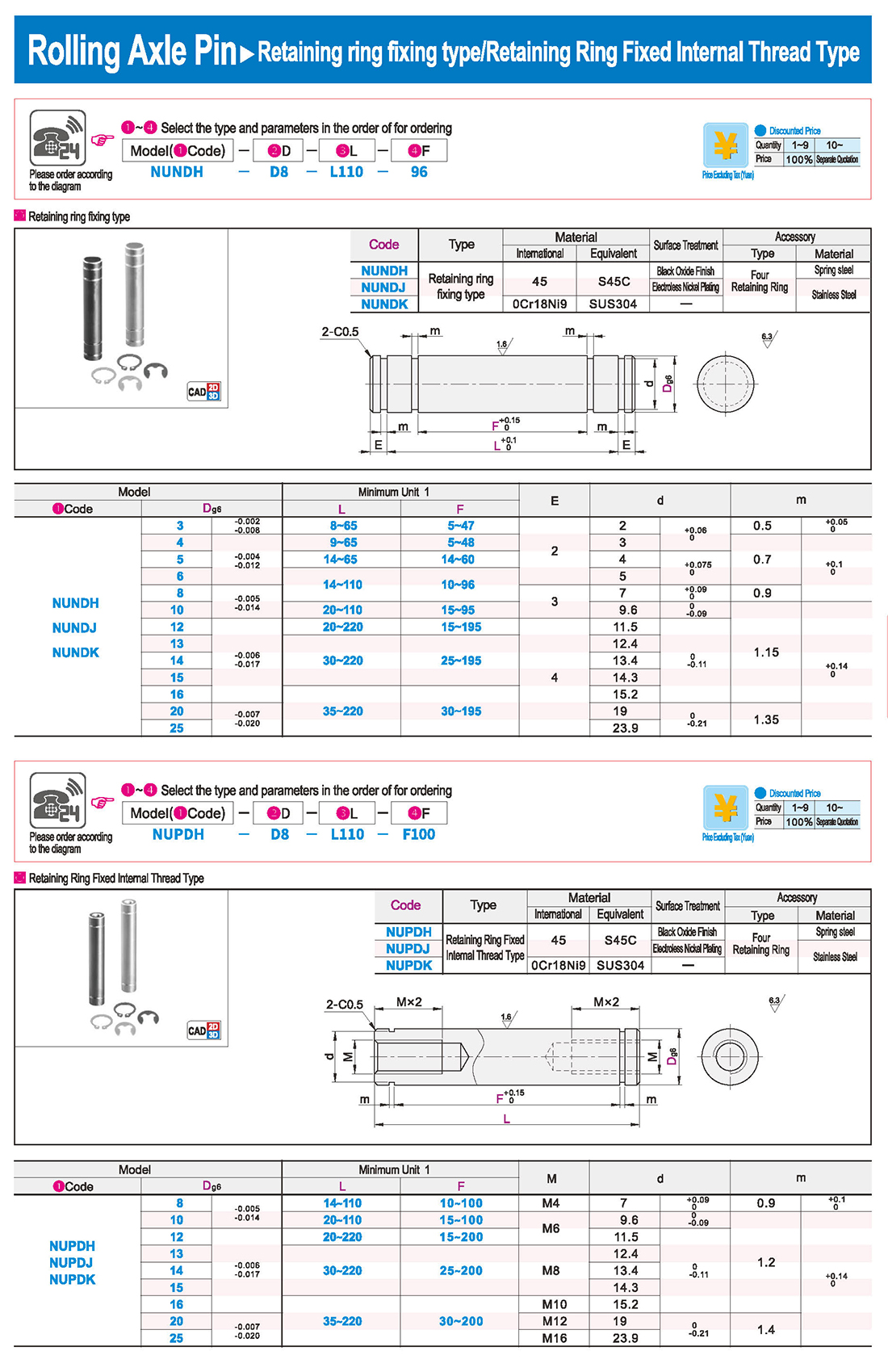

Nut fixing type, Tension pulley type, Split pin fixing type, Retaining ring fixing type

Hard chromium plating, coating thickness, Split pin, The tolerance refers to the L dimension, and others are general tolerances.

3.L Dimension Selection Type, L Dimension Specified Type, Accessory Split Pin Specification, Change split pin hole position (Note: L Dimension Selection Type is not applicable)

Change retaining ring groove position, Accessory retaining ring, Change internal thread diameter (Only applicable to the D specifications in the previous table)

Key fixing type, Lock screw fixing type, Double locking surface type (Only applicable to the lock screw fixing type)

4.Hinge Pin with Shoulder, Change Shoulder Thickness, Add Shoulder Stop Surface, Change Split Pin Position

With Hexagonal Hole Type, Ultra-thin Head Type, Zinc-plated U-shaped Nut, Stainless Steel U-shaped Nut, Change Thread Diameter

Change Thread Length, Hexagonal Hole Type Not Applicable, Shaft Diameter Tolerance Selection Type

T tolerance is the recommended tolerance when used with sleeveless bushings, Diameter d is a reference dimension, Only applicable to nut fixing type

Rolling Axle Pin, Retaining Ring Fixed Internal Thread Type

Step Screw for Fulcrum, Slotted Type, Head Cutting Type, Hexagonal Head Type, Add Relief Type

Free Specification Type, Fulcrum Pin, Short-head Hexagonal Hole Type

Step Bolt, Ultra-short Head Type, Short Head Type, Round Head Screw Type, Cross Slot Type

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

Introduction Specification Table

Specification Table Download

Download